Toro Groundsmaster 4500-D User manual

Other Toro Lawn Mower Accessories manuals

Toro

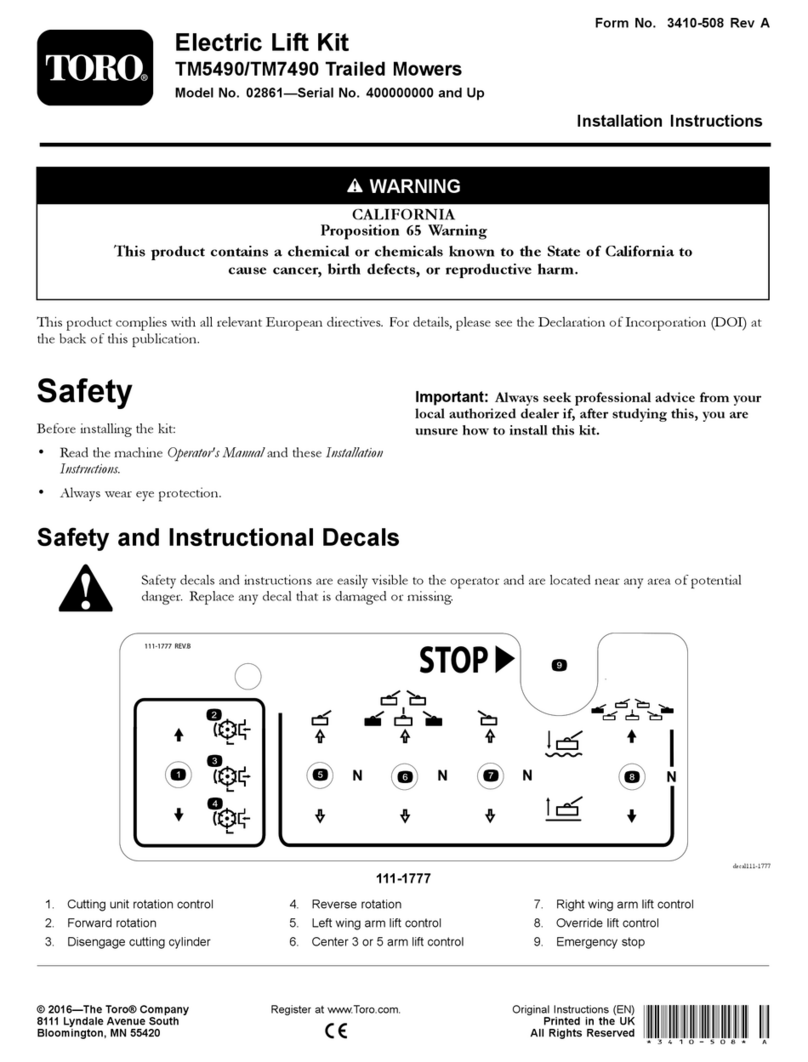

Toro 02861 User manual

Toro

