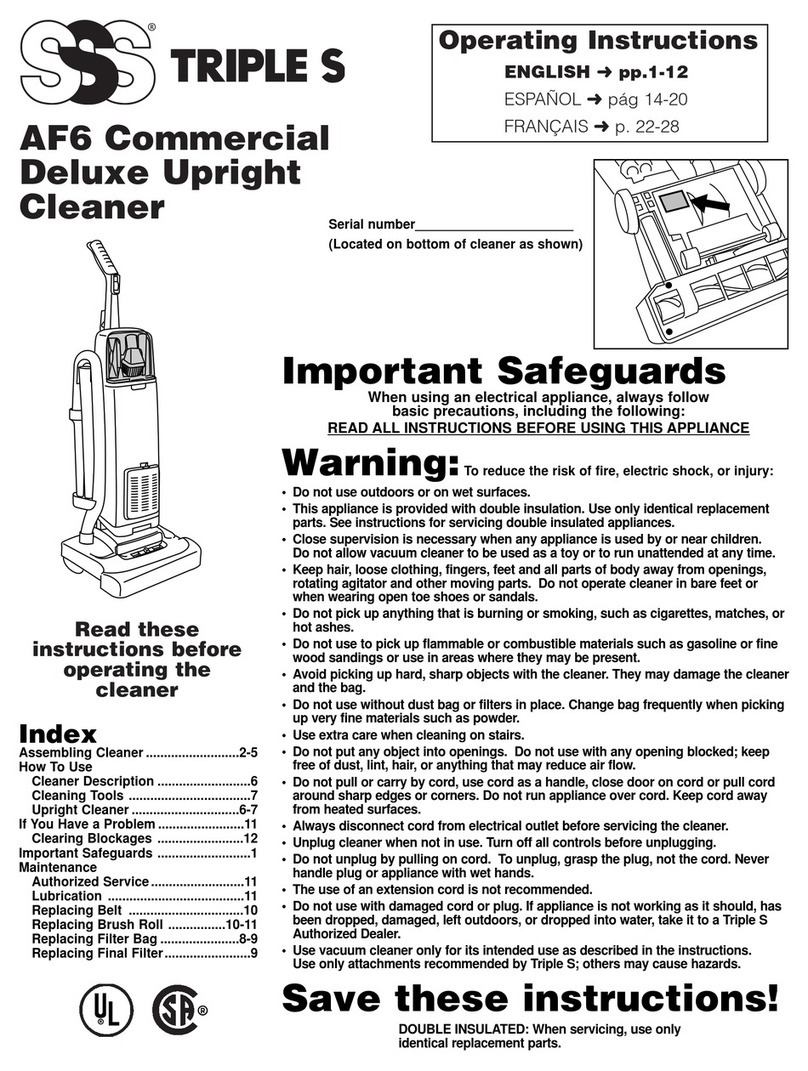

2 Owner’s Manual

INSPECTION

Carefully unpack and inspect your new vacuum for shipping damage. Each unit is

tested and thoroughly inspected before shipping. For instructions regarding any

shipping damage, contact your Triple S distributor immediately. All returns must

have a Return Authorization Number (RAN).

WARNINGS

uDO NOT vacuum with a frayed, worn, or damaged cord.

uDO NOT vacuum liquids or expose the vacuum to rain or water.

uDO NOT vacuum hazardous or toxic materials.

uDO NOT use to pick up flammable or hazardous materials.

