TPL VISION Ring 80 Manual

Technical User gUide

inTrodUcTion

This User Guide contains warnings and guidance for correct and safe operation of the product. These instructions

must be followed at all times. TPL Vision will not be held responsible for problems caused by using the product

contrary to these instructions and the Warranty will be deemed invalid.

Unpacking

This product is packed at the factory using suitable materials for safe transport. To open the package, do not use

any cutting blade to avoid damaging the product(s). Please use the delivered accessories if needed. (Do not use

any other products or equivalents to replace the delivered accessories). In the event of damage occurring during

shipping, it must be reported to the carrier at time of delivery (including noting the damage in writing on thedeliv-

ery documents). It is also your responsibility to notify TPL Vision in writing of the damage within 24 hours of receipt

of the package. If these instructions are not followed, TPL Vision reserves the right not to accept requests for

return and exchange of damaged products.

risk class

The applicable Standard EN-62471 classies LED Lighting into 4 groups (or classes) according to their degree of

hazard severity. The table below summarises the risks associated with our various standard products.

Colour Class Risk

Red 625 nm, Cyan

505 nm, White WHI 0none

IR 860 nm 1low

TPL Vision can provide guidance notes to minimise

photo-biological risks, including the nominal mini-

mum operating distance. Please contact TPL Vision

through your usual representative for this information.

TPL Vision recommends the use of the protection

glasses that are listed in its catalog.

BEWARE: infrared light is invisible to the eye.

Please refer to LED Indicators on the product

to determine if it is operating.

Technical User gUide P2/12

Fixing

During the set up, the light has to beswitched off

and unplugged.

Please use the xing holes designed for thatpur-

pose. We recommend the using of M5 screws

(not supplied) with a tightening torque from 0.5

to 1.5 Nm.

We also recommend the use of a threadlocker

(not supplied) to avoid any risk of loosening.

