TRIATEK HMS-1655 User manual

HMS-1655

Installation Manual

Version: 03.15.17

Triatek HMS-1655

Fume Hood Controller

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

CONTROLLER SETTINGS

HMS-1655 Fume Hood Controller Settings

HMS-1655

- 2 -

Fume Hood Name / Number

Unit Model Number and Serial Number (ESN)

Sidewall Sensor Input

Normal Operating Face Velocity

Sensor Linearization (enabled or disabled)

Sensor Input Mode (normal or inverted)

Sensor Input Range (zero-based or offset)

Occupied Mode Setpoint

Unoccupied Mode Setpoint

Decommissioned Mode Setpoint

Face Velocity Deadband

Analog Output

Operating Mode (Direct or PID)

Analog Output Range (zero-based or offset)

Analog Output Upper Limit (0 – 100%)

Analog Output Lower Limit (0 – 100%)

Analog Output Input Channel (AI-1 thru AI-4, TI-1 or TI-2)

Analog Output Action (Direct or Reverse)

Analog Output Range (zero-based or offset)

Sash Switch

Operating Mode (normally-open or normally-closed)

Delay Setting (0 - 240 secs)

Relay Output

Trigger Mode (Setpoints or Operating Mode)

Input Channel (AI-1 thru AI-4, TI-1 or TI-2)

Occupied Mode High Setpoint

Occupied Mode Low Setpoint

Triatek reserves the right to change product specifications without notice. Triatek reserves the right to change product specifications without notice.

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

CONTROLLER SETTINGS

HMS-1655 Fume Hood Controller Settings

HMS-1655

- 3-

Unoccupied Mode High Setpoint

Unoccupied Mode Low Setpoint

Relay Acting Mode (Direct or Reverse)

Delay Setting (0 - 180 secs)

PID Constants

Proportional Constant (0.5 – 100.0 %)

Integral Constant (0.0 – 100.0 %)

Derivative Constant (0.0 – 100.0 %)

Alarm Limits

Occupied Mode High Alarm Setpoint

Occupied Mode High Warning Setpoint

Occupied Mode Low Warning Setpoint

Occupied Mode Low Alarm Setpoint

Unoccupied Mode High Alarm Setpoint

Unoccupied Mode High Warning Setpoint

Unoccupied Mode Low Warning Setpoint

Unoccupied Mode Low Alarm Setpoint

Audible Alert

Enabled Input Channels (AI-1 thru AI-4, TI-1, TI-2)

Operating Mode (audible or silent)

Delay Time Base (secs or mins)

Delay Setting (0 – 60)

Alarm Quiet Period Starting Hour (0 – 23)

Alarm Quiet Period Ending Hour (0 – 23)

Engineering Units

Feet per Minute or Meters per Second

Triatek reserves the right to change product specifications without notice. Triatek reserves the right to change product specifications without notice.

Due to continuous improvement, Triatek reserves the right to change product specifications without notice. Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

