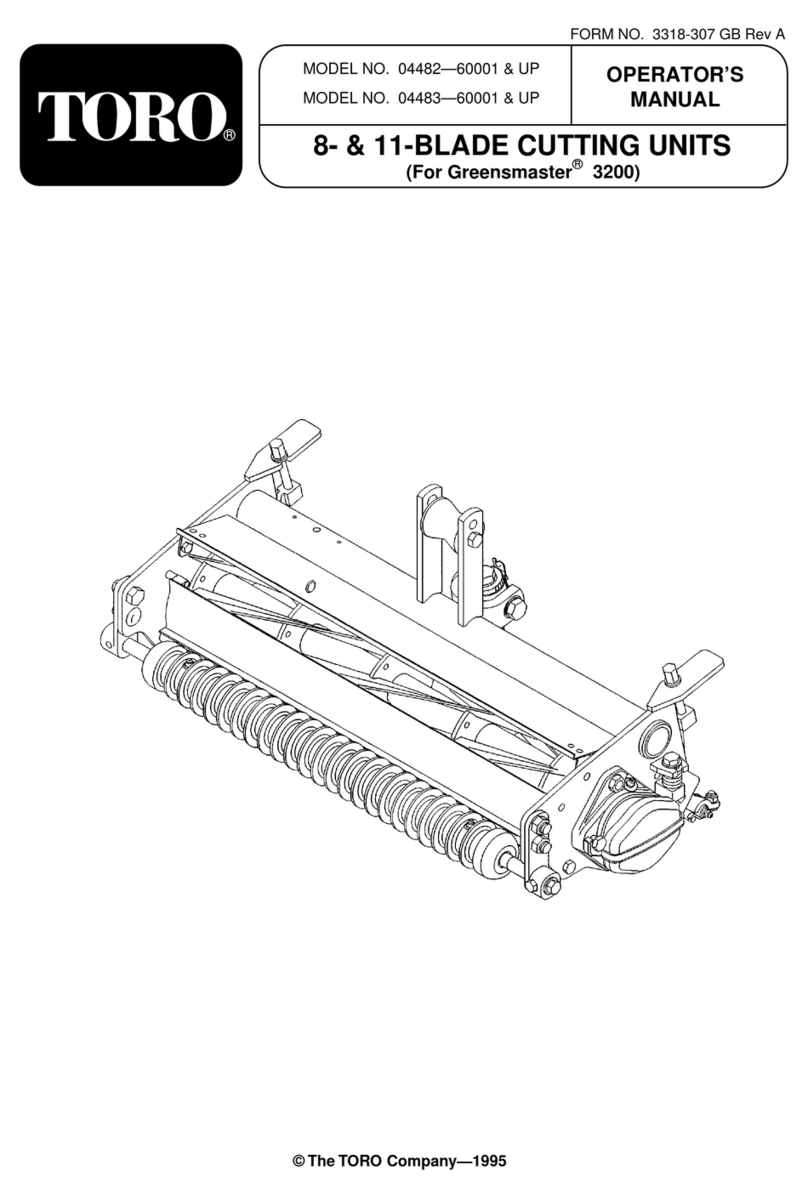

Note: When backlapping, the front units all operate

together, and the rear units operate together.

1. Position the machine on a level surface, lower the

cutting units, stop the engine, engage the parking

brake, and move the Enable/Disable switch to the

Disable position.

