OPERATING PROCEDURES

WARNING! For the safe operation of this machine

follow the instructions given in this booklet and the train-

ing given by your supervisor. Failure to do so can result

in personal injury and/or damage to machine and prop-

erty!

DO NOT OPERATE MACHINE IN AN EXPLOSIVE

ENVIRONMENT!

NEVER USE THIS MACHINE TO PICK UP VOLA-

TILE OR EXPLOSIVE MATERIALS!

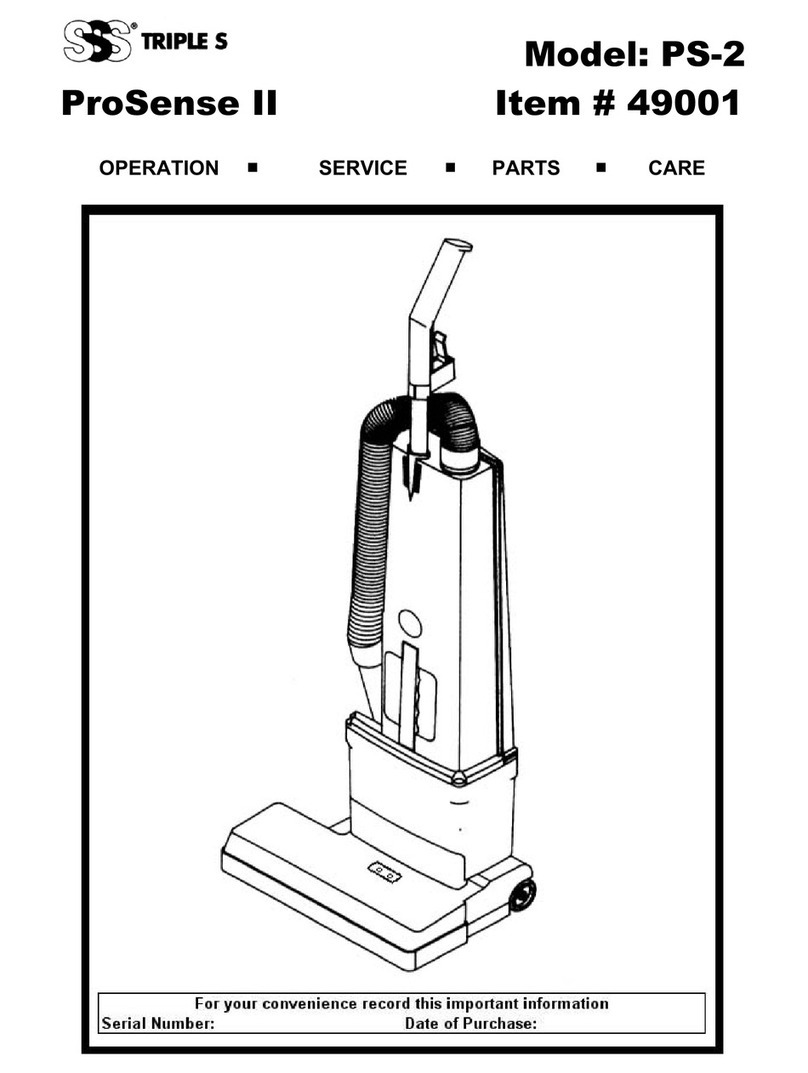

The model shown in this manual is intended for commer-

cial use.

PREPARATION

To prepare the machine for operation, make sure it is of

correct voltage and properly assembled. If in doubt, ask

your supervisor.

!If the vacuum is in its upright position (page 6), raise

the handle while supporting the vacuum, then slowly

lower the vacuum to the floor.