HMS-1655

- 4 -

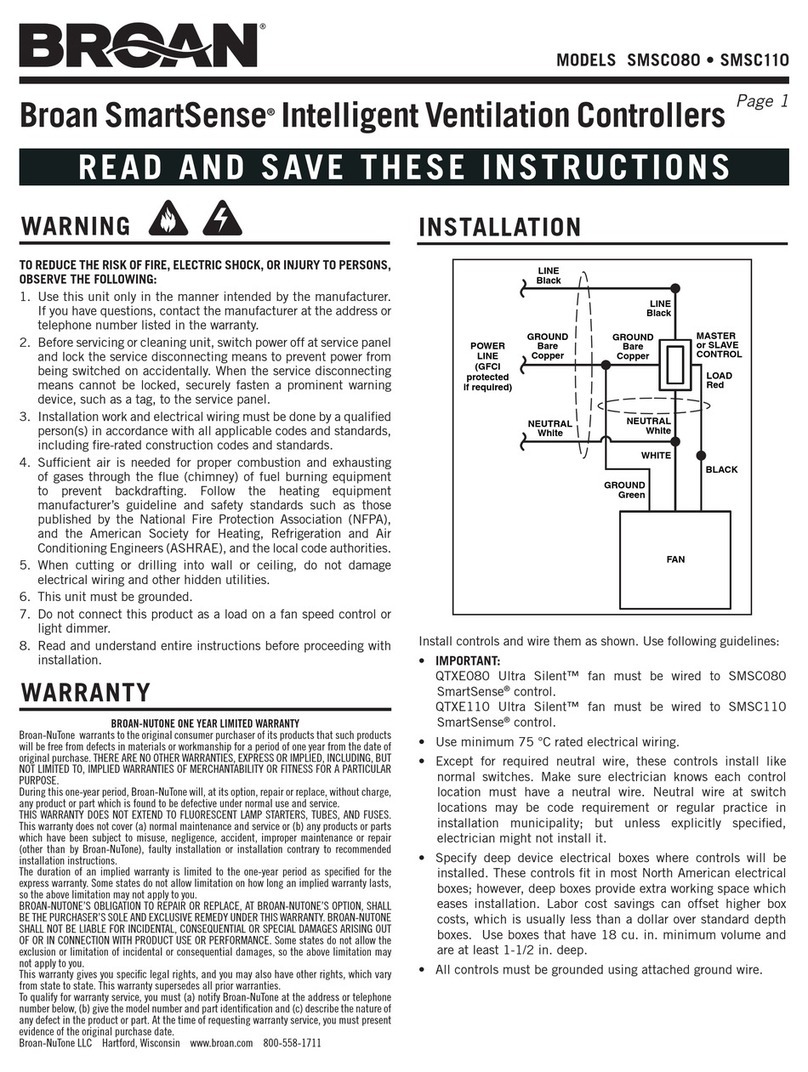

FAST ACTING

ELECTRONIC ACTUATOR

Controller Actuator

120/24VAC, 30Va Transformer

Supplied by Triatek

120/24VAC, 20Va Third Party

Transformer

CORRECT

CORRECT

Triatek reserves the right to change product specifications without notice. Triatek reserves the right to change product specifications without notice.

Warning

Failure to follow the wiring diagrams could result in damage to your equipment and could

void your warranty. Wiring diagrams can also be found at www.triatek.com.

Under no circumstances should a single transformer be split between actuator and controller. Doing so

will damage the actuator, the transformer, the controller or all units. A single 120/24V 30Va transformer is

required for the controller and a separate 120/24V 20Va transformer is required for the actuator.

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

SUBHEAD

Table of Contents

HMS-1655

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

- 5-

TABLE OF CONTENTS

Triatek reserves the right to change product specifications without notice. Triatek reserves the right to change product specifications without notice.

SPECIFICATIONS

……………………………………………………………………………………………………………………………6-7

GENERAL

Overview………………..……………………………………..............……………………………………………………………………8-9

Installation

…………………………………………………………….................……………………………………………………………………10

MOUNTING/WIRING

Case Dimensions………………………………………………............…………………………………………………………………………11

Display Mounting Hole Pattern…………………..........……….....…………………………………………………………………………………12

Controller Mounting Hole Pattern……………………………………….............…………………………………………………………………13

Sensor Mounting Hold Pattern/Placement………………………...........………………………………………………………………………14

Standard Sidewall Sensor (9-pin)…………………………........……………………………………………………………………………15

Analog Output to Pneumatic Actuator……………………………...….........…………………………………………………………………16

Analog Output to Electric Actuator………………….......…………......………………………………………………………………………17

Analog Input Single Flow Sensor……………………………….........…………………………………………………………………………18

Analog Input Dual Flow Sensors……………………….......……………………....……………………………………………………………19

Analog Input Sash Position Sensor………………………........…………….....………………………………………………………………20

Digital Input Occupancy Sensor………………………………….........……………………………………………………………………21

Power…………………………………………………………........……………………………………………………………………………22

Isolated Power Supply………………………………………...............……………………………………………………………………………23

COMMUNICATIONS

BACnet® MS/TP………………………………………………..........……………………………………………………………………………24

Metasys® N2 Open………………………………………………….............……………………………………………………………………25

BASIC PROGRAMMING

Introduction…………………………………………………………………………………………………………………………………26

Main Display Screen…………………………………………………………...……….....……........…………………………………………26

Configuring Fume Hood Monitor………………………........………………..........………………………………………………………………26

Calibrating Face Velocity Sensor………………………........………………..........………………………………………………………………27

