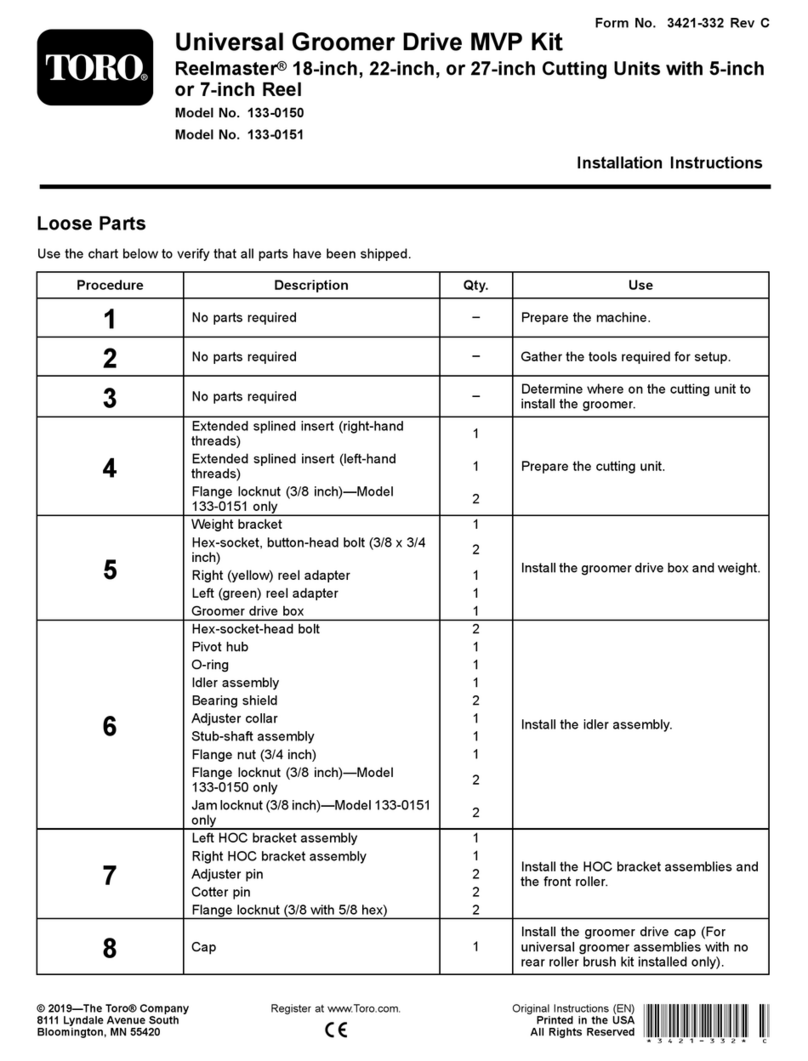

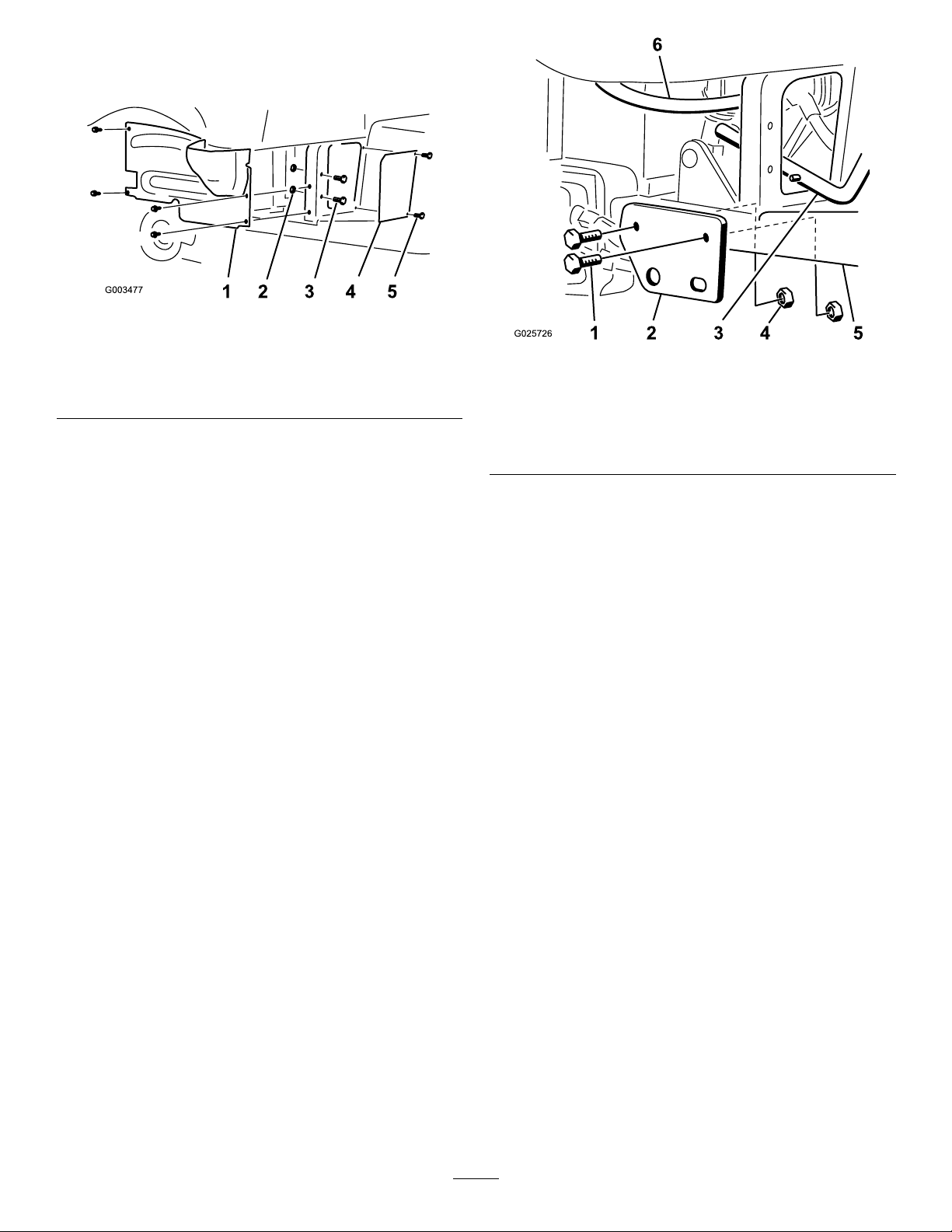

2.Looselyinstallthepivottubebracketontothe

rightside(Figure5).

3.Slidetheright-handsideofthepivottubeinto

therightsidepivottubebracket(Figure5).

