Operation

Introduction

Groomingisperformedintheturfcanopyabovethe

soillevel.Groomingpromotesverticalgrowthofgrass

plants,reducesgrain,andseversstolons,producing

adenserturf.Groomingproducesamoreuniform

andtighterplayingsurfaceforfasterandtrueraction

ofthegolfball.

Groomingshouldnotbeconsideredasareplacement

forverticutting.Verticuttingisgenerallyamore

rigorousandperiodictreatmentthatcantemporarily

damagetheplayingsurface,whilegroomingisa

routineandgentlertreatmentdesignedtomanicure

theturf.

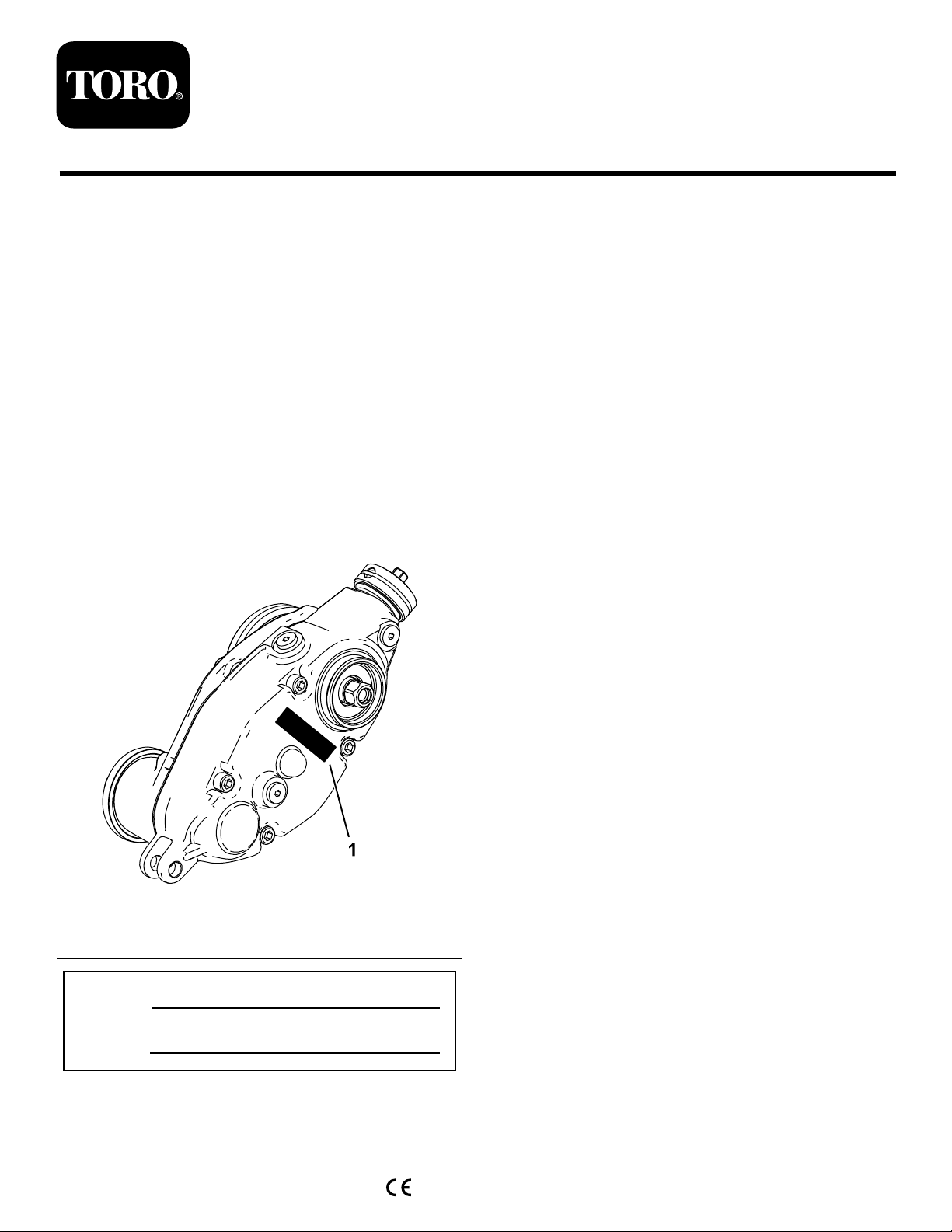

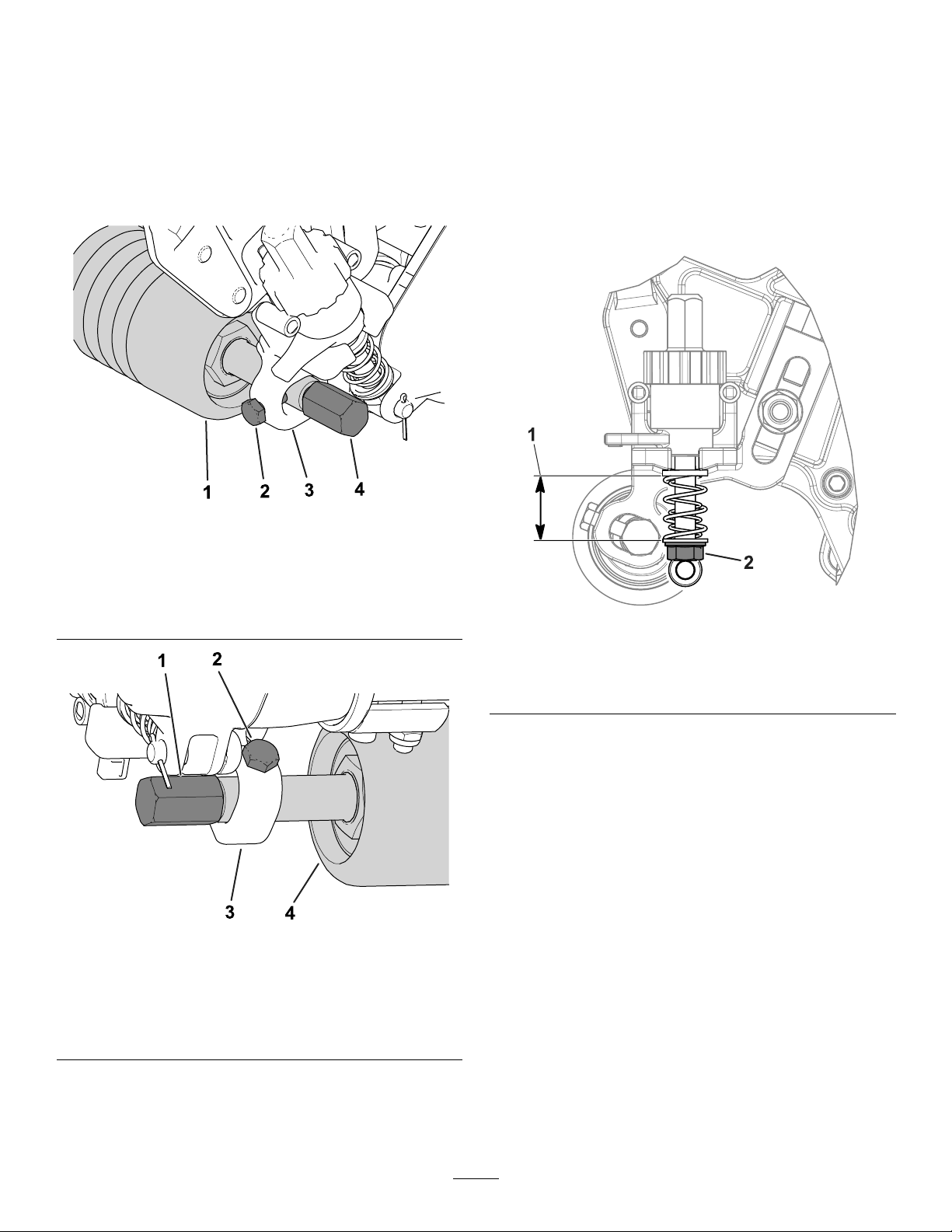

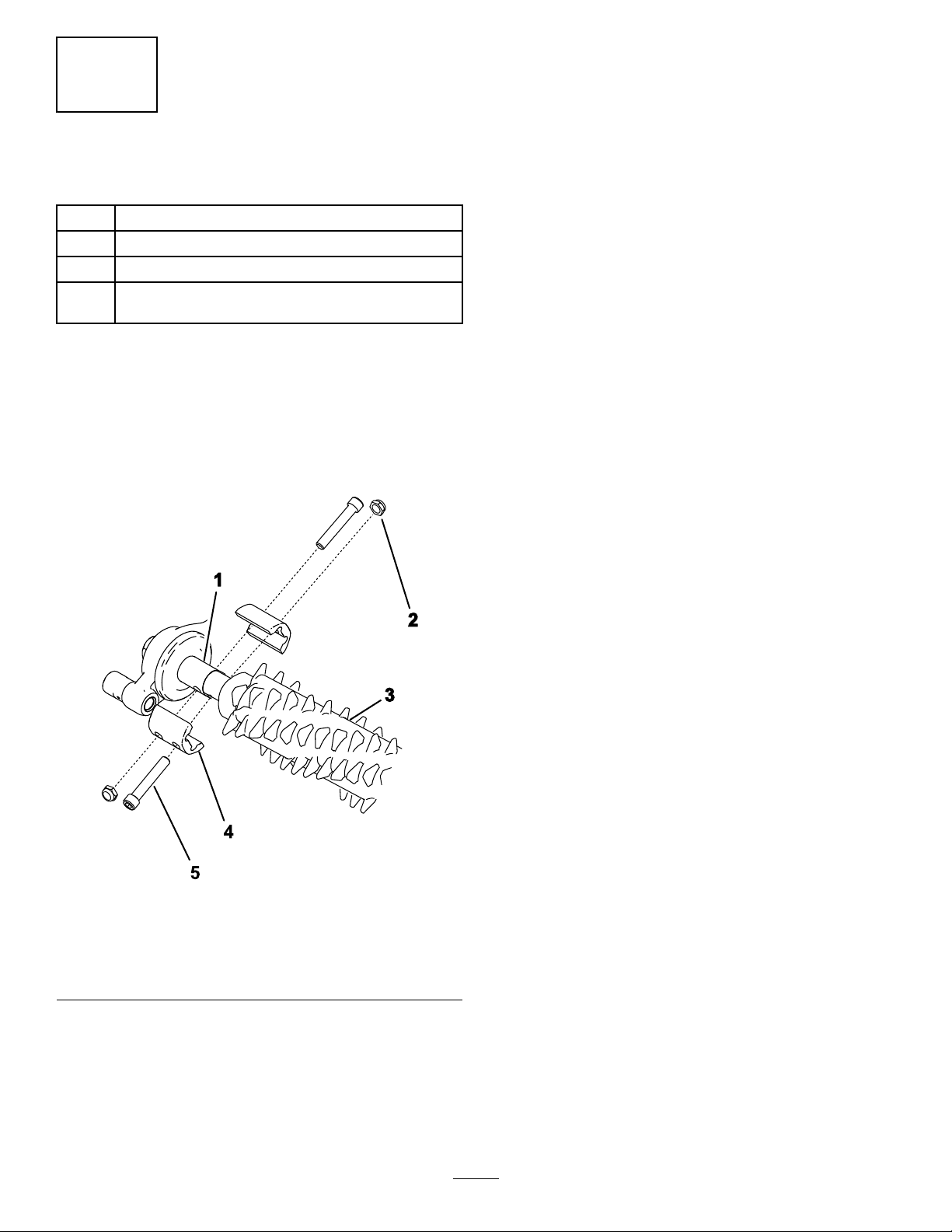

g006671

Figure18