Configuring Sash Position Sensor………………………........………………..........……………………………………………………………27

Calibrating Sash Position Sensor……………….......………………..........………………………………………………………………27

Configuring Sash Settings……………………......…........………………..........………………………………………………………………27

Selecting Sash Control Mode………………………........………………..........………………………………………………………………28

Calibrating the Sash Control Feature………………………........………………..........………………………………………………………28

Configuring Face Velocity Setpoints………………………........………………..........…………………………………………………………28

Configuring Face Velocity Alarm Setpoints………………………........………………..........…………………………………………………28

Changing Fume Hood Operating Mode………………………........………………..........……………………………………………………29

Configuring Analog Output for Exhaust Damper Control…………………….......………………………………………………………………29

Changing Network Settings………………………........………………..........………………………………………………………………29

Adding Password Security………………………........………………..........………………..........………………………………………………29

Changing Display Settings………………………................………………..........………………………………………………………………30

Built-in Diagnostics………………….............……........………………..........………………………………………………………………30

.

MODULE SETTINGS……………………………………………………………..............…………………………………………………………31-37

.

CLEANING THE HMS-1655 DISPLAY…………………………………….................……………………………………………………………38

COMPREHENSIVE WIRING DIAGRAM……………………………….................…....………………………………………………………39

FLOW DIAGRAMS

Unit Setup Tree…………………................................................………........……………………………………………………………………40

System Setup Tree………………………….....…..........................…..........……………………………………………………………………42

Display Setup Tree……………………………............................................……………………………………………………………………45

Diagnostics Menu Tree…………….............……………........................…………………………………………………………………………46

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

- 6 -

HMS-1655

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

Electrical

4 Analog Inputs………………………...…………………………………………………………………………………… 4-20mAdc, 0-5Vdc or 0-10Vdc

4 Analog Outputs…………………….....………………………………………………………………………………… 4-20mAdc, 0-5Vdc or 0-10Vdc

2 Thermistor Inputs…………………………………………………………………………………………………… NTC Type 2 or 3, 10kΩ @ 25˚C

4 Digital Inputs………………………………………………………………………………………… 0-5Vdc or 0-24Vdc, Active-High or Active Low

4 Relay Outputs ………………………………………………………………………………………………………………………………… 1A@24VDC

Control Signal Wire Size……………………………………………………………………………………………………………… 18-22 AWG minimum

Power Supply…………………Class 2, 24Vac ±10%, 30VA universal 120/240 to 24 Vac, 60/50 Hz, step-down isolation transformer provided

Communications

BACnet® MS/TP network…………………………………………………………………...………………… Two-wire Twisted Pair, RS-485 signaling

Metasys® N2 network………………………………………………………………………………………… Two-wire Twisted Pair, RS-485 signaling

Recommended Cable Type ………………………………………………………………………………………………………………… Belden 3107A

Touchscreen User Interface

LCD Size………………………………………………………………………………………...……………………………………………… 3.2” diagonal

LCD Type…………………………………………………………………………………….....……………………………………………… Transmissive

Resolution……………………………………………………………………………….....……………………………………………… 240 x 320 portrait

Viewing Area…………………………………………………………………………....…………………………………………… 50.60 mm x 66.80 mm

Color Depth……………………………………………………………………….....………………………………………………… 18-bit or 262K colors

Backlight Color…………………………………..………………………………………………………………………….....…………………………White

Luminous Intensity……………………....…………………………………………………………………………………..………………min 2500 cd/m2

GENERAL

Specications

Triatek reserves the right to change product specifications without notice. Triatek reserves the right to change product specifications without notice.

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

Mechanical

HMS-1655 Display Housing………………………………………………………………………………………………………… 3”W x 5”H x .1.13”D

HMS-1655 Controller Housing…………………………...………………………………………………………………………… 4.6”W x 6.6”H x 1.9”D

Environmental

Operating Temperature…………………………………………………………………………………………………………32° to 125° F Operating

Operating Humidity……………………………………………………………………………………………………10% - 95% RH, Non-condensing

HMS Air Flow Sensor

Type of Sensor ……………………………………………………………...…………………………………………………Thru-the-hood ultra sensitive

Face Velocity Accuracy…………………………………………………......…………………………………………………………0-200 FPM ± 2 FPM*

Dimensions……………………………………………………………………………………………......................……………… 2.5”H x 4.0”W x 2.0”D

NIST Traceable / Individual certification available as option

*@72°F ± 5°F

Venturi Valve (Order Separately)

Diameter……………………………………………………………………………………………………........………...………………8”, 10”, 12”, 14”O.D.

