TABLE OF CONTENTS

THANK YOU..............................................................................................................................................................2

GENERAL SAFETY INFORMATION........................................................................................................................3

WARRANTY .............................................................................................................................................................. 3

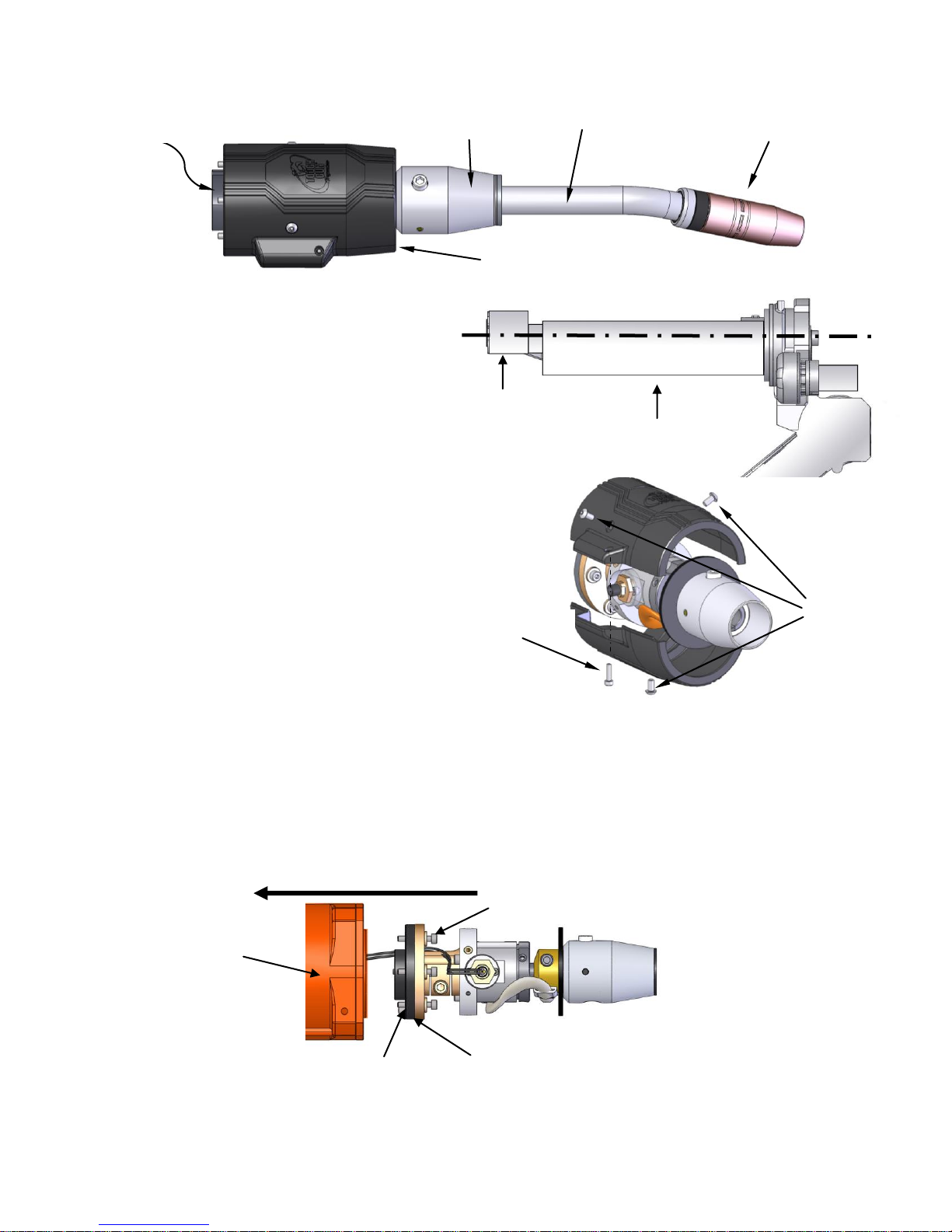

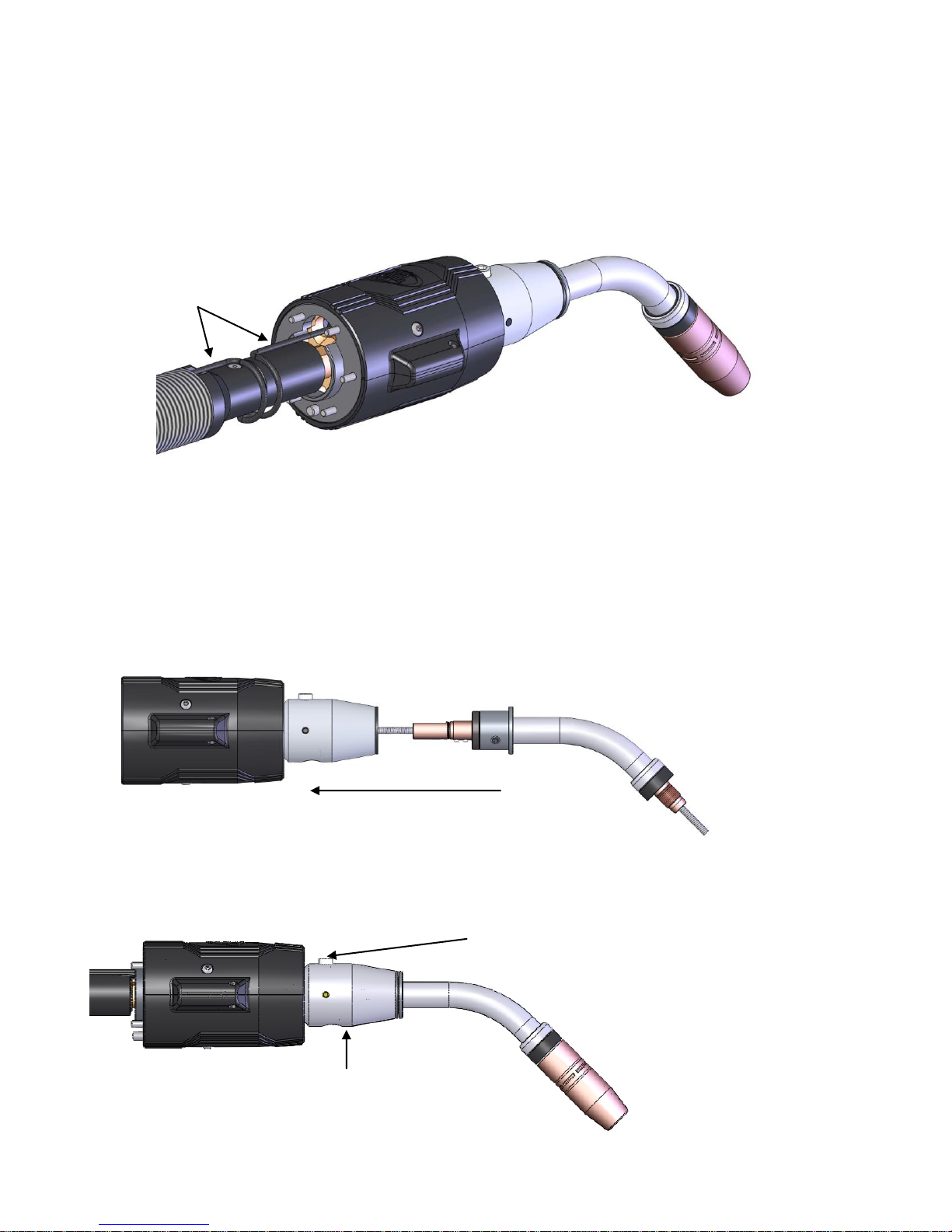

1.0 –COMPLETE ASSEMBLY OVERVIEW.............................................................................................................4

2.0 –INSTALLATION................................................................................................................................................5

STEP #1 - POSITIONING THE ROBOT ................................................................................................................5

STEP #2 - REMOVING OUTER COVER...............................................................................................................5

STEP #3 - INSTALLING GUN TO ROBOT............................................................................................................5

STEP #4 - CONNECTING LSR UNICABLE...........................................................................................................6

STEP #5 - INSTALLING NECK..............................................................................................................................6