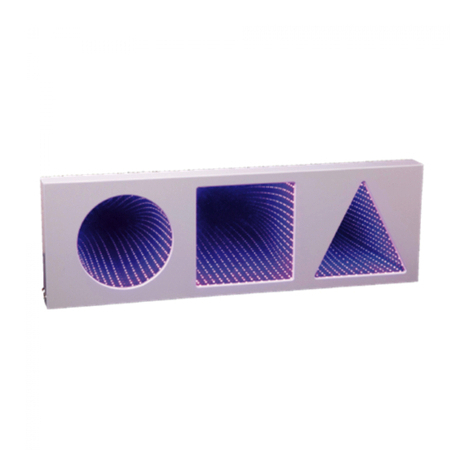

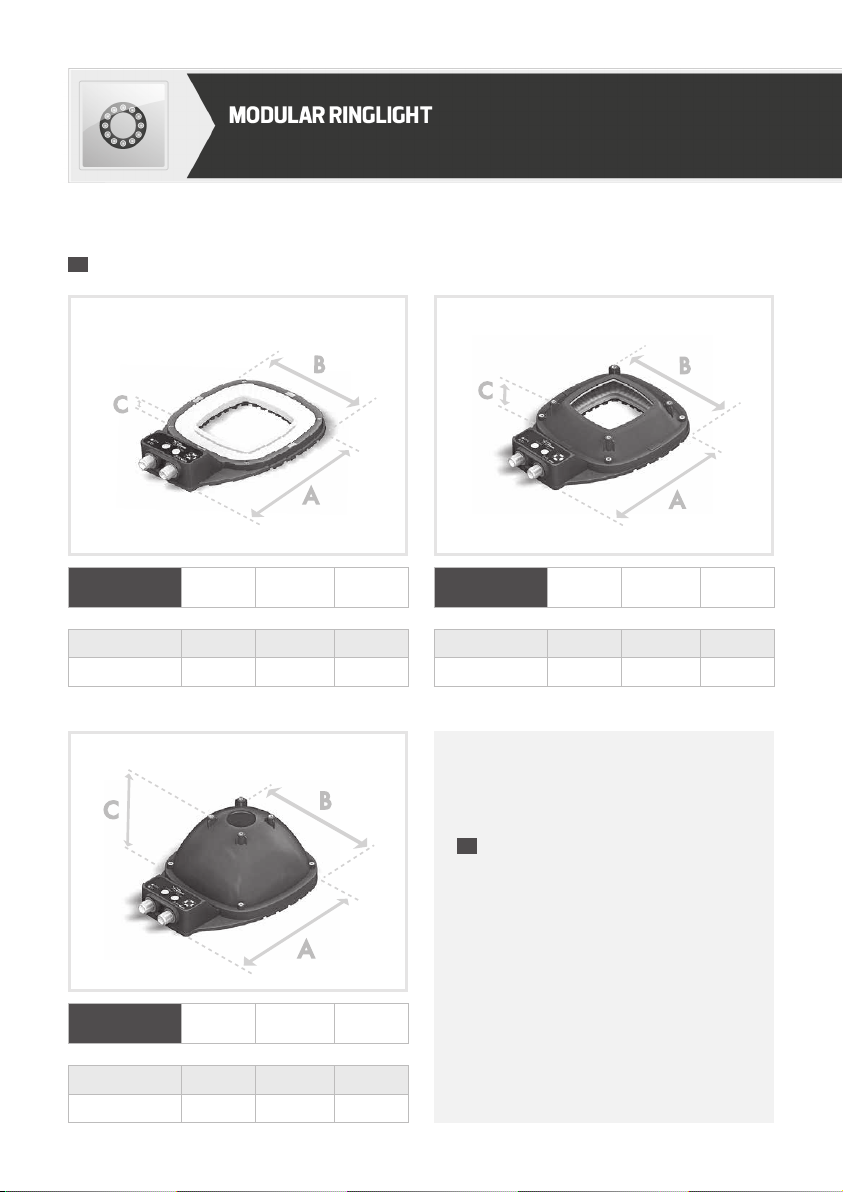

dimensions

DOME Length

(mm)

Width

(mm)

Height

(mm)

A B C

Dome 80 193 136 75

Dome 130 257 197 106.75

RING Length

(mm)

Width

(mm)

Height

(mm)

A B C

Ring 80 193 136 11*

Ring 130 257 197 11*

LOW ANGLE Length

(mm)

Width

(mm)

Height

(mm)

A B C

Low Angle 80 193 136 34.75

Low Angle 130 257 197 45.25

* with connectors: 31 mm.