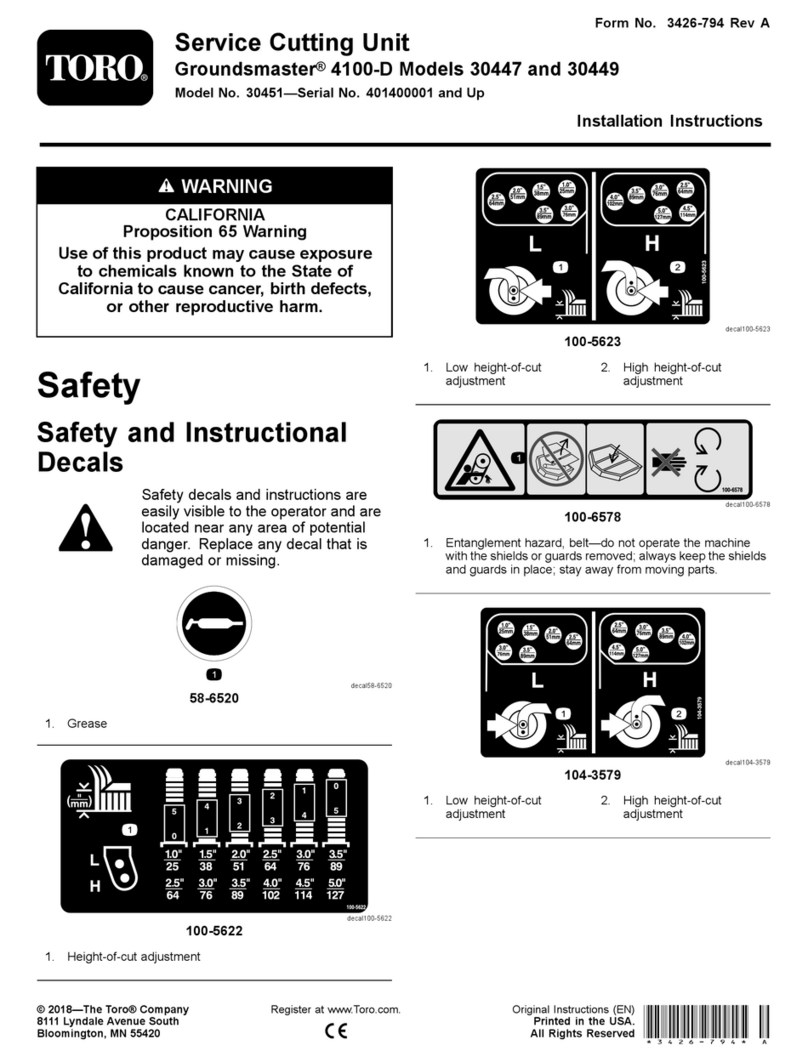

Toro 30447 User manual

Toro

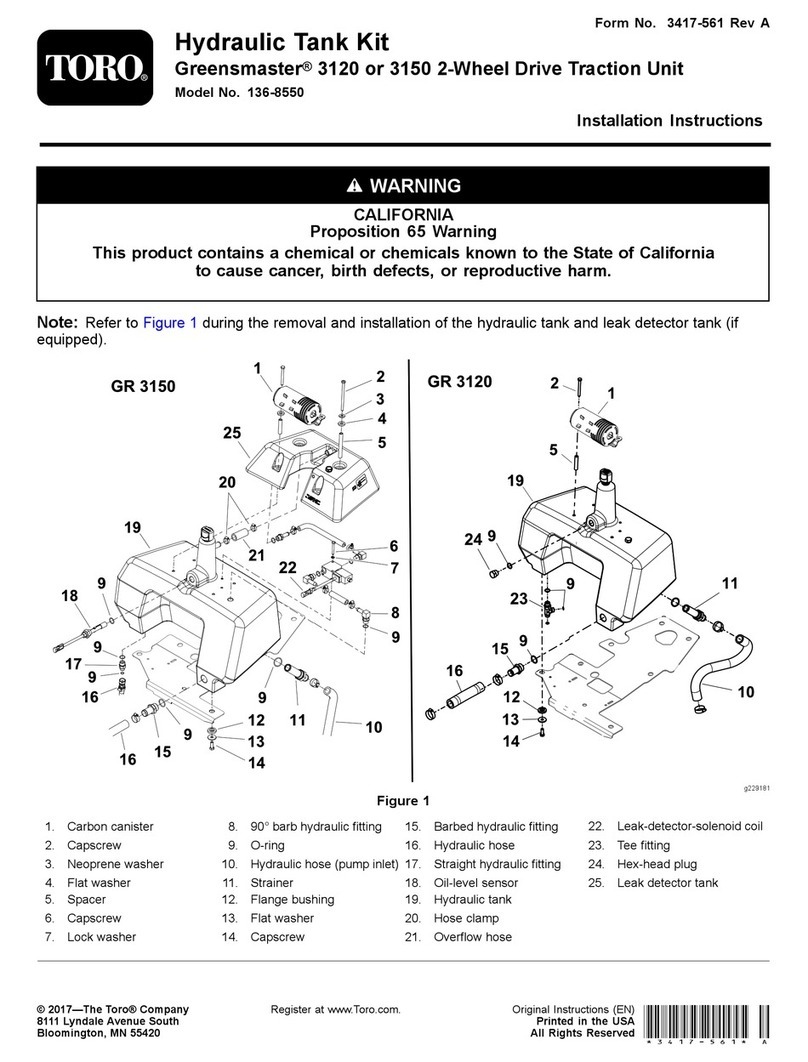

Toro 136-8550 User manual

Toro

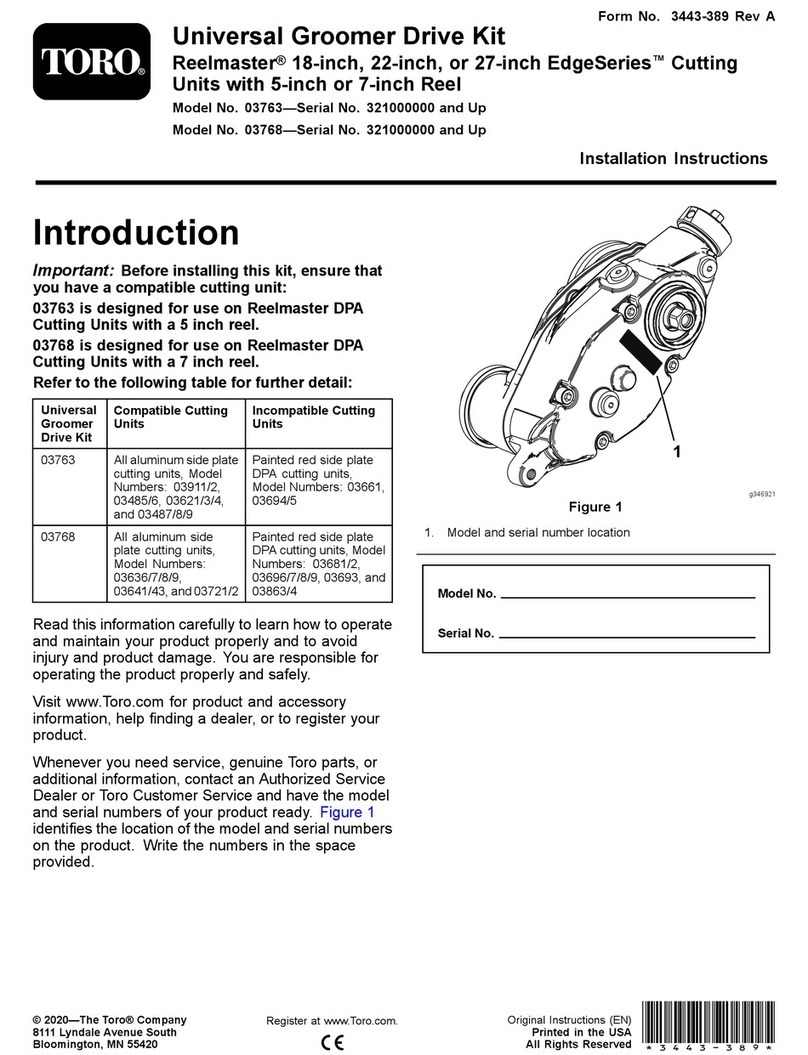