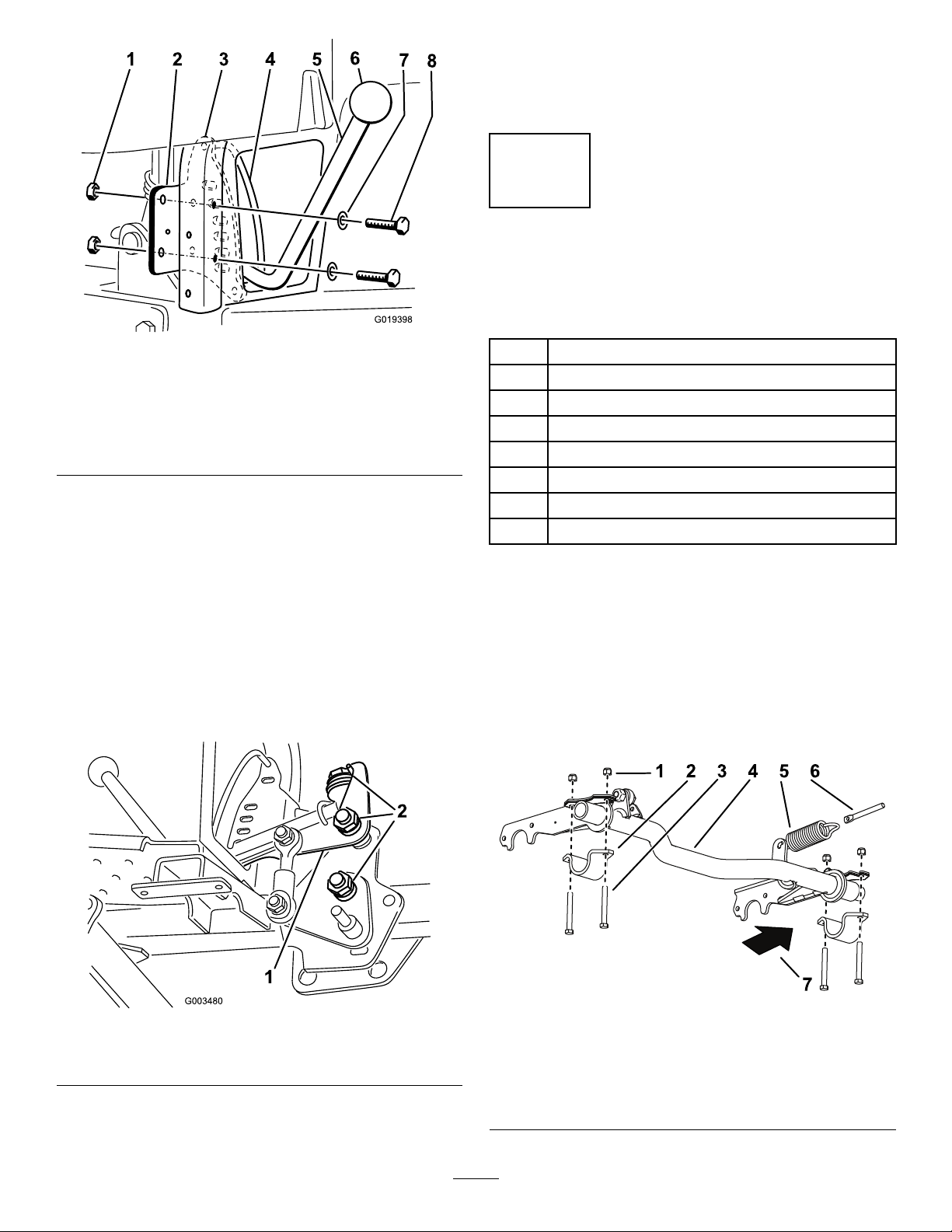

4.Insertthespringrodintotheholeinthespring

bracket,andlooselysecureitwithalocknut(3/8

inch).