P3/12

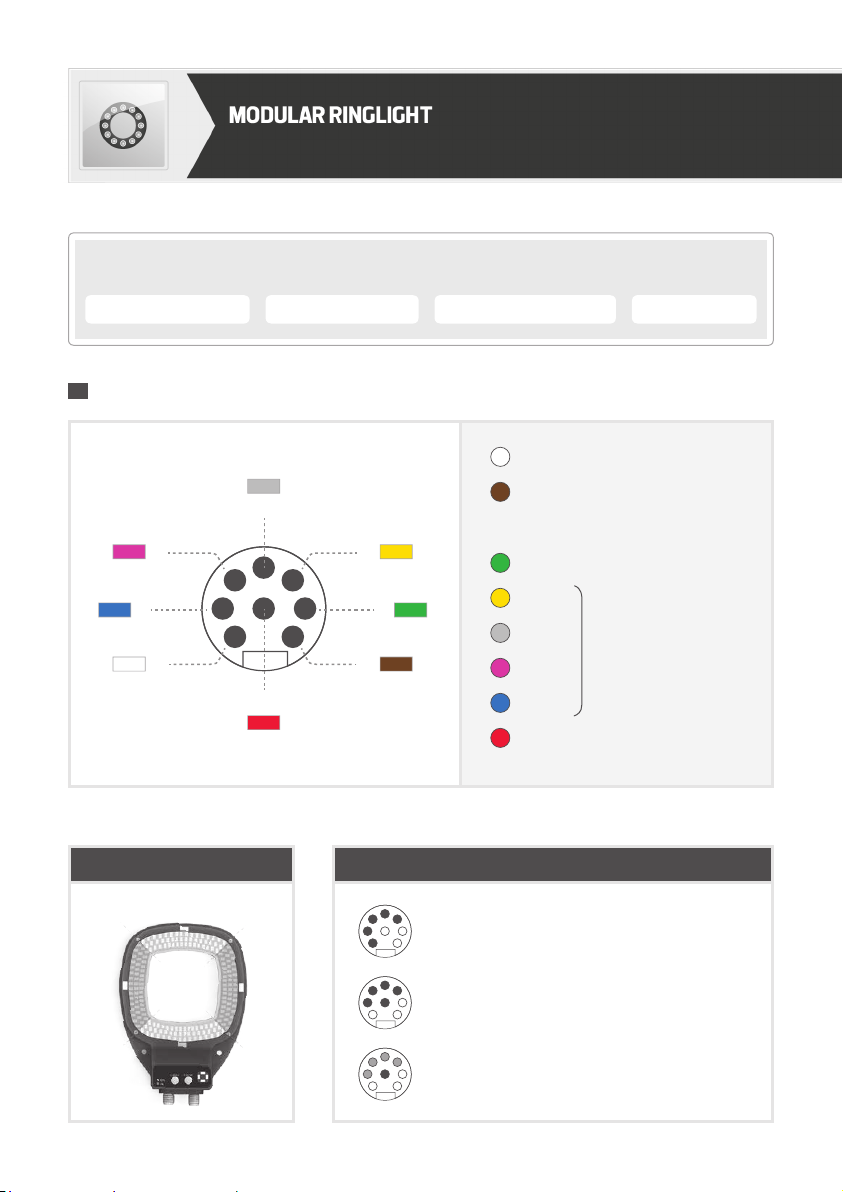

led indicaTors

Operating mode

Strobe

elecTrical connecTion

M12 – 5 MALE PINS M12 – 8 MALE PINS

nPOWER SUPPLY

nSTROBE

nDIMMING

nSECTOR CONTROL

nCOLOR CONTROL

nOVERDRIVE ENABLING

nLOCK KEYPAD

CONNECTION: M12 8 MALE PINS CONNECTOR

SECTOR CONTROL COLOR CONTROL OVERDRIVE ENABLING LOCK KEYPAD

Technical User gUide P4/12

REMOTE CONTROL PINOUT THROUGH PNP: 0-4V is OFF and 5-24V is ON.

ALL SECTORS +OVERDRIVE

ALL SECTORS CW +KEYBOARD DEACTIVATED

SECTOR CONTROL VIA M12 - 8 PINS

1

7

6

2

3

4

5

8

green

yellow

brown

blue

pink

white

red

grey

remoTe conTrol (connecTion)

1

24

3

1Active overdrive ➞ connect to 24VDC

2Change colours

➞ default colour: 1 (if not connected)

➞ colour 2 if connected to 24 VDC

3GND

4Sector 1

5Sector 2

6Sector 3

7Sector 4

8Deactivate keyboard and activate

the M12 8 pins connector

➞Connect to 24VDC

to turn ON

SECTORS MINIMUM WIRING

P5/12

M12 Connector 5 male pins

CONTINUOUS MODE :

2

4

1

+ 24 V

3GND

5DIM 0-10V

STROBE

NPN

STROBE

PNP

black

brown

blue

grey

white

+ 24 V

1

2

3

4

Ground

PNP

+ 24 V

NPN

1

2

3

4

Ground

or

5Dim 0-10V 5Dim 0-10V

+ 24 V

1

2

3

4

Ground

PNP

5Dim 0-10V

STROBE PNP

:

+ 24 V

NPN

1

2

3

4

Ground

STROBE NPN

:

5Dim 0-10V

EMC IMMUNITY CONNECTIONS: for greater

EMC immunity when using the light under Strobe

operation, congure the signal connections as

illustrated here. For Dimming, the Pin (5) should

be connected to avoltage between 0V and 10V to

ensure light output is correctly congured.

The M12 male connector 5 points is COM-

PLIANT with the M12 female connector 4 points.

In that case, thedimming option is not available.

sTrobe mode

PNP : from 5 to 24V for 100% ON. From 0 to 4V for 100% OFF.

NPN : less than 2V for 100% ON. Above 2.2V for 100% OFF. Max 24V.

sTrobe Triggering mode - pnp and npn

CONNECTION: M12 5 MALE PINS CONNECTOR

POWER SUPPLY STROBE DIMMING

+ 24 V

+ 24 V

1

2

3

4

Ground

PNP

5Dim 0-10V

STROBE PNP

:

+ 24 V

NPN

1

2

3

4

Ground

Ground

STROBE NPN

:

5Dim 0-10V

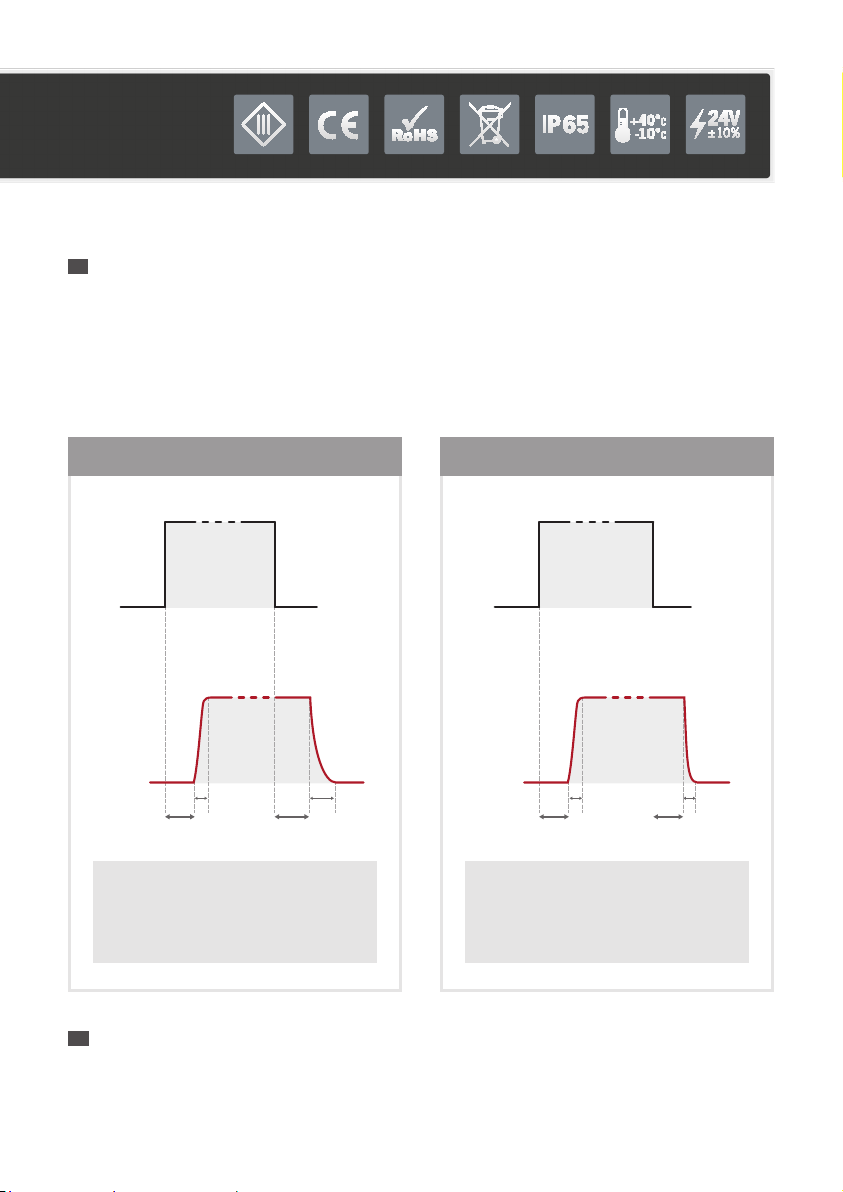

sTrobe Timing limiTs

• Standard version

Don’t exceed 310 Hz when strobing PNP/NPN in overdrive mode.

• Overdrive version

D max tmin t max max

frequency

100 % 5 µs CW 50 kHz

D max tmin t max max

frequency

10 % 5 µs 2 ms 310 Hz

[ D: duty cycle |t: pulse duration |CW: continuous working ]

Standard Mode

0 V

Active Overdrive

5 µs - CW

Overdrive Mode

24 V

Active Overdrive

2 ms max

10% duty cycle

Entrée Déclenchement

Sortie Éclairage

Triggering input

Light

10 µs 10 µs

Rise/Fall times in CW &

Overdrive Modes when under

PNP/NPN strobe control.

On time (t) & duty cycle (D)

in CW & Overdrive modes.

PNP/NPN

LED current

Courant Led

2 ms max

overdrive

Technical User gUide P6/12

sTrobing The lighT via pnp or npn behavioUr

P7/12

65 µs

80 µs

2 µs 25 µs

Change

Colours

LED

Current

65 µs

65 µs

10 µs 10 µs

Sector

Control

LED

Current

coloUrs secTors

Rising/falling times &

ON/OFF delays when changing colours

Rising/falling times &

ON/OFF delays when strobing sectors

with PNP at 24V

To control the LED Colour and illuminated Sector, the PNP or NPN trigger signal should be enabled in addition to

the Sector or Colour control signal(s). Timing diagrams below illustrate rise, fall and delay times.

If PNP and sectors are connected to 24V and if you strobe colours, there can be some delays between thetrigger

signal and the LED current.

If PNP is connected to 24V and you strobe sectors, there can be some delays between the trigger signal and

theLED current. In this conguration, you have protection for maximum 2ms.

sTrobing The lighT via coloUr & secTor inpUT behavioUr

If a trigger signal of more than 2ms is applied, the LED will only remain on for a maximum of 2ms.

Duty cycle protection: you can set a 10% duty cycle max.

If this is exceeded, internal protection circuitry will activate.

proTecTion in overdrive mode

Technical User gUide P8/12

power sUpply

Operational Voltage 24 V at the light input (±10%)

Absolute Maximum Voltage 30 V at the light input

Max. current consumption - strobe signal line 5 mA

Max. current consumption - remote control lines 5 mA

Max. current consumption - dimming control line 2 mA

dimming conTrol

20%

40%

60%

80%

100%

0 2 4 6 8 10

VOLTS

Dimming between 0 & 10 V.

