OPERATINGPROCEDURES

WARNING! For the safe operation of this machine

follow the instructions given in this booklet and

the training given by your supervisor. Failure to

do so can result in personal injury and/or damage

to machine and property!

DONOTOPERATEMACHINEINANEXPLOSIVEEN-

VIRONMENT!

NEVERUSE THIS MACHINETOPICK UPVOLATILE

OREXPLOSIVE MATERIALS!

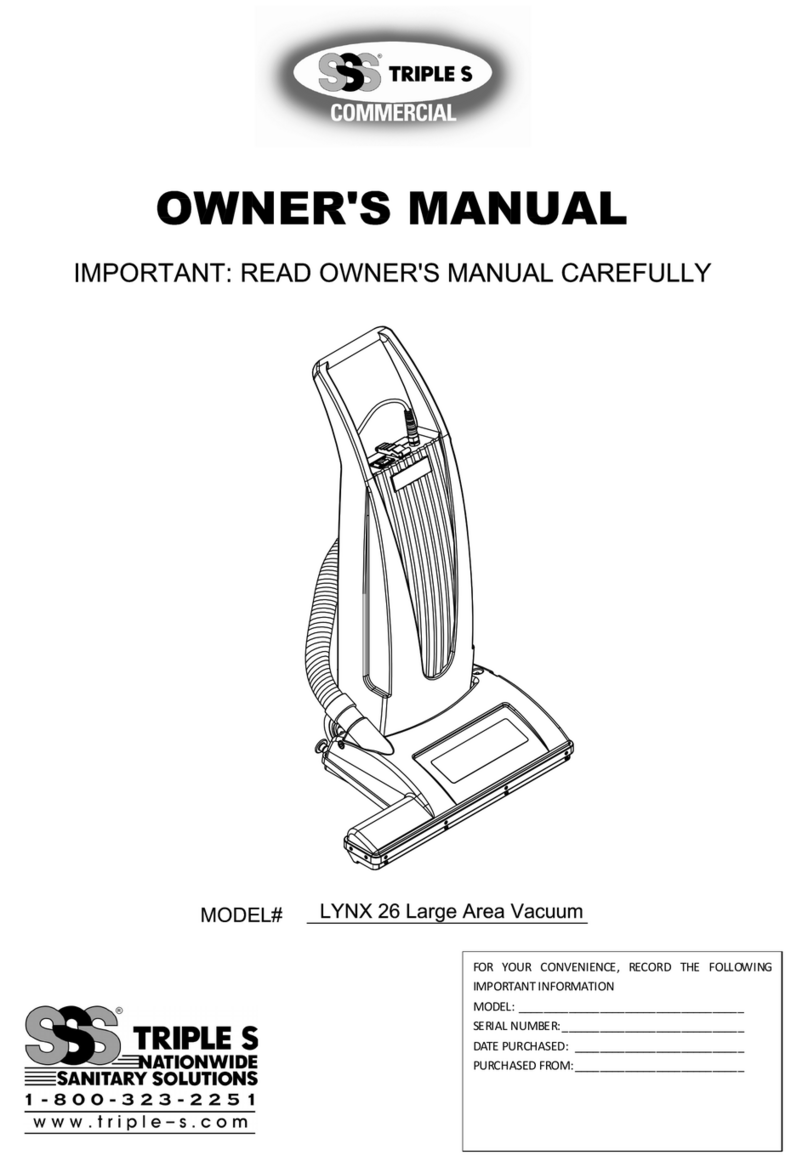

The model shown in this manual is intended for com-

mercial use.

PREPARATION

Topreparethe machineforoperation,make sure it isof

correct voltage and properly assembled. If in doubt,

askyour supervisor.

1. Ifthevacuumisinitsuprightposition(page6), raise

the handle while supporting the vacuum, then

slowly lower the vacuum to the floor.