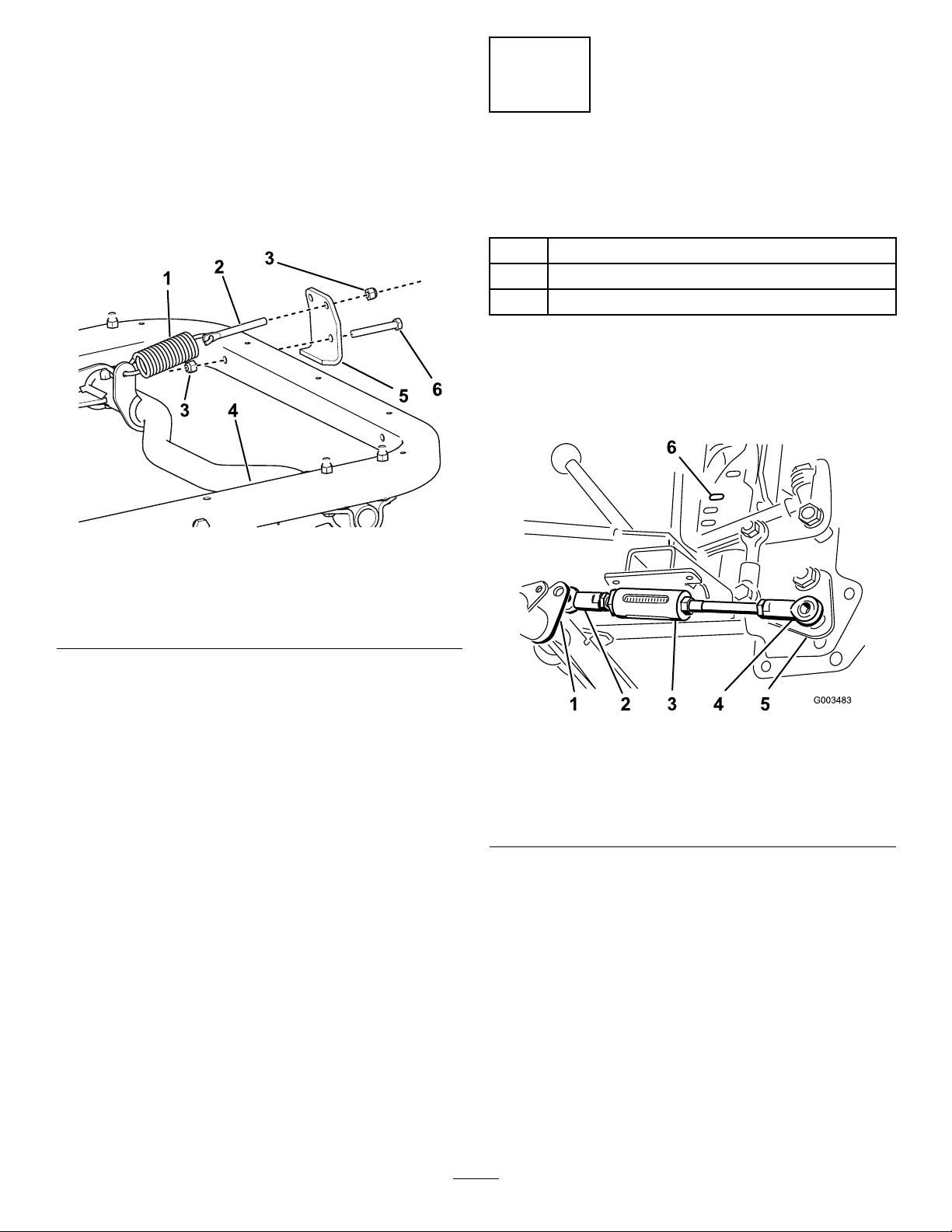

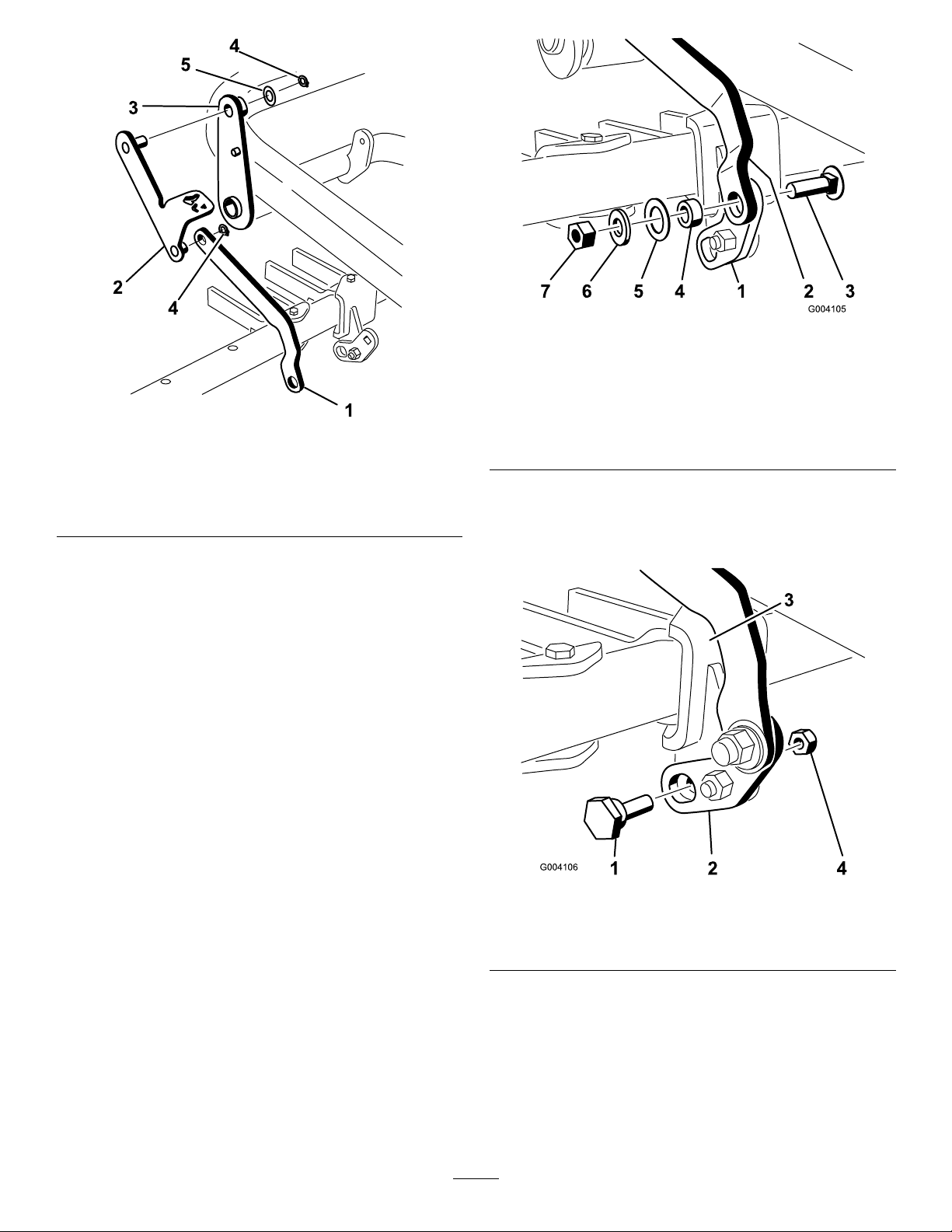

Note:Positionthespringrodasshownin

Figure6.

g346051

Figure6

1.Extensionspring4.Frame

2.Springrod5.Springbracket

3.Locknut(3/8inch)6.Bolt(3/8x2-3/4inch)

5.Raisetheleft-handsideofthepivottubetothe

frameandinstallitwithapivottubebracket,2

bolts(3/8x3inch),and2locknuts(3/8inch)

(Figure5).

6.Mountthespringbrackettothefrontframetube

withabolt(3/8x2-3/4inch)andalocknut(3/8

inch).

Note:Positionthespringbracketasshownin

Figure6.

7.Tightenallfasteners,butdonottightenthe

locknutthatsecurethespringrodatthistime.

4

InstallingtheAdjustable

RodAssembly

Partsneededforthisprocedure:

1Adjustablerodassembly

1Bolt(1/2x1-1/2inches)

2Locknut(1/2inch)