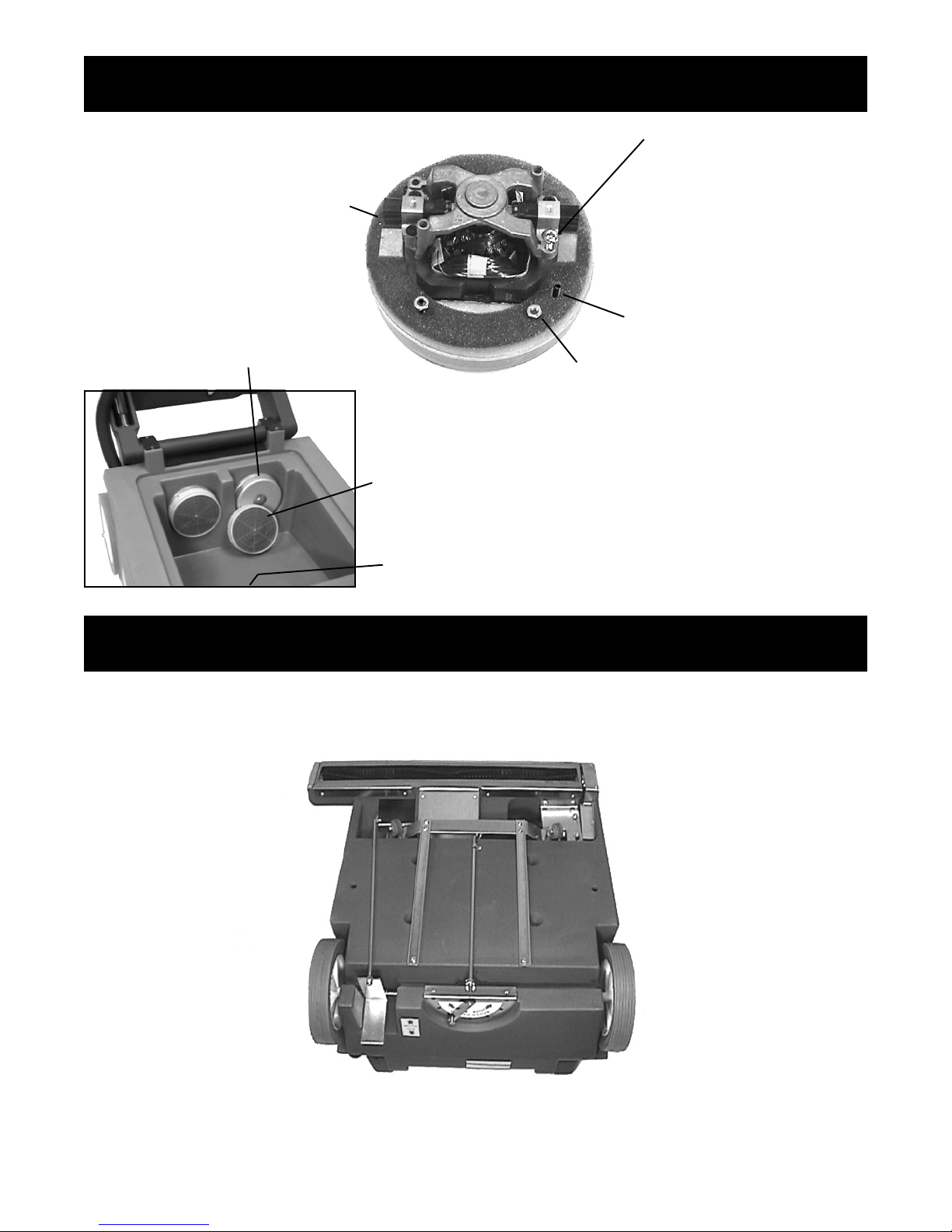

!Properly install the filter bag in the vacuum: Lift

the cover from the machine. The filter bag inlet is de-

signed with a rubber gasket that fits securely over the

bag adapter (page 7) in the cover. First push the filter

bag inlet over the adapter on the cover. Then from the

outside of the cover reach inside the adapter and push

the gasket on the rest of the way. Replace the filter

bag when full.

OPERATION

1. Plug the machine’s power cable into a properly

grounded outlet (see Grounding Instructions).

