Content

Content

1 General Information....................................................................................................... 8

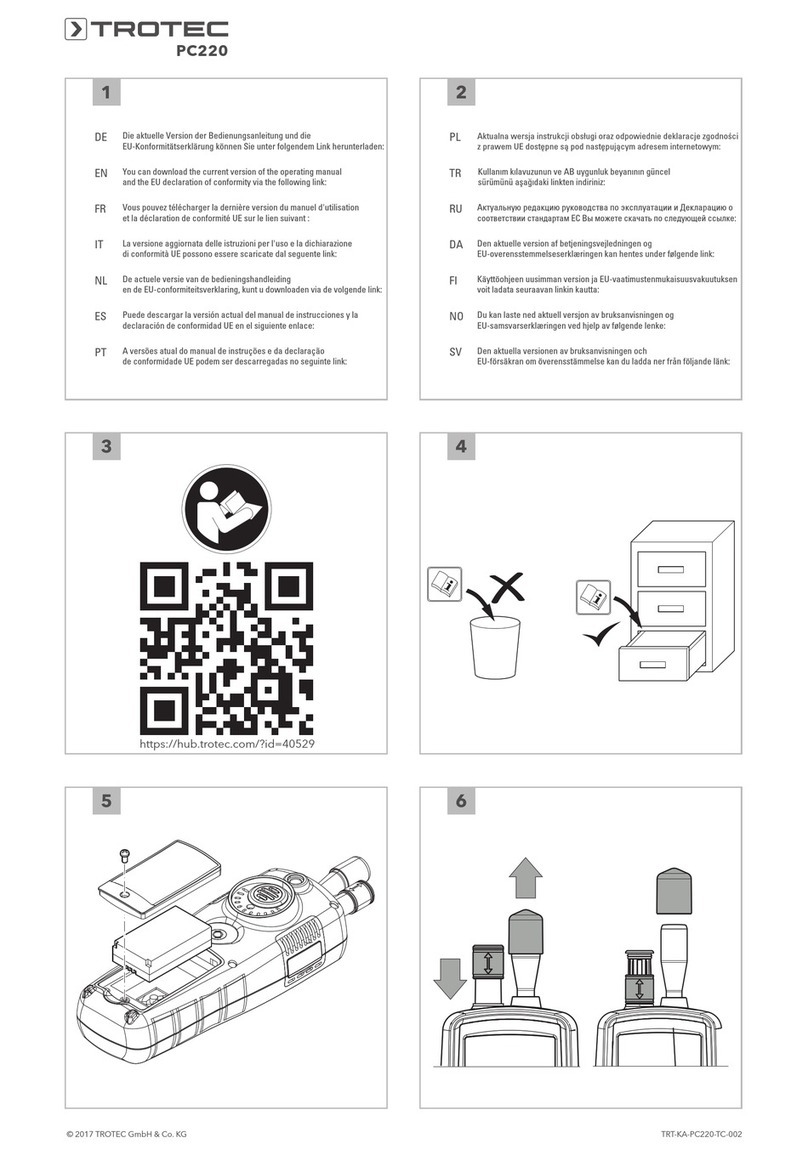

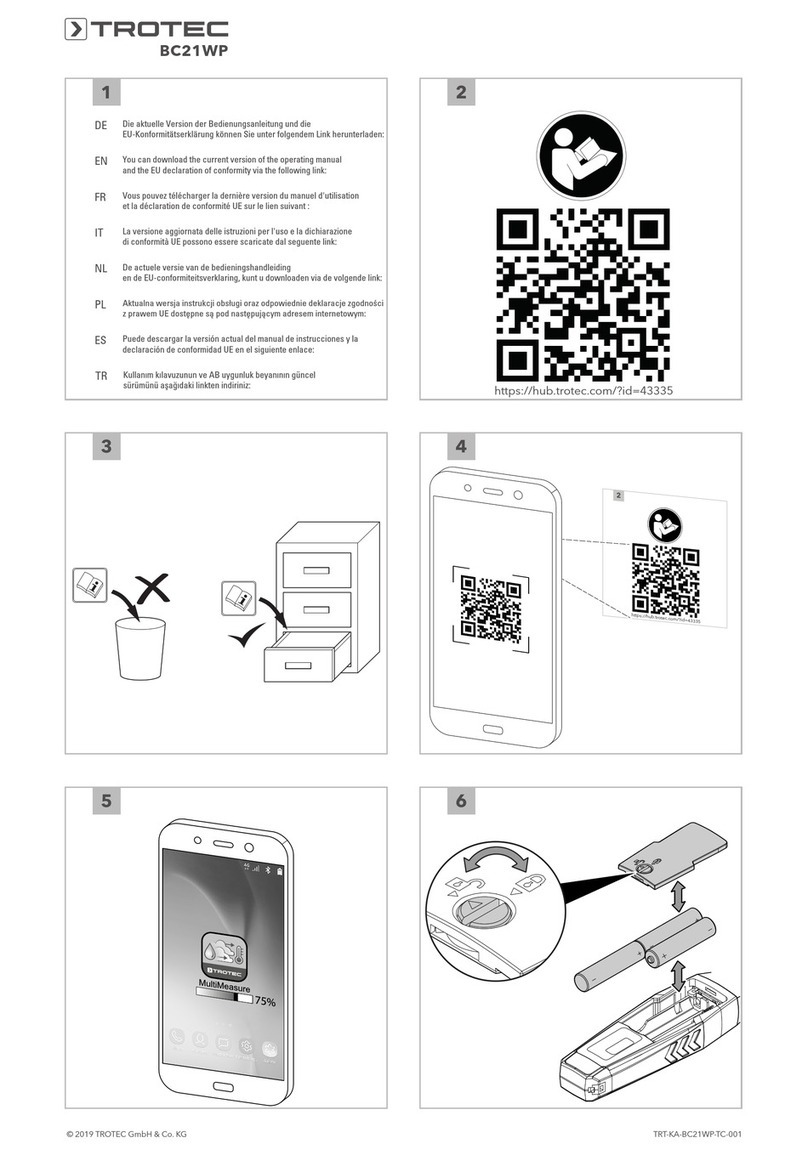

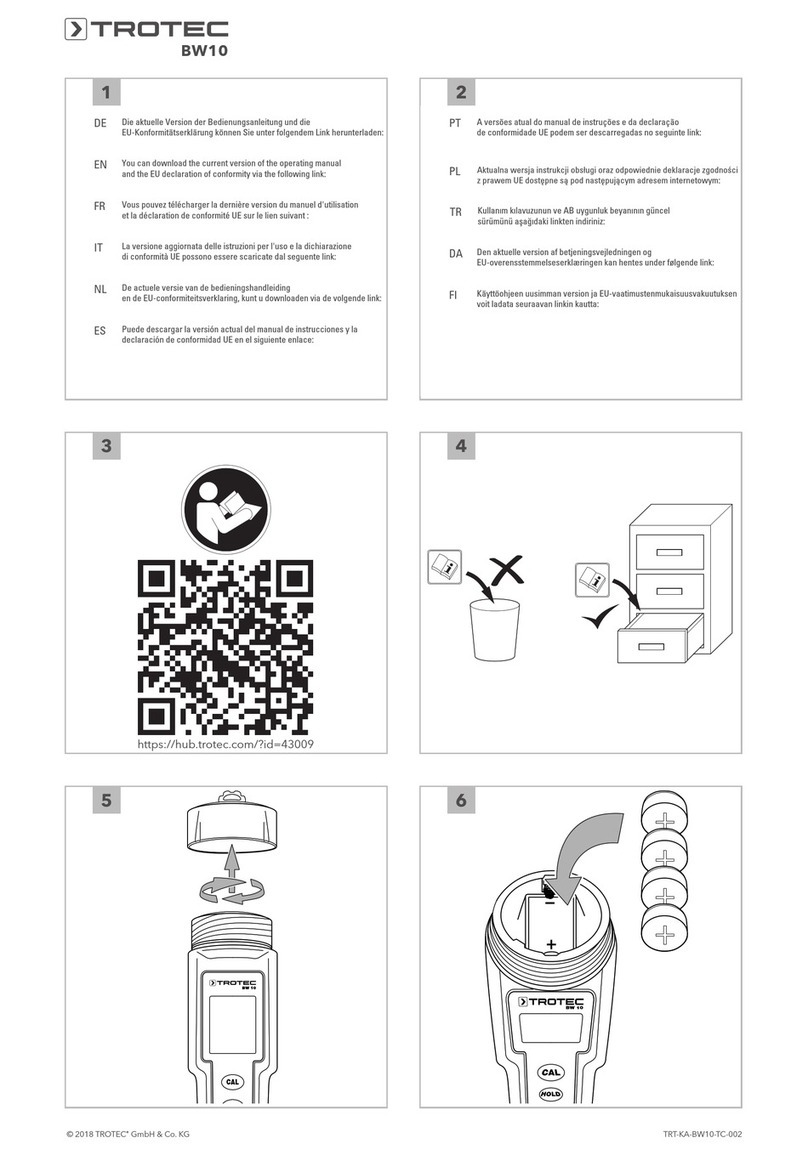

1.1 Information about this manual.................................................................................................................................8

1.2 Storage of the manual.................................................................................................................................................8

1.3 General instructions for using the manual............................................................................................................. 9

1.4 Explanation of symbols...............................................................................................................................................9

1.5 Applicable health and safety requirements..........................................................................................................10

1.6 Liability and warranty................................................................................................................................................13

1.7 Scope of delivery (standard configuration).......................................................................................................... 13

1.8 Type plate.....................................................................................................................................................................14

2 Laser machine hazards................................................................................................. 15

3 Safety........................................................................................................................... 18

3.1 General safety notes.................................................................................................................................................. 18

3.1.1 Intended use............................................................................................................................................................ 18

3.1.2 Improper use............................................................................................................................................................19

3.1.3 Temporal limits of the machine.......................................................................................................................... 19

3.1.4 Machine modification............................................................................................................................................ 20

3.1.5 Emergency stop.......................................................................................................................................................20

3.1.6 Operating modes.................................................................................................................................................... 20

3.1.7 Applicable safety regulations............................................................................................................................... 20

3.2 Laser safety.................................................................................................................................................................. 21

3.2.1 Laser classification..................................................................................................................................................21

3.3 Areas of responsibility............................................................................................................................................... 23

3.3.1 Operator’s obligations............................................................................................................................................23

3.3.2 Responsibilities of the operating personnel..................................................................................................... 23

3.4 Requirements for operating an service personnel..............................................................................................24

3.5 Machine identification (warning and safety stickers)......................................................................................... 24

3.6 Secondary (indirect) hazards...................................................................................................................................26

3.6.1 Fire hazard................................................................................................................................................................26

3.6.2 Gases, fumes and dust.......................................................................................................................................... 26

3.6.3 Exhaust system........................................................................................................................................................26

3.7 In case of emergency.................................................................................................................................................27

4 Technical Data.............................................................................................................. 28

4.1 Electrical requirements of the machine................................................................................................................ 28

4.2 Connecting a cooling unit from Trotec Laser GmbH..........................................................................................28

5 Before commissioning.................................................................................................. 29

5.1 Unloading, inspection and reporting faults..........................................................................................................29

5