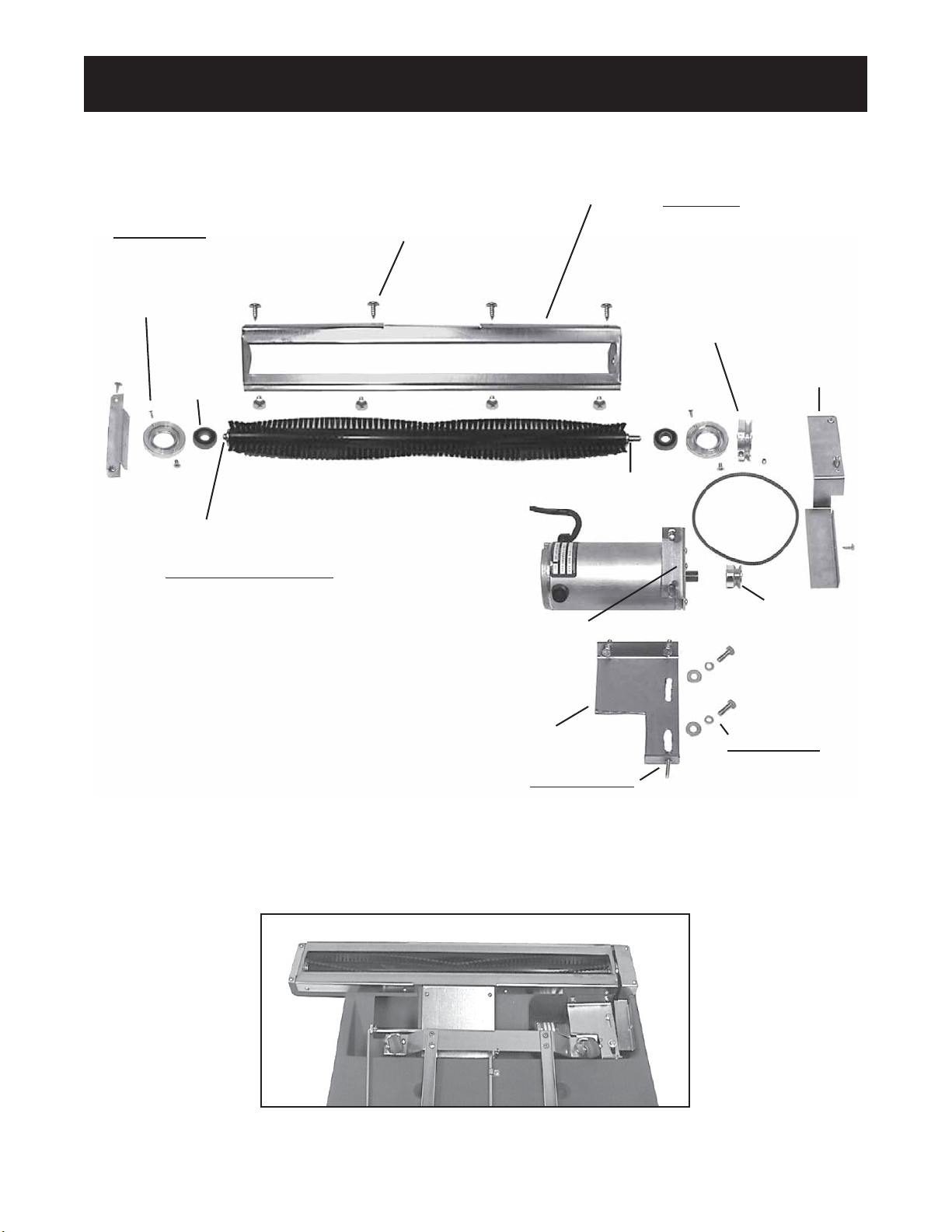

2. Properly install the filter bag in the vacuum:

Liftthecover from the machine. The filter baginlet

is designed with a rubber gasket that fits securely

over the bag adapter (page 7) in the cover. First

pushthefilterbaginletovertheadapteronthecover.

Thenfrom the outside of thecoverreachinside the

adapterand push thegasketonthe rest oftheway.

Replacethefilterbagwhenfull.

