Installation Manual

03F10RN T1 2021.4

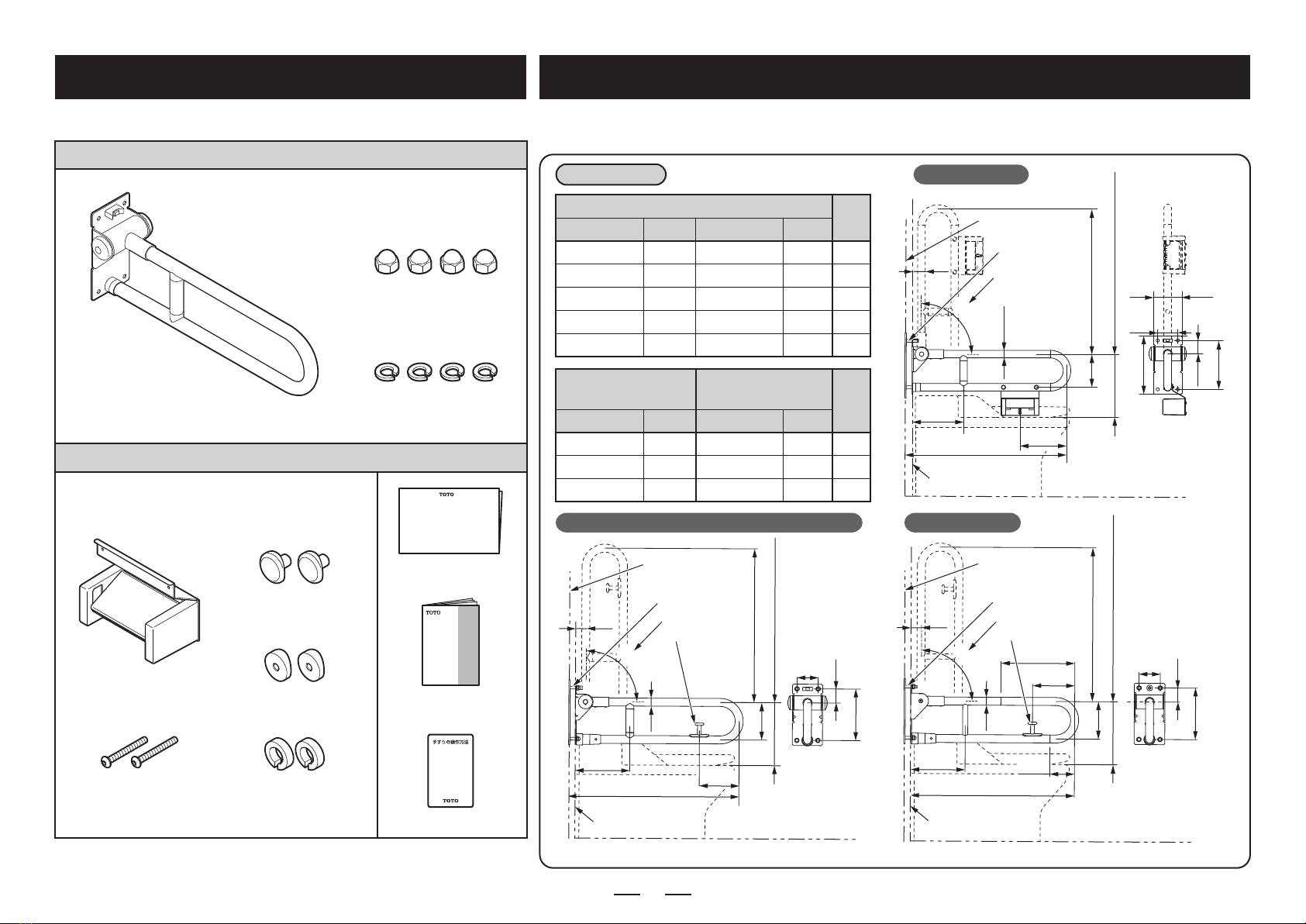

Flip-Up Type Handrail for Public Use

Follow the instructions in this installation manual to fully fulll the functions of this product. After installation, give full explanation on how to use this product to the customer.

1

1. Safety Precautions (Be sure to observe these instructions.)

Please read these “Safety Precautions” before installation, and install the product correctly.

WARNING

●This instruction manual shows various symbols to

correctly install the product in order to prevent harm to

customers and other users, and damage to property.