CFMRange………………………………………………………………………………………………………………………………………………35-2100

Materials …………………………………………………………………………………………………… Aluminum, Stainless Steel, Heresite Coating

Insulation…………………………………………………………………………………………………………………………………………Optional

Actuation………………………………………………...……………………………………………………………………………Electronic or Pneumatic

Part Number Guide

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.Triatek reserves the right to change product specifications without notice.

- 7-

HMS-1655

Triatek reserves the right to change product specifications without notice.

GENERAL

Specications

*Accuracy is ± 5FPM when velocity drops below 60FPM or exceeds 140 FPM

HMS1655 -1-1

Sensor Type Sash Sensor

1 = single smart sidewall sensor blank = sash sensor not included

2 = dual smart sidewall sensor S = sash position sensor included

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

Triatek’s HMS-1655 Fume Hood Controller is an ultra-sensitive

instrument used to monitor and/or control the fume hood face velocit,

and is capable of measuring and displaying face velocities from zero to

200 ft/min (1.016 m/sec) with an accuracy of ±2 ft/min.

Key features of the HMS-1655 include:

• Three selectable control modes available: sidewall only, sash position

only, sash with sidewall for closed-loop performance

• Comprehensive closed-loop sash control with sidewall velocity sensing

• Full-color touchscreen display with programmable display options and

adjustable backlight

• Intuitive user interface simplifies setup and configuration of unit

• Safety Halo™ provides full 180ovisibility from anywhere in laboratory

• Audible and visual alarms

• Auxiliary universal analog inputs for use with optional sensors

• Four independent proportional-integral-derivative (PID) control loops

for controlling damper actuators, speed drives, hot water valves,

humidifiers, etc.

• Digital input used to monitor an optional fume hood sash switch, zone

presence sensor or emergency override switch.

• Relay outputs used for transmitting alarm condition to remote location

• Dedicated thermistor inputs for temperature monitoring and/or control

applications

• Multi-level password protection of touchscreen user interface

• Field calibration of both sidewall velocity sensor and optional sash

position sensor

• Multi-protocol native (BACnet®, Metasys® N2) for easy integration

with any building management system (BMS)

• Manual override of analog and relay outputs assist with test and

balance procedures

• Comprehensive real time view diagnostics tool displays built into each

unit

• Easy-to-install backplane/backplate assembly facilitates permanent

termination of all wiring

The HMS-1655 has bold, modern graphics and integrates Triatek’s

signature Safety Halo™ status indicator. This feature significantly

enhances the alarm status indication of the HMS-1655 by providing full

180° visibility of the color-coded hood statuses.

Not only can you see the status while standing directly in front of the

fume hood, you can now have full visibility from virtually anywhere in

the laboratory. The HMS-1655’s Safety Halo™ is shipped from the

factory enabled at full brightness, but may be dimmed or even disabled

completely.

The HMS-1655 is equipped with a 3.2” diagonal full-color touchscreen

display in portrait orientation (240 x 320). The password-protected menu

tree is very intuitive and simplifies the setup and configuration of the unit.

The menus incorporate touch-based interfaces such as sliders, radio

buttons, and dialog popups to facilitate the ease-of-use of the HMS-

1655.

The display implements bright graphical color changes to indicate the

three different alarm status indication of the monitored fume hood. These

graphical backgrounds indicate “Normal” when the face velocity is within

defined limits, “Warning” when the face velocity is approaching an out-of-

limits condition, and “Alarm” when the face velocity is outside the defined

acceptable and safe limits. The face velocity ranges for these conditions

are easily configured by the user for the specific installation, either

directly from the touchscreen display or over the network from the BMS.

Alarm conditions may be defined by the user, in terms of desired face

velocity settings for the fume hood being monitored. When an alarm

condition occurs, it may be annunciated in four user-definable ways: 1)

on the display, 2) with an audible alarm, and 3) transmitted via contacts

to a remote monitoring location and 4) over the BMS network. The alarm

will automatically reset when the unit has sensed that the fume hood

face velocity has returned to proper limits. The operator may easily mute

the audible alarm by tapping the Alarm Audible button at the bottom of

the touchscreen display.