OPERATION

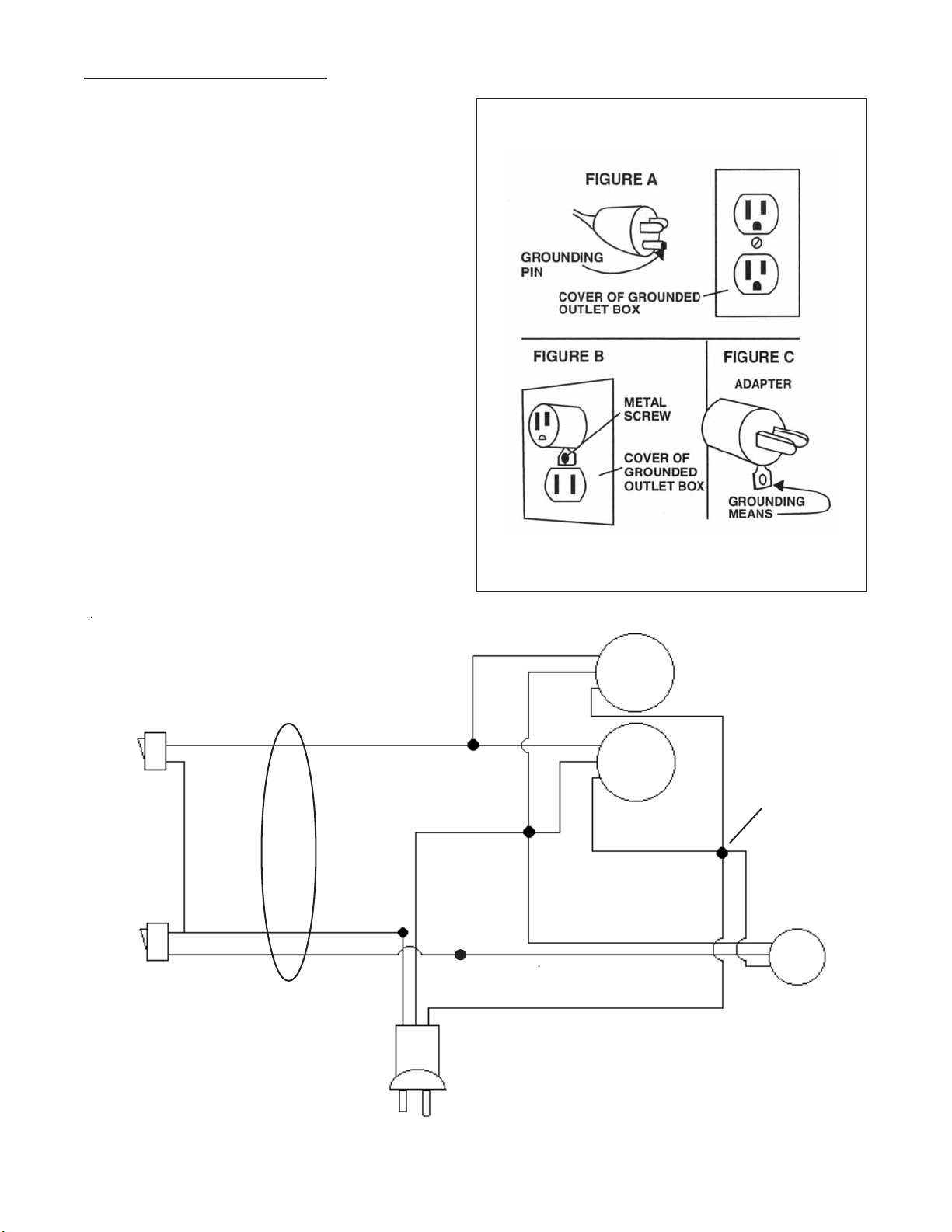

1. Plug the machine’s power cable into a prop-

erlygrounded outlet (seeGroundingInstructions).

