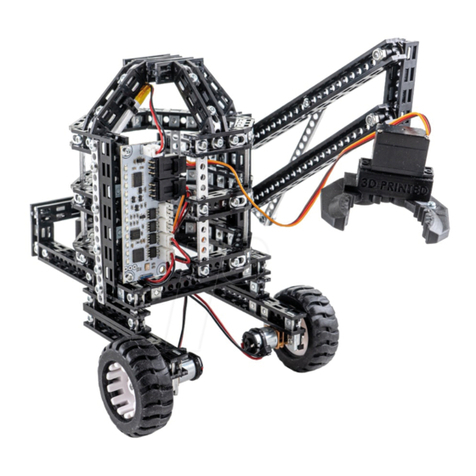

Totem T.R.U.C.K. User manual

Strip brackets:

5x 40mm

(8 holes)

Mechanical parts needed to build this model

20x

C-Bracket

20x

2-hole Simple

171x

Bolt M3 6mm

12x

Bolt M3 12mm

177x

Nut M3 6x10

16x

2-hole 45

16x

Double side ller

3x

L-bracket

3x

Bolt M3 35mm

3x

12mm Hex Wheel Fix

3x

Bearing Axle

6x

Bearing M8 16mm

6x

Bearing Barrel

23x

Lock Nut M3

13x

Bolt M3 16mm

3x

Bolt M3 8mm

6x

Beam Plug

3x

Nut M3 5.5x5.5

2x

Distance tower 6mm

1x

DC motor distance part

4x

3-hole bracket

1x

25mm geared motor

1x

25mm motor bracket

1x

12mm Hex wheel- x

11x

L-Twisted

6x

L-Twisted mirror

1x

Servo SG-5010

4x

2-hole 90

5x 40mm

Beam lengths:

2cm : 15x

3cm : 4x

4cm : 15x

5cm : 8x

6cm : 2x

7cm : 1x

8cm : 3x

9cm : 2x

12cm: 3x

15cm: 2x

16cm: 2x

17cm: 2x

3x

Lock Nut M4

4x

Nylon Standoff 7mm

2x

Brass Standoff M3 8mm

4x

RC Wheels 65mm

4x

Bolt M4 10mm

Helpful tools not supplied in the kit:

8x

Nylon Standoff 8mm

Zip Ties:

5x 100mm

5x 40mm

3x18650 Li-ion pack

and charger.

X2

X3

FB30

FB53

BC1

Electronics parts needed to build this model

Function board 53 - DC

motor and 2 channel servo

board. Allows you to control

direction and speed of the

motor. Can control up to 1A

motor at 18V.

Function board 30 - power

board. Provides up to 2A

currents at 5V for Totem bus.

Has integrated overcurrent

and short-circuit protection

circuits. Accepts power

supplies up to 18V.

Base board X2 - Micropro-

cessor board which can

control any function board

you connect on top of it. In

this kit it controls the motor

and servo.

Base board X3 -

Microprocessor board with

Bluetooth bridge. I connects

to your mobile phone, and

sends commands to the

other X2 baseboard.

Battery connector board 1

- This board connects the Li-

ion battery to the electronics

in the car. The switch either

puts the board in charge or

run mode.

Battery power cable

20cm 2-wire (JST PH 2mm)

Battery +5V power cable

20cm 4-wire (JST PH 2mm)

Totem Bus cable

15cm 6-wire atcable

DC motor cable

15cm 6-wire atcable

1

4x

Beams : 4 x 5cm , 8 x 4cm , 8 x 2cm

Start by building 4 pcs. Wheel

Arches. They are Sub-assembly “A”.

All Sub-assemblies will get

alphabetical names “A” - “Z”

40x

Bolt M3 6mm

40x

Nut M3 6x10

A

16 x

2-hole 45

16x

Double side ller

Double side ller

This part is shown as

green, so it’s easier to

identify in the pictures. It

is in reality black.

TIP:

Insert the Double Side

Filler AFTER one side of

the bracket is loosely

xed. Fix the 2 bolts tight

as the last step.

8x

L-Twisted

Build step-number

2

2x

4x sub- assembly A , Beams: 4 x 5cm , 2 x 16cm

Combine the Wheel Arches “A”

into 2 Sub-assemblies “B”.