Toro Universal Groomer Drive Kit User manual

Toro

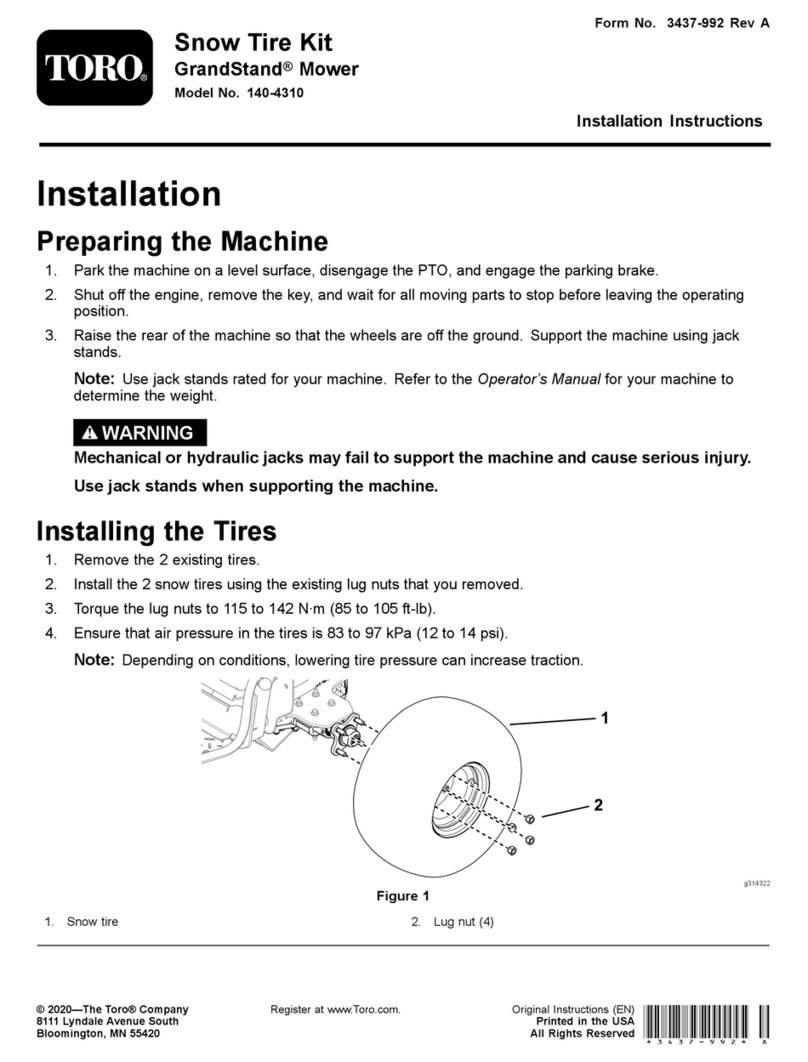

Toro 140-4310 User manual

Toro

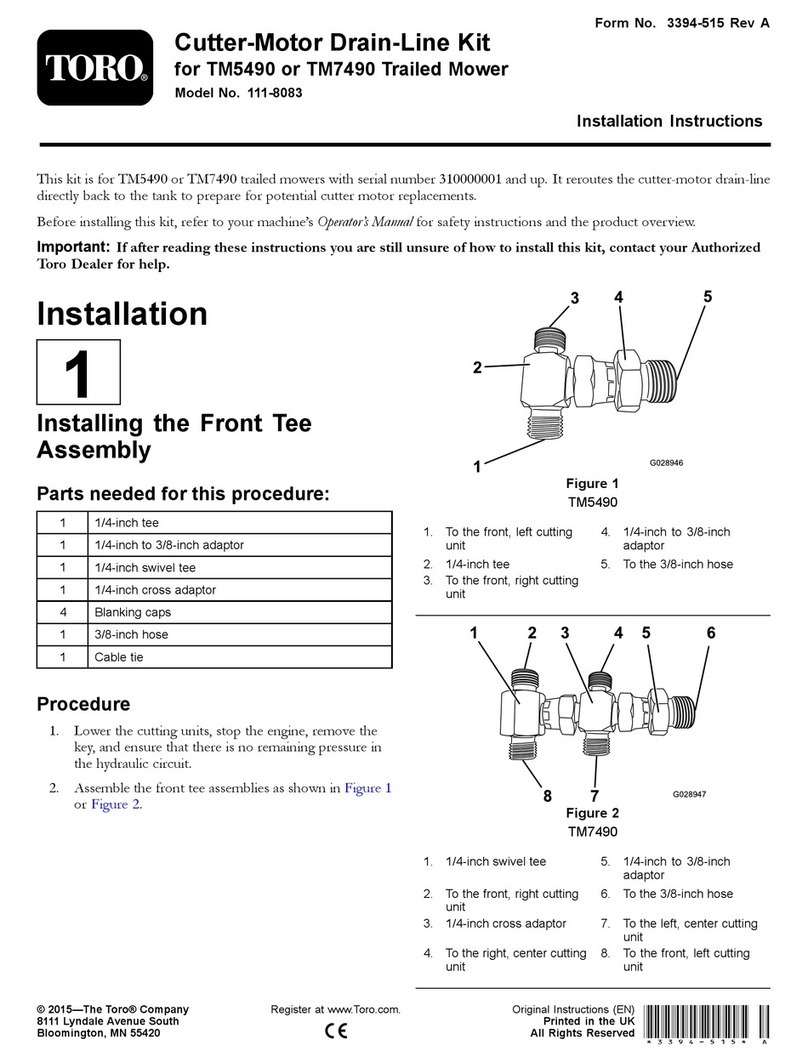