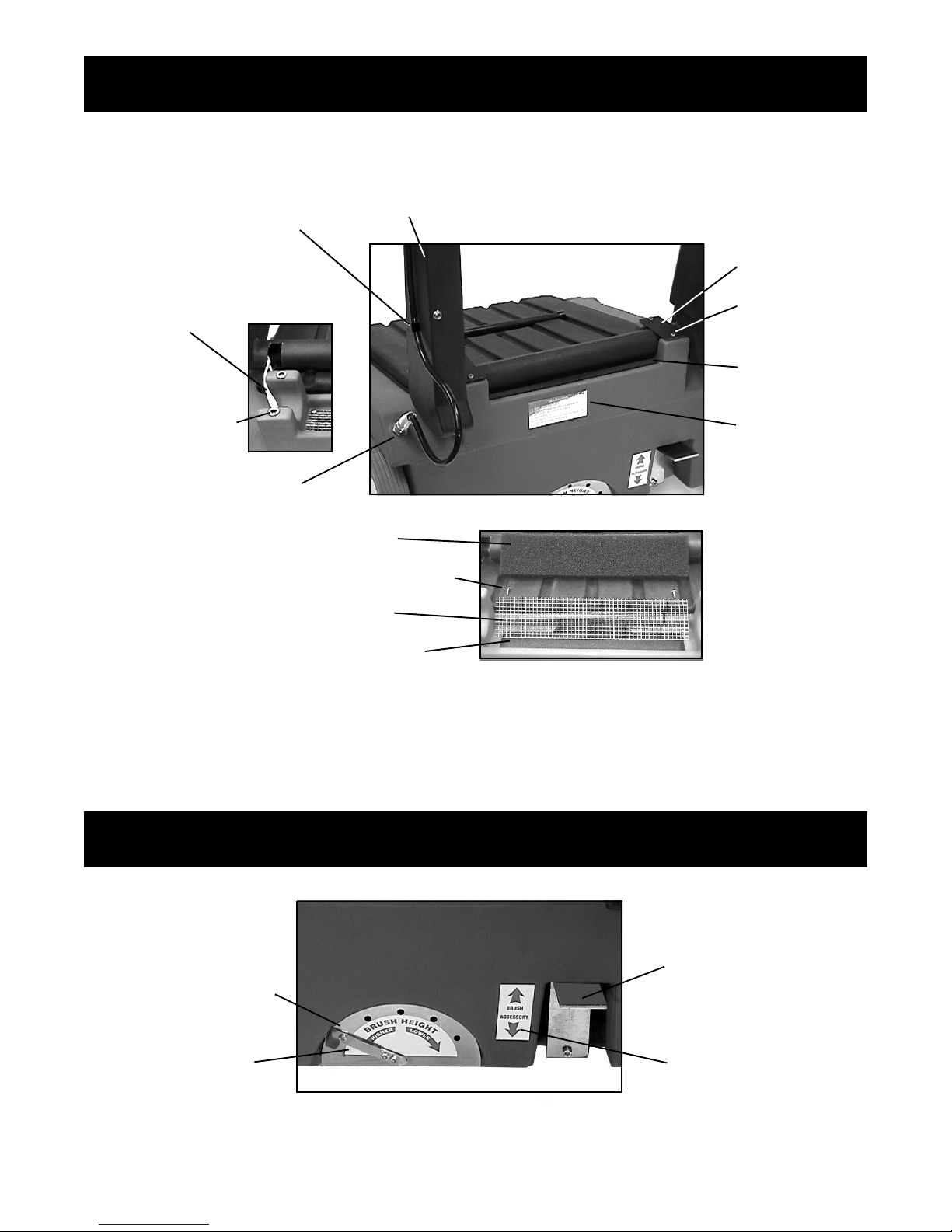

2. The foot pedal should be raised to the “BRUSH”

position (page 8) for wide area vacuuming.

3. Adjust the brush height with the lever located on

the rear of the machine near the floor (page 8).

4. Turn the vacuum switch ON (rocker switch on

operator’s right, page 7).

5. Turn the brush switch ON (rocker switch on

operator’s left, page 7) and begin vacuuming.

