Safety

ThemachinemeetstherequirementsofSAEJ2258.

SafeOperatingPractices

Important:Themachineisdesignedprimarilyasan

off-roadvehicleandisnotintendedforextensiveuse

onpublicroads.

Whenusingthemachineonpublicroads,followall

trafcregulationsanduseanyadditionalaccessories

thatmayberequiredbylaw,suchaslights,turnsignals,

slowmovingvehicle(SMV)sign,andothersasrequired.

TheWorkmanwasdesignedandtestedtooffersafeservice

whenoperatedandmaintainedproperly.Althoughhazard

controlandaccidentpreventionpartiallyaredependent

uponthedesignandcongurationofthemachine,these

factorsarealsodependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedintheoperation,

maintenanceandstorageofthemachine.Improperuseor

maintenanceofthemachinecanresultininjuryordeath.

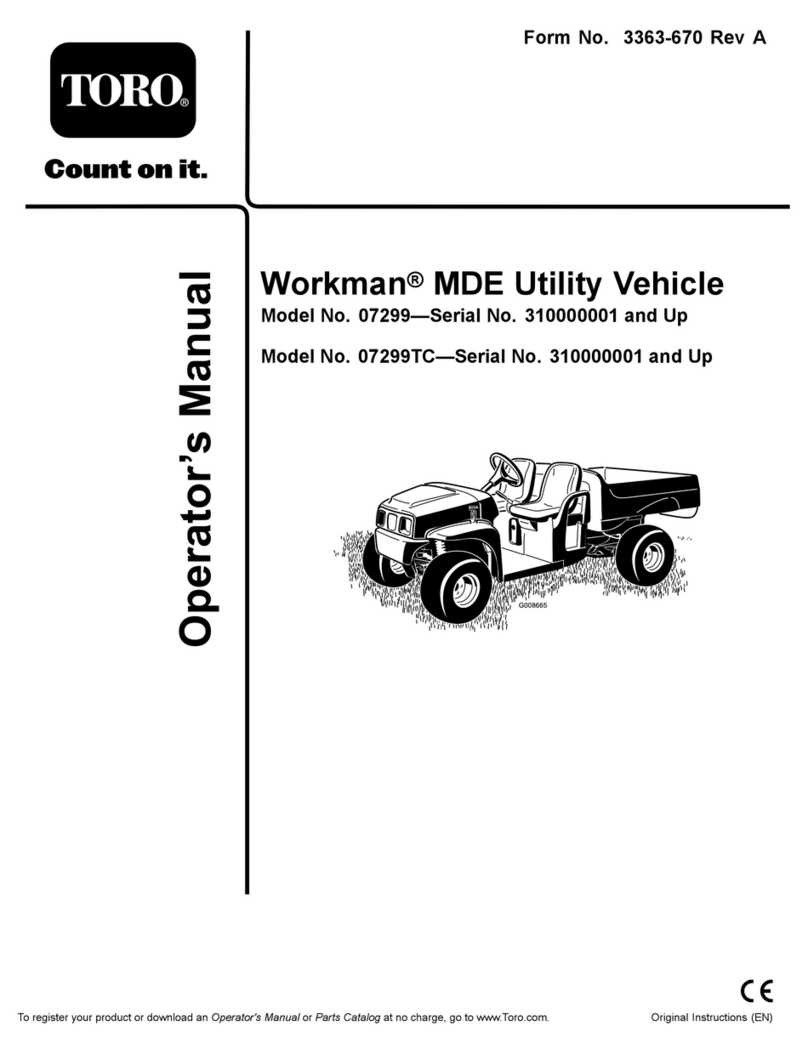

Thisisaspecializedutilityvehicledesignedforoff–roaduse

only.Itsrideandhandlingwillhaveadifferentfeelthanwhat

driversexperiencewithpassengercarsortrucks.Sotaketime

tobecomefamiliarwithyourmachine.