Toro 111-8083 User manual

Toro

Toro 144-1620 User manual

Toro

Toro 136-9045 User manual

Toro

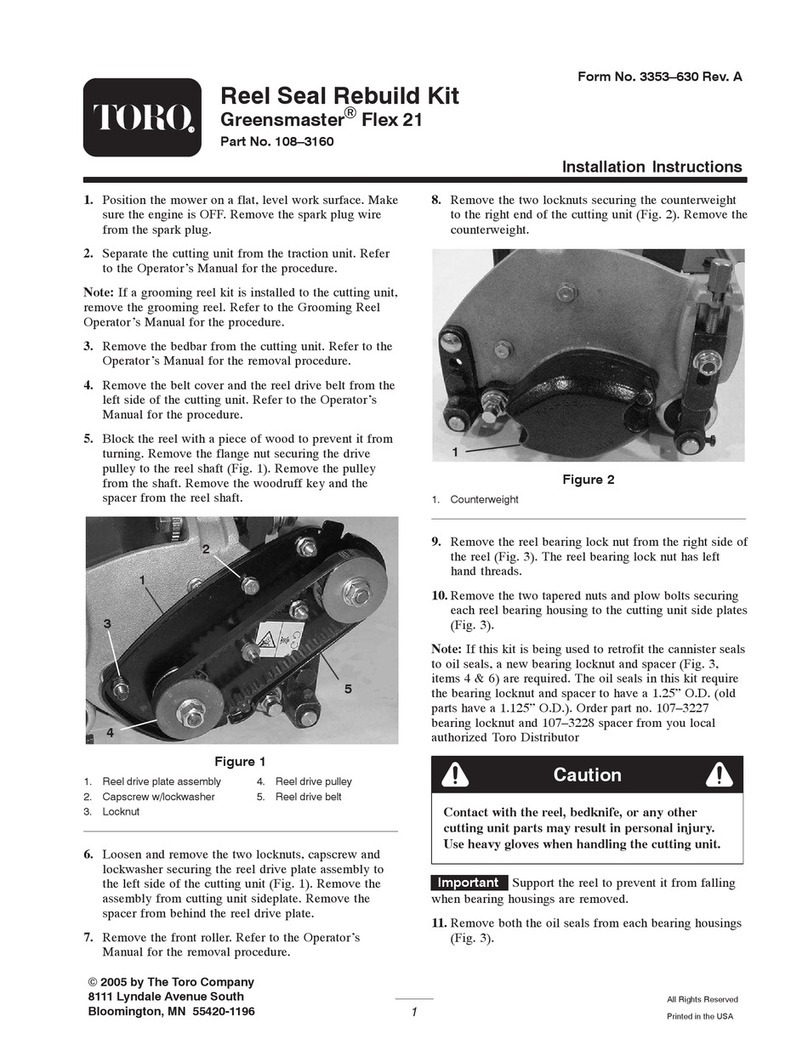

Toro 108-3160 User manual

