Tousethemower:

1.Cleanandgreaseallfrontattachments.

2.Removethedriveshaft.

3.Installthefrontdeck.

Attachments

ReadtheOperator'sManualsuppliedwiththe

attachmentbeforeoperating.

Ensurethatthehydraulicquickcouplersarefreeof

anycontaminantsbeforeconnecting.

Keeptheoutputshaftoiledtopreventrust.

DonotoperatethePTOwiththeattachmentinthe

raisedposition.NoisefromthePTOdrivelinewillbe

evident.

Installtheattachmentasfollows:

•Removeanyattachmentfromthemachine.Follow

attachmentsupplier'srecommendationforsafe

blockingandstorage.

•Drivethemachineintopositionbehindthe

attachmentadapter.Raisethemachineadapter

intotheattachmentadapter.

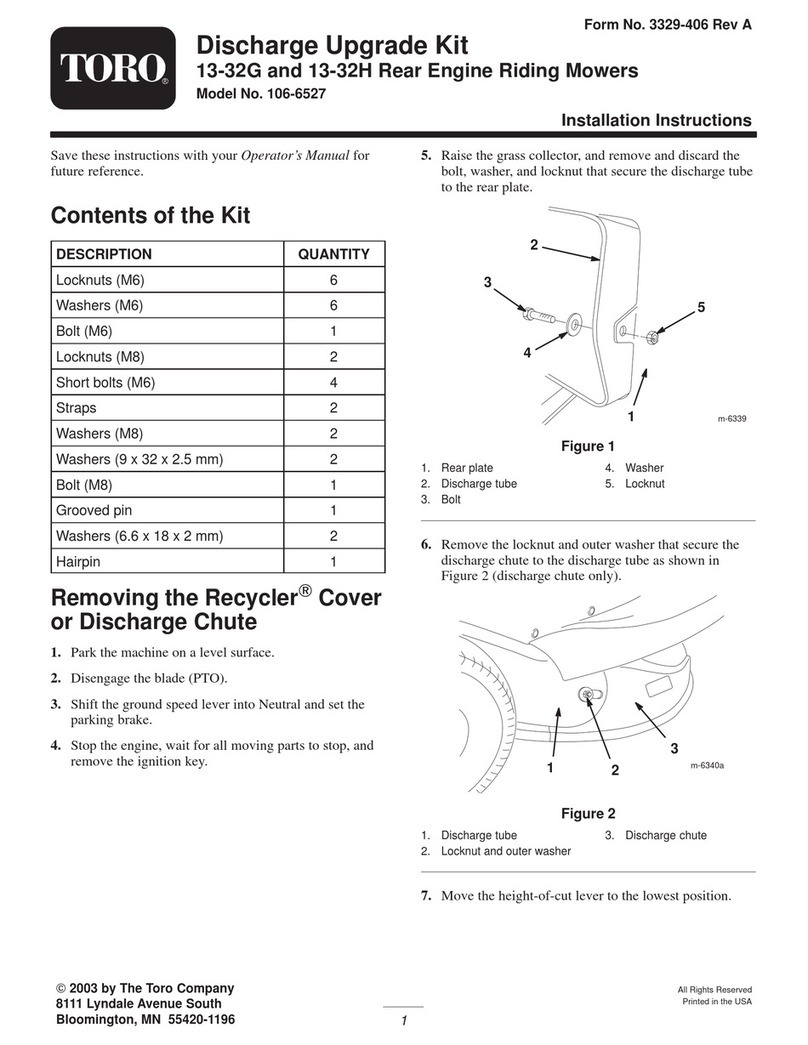

•Securetheadapterstogetherwiththeattachment

pinandhairpincotterasshowninFigure14.

Formoreabusiveloadinganutandboltmaybe

substituted.