1.Grassrunners(stolons)2.Thatch

Groomingbrushesarelessintrusivethanconventional

groomingbladeswhenadjustedtolightlycontactthe

turfcanopy.Brushingmaybebetterfortheultra-dwarf

cultivars,sincethesegrasstypeshaveanupright

growthpatternanddonotllinwellthroughhorizontal

growth.Brushescaninjureleaftissueiftheyareset

topenetratetoodeeplyintothecanopy.

Groomerbladesshouldneverpenetratethesoil.They

areeffectiveincuttingrunnersandremovingthatch.

Becausegroominginjuresleaftissue,avoidgrooming

duringperiodsofhighstress.Coolseasonspecies,

suchascreepingbentgrassandannualbluegrass,

shouldnotbegroomedduringhigh-temperature(and

high-humidity)periodsinmidsummer.

Manyvariablesaffecttheperformanceofgrooming,

including:

•Thetimeoftheyear(i.e.,thegrowingseason)and

theweatherpattern

•Thegeneralconditionofeachgreen

•Thefrequencyofgrooming/cutting—bothhow

manycuttingsperweekandhowmanypasses

percutting

•Theheight-of-cutsettingonthemainreel

•Theheight/depthsettingonthegroomingreel

•Howlongthegroomingreelhasbeeninuseon

thegreen

•Thetypeofgrassonthegreen

•Theoverallgreensmanagementprogram(i.e.,

irrigation,fertilizing,spraying,coring,overseeding,

etc.)

•Trafc

•Stressperiods(i.e.,hightemperatures,high

humidity,unusuallyhightrafc)

Thesefactorscanvaryfromgreentogreen.Inspect

thegreensfrequentlyandchangethegrooming

practiceasneeded.