The meanings of those symbols are as follows:

●The following symbols are used to classify

and explain instruction that must be followed.

When this appears next a topic, this

indicates that ignoring this symbol

and mishandling the product could

result in death or serious injury.

The symbol indicates

something that is “Prohibited.”

The symbol on the left indicates

“Do not disassemble.”

The symbol indicates

something that “Must be

implemented.” The symbol on

the left indicates “Required.”

Prohibit

Do not

disassemble

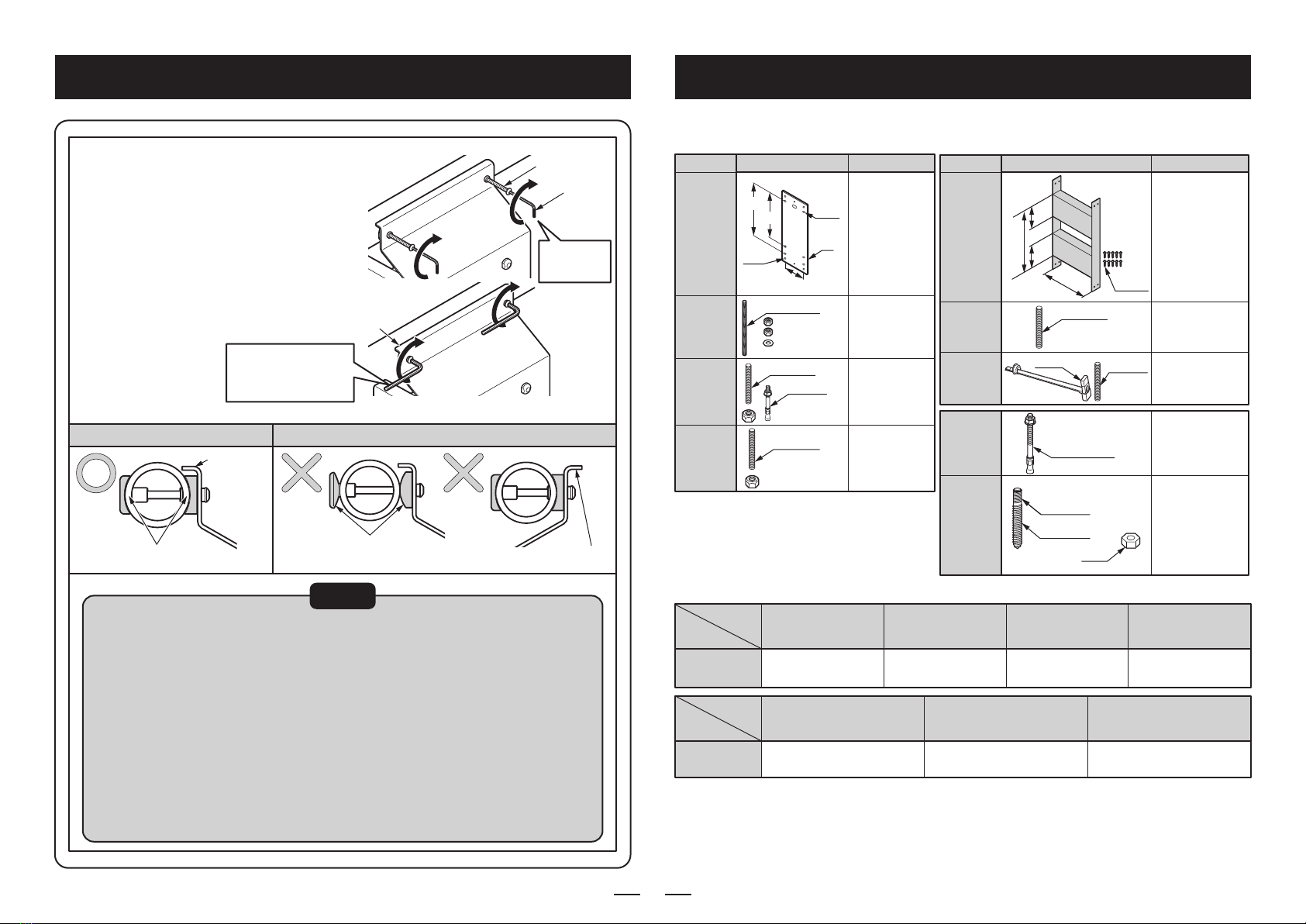

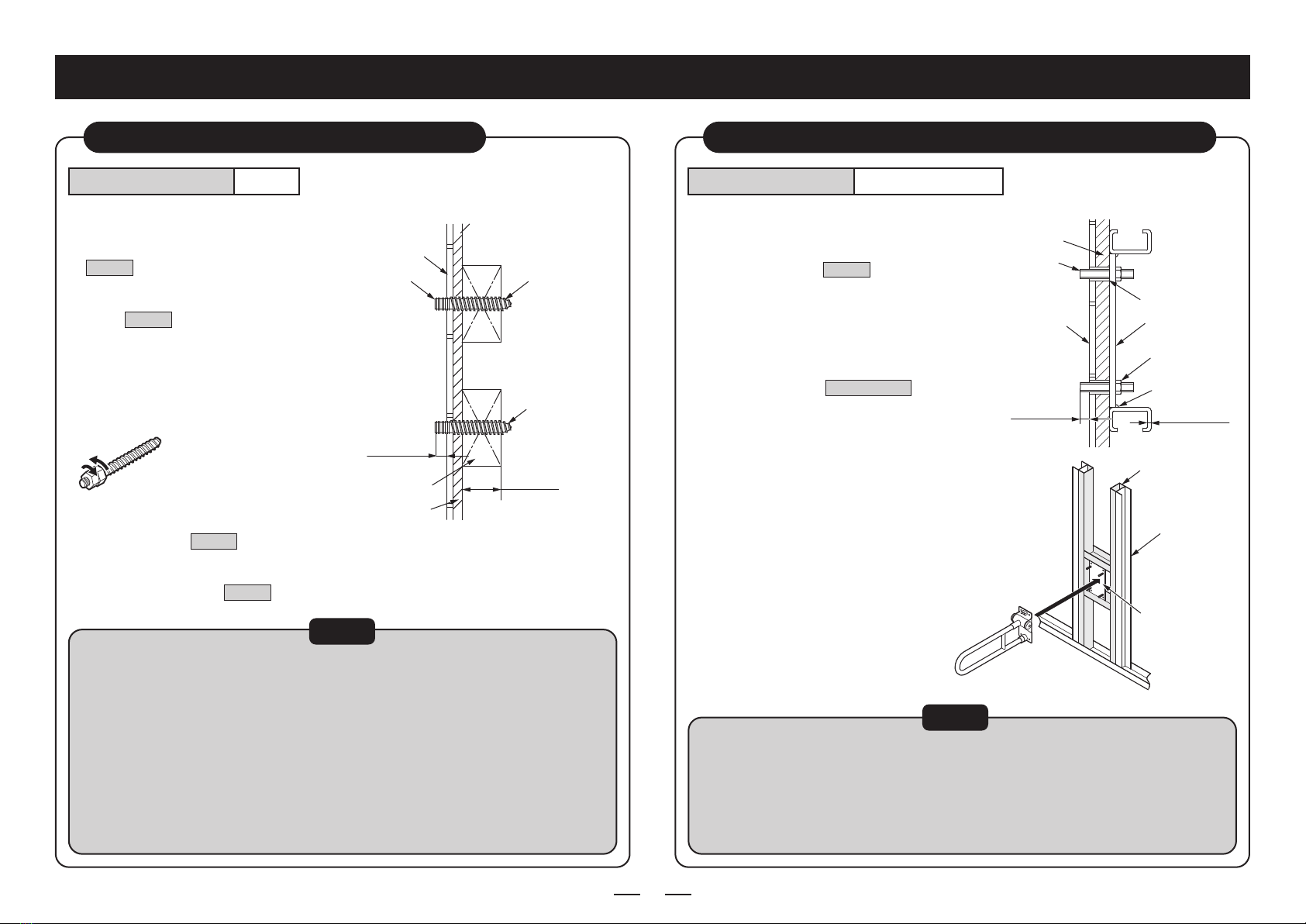

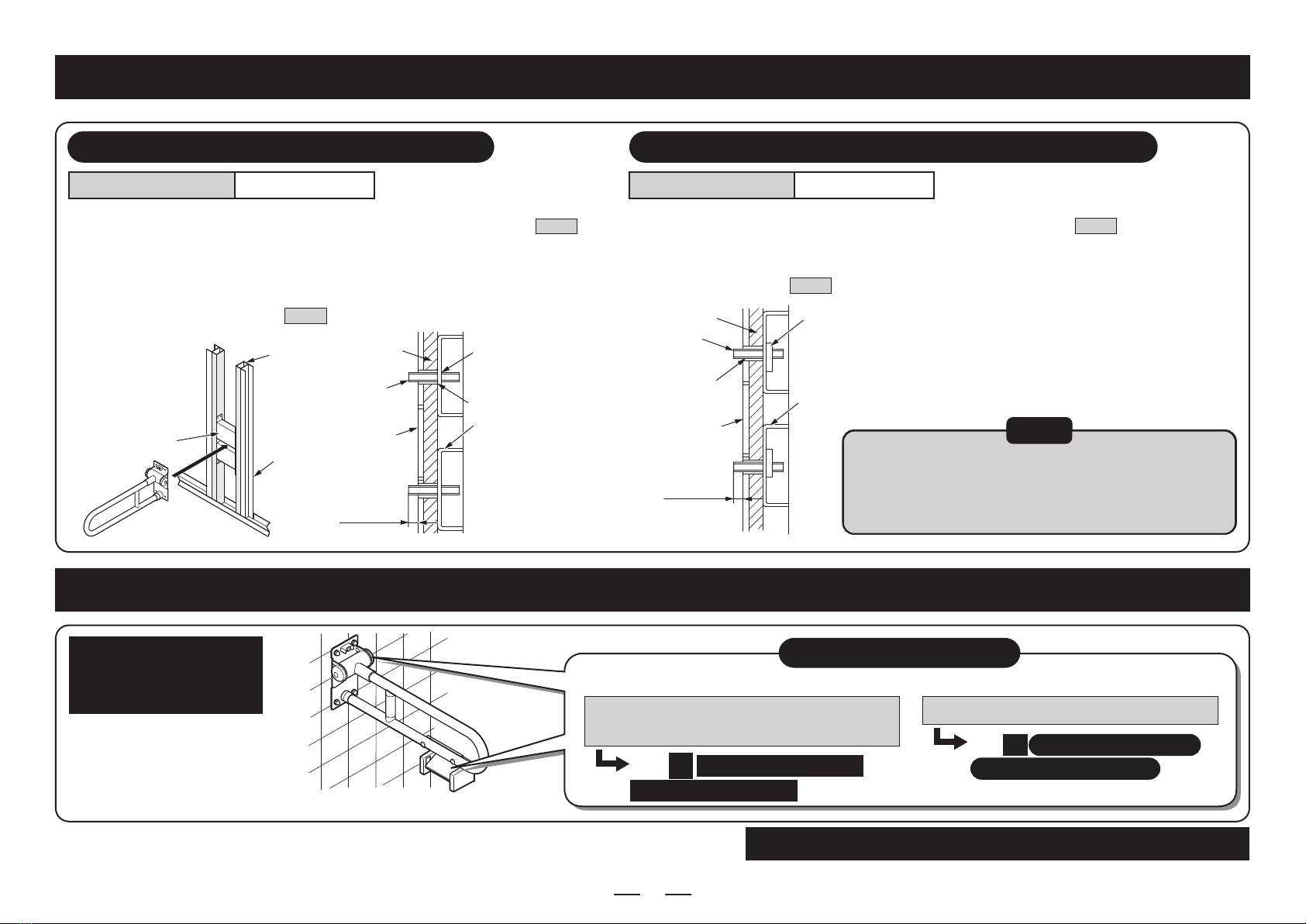

T112H Type

T113H Type

T114H Type

Required

T

O

T

O

-

d

e

s

i

g

n

a

t

e

d

Reinforcement

WARNING

Required

No

backlash

WARNING

Do not install the product in places where water

may be splashed over the product or in humid

places, including outdoor and in a bathroom.

Doing so could cause the functions of the movable handrail to be

damaged and may result in injury.