8x

Bolt M3 6mm

8x

Nut M3 6x10

B

#2

#15

#2

#4

Whenever you see a “#nn”

character, it means “slot number” in

the I-beam the nut is inserted.

In this white rectangle you

will nd additional guidance

for building.

The blue section

shows you what

parts you need to

build each step.

3

#1

The Sub-assembly “C” will

combine the 2 wheel arch

assemblies “B” into the cars lower

frame in the next step.

6 x

Bolt M3 6mm

6x

Nut M3 6x10

C

#17

#1

#8

2x

L-bracket

Beams : 2 x 17 cm

1x

#8

#17

4x

2-hole Simple

This rectangle

shows the result

you have after

nished building

the current step.

This section of a building

step is the exploded view

that guides you how to

build the current step.

It is the most important

part of the instructions for

each step.

4

Use the previous sub-assembly

“C” to combine the 2 “B” assemblies

into a lower frame for the car.

Since the wheel arches contain

45 degree geometry, we use

adjustable angled L-brackets to t

them.

D

Sub-assemblies : 2x B , 1x C

6x

M3 6mm bolt

1x 6x

Nut M3 6x10

#6

#11

We give each sub

-assembly a letter, so

later we can refer to

it when combining

with other sub-

assemblies.

Here we show how

many equal parts to

make of this sub-

assembly.

Adjust the

L-bracket

position so the

arches looks

straight.

5

1x

Sub-assemblies: 1x D

It’s time to x the servo motor to

the car’s frame. It’s enough to use 2

bolts in a diagonal to x the servo.

Start with putting the rectangular

nuts into the beam, and then

screw the 8mm standoff to the

beams as shown. Then position the

servo (some tweaking needed) and

x it.

D + servo

2x

M3 6mm bolt

2x

Nut M3 6x10

#1 #5

#4

#1

1x

Servo SG-5010

Upper

slot

2x

Brass Standoff M3 8mm

6

1x

Sub-assemblies: 1x D + strip bracket 40mm

In this step you will make the

servo actuator steering arm. The 2

lock nuts should in this step only

be entered with a few turns. This

makes step 18 easier later. They will

be tightened more in step 18.

D cont

2x

Lock nut M3

2x

M3 12mm bolt

1x

L-Twisted mirror

1x

The servo arm with

bracket will later

be attached to the

steering mechanism

(Step 18).

Strip bracket 40mm

7

1x

Beams : 2x 9cm, 5x 4cm

This step is to make the case

that houses and xes the steering

mechanism. First you make 4

“legs”, then connect them with

9cm beams into 2 halves. Then

combine the 2 halves with a 4cm

beam. Then attach 2pcs 2-hole 90

brackets as shown in the drawing.

N

18x

M3 6mm bolt

18x

Nut M3 6x10

8x

C-Bracket

2x

2-hole Simple

2x

2-hole 90

Make 4 pcs:

4x

Make 2 pcs:

2x

Brackets

in lower

position.

8

In this step you will build the

wheel barrels. You start by putting

the 2 bearings onto the bearing

axle part (green in picture). The

wheel hex x (blue in picture) with

M4 lock-nut inserted, is put into

one barrel half. Then clamping the

2 barrel halves over the bearings

and wheel hex x.

E

3x

3x

M3 35mm bolt

3x

12mm Hex Wheel Fix

3x

Bearing Axle

6x

M8 16mm Bearing

6x

Bearing Barrel

9x

Lock nut M3

6x

M3 12mm bolt

OBS!:

Lock nut M4

OBS!:

Lock nut M3

3x

Lock nut M4

TIP:

To fasten lock nuts: First enter

nuts with ngers. Use either a

small at screwdriver or pliers to

help hold the nut.

Making the wheels barrels.

A

B

Sub-steps. First do

“A” then “B” , “C”

and so on.

OBS:

Many parts are

shown with

colors for clarity,

and are often

black in reality.

9

Beams : 2 x 4cm

The sub assembly “F” is the

vertical steering column. They will

later be part of the whole steering

mechanism.

4x

Bolt M3 6mm

4x

Nut M3 6x10

F

4x

C-Bracket

2x 2x

M3 8mm bolt

4x

Beam Plug

2x

Nut M3 6x6

OBS:

The orientation

and position of

the beam-plug is

important.

(It is black in

reality) OBS:

The bolt must be

in the center of

the beam.