With 0V applied to the Dimming pin,

theproduct is at 100% of its lighting

power. With 10V applied, it is reduced

to30% oflighting power.

secTor conFigUraTions

1

24 3

1

24

3

1

24

3

1

24

3

A B C

P9/12

The Modular Ringlight works in manual control and

continuous working (CW) mode by default. To use

theremote control, youneed to connect the 8 pin cable

and apply PNP signals to the relevant pins. TheModular

Ringlight has Teach and Run mode.

keypad conTrol

Colour and Sector Selection

• Program settings: push the 2 buttons together

for 3 - 4 seconds,

• Change settings: 1 push of Colour and / or

Sector button(s) until desired configuration

is selected,

• Save settings: push the 2 buttons together

for3 - 4 seconds.

User saFeTy

Do not modify or dismantle all or part of the product.

Respect the power supply voltages and the connection terminals.

Ensure power supply is switched off whilst connecting product and turn on only once product

isfully connected. Failure to do this may damage the product and invalidate theWarranty

Do not stare at the lighting source directly.

Follow advice below for installation to minimise operator exposure to the light source.

INSTALLATION GUIDANCE:

• Forbid or limit the direct access to the lighting source (exposure into the radiation axis).

• Establish a security perimeter to prevent the operators from approaching the lighting source beyond therecom-

mendations of the manufacturer.

• If the workstation permits it, introduce a lter that will stop the lighting radiation under a xed or adjustable

frame between the source and the operator. When these measures cannot be implemented, supply theoper-

ators with glasses (class 4) available from TPL Vision, or with a dedicated protective mask, that will stop

thelighting radiation.

It is the responsibility of the persons installing this product to ensure that all means possible (such as those stated

above) have been implemented to reduce exposure of the machine operators to the light emitted from this product.

Colour selection

Sector

selection

Technical User gUide P10/12

eqUipmenT mainTenance

warranTy inFormaTion

CLEANING (when the product is switched off)

Please use a soft and dry cloth. Do not use any abrasive material. Do not use any cleaning solvent or aggressive

chemical product. TPL Vision recommends to use isopropyl alcohol.

Further information on the applicable Warranty can be found on the TPL Vision website:

https://www.tpl-vision.com/warranty/

operaTing condiTions

-10° to +40°C / 80% of humidity without condensation. Not for outdoor use.

No thermal shock (maximum temperature variation: 10°C in 24h).

binning inFormaTion

advised bandpass FilTers

TPL Vision is extremely careful about BIN sorting in the selection ofLEDs for their products.

Specifically for the Cyan series on this product, the human eye is very sensitive to colour variations. Itmay appear

to the customer that they do not appear the same between two cyan LED products. Despite any noticeable

differences, the peak wavelength variation does not exceed 10nm.

Here are thefollowing bandpass camera filters we recommend to fit with the Modular Ringlight:

• White LEDs: no filter • Red LEDs: BP 635

• Infrared LEDs: LP 830 • Cyan LEDs: BP 505

Further information on the TPL Vision website.

P11/12

associaTed accessories

M12 8 pins

Remote control

3 m Ref: C-M12-8P-3M

5 m Ref: C-M12-8P-5M

10 m Ref: C-M12-8P-10M

M12 5 pins

Power supply

2 m Ref: C-M12-5P-2M

5 m Ref: C-M12-5P-5M

10 m Ref: C-M12-5P-10M

Mounting

80mm & 130mm

Ref: TPL-MOUNT-MR

www.tpl-vision.com

TPL VISION

IS AN ISO9001

CERTIFIED MANUFACTURER

+44 (0)1738 310 392 contact@tpl-vision.co.uk

Brenchley House, School Road

Charing, Kent TN27 0JW

United Kingdom

Features and presentations liable to changes without notice. Ref.UG-030301-B1, 2020/11 edition.

This manual suits for next models

5

Table of contents

Other TPL VISION Lighting Equipment manuals

TPL VISION

TPL VISION SDOME II 130 User manual

TPL VISION

TPL VISION M-EBAR User manual

TPL VISION

TPL VISION LITE LBAR+ Series User manual

TPL VISION

TPL VISION SQUARE LIGHT RGB User manual

TPL VISION

TPL VISION Modular Ringlight Operation and maintenance manual

TPL VISION

TPL VISION BLBAR+ User manual

TPL VISION

TPL VISION TRING User manual

TPL VISION

TPL VISION THINLED 1 User manual

TPL VISION

TPL VISION MEDIUM MBACK User manual