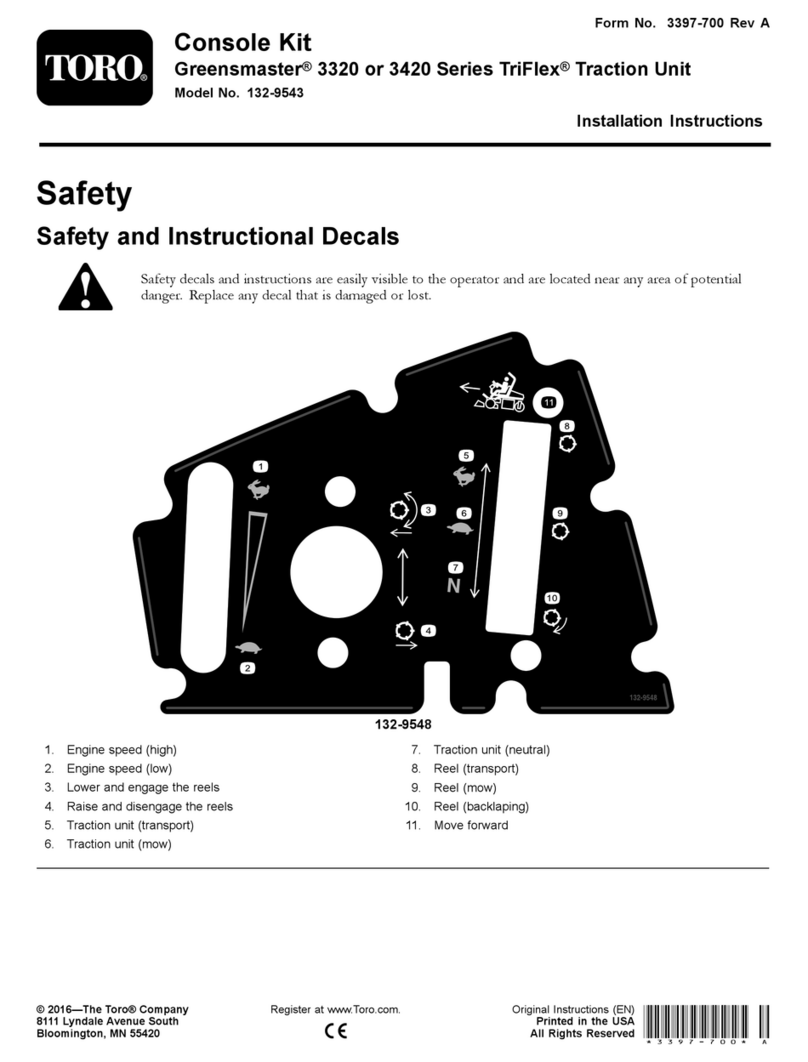

2. Unlock and raise the seat to expose the controls.

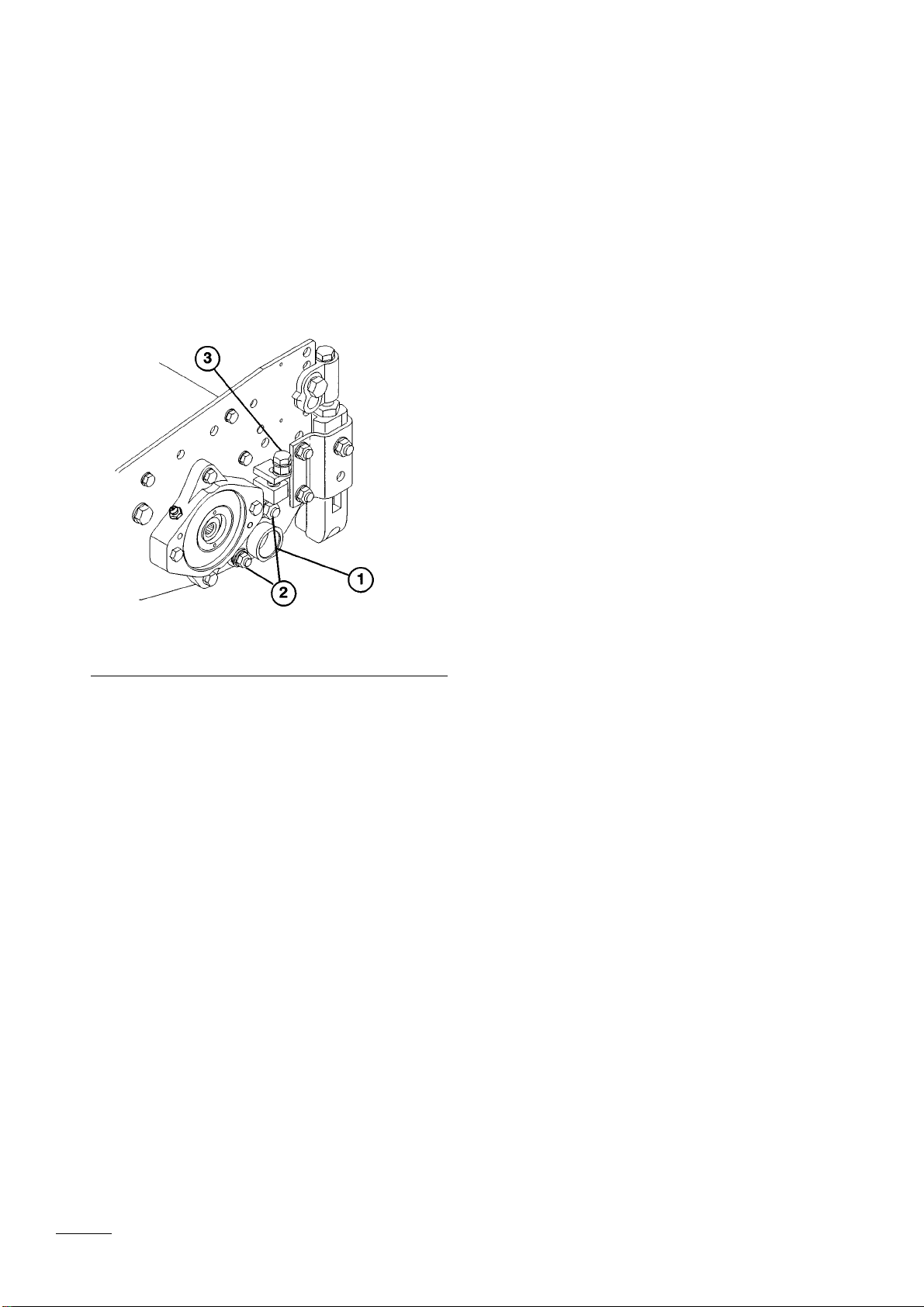

3. Open the control cover and turn the height-of-cut

selection knob to position “P”.

Note: Backlapping speed may be increased by

moving the height-of-cut selection knob toward to

‘A”. Each position will increase speed

approximately 60 rpm. After changing the selector,

wait 30 seconds for the system to respond to the

new speed target.

4. Make initial reel-to-bedknife adjustments for

backlapping on all cutting units that are to be

backlapped.

5. Start the engine and run it at idle speed.

6. Select either front or rear on the backlap switch to

determine whether front or rear reels will be

backlapped.

7. Move the Enable/Disable switch to the Enable

position. Move the Lower Mow/Lift control

forward to start backlapping operation on

designated reels.