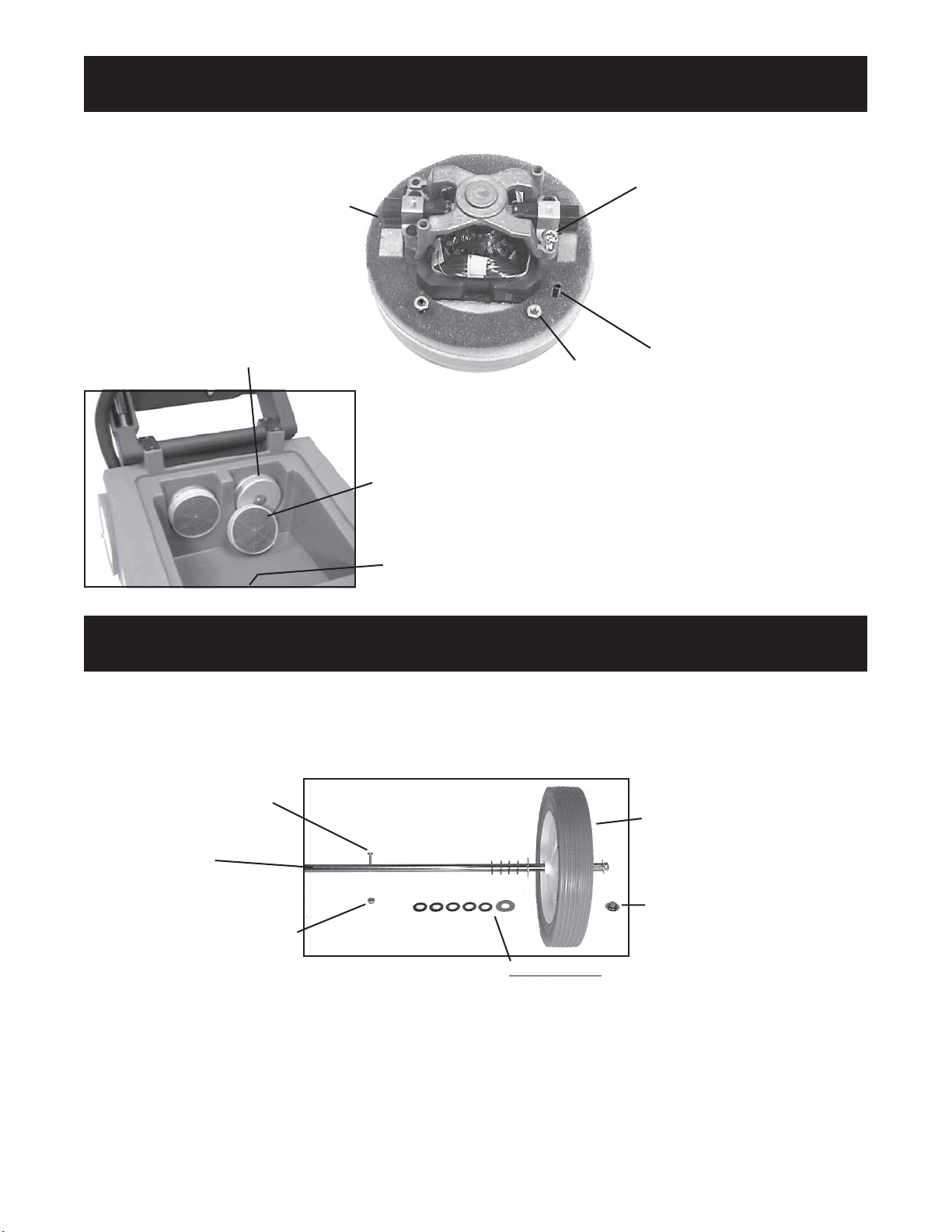

2. Thefoot pedalshould beraised tothe “BRUSH”

position(page 8) for wideareavacuuming.

3. Adjust the brush height withtheleverlocatedon

therearofthemachine near the floor (page 8).