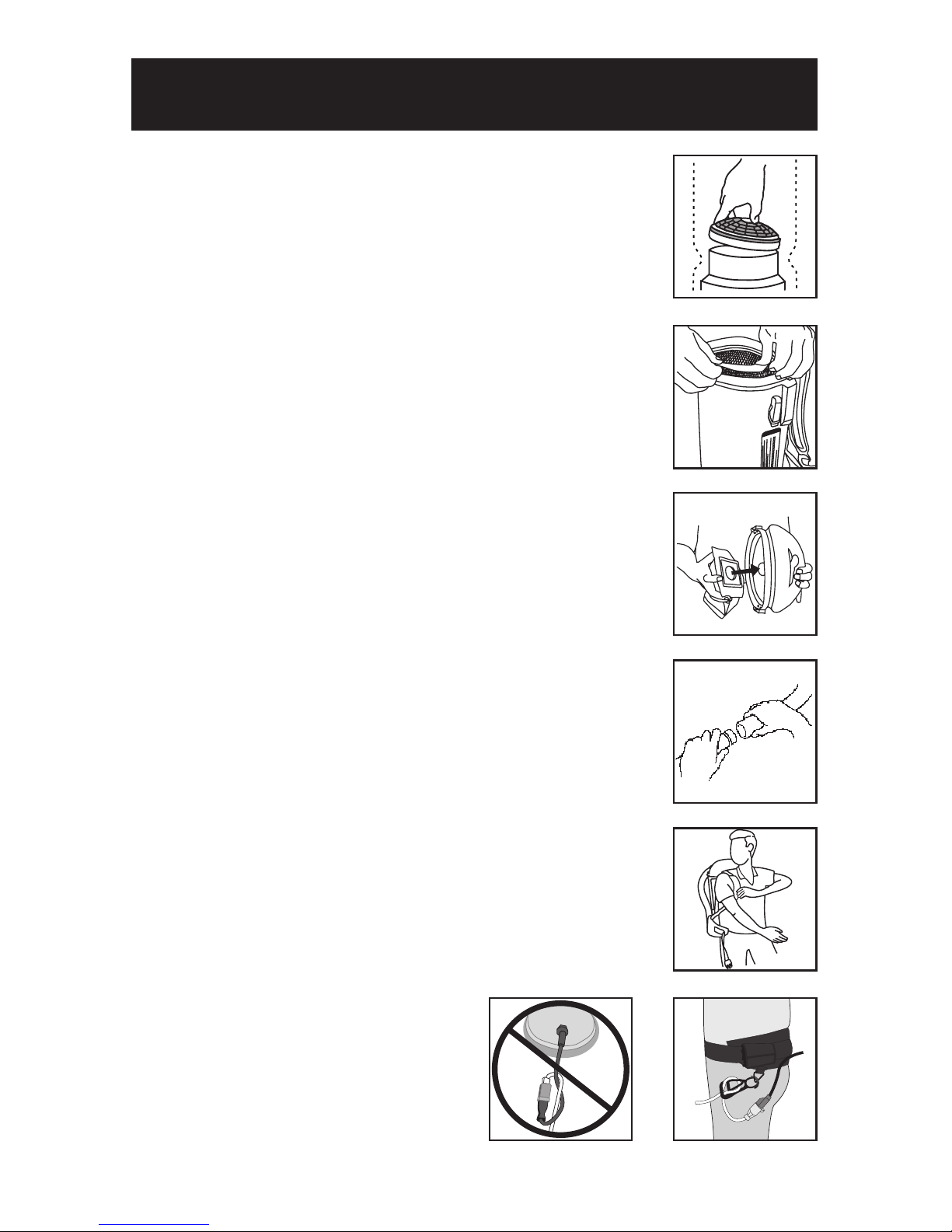

MOTOR

Electric thru-flow vacuum motors must never be used in applications in which wet

or moist conditions are involved, where dry chemicals or other volatile materials are

present, or where airflow may be restricted or blocked. Such motors are designed to

permit the vacuumed air to pass over the electrical wiring to cool it. Therefore, any

liquid (including water), dry chemical, or other foreign substance that would come

in contact with electrical conductors could cause combustion (depending on volatil-

ity) or electrical shock. Failure to observe these precautions could result in property

damage and severe personal injury, including death in extreme cases.