The HMS-1655 provides four universal analog outputs, which may be

configured for either current loop operation or for voltage operation. Each

analog output may be configured for proportional operation to provide

a linear signal to the BMS, or for PID control operation for closed-loop

feedback control of damper actuators, variable frequency (speed) drives,

hot water valves, humidifiers, or other analog-controlled devices.

Each universal analog output may be field-configured for the required

application using onboard configuration dipswitches on the controller

module. Each analog output may also be temporarily overridden using

the built-in diagnostic tools for troubleshooting during the installation and

commissioning phase.

For those applications requiring monitoring and/or control based on

temperature variances, the HMS-1655 provide two dedicated thermistor

GENERAL

Overview

HMS-1655

Triatek reserves the right to change product specifications without notice.

- 8-

Triatek reserves the right to change product specifications without notice.

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

inputs in addition to the four universal analog inputs. Therefore, a total

of six analog inputs are available for control applications. The two

thermistor inputs may be used with negative temperature coefficient

(NTC) Type 2 or Type 3 sensors.

The HMS-1655 provides four relay outputs, which may be configured

for either direct-acting or reverse-acting operation, and may have a

programmable delay associated to meet the specific needs of the

required application.

A unique feature of the HMS-1655 is its ability to trigger a relay output

for the purpose of activating an optional automatic sash closer device,

thereby keeping an unattended fume hood with an open sash safe

for occupants of the lab. Each relay output may also be temporarily

overridden using the built-in diagnostic tools for troubleshooting during

the installation and commissioning phase.

The HMS-1655 provides four digital Iinputs that may be used for

monitoring sash switches, override switches, flow switches, occupancy

sensors or other devices with binary outputs. The configuration and

operation of each input may be configured by the user to define the

effect of a change in its state.

Each digital input may have a programmable delay duration associated

with it. Each digital input may be configured for either normally-closed

or normally-open operation, and may also be configured to be active-

high or active-low triggered. The global configuration of the digital inputs

is field selectable through the use of a configuration switch on the

controller unit.

The HMS-1655 provides four relay outputs that may be used for remote

alarm annunciation or pilot control functions. The operation of each

output may be configured by the user to define the exact fume hood face

velocity values above and below which the output will operate. Delay

times before activation may be specified to minimize nuisance alarms.

Each relay output may be configured for either direct action or reverse

action. The configuration of each relay output is field selectable through

the password-protected user menus.

The user may set up multiple multi-level passwords to prevent

unauthorized or casual access to the HMS-1655 configuration settings.

Up to ten passwords of up to eight digits may be programmed, with each

having one of four associated access levels. Administrators and Facility

Management personnel may have unrestricted access, while general

staff may be assigned restricted access passwords which limit the

functionality of the user menus.

Fume hood operating mode selection of occupied, unoccupied, or

decommissioned may be protected using limited access passwords,

thereby eliminating the need for keylock switches and keys. However, an

optional keylock switch may be used to further control access to change

in operating modes.

The HMS-1655 provides native support for multiple networking protocols,

including BACnet®MS/TP and Metasys®N2 Open. For applications

requiring LonWorks networking capability, contact the factory about

Triatek’s HMS-1655L series. With multi-protocol native support, the

HMS-1655 is able to communicate fume hood status information to the

building automation system, regardless of which protocol is used. The

configuration of the desired protocol is field selectable through the use of

miniature dipswitches on the controller unit.

The HMS-1655 provides a unique set of built-in diagnostics tools for

the troubleshooting process during the installation and commissioning

phase. The built-in diagnostics tools include manual override capabilities

for both analog outputs and relay outputs, and a comprehensive real-

time view capability that allows the real-time values and states of

each analog and digital input and output to be displayed conveniently.

These are extremely useful tools used to facilitate the verification and

certification processes conducted by typical test and balance personnel

during the commissioning of the system. There are also options for

storing configuration settings and for restoring those settings, as well

as performing a complete restoration of the factory default configuration

settings.