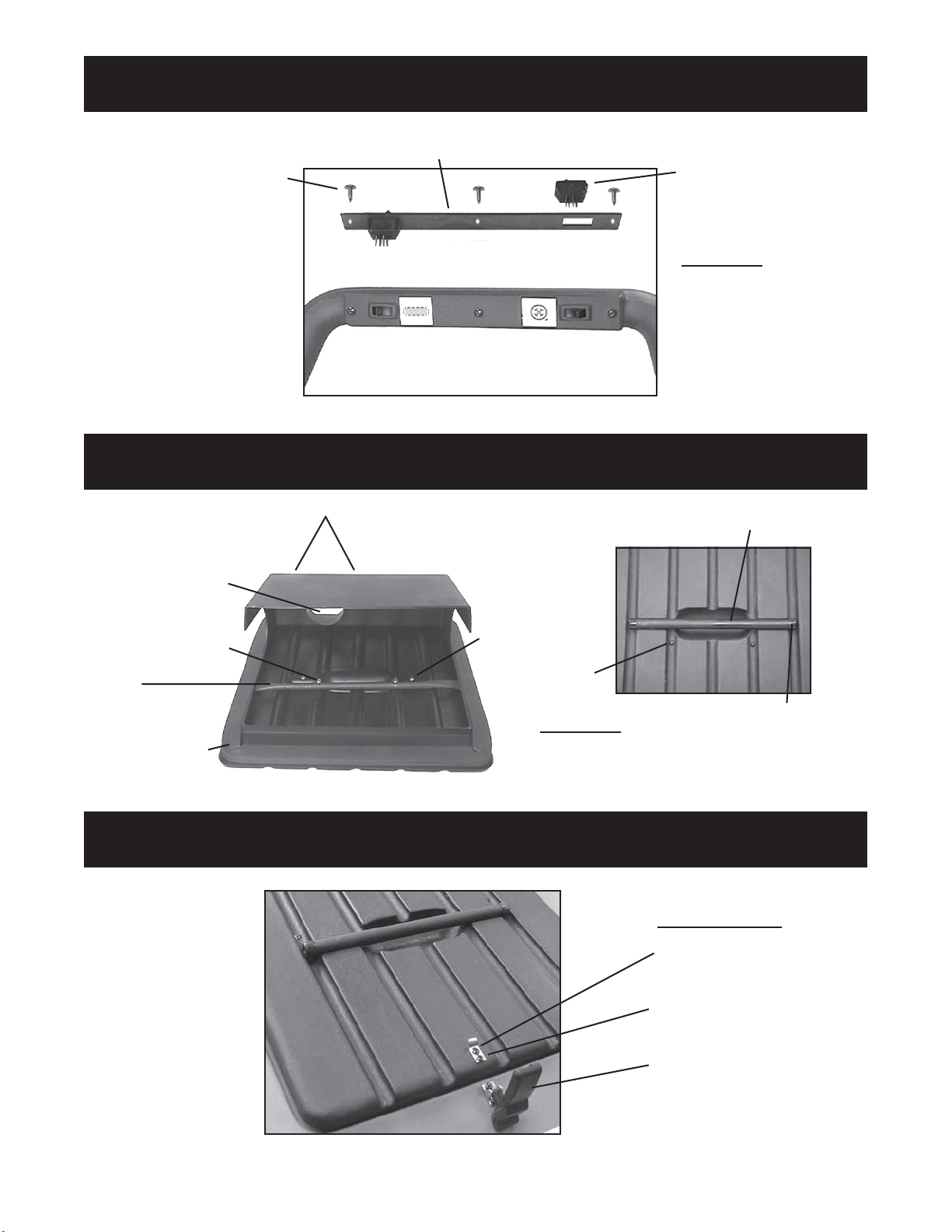

4. Turn the vacuum switch ON (rocker switch on

operator’sright,page 7).

5. Turn the brush switch ON (rocker switch on

operator’s left, page 7) and begin vacuuming.

