TPL VISION UK

Brenchley House – School Road – Charing – Kent TN27 0JW – UK

Tel. +44 (0)1738 310 392 – www.tpl-vision.com

User gUideUser gUide P4/4

Features and presentations liable to changes without notice. Ref.UG-050502-D1, 2020/07 edition.

Preamble

This Technical User Guide contains warnings and guidance for correct and safe operation of the product. Theseins-

tructions must be followed at all times. TPL Vision will not be held responsible for problems caused by using

theproduct contrary to these instructions and the Warranty will be deemed invalid.

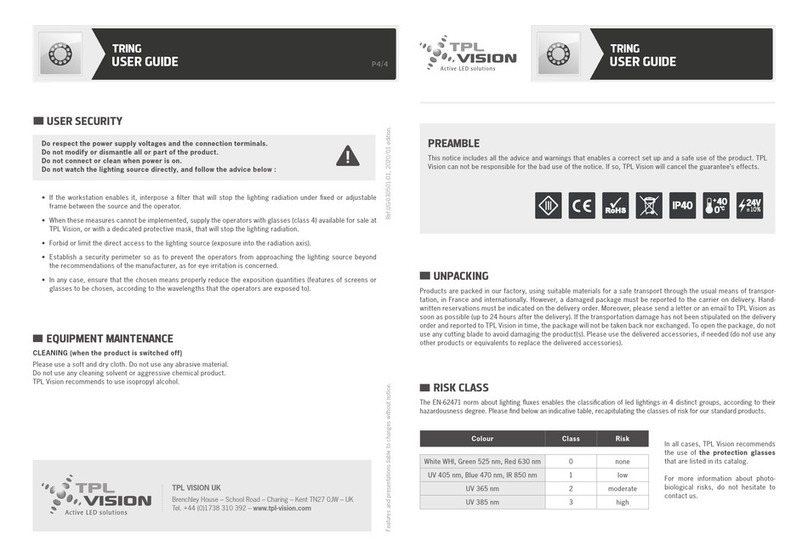

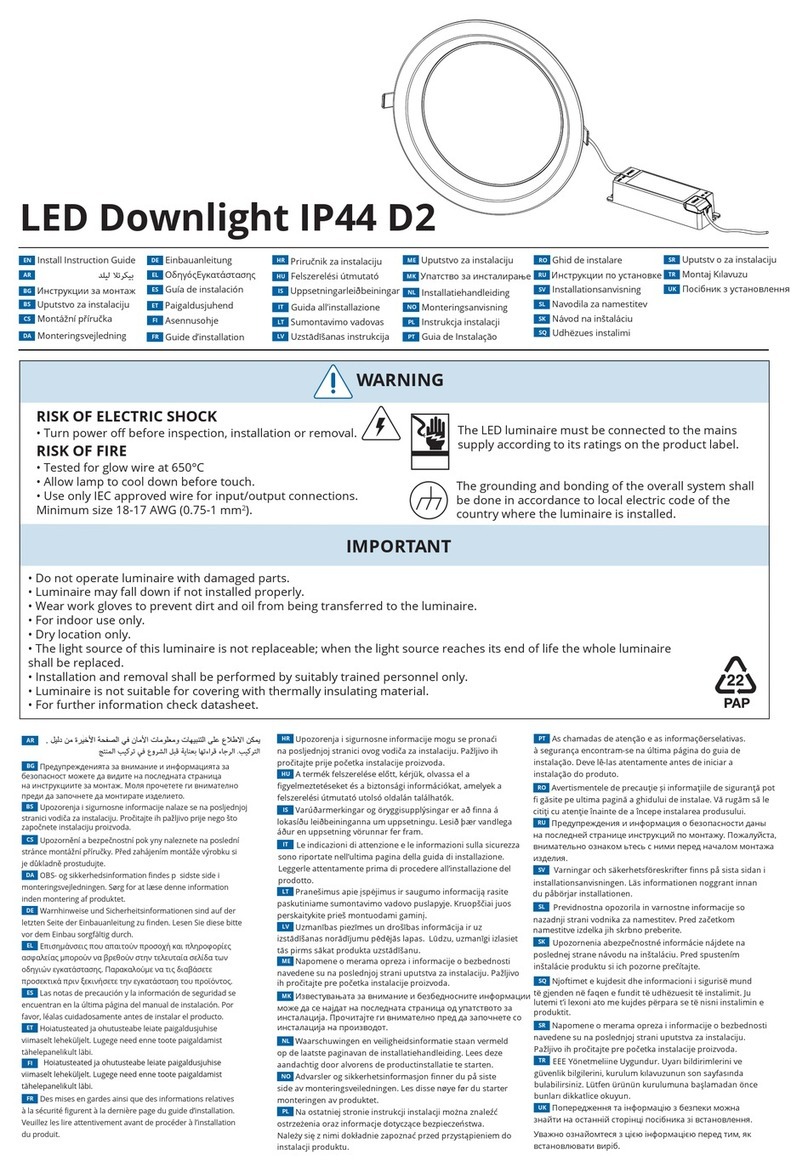

risk class

Colour Class Risk

White WHI, Green 525 nm, Red 630 nm 0none

UV 405 nm, Blue 470 nm, IR 850 nm 1low

UV 365 nm 2moderate

UV 385 nm 3high

In all cases, TPL Vision recommends

the use of the protection glasses

that are listed in its catalog.