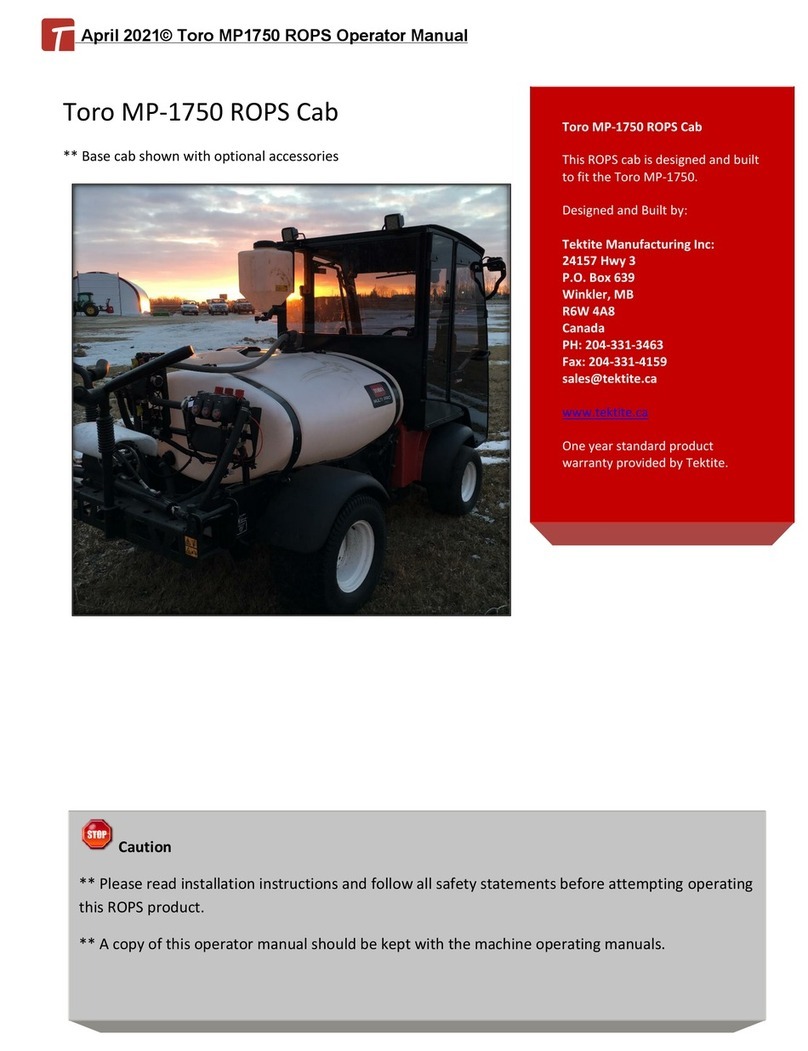

Notalloftheattachmentsthatadapttothemachine

arecoveredinthismanual.SeethespecicOperator’s

Manualprovidedwitheachattachmentforadditionalsafety

instructions.Readthesemanuals.

Toreducethepotentialforinjuryordeath,complywith

thefollowingsafetyinstructions:

Supervisor’sResponsibilities

•Makesureoperatorsarethoroughlytrainedandfamiliar

withtheOperator’sManualandalllabelsonthevehicle.

•Besuretoestablishyourownspecialproceduresand

workrulesforunusualoperatingconditions(e.g.slopes

toosteepforthesafeoperationofthemachine).

BeforeOperating

•Operatethemachineonlyafterreadingandunderstanding

thecontentsofthismanual.Areplacementmanualis

availablebysendingcompletemodelandserialnumber

to:TheToro®Company,8111LyndaleAvenueSouth,

Minneapolis,Minnesota55420.

•Thismachineisdesignedtocarryonlyyou,the

operator,andonepassengerintheseatprovidedbythe

manufacturer.Nevercarryanyotherpassengersonthe

vehicle.

•Becomefamiliarwiththecontrolsandknowhowtostop

theenginequickly.

•Neveroperatethemachinewhenundertheinuence

ofdrugsoralcohol.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,orsneakers.

Donotwearloosettingclothingorjewelrywhichcould

getcaughtinmovingpartsandcausepersonalinjury.

•Wearingsafetyglasses,substantialsafetyshoes,long

pants,andahelmetisadvisableandrequiredbysome

localsafetyandinsuranceregulations.

•Neverallowchildrentooperatethemachine.Never

allowadultstooperateitwithoutproperinstructions.

Onlytrainedandauthorizedpersonsshouldoperate

thismachine.Makesurealloperatorsarephysicallyand

mentallycapableofoperatingthemachine.

•Keepeveryone,especiallychildrenandpets,awayfrom

theareasofoperation.

•Checkthesafetyinterlocksystemdailyforproper

operation.Ifaswitchshouldmalfunction,replacethe

switchbeforeoperatingmachine.

•Keepallshields,safetydevicesanddecalsinplace.Ifa

shield,safetydeviceordecalismalfunctioning,illegible,

ordamaged,repairorreplaceitbeforeoperatingthe

machine.

•Beforeoperatingthevehicle,alwayscheckallpartsof

thevehicleandanyattachments.Ifsomethingiswrong,

stopusingvehicle.Makesuretheproblemiscorrected

beforevehicleorattachmentisoperatedagain.

•Useonlyanapprovednonmetal,portablefuelcontainer.

Staticelectricdischargecanignitefuelvaporsinafuel

containerthatisnotgrounded.Removethefuelcontainer

fromthebedofthemachineandplaceitontheground

andawayfromthevehiclebeforelling.Keepthe

nozzleincontactwiththecontainerwhilellingthefuel

container.Removeequipmentfrombedofthemachine

beforefuelingit.

•Operatethemachineonlyoutdoorsorinawellventilated

area.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

4