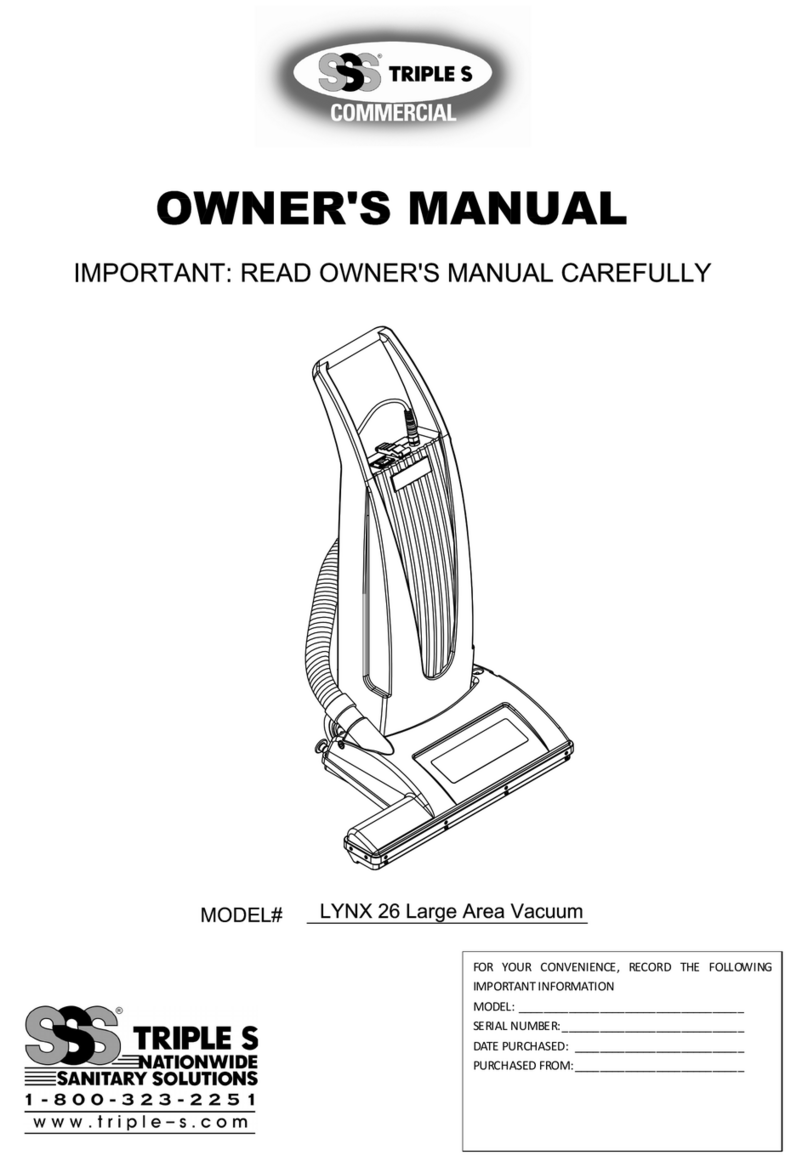

OPERATION WITH TOOLS

Three on-board tools are available for the vacuum: the dust-

ing tool, crevice tool and turbo tool (page 6). Twenty (20)

feet of hose is provided which allows access to rooms with-

out moving the machine.

1. The brush and vacuum switches should be turned

OFF.

2. Depress the foot pedal to the “ACCESSORY” posi-

tion.

3. Remove the rigid portion of the accessory hose from

its’ storage area in the handle and attach the tool of

choice.

4. Turn the vacuum switch ON and begin.

Note: The vacuum switch should be OFF when switching

the foot pedal between the accessory and the brush posi-

tions.

MAINTENANCE

ALWAYS turn the brush and vacuum motor switches

OFF and UNPLUG the power cord from the electrical

outlet before doing any clean-up or repairs, and when

the machine is left unattended.

AFTER EACH USE:

1. Vacuum filter bag: If the bag is full or damaged in-

stall a new one.

Filter Bag, 10 Pack – Part Number 650602

Cloth Bag (optional) – Part Number 650601

2. Power cord and plug: Check for cuts or nicks; if

damaged, have the cord replaced at a factory autho-

rized service center.

3. Casters and Wheels: Remove any strings or debris

that may restrict the free movement of the casters.

4. Tools: Inspect the tools to ensure there is no obstruc-

tion of airflow. Remove any debris found.

5. Brush: Remove any strings or debris. Replace if be-

comes worn or damaged.

Storage: The handle may be folded down and the

machine stored upright to reduce storage space require-

ments. Store the machine in a clean dry area.

4