For more information about photo-

biological risks, do not hesitate to

contact us.

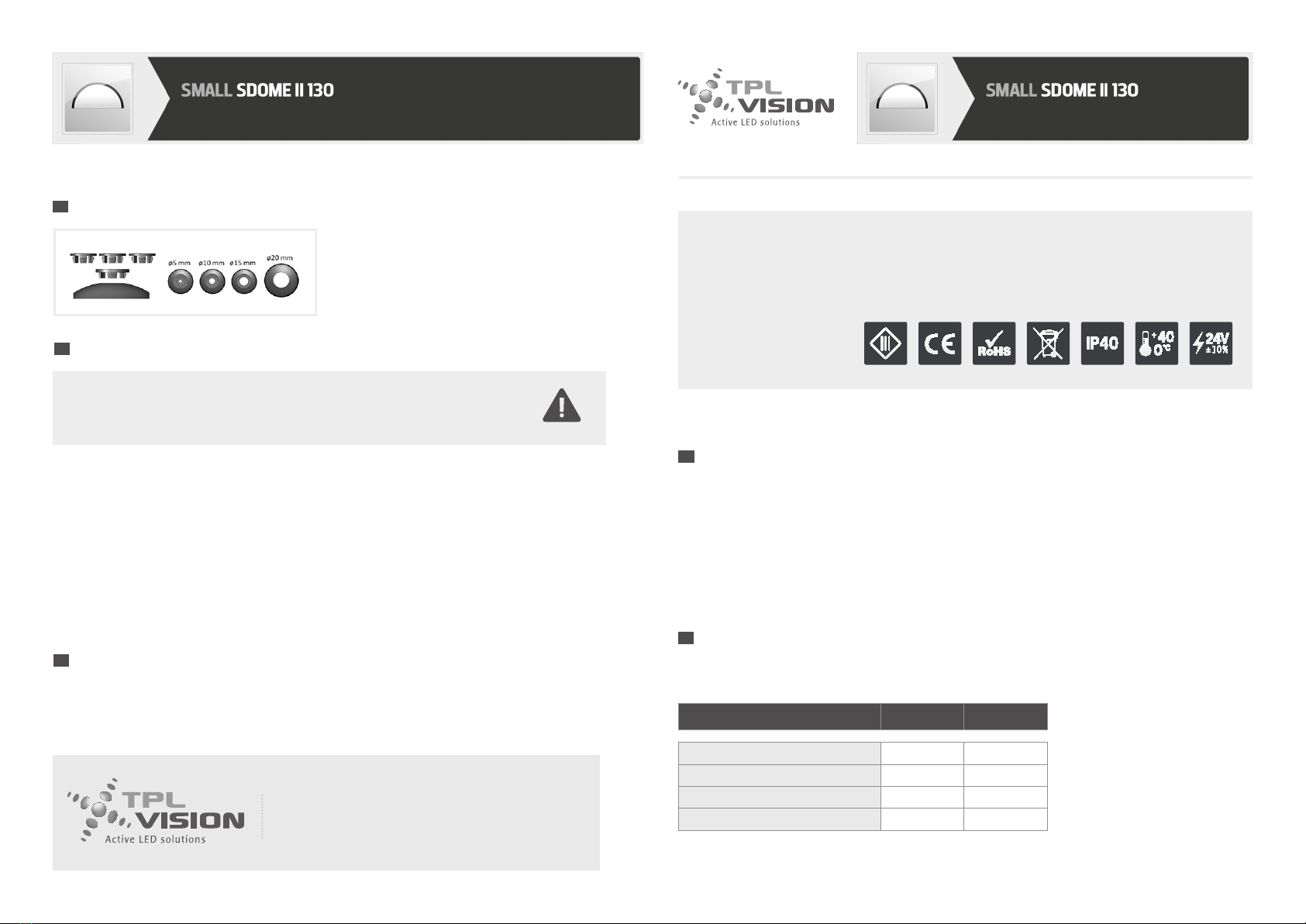

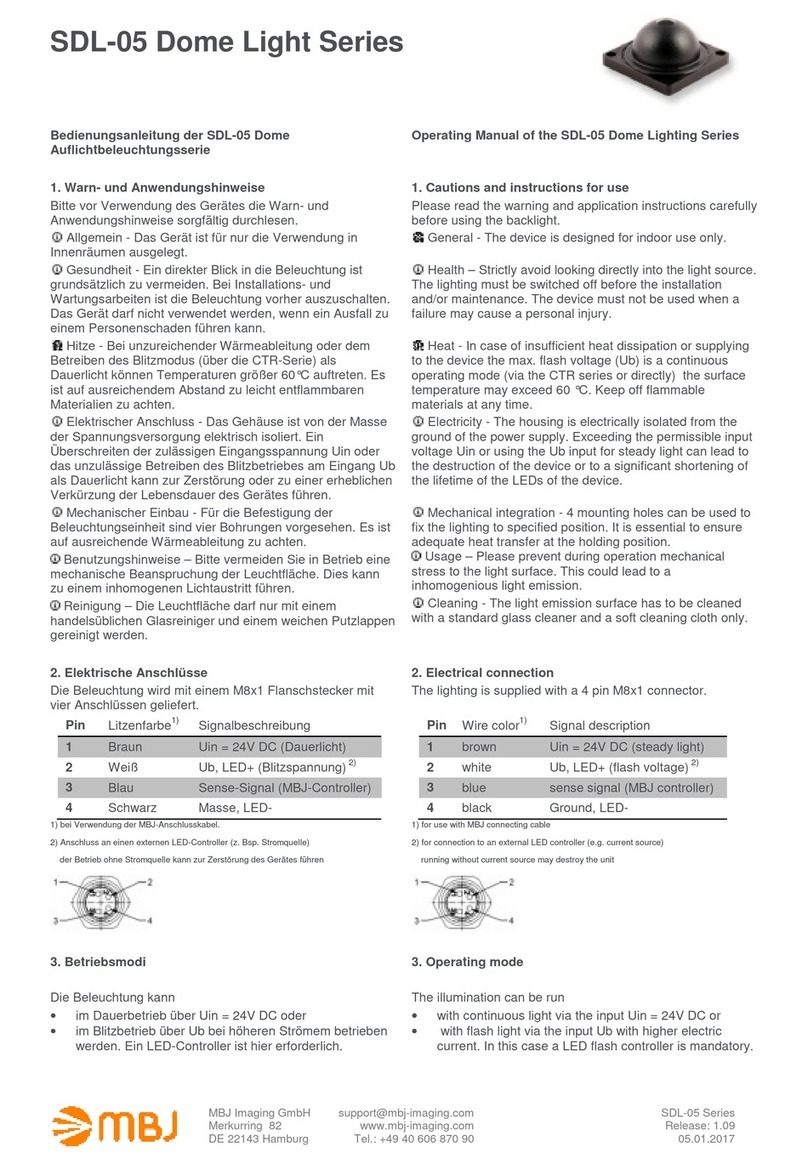

By default, the hole located on the top of the SDOMEII130

has a diameter of 35 mm. The SDOME II 130 is delivered

along with 4 accessories to be clipped on the top.

If the camera’s eld of vision allows it, these clips help

to reduce the diameter and then, to decrease the drop

shadow over the workpiece.

User secUrity

Do respect the power supply voltages and the connection terminals.

Do not modify or dismantle all or part of the product.

Do not connect or clean when power is on.

Do not watch the lighting source directly, and follow the advice below :

• If the workstation enables it, interpose a lter that will stop the lighting radiation under xed or adjustable

frame between the source and the operator.

• When these measures cannot be implemented, supply the operators with glasses (class 4) available for sale at

TPLVision, or with a dedicated protective mask, that will stop the lighting radiation.

• Forbid or limit the direct access to the lighting source (exposure into the radiation axis).

• Establish a security perimeter so as to prevent the operators from approaching the lighting source beyond

therecommendations of the manufacturer, as for eye irritation is concerned.

• In any case, ensure that the chosen means properly reduce the exposition quantities (features of screens or

glasses to be chosen, according to the wavelengths that the operators are exposed to).

eqUiPment maintenance

settings

The EN-62471 norm about lighting uxes enables the classication of led lightings in 4 distinct groups, according to their

hazardousness degree. Please nd below an indicative table, recapitulating the classes of risk for our standard products.

CLEANING (when the product is switched off)

Please use a soft and dry cloth. Do not use any abrasive material.

Do not use any cleaning solvent or aggressive chemical product.

TPL Vision recommends to use isopropyl alcohol.

UnPacking

Products are packed in our factory, using suitable materials for a safe transport through the usual means of transpor-

tation, in France and internationally. However, a damaged package must be reported to the carrier on delivery. Hand-

written reservations must be indicated on the delivery order. Moreover, please send a letter or an email to TPL Vision as

soon as possible (up to 24 hours after the delivery). If the transportation damage has not been stipulated on the delivery

order and reported to TPL Vision in time, the package will not be taken back nor exchanged. To open the package, donot

use any cutting blade to avoid damaging the product(s). Please use the delivered accessories, if needed (do not use any

other products or equivalents to replace the delivered accessories).