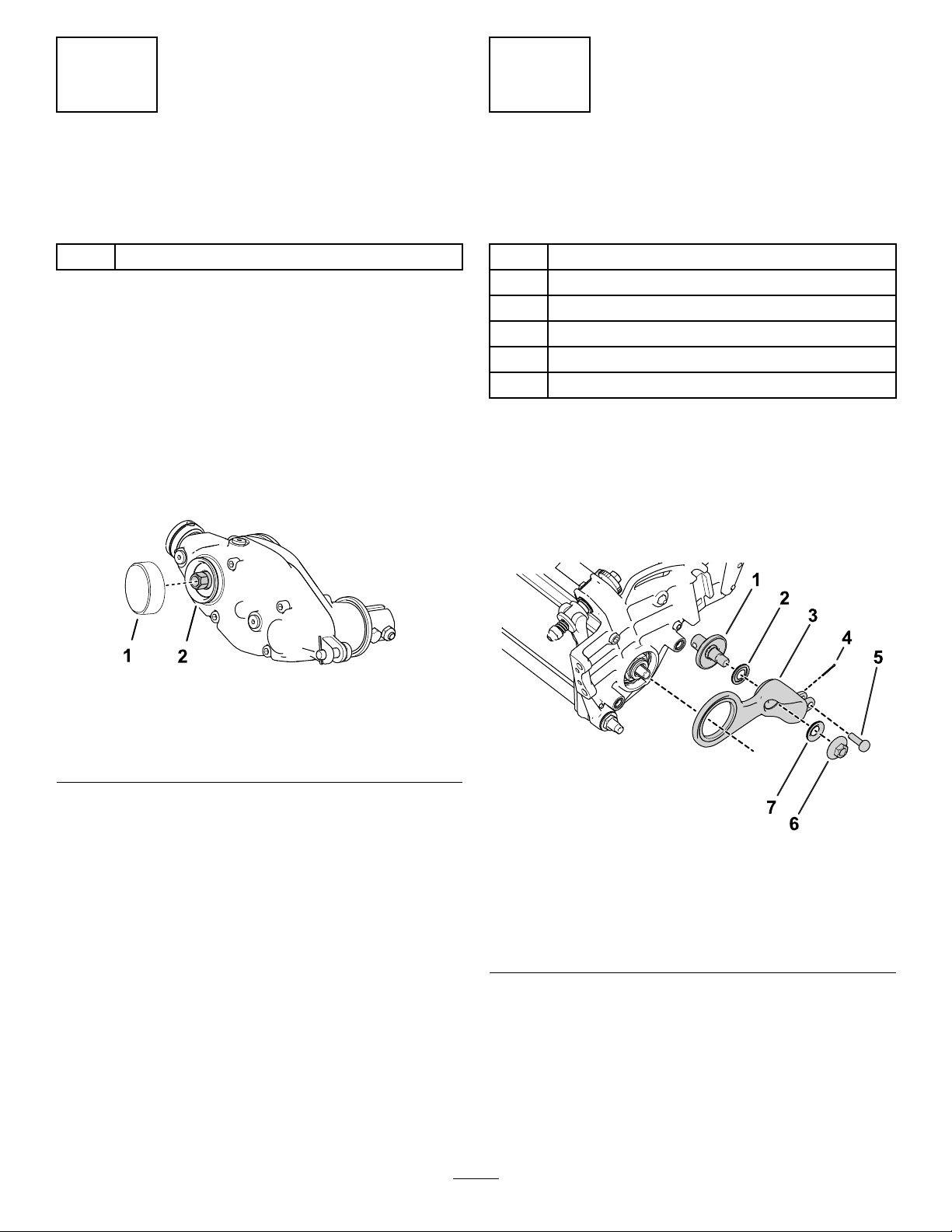

Variousgroomingshaftassembliesareavailable.The

13mm(1/2inch)spacingallowsyoutogroomslightly

deepertocutstolonswithoutthinningouttheturf

excessively.Byremovingspacersandaddingblades

orbyaddingspacersandremovingblades,youcan

adjustthespacingbetweenthegroomerandbladeto

6mm(1/4inch)or19mm(3/4inch).

Note:Groomwitha6mm(1/4inch)bladespacing

forfast-growthperiods(springthroughearlysummer)

tothinoutthetoplayerofthecanopy.Groomwith

a19mm(3/4inch)bladespacingforslowergrowth

periods(latesummerthroughfallandwinter).During

high-stressperiods,usingthegroomingreelmay

causedamagetotheturf.

Note:Usingthegroomerreelimproperlyortoo

aggressively(i.e.,toodeeportoofrequentgrooming)

mayunnecessarilystresstheturf,causingsevereturf

damage.Usethegroomercautiously.

Note:Continuechangingthedirectionofcut

wheneveryouusethegroomer.Thisenhancesthe

effectsofthegrooming.

Note:Operatethegroomerinastraightlineasmuch

aspossible.Usecautionwhenturningwhileoperating

thegroomer.

10