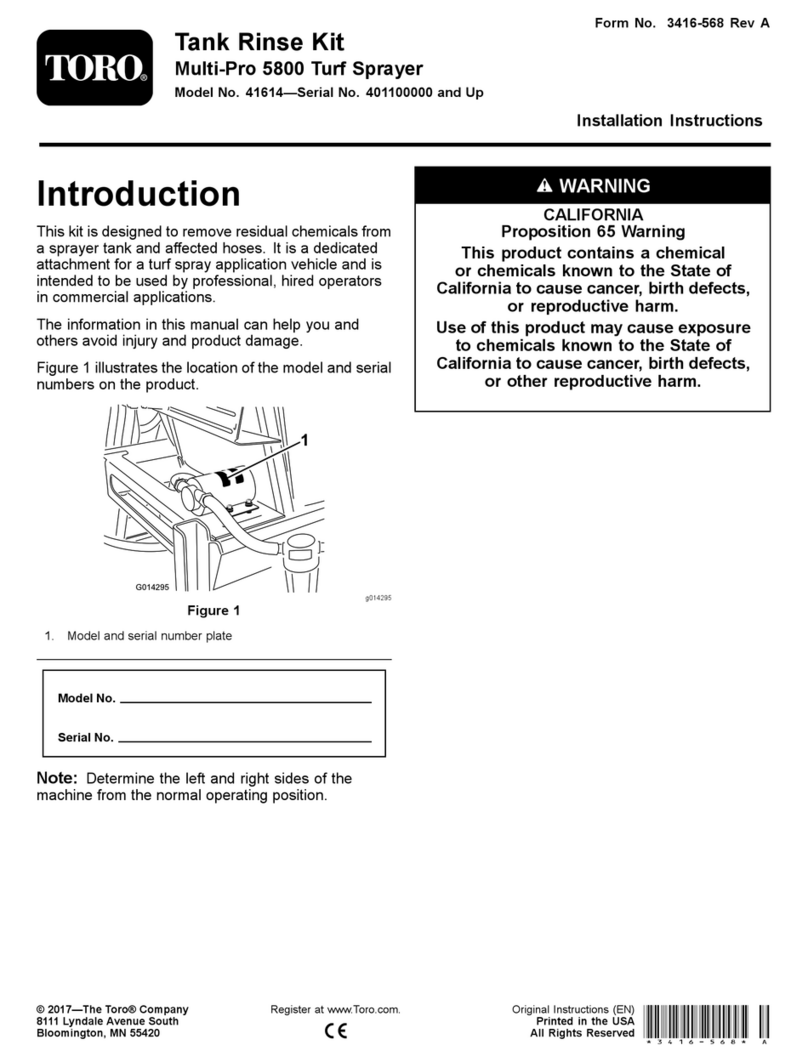

g004972

Figure14

1.Attachmentpin3.Machineadapter

2.Cotterpin4.Attachmentadapter

FrontAttachtoMowerDeck

Conversion

Removingthedeck

1.Onaatlevelsurfaceraisedecktohighest

position.

2.Place2furnituredolliesundereachendofthe

deckandloweritsoitrestsonthedollies.

3.Removethebolts(5/16inch)andremovethe

pinsfromthedrag-linksoneachsideofthedeck.

4.Removethefourretainerclipsandclevispins

fromthechainssuspendingthedeck.

5.Removetherollpinandloosenthebolts

securingthedriveshafttothedeck.

6.Slidethedriveshaftoffofthedeckgearboxand

secureittotheframeofthemachinewitha

bungiecordorstrap.

7.Thedeckcannowberolledoutfromunderthe

machine.

8.Ifpreparingthemachineforwinterwork,itwould

beadvisabletoremovethedeckhangingchains.

Attachingthedeck

1.Ifthedeckchainswereremovedfromthelift

arms,reinstallthem.

2.Raisethedrag-linksonthedeckwithaprybar

andplaceablock(6x2x4inch)undereach

onetoliftthearmup.Usecaution,asthere

willbeenergystoredinthetorsionspring.

3.Raisethefrontofthemachinesothereis

enoughclearancetoslidethedeckunderneath,

andlineupslotswiththedrag-link.

4.Slowlylowerthemachineoverthedraglinks

untiltheholeslineupintheframe.Insertthe

pinsandsecureitwithbolts(5/16inch).

5.Raisethemachineslightlyuntiltheblockcanbe

easilyremovedfromunderneaththedrag-links.

6.Lowerthemachineuntilthechainscanbe

attachedwithclevispinsandretainerclips.The

machinemyneedtobestartedandtheliftarms

loweredtothelowestpositionsothechainswill

reachthedeck.

7.Afterthedeckisattached,slidethedriveshaft

overthegearboxsplineuntiltheholesare

aligned.Inserttheroll-pinsandtightenthetwo

boltsonthedriveshaft.

8.Startthemachineandraisethedeckhigh

enoughtoremovethefurnituredollies.

9.Toadjustandverifytheheightofcut,consultthe

Owner'sManual.

10