Toro

Toro 144-2688 User manual

Toro

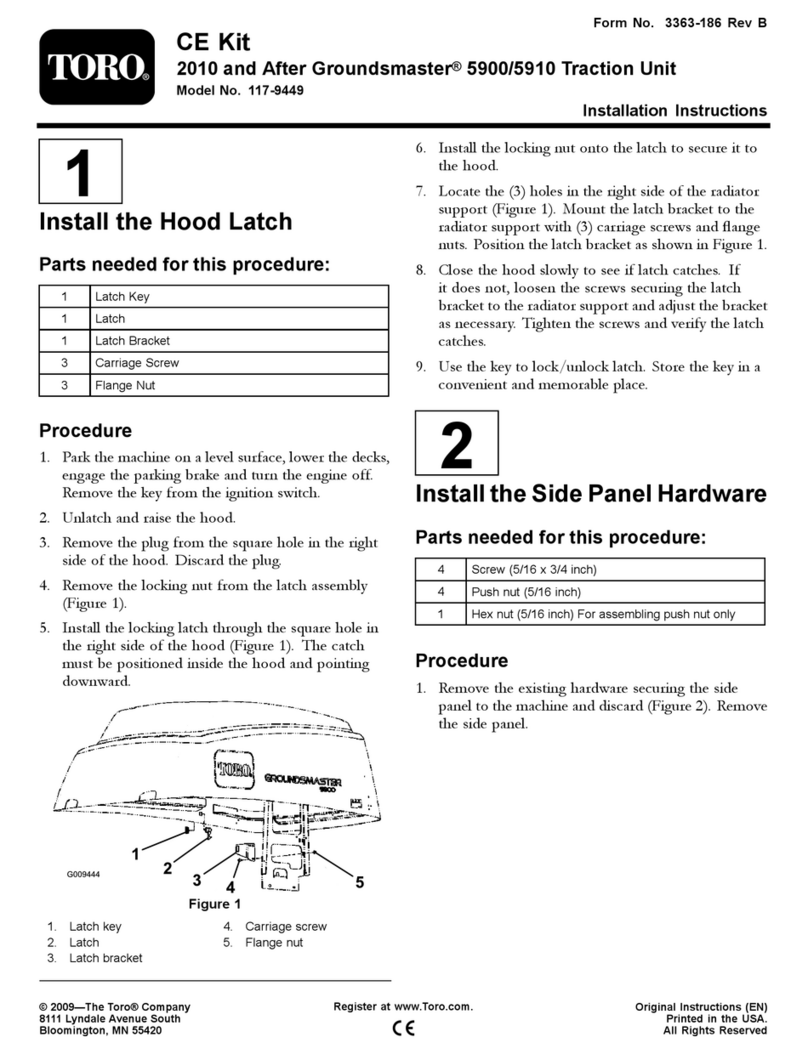

Toro 117-9449 User manual

Toro

Toro 147-0090 User manual

Toro

