TRU-BLU K9000 2.0 User manual

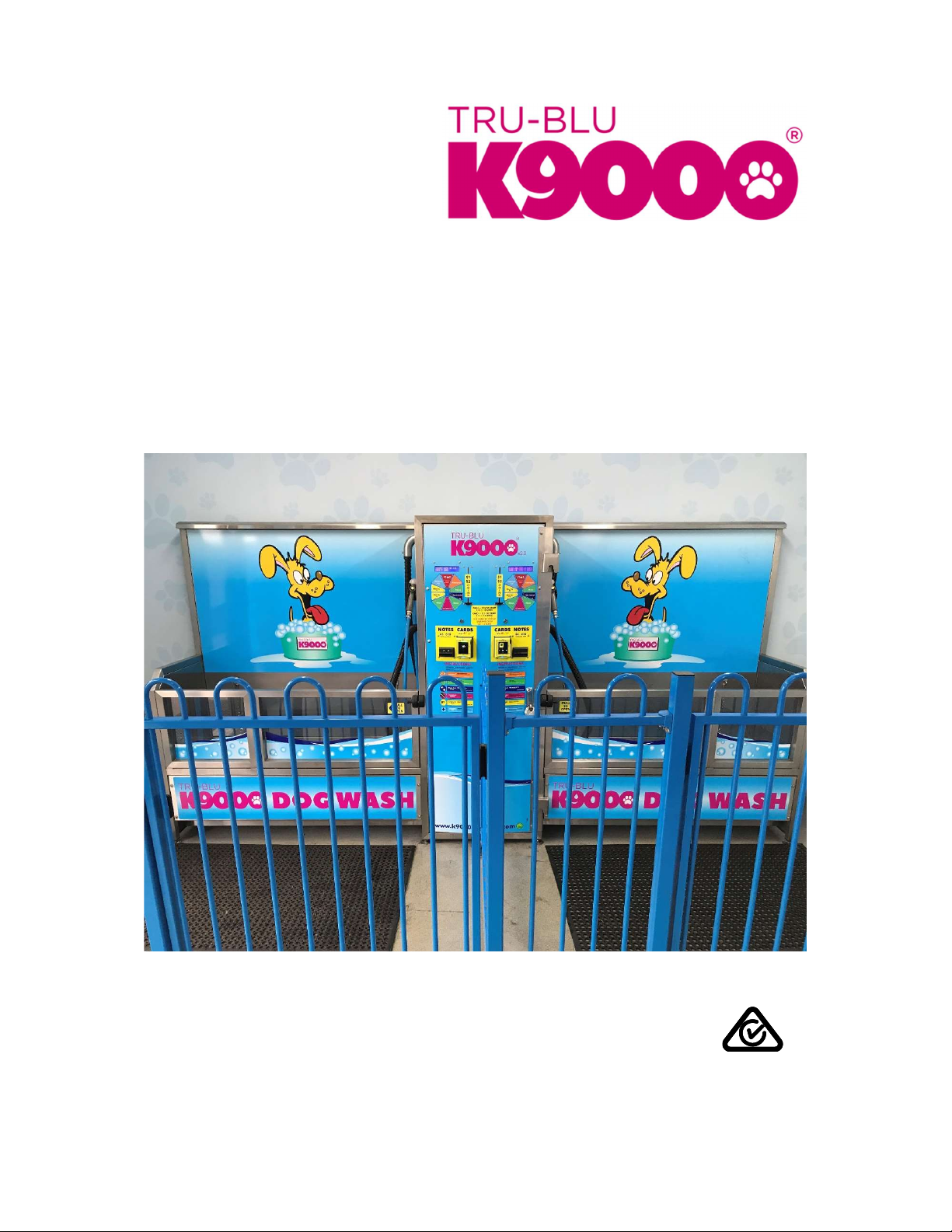

K9000 2.0 Twin Dog Wash

Operators Manual

© Copyright 2016, Tru Blu Dog Wash, All rights reserved. K9000® is a registered trademark

of Tru Blu Dog Wash.

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page ii

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

© Copyright 2016, Tru Blu Dog Wash, All rights reserved. K9000® is a registered trademark

of Tru Blu Dog Wash.

