CONTENTS

EN

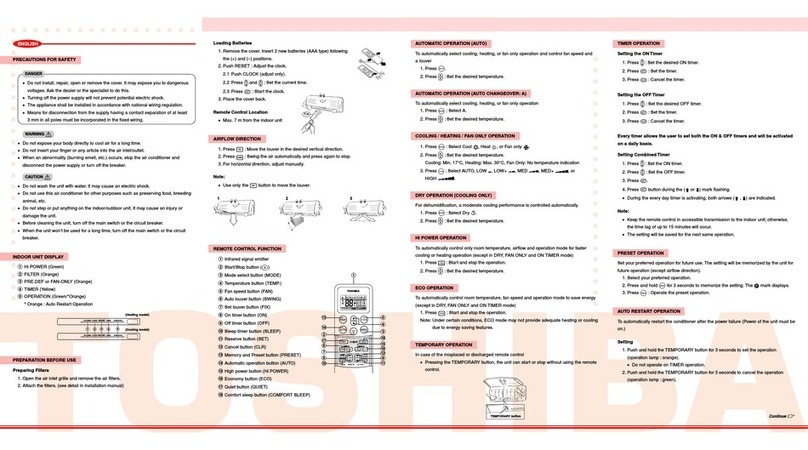

PRECAUTIONS FOR SAFETY...........................................................................................................................................1

ACCESSORY PARTS.........................................................................................................................................................5

INSTALLATION DIAGRAM OF INDOOR AND OUTDOOR UNITS ...................................................................................6

Optional Installation Parts...............................................................................................................................................6

INDOOR UNIT.....................................................................................................................................................................7

Installation Place.............................................................................................................................................................7

Cutting a Hole and Mounting Installation Plate...............................................................................................................7

How to Install Indoor Unit................................................................................................................................................8

Concealed Installation.....................................................................................................................................................9

How to open the air inlet grille.......................................................................................................................................10

How to use the heat insulation block ............................................................................................................................10

OUTDOOR UNIT...............................................................................................................................................................10

Installation Place...........................................................................................................................................................10

Precautions about Installation in Regions with Snowfall and Cold Temperatures ........................................................11

Draining the Water ........................................................................................................................................................ 11

Refrigerant Piping Connection...................................................................................................................................... 11

Evacuating ...................................................................................................................................................................12

Wiring Connection.........................................................................................................................................................12

Electrical Work ..............................................................................................................................................................12

OTHERS............................................................................................................................................................................13

Gas Leak Test ...............................................................................................................................................................13

Setting of Remote Control Selector Switch...................................................................................................................13

Remote Control A-B Selection ......................................................................................................................................13

Test Operation ..............................................................................................................................................................13

Auto Restart Function Setting ......................................................................................................................................13