Toro Groundsmaster 200 Series User manual

Toro

Toro 03185 User manual

Toro

Toro Z Master 500 Series User manual

Toro

Toro 110-6506 User manual

Toro

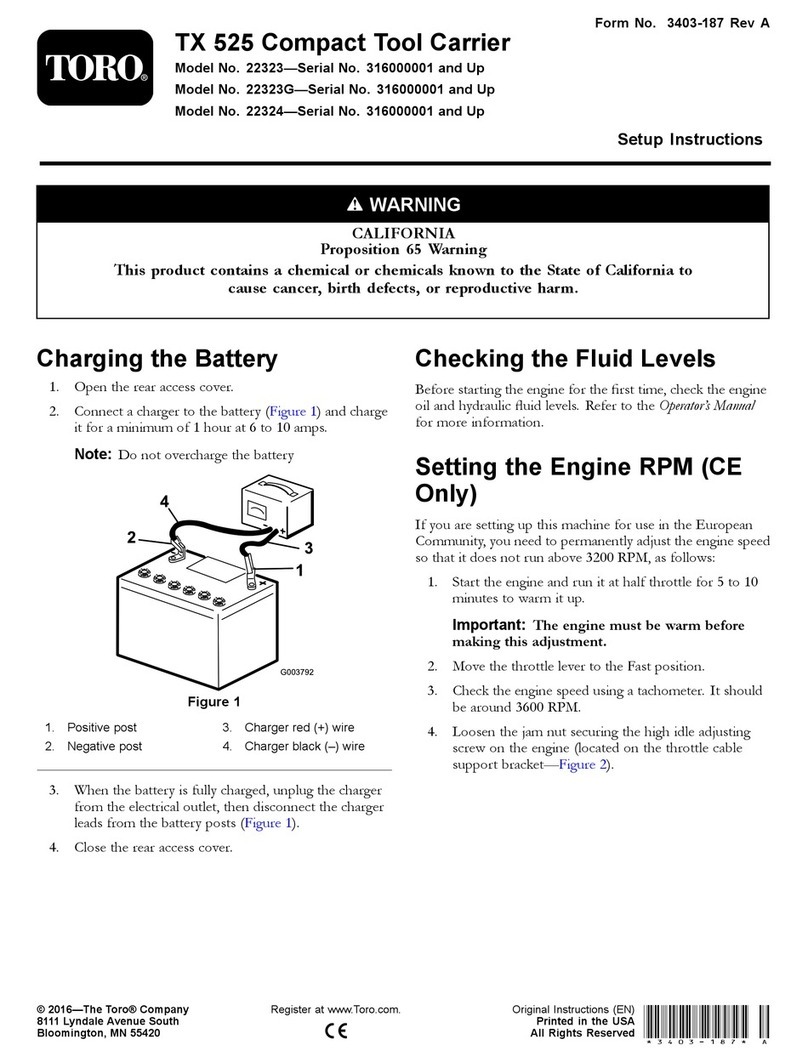