The HMS-1655 incorporates an innovative backplane/backplate

assembly which greatly facilitates the installation process and permits all

wiring terminations to be permanent. The HMS-1655 serves as a direct

drop-in functional replacement for all previous models of HMS-1600

series of BACnet®/N2® fume hood controllers.

SUBHEAD

Overview

HMS-1655

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

- 9 -

Triatek reserves the right to change product specifications without notice.

GENERAL

Triatek reserves the right to change product specifications without notice.

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

This section will illustrate a typical method of installing the HMS-1655

to a fume hood. Tools required include: drill, 3/8 drill bit, 1/8 drill bit,

Phillips #2 screwdriver, standard medium blade screwdriver, silicone

sealant.

1. Proper location of the sensor is very important for obtaining

the best possible operation of the HMS-1655. The system

uses through-the-wall sensing to measure the internal negative

pressure of the fume hood to accurately determine the face

velocity. The sensor must be located in a position that is least

affected by turbulent air within the hood. See illustration on page

14. There are two types of fume hood arrangements which need

to be considered: By-Pass and Non-By-Pass.

• Front-to-Back Position – With either type of fume hood

arrangement, the sensor is best located approximately six

inches back from the vertical sash track.

• Vertical Position (By-Pass) – Locate the sensor vertically

in the center of the region between the bottom of the sash in

the fully open position and the bottom edge of the by-pass

opening.

• Vertical Position (Non-By-Pass) – Locate the sensor

vertically six inches above the bottom of the sash in the fully

open position.

2. See page 14 for dimensions and suggested mounting

arrangements of the Triatek flow sensor on the hood wall.

NOTE: Be certain that sensor reference port is in laboratory

room air. If necessary to obtain this, use Triatek HMS-1600-

PLATE mounted on exterior panel of the fume hood.

3. Apply silicone sealant around the sensor immediately prior to

mounting the assembly to its mounting surface. Be careful to

avoid getting sealant in the sensor port.

4. See page 12 for mounting details for the HMS-1655 display unit.

The preferred location is eye level, usually on one of the side

bezel panels. Please note that the display unit is cable connected

to the control unit, and provision must be made to route the cable

without interference with the fume hood sash or sash cable. The

control unit is typically secured in a convenient location on top of

the fume hood.

5. At the HMS-1655 backplane, assuming the colors of the

3-conductor signal cable being red, black, and green, connect the

leads to the terminals as follows:

Red: Digital SNS_PWR

Black: AGND

Green: AI_1

Modules with the 9-pin terminal block, connect the 3-conductor

signal cable as follows:

Red: +Vin

Black: GND

Green: Vo

6. Power supply connections - input voltage must be Class 2, 24

VAC or 24 VDC. A step-down isolation transformer is supplied

with the HMS-1655. Triatek recommends that the HMS unit be

powered using the supplied transformer, and that only one unit be

powered with each transformer. Do not power any other device

with the same transformer. See pages 22 and 23 for connection

details.

7. All wiring should conform to the local regulations and the National

Electrical Code. Take precautions to prevent routing the sidewall

sensor wiring in the same conduit as line voltage or other

conductors that supply highly inductive loads such as generators,

motors, solenoids or contacts, etc. For all wiring connections, use

22 AWG or larger.

8. After the installation is complete, apply power to the unit, open the

sash to a normal operating position and observe the flow reading

on the touchscreen display.

GENERAL

Installation

HMS-1655

- 10 -

Triatek reserves the right to change product specifications without notice. Triatek reserves the right to change product specifications without notice.

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.Triatek reserves the right to change product specifications without notice.

3"

5"

3/4

"

3/4

"

®

MOUNTING/WIRING

HMS-1655

- 11 -

Right Side

View

Left Angle

Side View

Case Dimensions

Triatek reserves the right to change product specifications without notice.

1.13”

Cable provided terminated at

control unit

Control Unit

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

MOUNTING/WIRING

Display Mounting Hole Pattern

HMS-1655

Triatek reserves the right to change product specifications without notice.

- 12 -

Triatek reserves the right to change product specifications without notice.

The HMS-1655 display backplate may be mounted directly to a standard single-gang wall

box using the two slots along the centerline. Use the backplate as a template to mark the

mounting holes and the cable access hole at the center of the backplate.