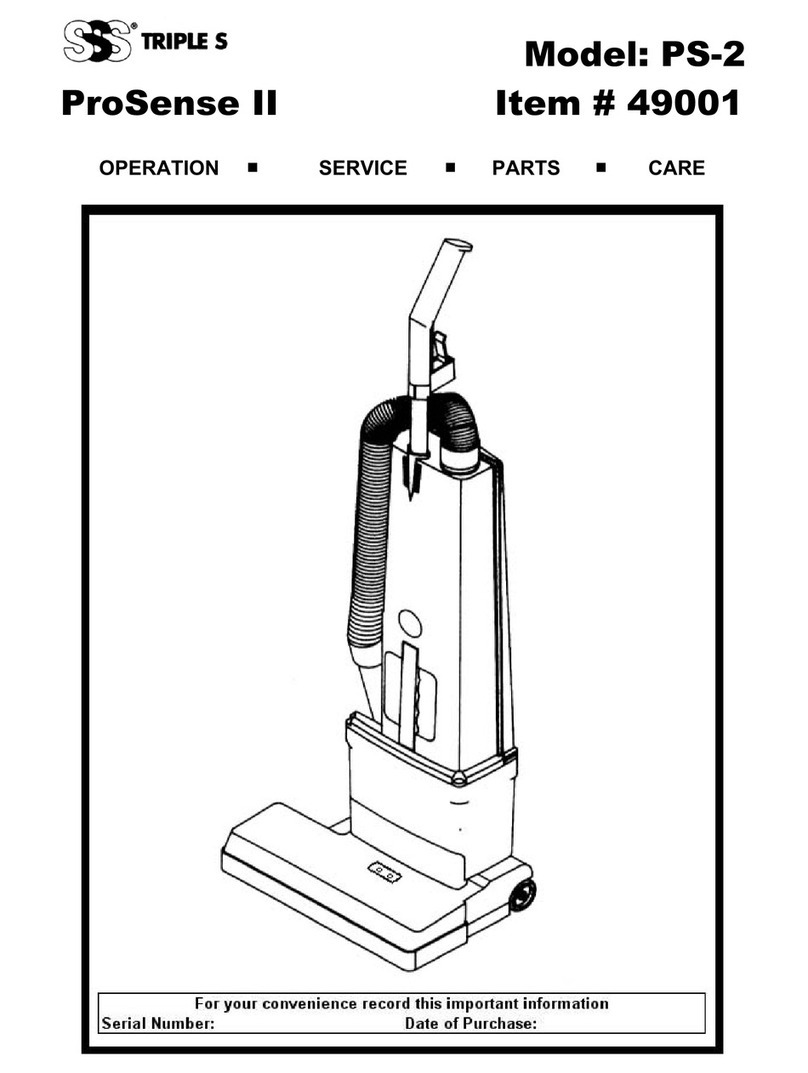

OPERATION WITH TOOLS

Threeon-boardtoolsareavailableforthe vacuum: the

dustingtool,crevice tooland turbotool (page6). Twenty

(20) feet of hose is provided which allows access to

roomswithout moving the machine.

1. The brush and vacuum switches should be

turned OFF.

2. Depress the foot pedal to the “ACCESSORY”

position.

3. Removethe rigid portionof the accessoryhose

from its storage area in the handle and attach the

tool of choice.

4. Turn the vacuum switch ON and begin.

Note:Thevacuum switch should be OFF when switch-

ingthe footpedalbetween the accessoryandthe brush

positions.

MAINTENANCE

ALWAYSturnthe brush andvacuummotor switches

OFF and UNPLUG the power cord from the electri-

cal outlet before doing any clean-up or repairs,

and when the machine is left unattended.

AFTEREACHUSE:

1. Vacuum filter bag: If the bag is full or damaged

install a new one.

Filter Bag, 10 Pack – Part Number 54354

Cloth Bag (optional) – Part Number 54356

2. Power cord and plug: Check for cuts or nicks; if

damaged, have the cord replaced at a factory au-

thorizedservice center.

3. Casters and Wheels: Remove any strings or de-

bristhat mayrestrictthe freemovementof thecast-

ers.

4. Tools: Inspect the tools to ensure there is no ob-

structionof airflow. Removeany debris found.

5. Brush: Remove any strings or debris. Replace if

becomesworn or damaged.

Storage: Thehandlemaybefoldeddownandthe

machinestoreduprightto reduce storage space

requirements. Store the machine in a clean dry area.

4