Toro 22324 Manual

Toro

Toro 140-5036 User manual

Toro

Toro 31200 User manual

Toro

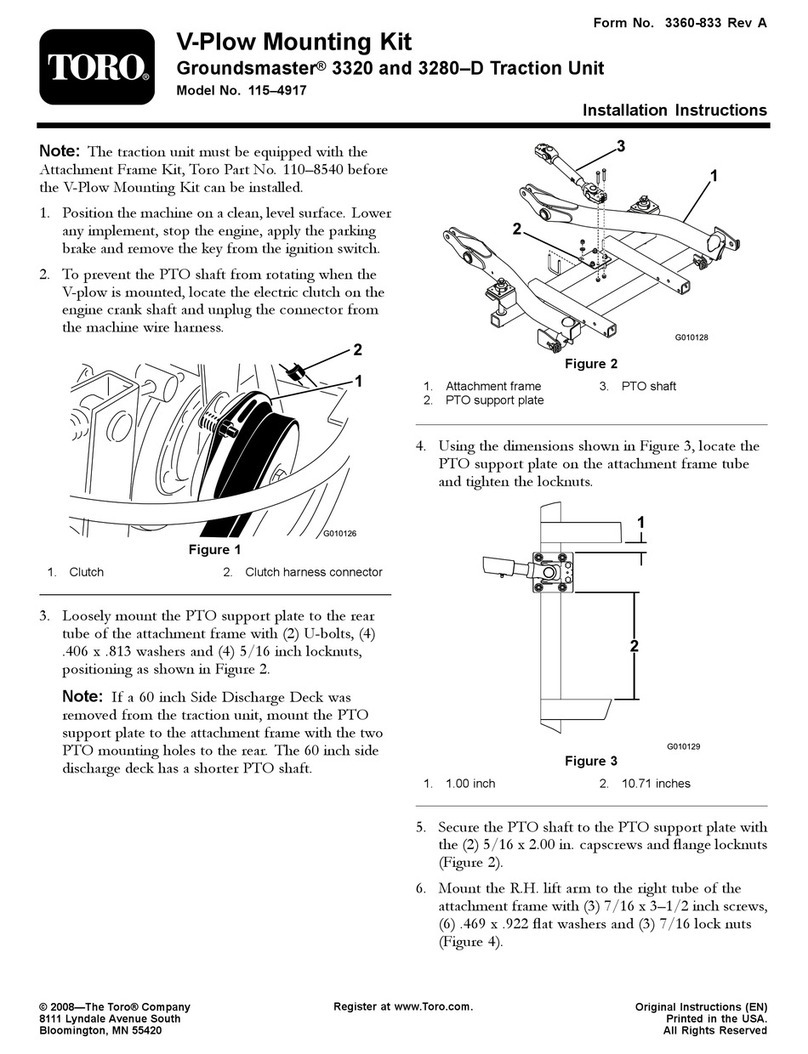

Toro 115-4917 User manual