All requests and enquiries regarding the use of, and availability of this manual are to be

directed to:

Tru Blu Dog Wash

Factory No. 1

34 Caramut Road

Warrnambool

Victoria 3280

Australia

Tel: +61 (0)3 5562 9088

Fax: +61 (0)3 5562 9022

Email: [email protected]m.au

Website: www.trubludogwash.com.au

www.findadogwash.com

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page iii

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

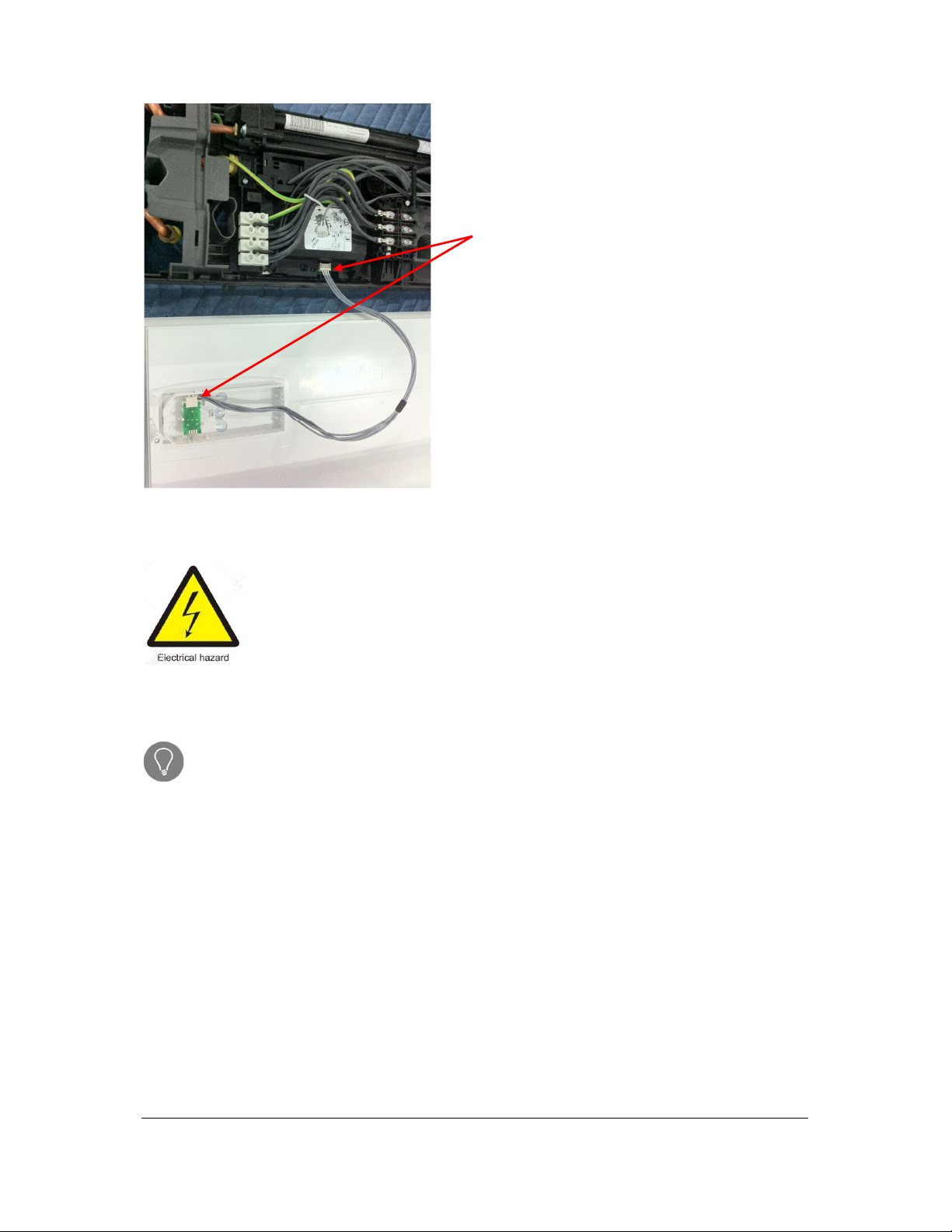

Explanation of symbols used in this manual

Warning

Tip

Important - Take note

Regulatory Compliance Mark

Electrical Hazard

European Conformity

Date

Summary of Changes

Sections Changed

/Added

Author/s

Version

13/02

/201

9

New

Manual

All

Phil Worrell

V

1.0

Version

1.0

Status

Published

Date

1

5/07

/2019

Author/s

Phil Worrell

Build Approver

Darryn Polack

Sales Approver

Tim

Darmanin

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page iv

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

Table of Contents

1 K9000 2.0 Twin Inspection and Acceptance on Delivery: ............................................... 6

1.1 K9000 2.0 Twin System Specifications .................................................................... 7

2 Installation ...................................................................................................................... 8