3.04”

5.05”

ø 0.143”

ø 0.143”

ø 0.750”

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.Triatek reserves the right to change product specifications without notice.

MOUNTING/WIRING

Controller Mounting Hole Pattern

HMS-1655

Triatek reserves the right to change product specifications without notice.

- 13 -

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

MOUNTING/WIRING

Sensor Mounting Hole Pattern and Placement

HMS-1655

Triatek reserves the right to change product specifications without notice.

- 14 -

Triatek reserves the right to change product specifications without notice.

Sensor Placement - Non By-Pass Type

6.00"

6.00"

Ø 0.50"

The P1 Port must be

referenced to the laboratory

air for proper operation and

should be a located away from

air turbulence

(such as supply or exhaust

diffusers).

Bottom edge

of sash in

uppermost

position (not

operating

height).

Sensor

If the hood is bypassed

or in close proximity to items

like baffles, deflectors, etc.,

contact the factory.

3

1

/8”

43/

8

”

1/8DIA (typ 4 places)

3/8DIA

11/2”

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.Triatek reserves the right to change product specifications without notice.

MOUNTING/WIRING

Standard Sidewall Sensor (9-pin)

HMS-1655

Triatek reserves the right to change product specifications without notice.

- 15 -

NC

NC

GND

NC

NC

NC

Vo

GND

+Vin

NC

NC

GND

NC

NC

NC

Vo

GND

+Vin

FIGURE 2

Alternate Sensor

Mounting

Interior of

Fume Hood Flexible Tubing (3 ft.

Supplied)

This port must be referenced

to laboratory air for proper

orientation and should be located

away from turbulence.

Exterior of

Fume Hood

FIGURE 1

Preferred Sensor

Mounting

Interior of

Fume Hood Flexible Tubing (3 ft.

Supplied)

This port must be referenced

to laboratory air for proper

orientation and should be located

away from turbulence.

Exterior of

Fume Hood

To HMS 1655

To HMS 1655

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

MOUNTING/WIRING

Analog Output to Pneumatic Actuator

HMS-1655

Triatek reserves the right to change product specifications without notice.

- 16 -

Triatek reserves the right to change product specifications without notice.

110 24

Controller Configuration Dipswitch Settings

S1 - 1 = OFF, S1 - 5 = OFF (AI - 1 set as 0-5V Input)

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.Triatek reserves the right to change product specifications without notice.

MOUNTING/WIRING

Analog Output to Electric Actuator

HMS-1655

Triatek reserves the right to change product specifications without notice.

- 17 -

Controller Configuration Dipswitch Settings

S1 - 1 = OFF, S1 - 5 = OFF (AI - 1 set as 0-5V Input)

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

SUBHEAD

HMS-1655

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

- 18 -

MOUNTING/WIRING

Analog Input Single Flow Sensor

Triatek reserves the right to change product specifications without notice.

Controller Configuration Dipswitch Settings

S1 - 1 = OFF, S1 - 5 = OFF (AI - 1 set as 0-5V Input)

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

MOUNTING/WIRING

HMS-1655

- 19 -

Analog Input Dual Flow Sensors

NOTE: If using legacy sidewall sensor module,

the three terminals are +, IN, and G. The + terminal

should be connected to +10V; IN should be

connected to AI_1, and G should be connected to

AGND at the HMS-1655 backplane.

Triatek reserves the right to change product specifications without notice. Triatek reserves the right to change product specifications without notice.

Controller Configuration Dipswitch Settings

S1 - 1 = OFF, S1 - 5 = OFF (AI - 1 set as 0 - 5V Input)

S1 - 2 = OFF, S1 - 6 = OFF (AI - 2 set as 0 - 5V Input)

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

SUBHEAD

HMS-1655

Due to continuous improvement, Triatek reserves the right to change product specifications without notice.

- 20 -

MOUNTING/WIRING

Analog Input Sash Position Sensor

Triatek reserves the right to change product specifications without notice. Triatek reserves the right to change product specifications without notice.

Default input for sash

sensor is AI-2, but may

also be terminated at AI-3

or AI-4.

Controller Configuration Dipswitch Settings

S1 - 2 = OFF, S1 - 6 = ON (AI - 3 set as 0-10V Input)

Table of contents

Other TRIATEK Controllers manuals