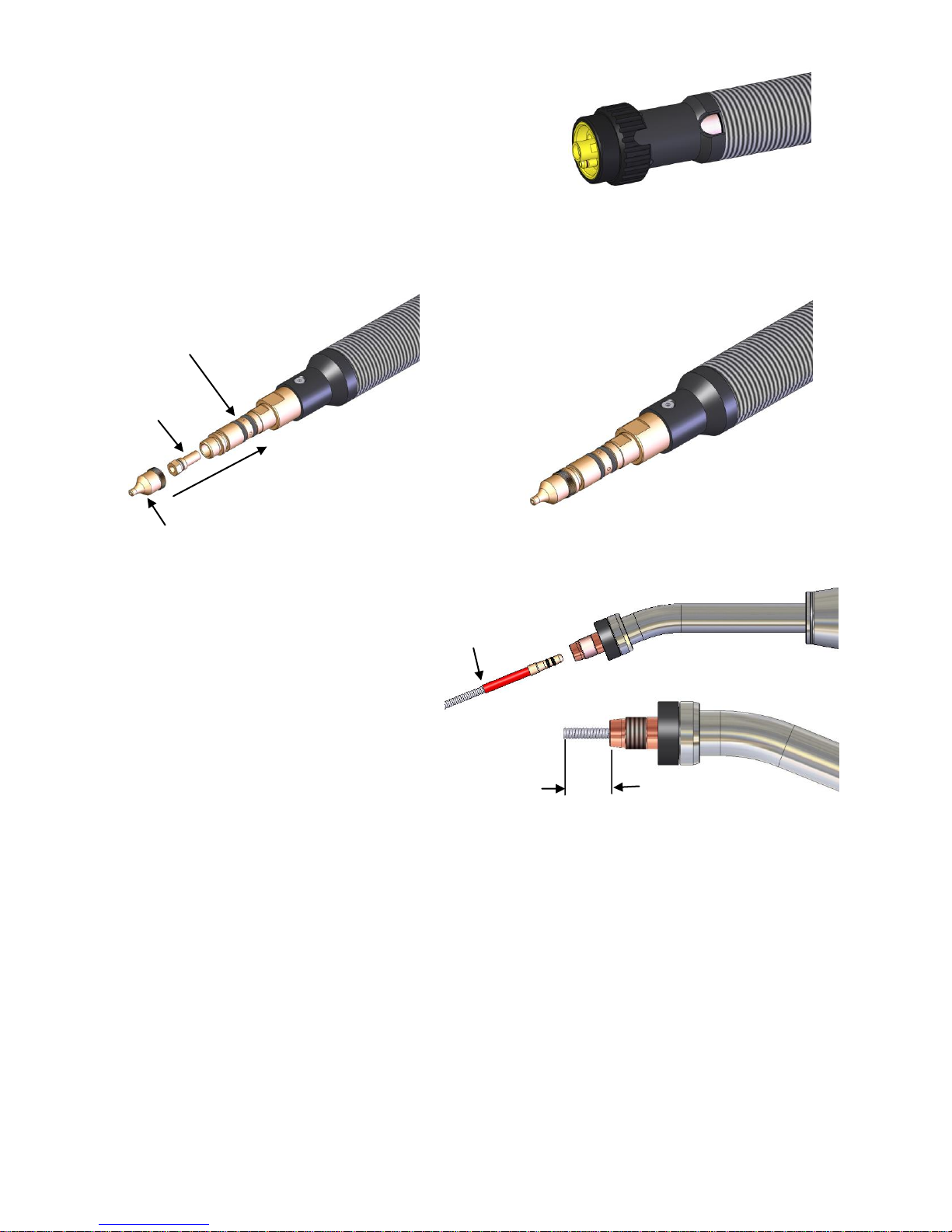

STEP #6 - INSTALLING POWER PIN TO THE LSR UNICABLE..........................................................................7

STEP #7 - INSTALLING QUICK LOAD LINER......................................................................................................7

