Toshiba VF-NC3C User manual

Other Toshiba Inverter manuals

Toshiba

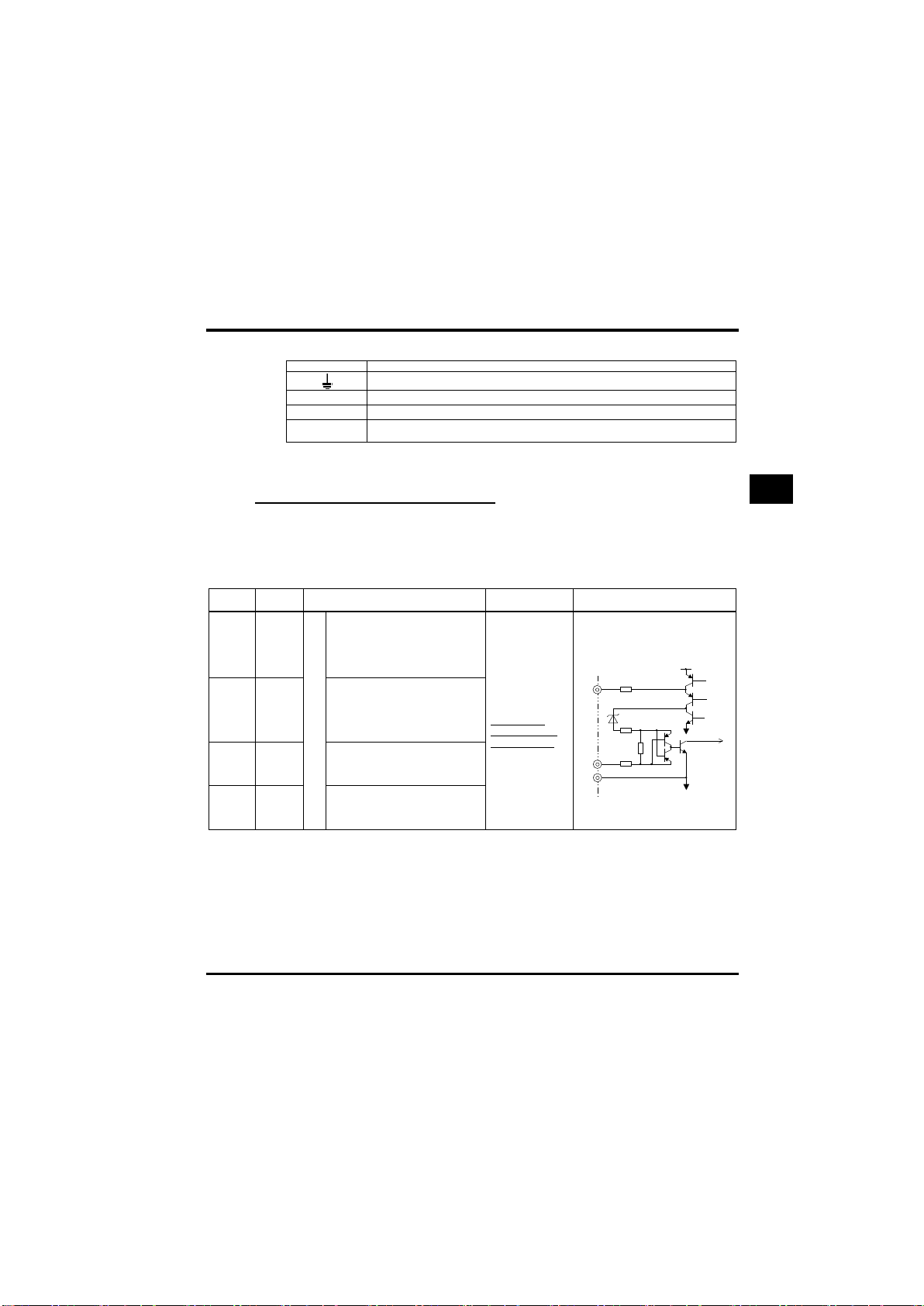

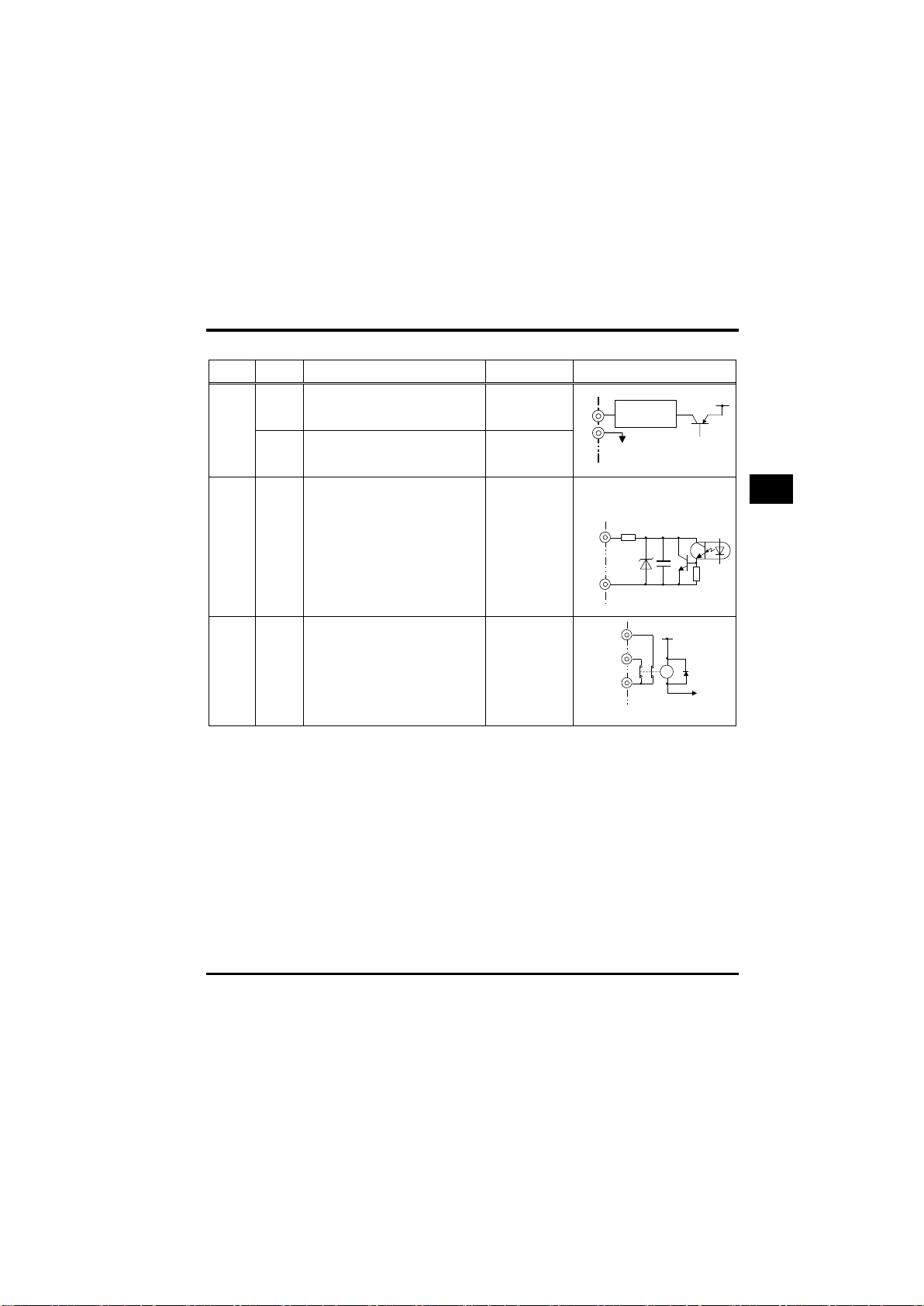

Toshiba DEV002Z User manual

Toshiba

Toshiba VF-SX User manual

Toshiba

Toshiba TOSVERT VF-S11 User manual

Toshiba

Toshiba TOSVERT VF-S11 User manual

Toshiba

Toshiba TOSVERT VF-FS1 Series User manual

Toshiba

Toshiba DEV001Z Parts list manual

Toshiba

Toshiba RAS-25PKVSG-ND User manual

Toshiba

Toshiba LONWORKS option unit Parts list manual

Toshiba

Toshiba TOSVERT VF-A7 User manual

Toshiba

Toshiba TOSVERT VF-S15 series User manual

Toshiba

Toshiba TOSVERT VF-AS1 Series User manual

Toshiba

Toshiba TOSVERT VF-AS1 Series User manual

Toshiba

Toshiba Q9 True Torque Control2 Adjustable Speed... User manual

Toshiba

Toshiba VF5X-4575 User manual

Toshiba

Toshiba TOSVERT VF-S15 series Parts list manual

Toshiba

Toshiba TOSVERT VF-nC3 User manual

Toshiba

Toshiba G7 User manual

Toshiba

Toshiba TOSVERT VF-AS1 Series User manual

Toshiba

Toshiba Tosvert VF-A3 User manual

Toshiba

Toshiba TOSVERT VF-AS3 User manual