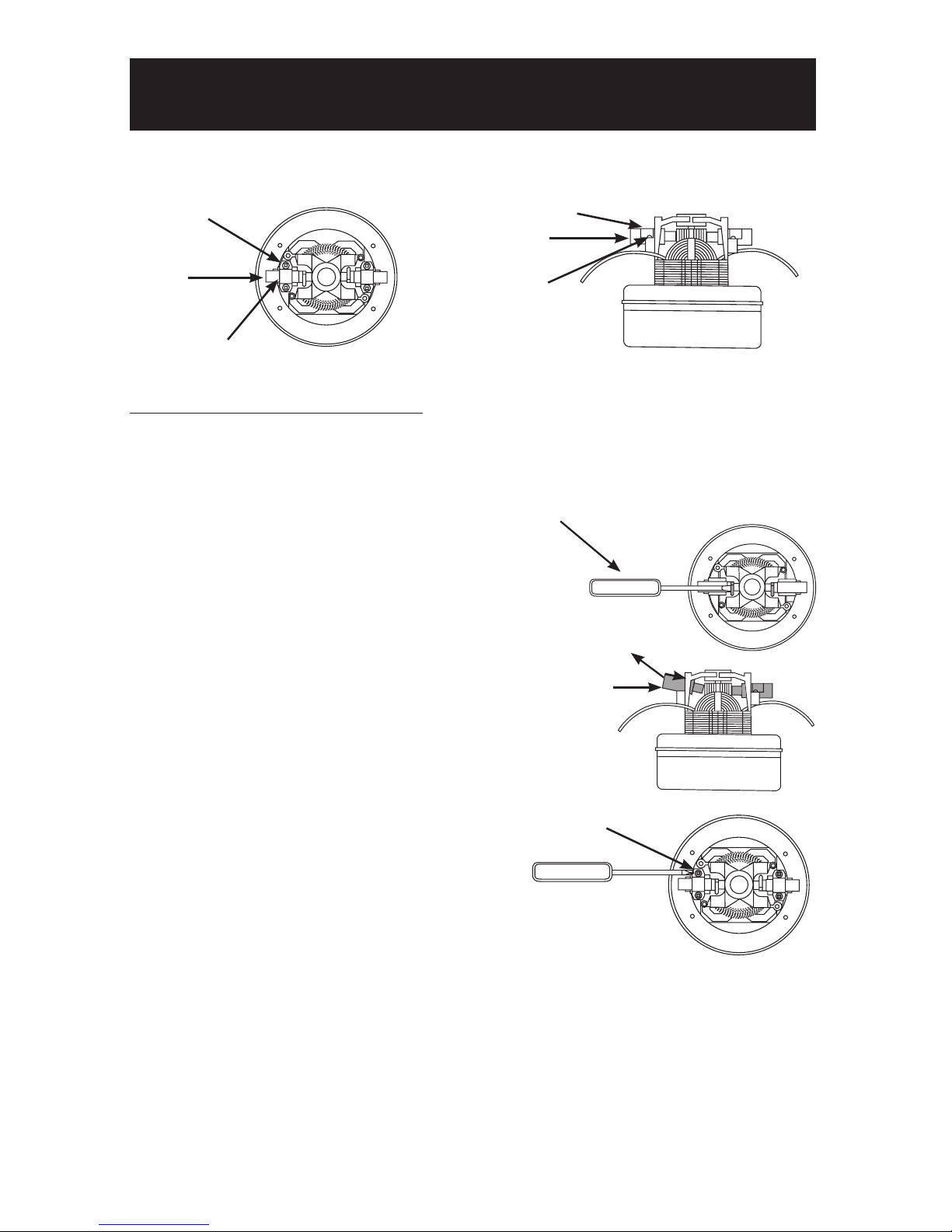

ELECTRICAL

Excluding the 220 V motors, vacuum motors operate on a standard 120 volt, 60 Hz,

AC circuit. Severe changes in voltage, high or low, can cause damage to the motor

and premature motor failure. Model numbers and specifications can be obtained by

calling your Triple S distributor.

GROUNDING INSTRUCTIONS—COMMERCIAL-RATED UNITS

COMMERCIAL-RATED VACUUMS MUST BE GROUNDED. If the vacuum should

malfunction or stop working, grounding provides a path of least resistance for

electrical current, thereby reducing the risk of electrical shock. This unit is equipped

with a cord that has an equipment-grounding conductor and grounding plug.

The plug must be inserted in an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances. Cutting off the ground

wire or using a cord that is not equipped with a ground plug will void the warranty

on the unit, and Triple S will accept NO liability associated with the unit.

Improper connection of the equipment-grounding connector conductor can result

in a risk of electrical shock. Check with a qualified electrician or service person if

you doubt that the outlet is properly grounded. Do not modify the plug provided

with the vacuum. If it will not fit the outlet, have a proper outlet installed by a

qualified electrician.

INTRODUCTION