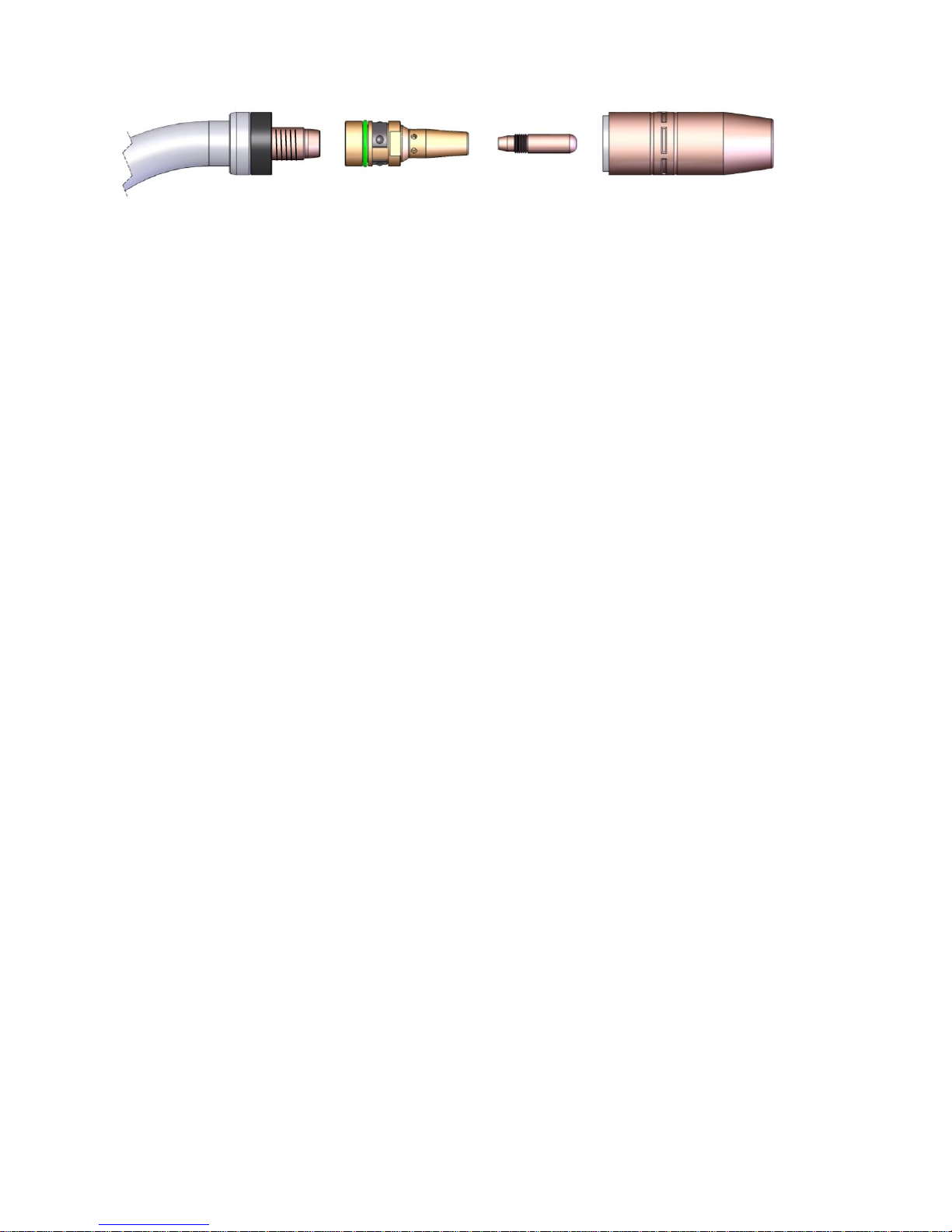

STEP #8 - INSTALLING CONSUMABLES ............................................................................................................8

STEP #9 - INSTALLING GUN TO WIRE FEEDER................................................................................................8

3.0 –MAINTENANCE................................................................................................................................................9