Procedure

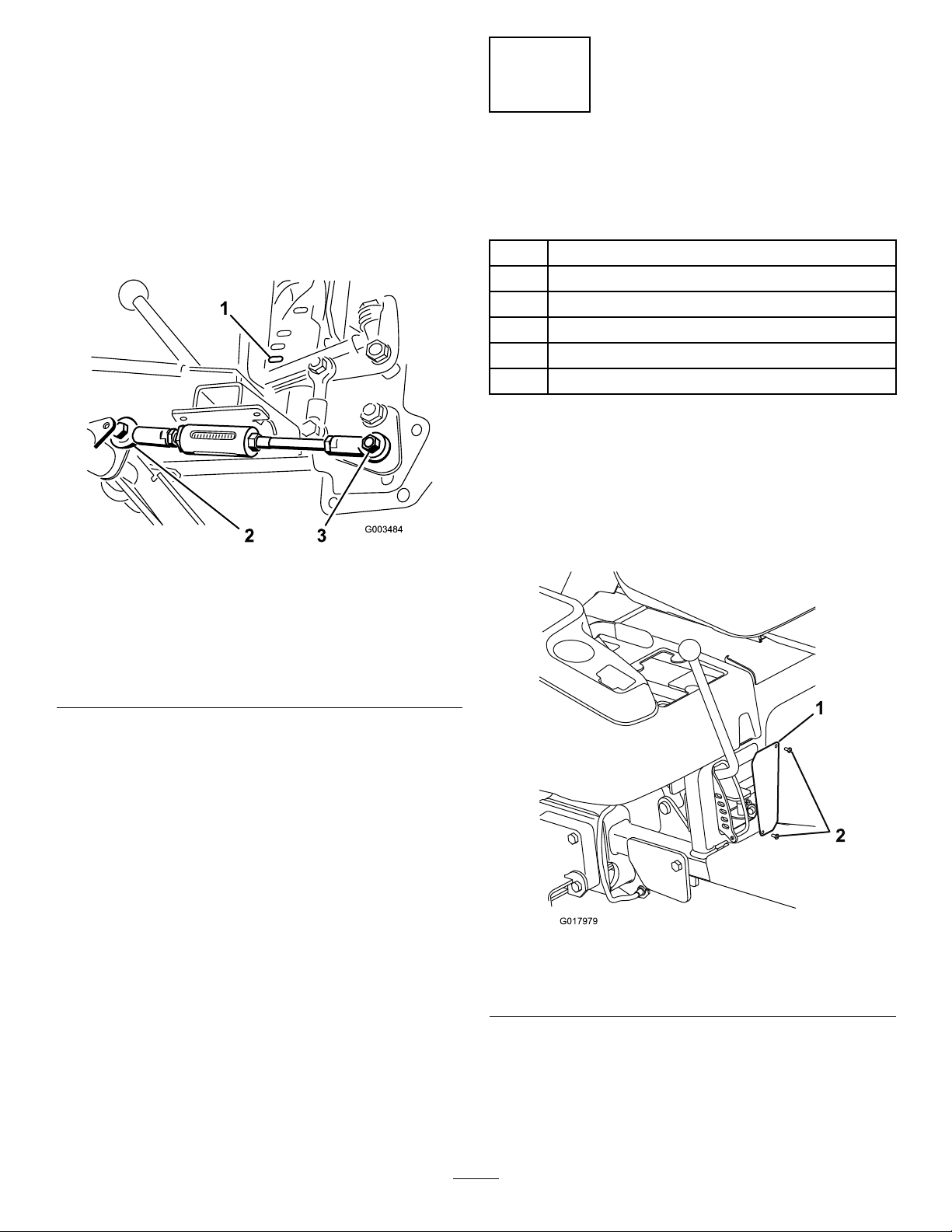

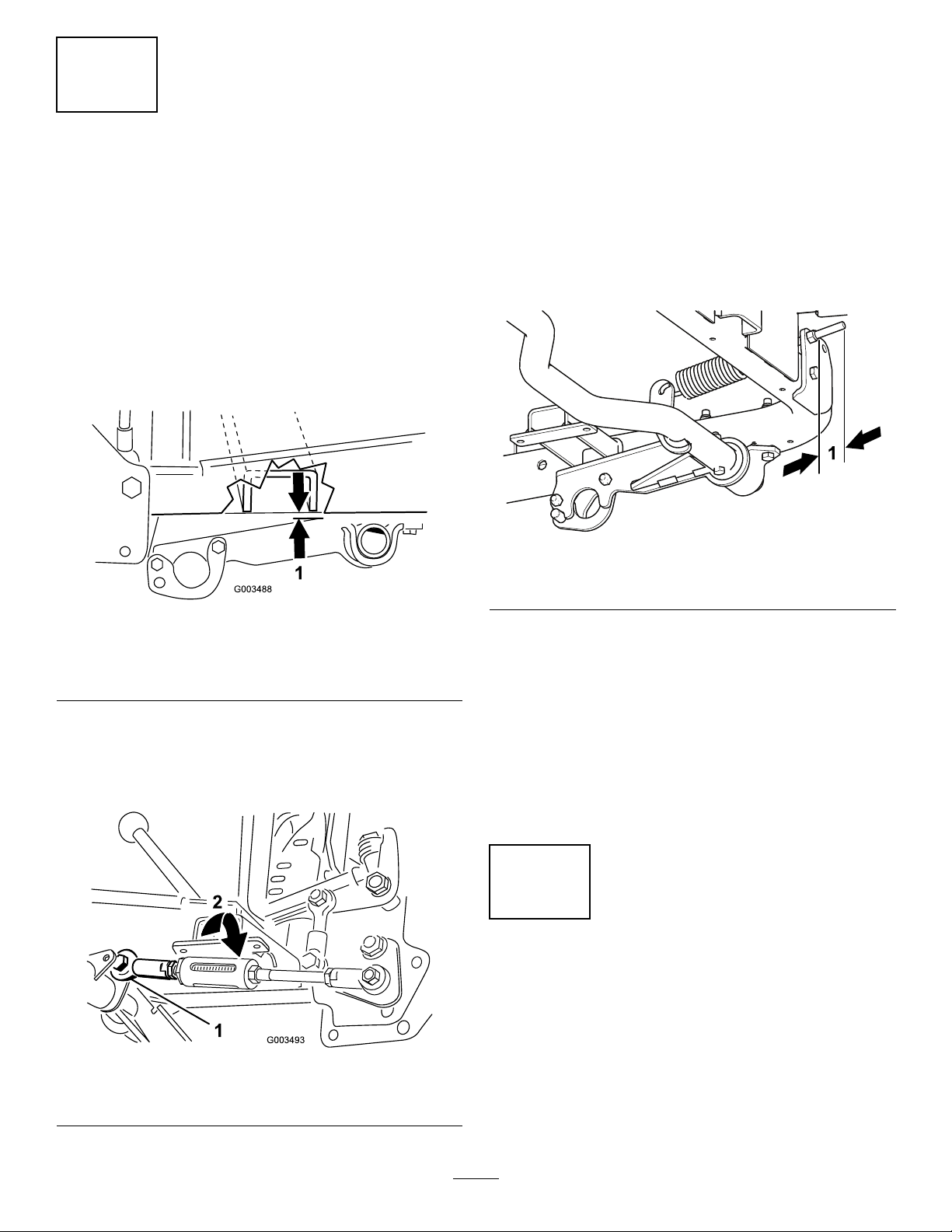

1.Positiontheballjointoftheshortendofthe

adjustablerodassemblytotherightofthe

adjustablerodleveronthepivottube(Figure7).

g003483

Figure7

1.Adjustablerodleveronthe

pivottube

4.Long-endballjoint

2.Short-endballjoint5.Lifthandleassembly

3.Adjustablerod6.Seconddetentposition

2.Movethelifthandletotheseconddetent

positionfromthetop.

3.Placetheballjointonthelongendofthe

adjustablerodassemblyoverthestudonthe

bottomonthelifthandleassemblyandloosely

secureitwithalocknut(1/2inch)(Figure7).

Note:Youcanmovethepivottubeupordown

initsbracketstogainclearanceformounting

theadjustablerod.

4.Movethelifthandleallthewaydownwardtothe

bottomdetentposition.

5.Movetheballjointontheshortendofthe

adjustablerodaroundtheadjustablerodlever

5