10

In following steps, these parts

will be used to x the steering

columns “F” to the rest of the

steering mechanism. Remember to

make 2 of each.

G1 , G2

4x

Bolt M3 6mm

4x

Nut M3 6x10

2x+2x

Beams : 4 x 3cm, 4x strip brackets 40 mm

G1

G2

4x

Strip bracket 40mm

OBS:

Please take care to

make these parts

correct. Double-

check the parts

before going to the

next step.

11

Sub-assemblies: 2x F , 4x G

In this step you will combine the

2 “F” Sub-assemblies with the “G1

and G2”. Note that we make two

mirrored sub-assemblies, “H1” and

“H2”. One is for right side of car, the

other is for the left. Use lock nuts

M3 and tighten them just enough

to get a smooth rotation “hinge”

movement.

H1 & H2

1x + 1x 4x

Lock nut M3

H1 H2

4x

M3 12mm bolt

FF

G2

G2

G1

G1

OBS:

Take care to

orient the

G1 and G2

correct. Strip

brackets

in lower

position!

OBS:

The hole in the

Beam Plug must

be in lower

position.

12

Find your previously assembled

“E” Sub-assemblies, and use lock

nut M3 to attach them to the

previous steps “H1” and “H2” parts.

Tighten the M3 nuts enough so

parts are not loose.

I1 + I2

1x + 1x

Sub-assemblies: 2x E , 2x H

2x

Lock nut M3

TIP:

Use an allen key

for M3 when

tightening the

lock-nuts. Use

a plier or socket

for the lock-nut.

Tighten well.

13

Beams 2x 2cm

The part “J1 and “J2” functions as

the arms to the steering column.

The 2 angled brackets is xed in a

special way to the beams. They are

put in contact with the 6x10mm

nut and screwed to it. The reason is

to get steering geometry distances

correct.

J1 & J2

1x + 1x

J1

J2

OBS:

Non-standard

joint between

bracket and

bolt/nut.

4x

M3 6mm bolt

4x

Nut M3 6x10

2x

2-hole Simple

1x

L-Twisted

1x

L-Twisted mirror

Push the

brackets all

in close to

the beams.

14

This part “H” will connect the

right and left part of the steering

mechanism from previous steps.

Note that the adjustable brackets

should be xed in the “outer”

position. See detailed picture in

circle above.

K

2x

M3 6mm bolt

2x

Nut M3 6x10

1x

Beam : 1x 8cm

1x

L-Twisted

1x

L-Twisted mirror

Pull the

brackets

all out

sideways.

15

1x

Sub-assemblies: 1x J1, 1x J2, 1x K

This step connects “K” to the 2

“J” arms. Use 2 distance towers,

length 6mm as shown. Tighten the

lock nuts just enough to get a good

smooth pivot action. Not too loose

either.

L

2x

Distance tower 6mm

2x

M3 16mm bolt

2x

Lock nut M3

K

J1

J2

OBS:

Note the position

of the L-twisted

brackets!

16

1x

Sub-assemblies: 1x I1 + 1x I2 + 1x L

It’s time to connect the parts from

previous steps into the complete

Sub-assembly of the movable

parts in the steering mechanism.

The 2 arms are connected to the

vertical beams as shown.

M

2x

M3 6mm bolt

2x

Nut M3 6x10

A

C

B

17

1x

Sub-assemblies : D + M

Now you will attach the steering

mechanism “M” to the frame “D”.

Use 16mm M3 bolts going through

the 3cm beams in the lower

steering part, into the rectangular

nuts as shown. The steering will

feel “loose”, but later the upper

part will be xed.

O

4x

M3 16mm bolt

4x

Nut M3 6x10

#1

#7

#8

#7

#8

OBS : Model is seen from the underside !

The upper arms will

be xed later.

Table of contents

Other Totem Robotics manuals

Totem

Totem Lucas the Robot User manual

Totem

Totem Mini Trooper User manual

Totem

Totem MINI SPIDER User manual

Totem

Totem MINI SHOOTER User manual

Totem

Totem Mini Lab Product information sheet

Totem

Totem Motor-Wheel Platform User manual

Totem

Totem LarvaMobile User manual

Totem

Totem LADYBUG User manual

Totem

Totem LIFT MOBILE User manual

Totem

Totem Gripper Bot User manual