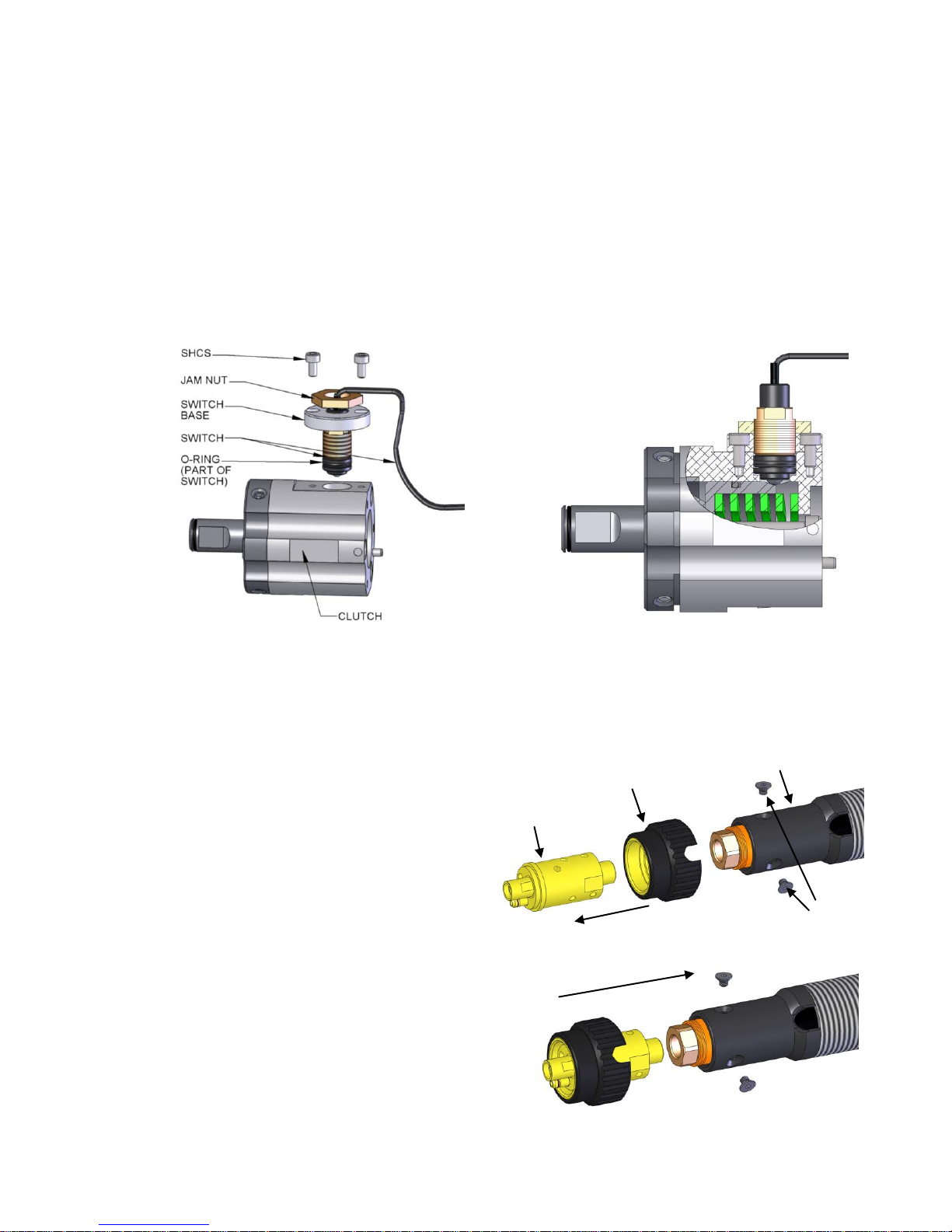

3.1 REPLACEMENT / ADJUSTMENT OF CLUTCH LIMIT SWITCH...................................................................9

3.2 REPLACEMENT OF EURO CONNECTION...................................................................................................9

3.3 REPLACEMENT OF QUICK LOAD™LINER................................................................................................10

4.0 –TECHNICAL DATA ........................................................................................................................................11

4.1 GUN CONFIGURATIONS.............................................................................................................................11

4.2 CENTER OF MASS.......................................................................................................................................11

4.3 AMPERAGE RATINGS*................................................................................................................................12

5.0 –EXPLODED VIEW & PARTS LIST –K5800..................................................................................................12

6.0 –PARTS LISTS FOR K5800A, K5800W, & K5800AW MODELS...................................................................13

6.1 WIRE BRAKE FOR K5800W MODELS........................................................................................................13

6.2 AIR BLAST FOR K5800A & K5800AW MODELS........................................................................................13

7.0 –ORDERING INFORMATION ..........................................................................................................................14

THANK YOU...

…for selecting a Tregaskiss TOUGH GUN™ ThruArm™G1 Series Robotic MIG Gun. Manufacturing operations

demand extremely dependable robotic equipment. With this in mind, the TOUGH GUN™MIG Gun was designed

and engineered to be a reliable tool to support high production within a robotic cell. As the name implies, the

TOUGH GUN MIGGun is made from durable materials and components engineered to perform in a rugged

welding environment. Your TOUGH GUN MIG Gun is completely assembled and ready to weld, and has

undergone numerous quality checks to ensure high performance.

The instructions and illustrations in this technical guide make it easy for you to maintain your TOUGH GUN

Robotic MIG Gun. Please read, understand, and follow all safety procedures. Keep this Technical Guide

booklet as a handy reference when ordering complete guns, parts and special options. For technical support

and special applications, please call the Tregaskiss Technical Service Department at 1-855-MIGWELD

(644-9353) or fax 1-877-737-2111. Our trained technicians are available between 8:00 a.m. and 5:00 p.m. EST,

and will answer your application or repair questions.

Tregaskiss employees build TOUGH GUN MIG Guns for the world’s welding professionals. We are always

striving to improve our products and services, and would appreciate receiving your suggestions or comments.

Please contact us immediately if you experience any safety or operating problems.