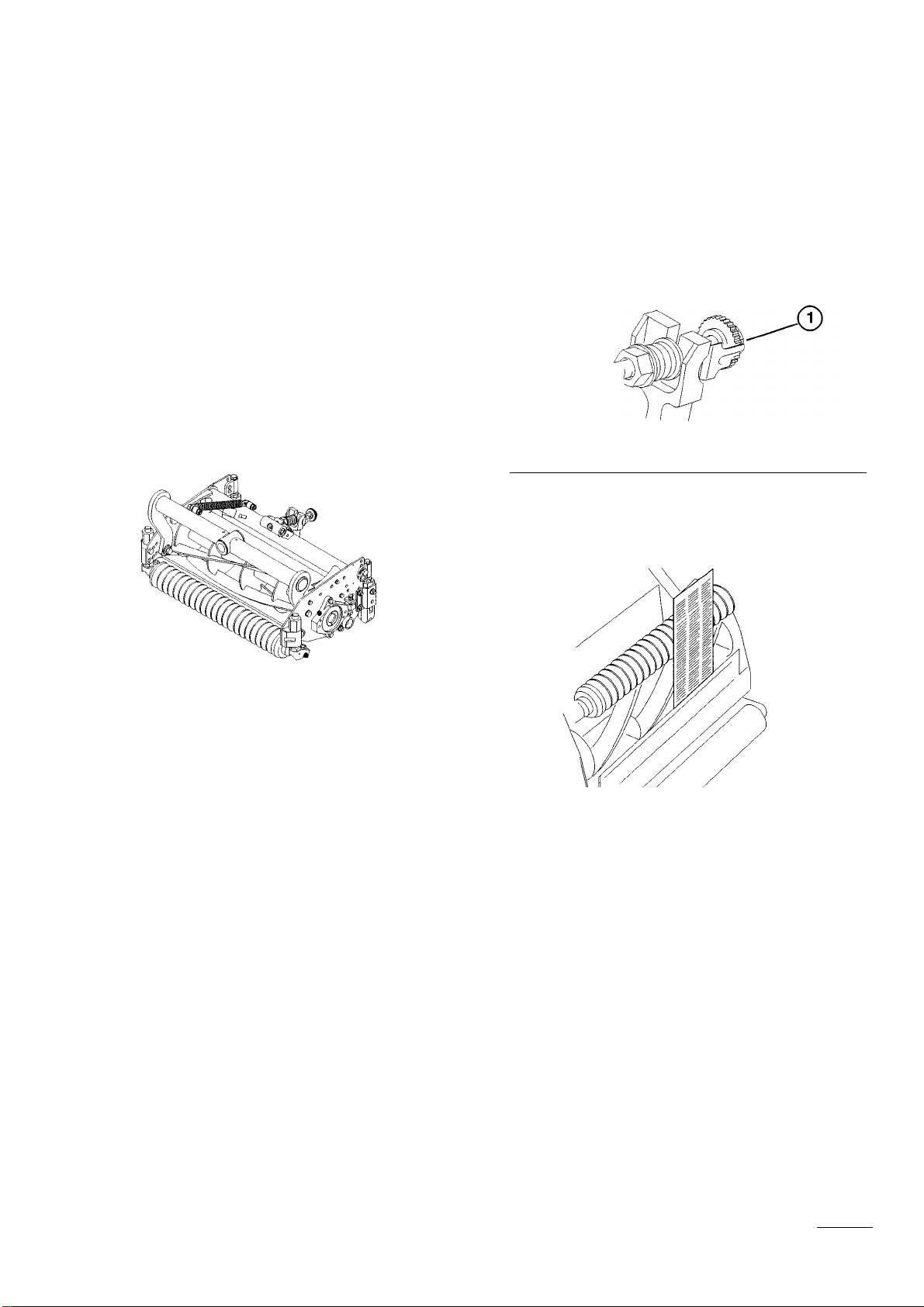

8. Apply lapping compound with a long handle brush

(Toro Part No. 29-9100). Never use a short handled

brush.

9. If reels stall or become erratic while backlapping,

the reel control light will begin to blink and the

reels will turn off. If this occurs, turn the height-

of-cut selection knob one position closer to “A’.

Then toggle the Enable/Disable switch to the

Disable position followed by the Enable position.

To resume backlapping, move the Lower Mow/Lift

control lever forward.

10. To make an adjustment to the cutting units while

backlapping, turn reels OFF by moving the Lower

Mow/Raise lever rearward; move the

Enable/Disable switch to Disable and turn the

engine OFF. After adjustments have been

completed, repeat steps 5–9.

11. Repeat the procedure for all cutting units to be

backlapped.

12. When backlap operation has been completed,

return the backlap switch to OFF, lower the seat

and wash all lapping compound off the cutting

units. Adjust cutting unit as needed.

IMPORTANT: If the backlap switch is not returned to

the OFF position after backlapping, the cutting units

will not raise or function properly.

9

Reels may stall while backlapping. do not attempt to

restart the reels by hand, or touch the reels while

backlapping. Stop the engine and turn the height-of-

cut knob one position toward “A”.

DANGER

To avoid personal injury, never place hands

or feet in the reel area while the engine is

running. Changing engine speed while

backlapping may cause reels to stall. Never

change engine speed while backlapping. Only

backlap at idle engine speed. Never attempt to

turn reels by hand or foot while the engine is

running.

DANGER

To avoid personal injury, be certain that you

are clear of the cutting units before

proceeding.

DANGER

Backlapping Cutting Units