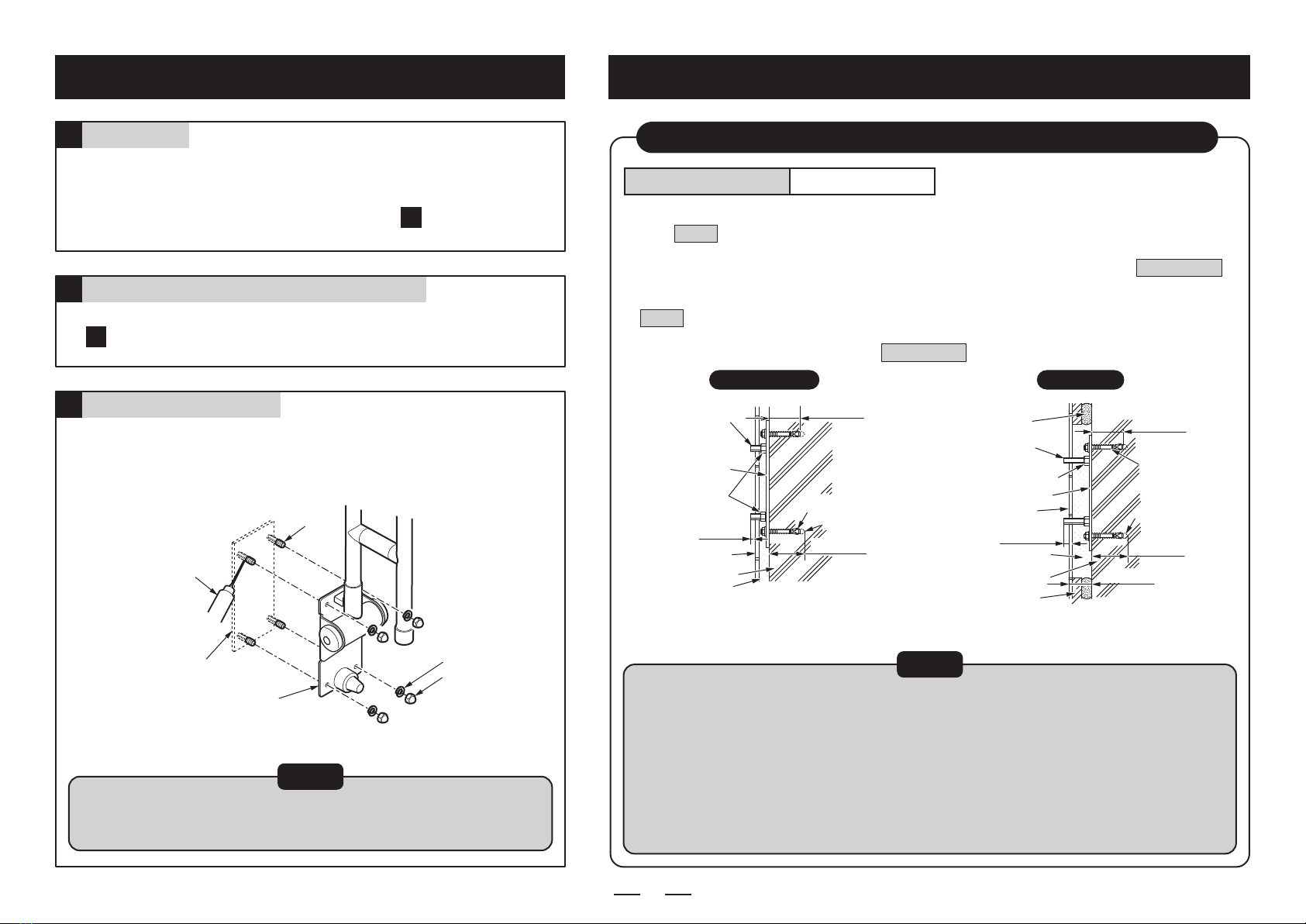

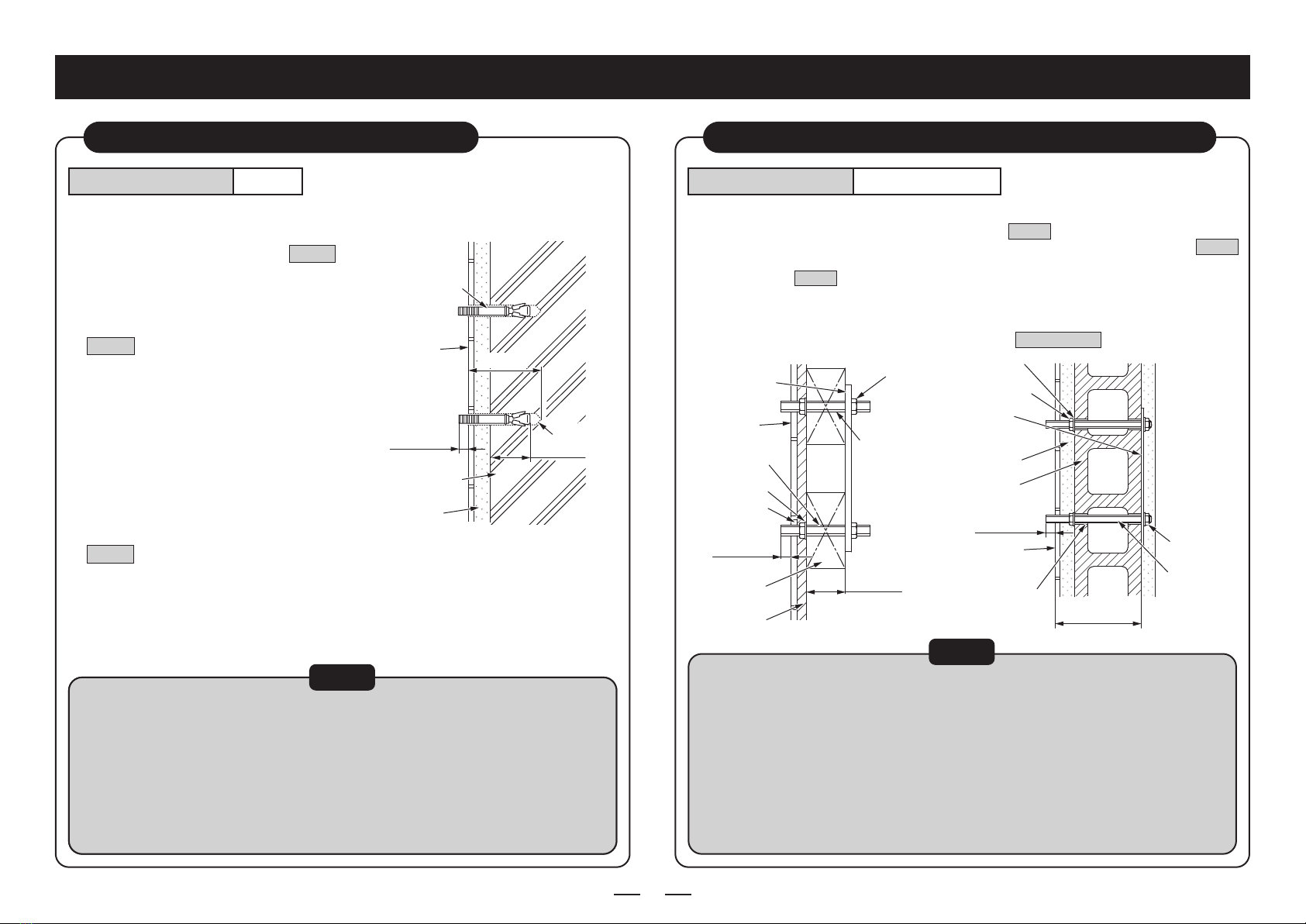

When the product is used in wet areas such

as a restroom, be sure to apply sealant

around the mounting holes.

If sealant is not applied, water may enter the back of the wall

and cause the product to come off or the wall to collapse,

which could result in user’s fall and injury.

Be sure to use TOTO-designated xing

brackets.

If TOTO-designated xing brackets are not used, the

handrail may come off or the wall may collapse, which could

result in user’s fall and injury.

Make sure that the base has sufcient

thickness and is reinforced, and install the

handrail by the specied installation method.

If the base does not have sufcient thickness or is not

reinforced, and if you do not follow the specied installation

method for each base, the handrail may come off or the wall

may collapse, which could result in user’s fall and injury.

Make sure that the handrail has no backlash

after the installation is complete.

If the handrail has backlash, it may come off or the wall may

collapse, which could result in user’s fall and injury.

Anyone other than service engineers must not

disassemble, repair, or modify the product.

Failure to observe this warning could cause a user to fall due to the

damage or coming-off of the handrail and may result in injury.

Be sure to install this product on a strong wall

or building structure.

If the product is installed directly on a wall that is not strong enough,

including a soil wall and a gypsum board wall, it may come off or the

wall may collapse, which could result in user’s fall and injury.