2.1 Assembling the Dog Wash .....................................................................................10

2.2 Levelling and Positioning the Dog Wash ................................................................13

2.3 Connecting the Water Supply and Waste connection to the Dog Wash. .................14

2.3.1 Connecting the Water Supply ..........................................................................14

2.3.2 Adjusting the Water Pressure ..........................................................................15

2.3.3 Hot Water ........................................................................................................16

2.3.3.1 Site Supplied Hot Water ...........................................................................16

2.3.3.2 On Board Instantaneous Hot Water Unit ..................................................17

2.3.4 Connecting the Waste .....................................................................................20

2.3.4.1 Existing Sites ...........................................................................................20

2.3.4.2 New Sites .................................................................................................20

2.3.5 Back Flow Protection Device ...........................................................................21

2.4 Connecting the Power – For Your Electrician .........................................................21

2.5 Completing the Installation .....................................................................................23

3 Commissioning the Unit.................................................................................................24

4 Main Board Components ...............................................................................................25

4.1 Dog Wash Main Board with Iwaki EJ Series Pumps ...............................................25

4.1.1 Control Module ................................................................................................26

4.1.2 Product Dosing Pump Factory Settings (Iwaki EJ Series Pumps) ...................27

4.1.3 Bleeding Product Dosing Pumps (Iwaki - EJ Series Pumps) ...........................28

4.1.4 Iwaki Dosing Pump – EJ Series Exploded View ..............................................29

5 Approved Products ........................................................................................................30

6 Water Temperature .......................................................................................................31

6.1 K9000 2.0 Twin with Site Supplied Hot Water ........................................................31

6.2 K9000 2.0 Twin with On Board Hot Water Unit .......................................................32

7 Cash Box Components .................................................................................................33

7.1 Coin, Note & Credit Card Box with highlighted components ...................................33

7.2 Coin Acceptor – Coin Activation .............................................................................34

7.3 Coin Acceptor – Removal .......................................................................................36

7.4 Coin Acceptor Cleaning ..........................................................................................37

8 Note Acceptor (Mei) ......................................................................................................38

8.1 Note Acceptor Fault Codes ....................................................................................38

8.2 Note Acceptor Removal .........................................................................................39

8.3 Note Acceptor Cleaning .........................................................................................40

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page v

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

9 Note Acceptor (GBA ST1) .............................................................................................41

9.1 Cassette Fitting / Removal .....................................................................................41

9.2 Cleaning the Validator Note Path ...........................................................................42

9.3 Clearing a Note Jam...............................................................................................43

9.4 Troubleshooting .....................................................................................................44

10 Dryer ..........................................................................................................................45

10.1 By-Pass Dryer - Operation (Summer/Winter)..........................................................45

10.2 Heated Dryer - Operation (Heat Settings) ...............................................................46

10.3 Dryer Hose Connection ..........................................................................................47

11 Override Key (Wash down Key) .................................................................................48

12 Dog Wash K9000ECU Board Operating & Service Menu Programming Instructions .49

12.1 Service Menus .......................................................................................................49

12.1.1 Service Menu 1: PROGRAM MODE ...............................................................50

12.1.2 Service Menu 2: TEST ....................................................................................51

12.1.3 Service Menu 3: AUDIT ...................................................................................52

12.1.4 Service Menu 4: INFO .....................................................................................52

12.1.5 Service Menu 5: IMPORT ...............................................................................52

12.1.6 Service Menu 6: EXPORT ...............................................................................52

13 Floor Lifting Tool ........................................................................................................53

14 Operator Maintenance ...............................................................................................54

14.1 Maintenance Schedule ...........................................................................................54

14.2 External Maintenance Items ...................................................................................56

14.3 Dryer Maintenance .................................................................................................57

14.4 Cleaning .................................................................................................................58

15 General Information ...................................................................................................61

15.1 Canine parvovirus ..................................................................................................61

15.2 Instruction “How to Videos” ....................................................................................61

16 MSDS Attachments ...................................................................................................62

16.1 Material Safety Data Sheet (MSDS) Fido’s Everyday Shampoo .............................62

16.2 Material Safety Data Sheet (MSDS) Fido’s Crème Conditioner ..............................62

16.3 Material Safety Data Sheet (MSDS) Fido’s Fre-Itch Rinse Concentrate .................62

16.4 Material Safety Data Sheet (MSDS) Fido’s Hydrobath Flush ..................................62

17 Maintenance Record ..................................................................................................63

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 6

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

1

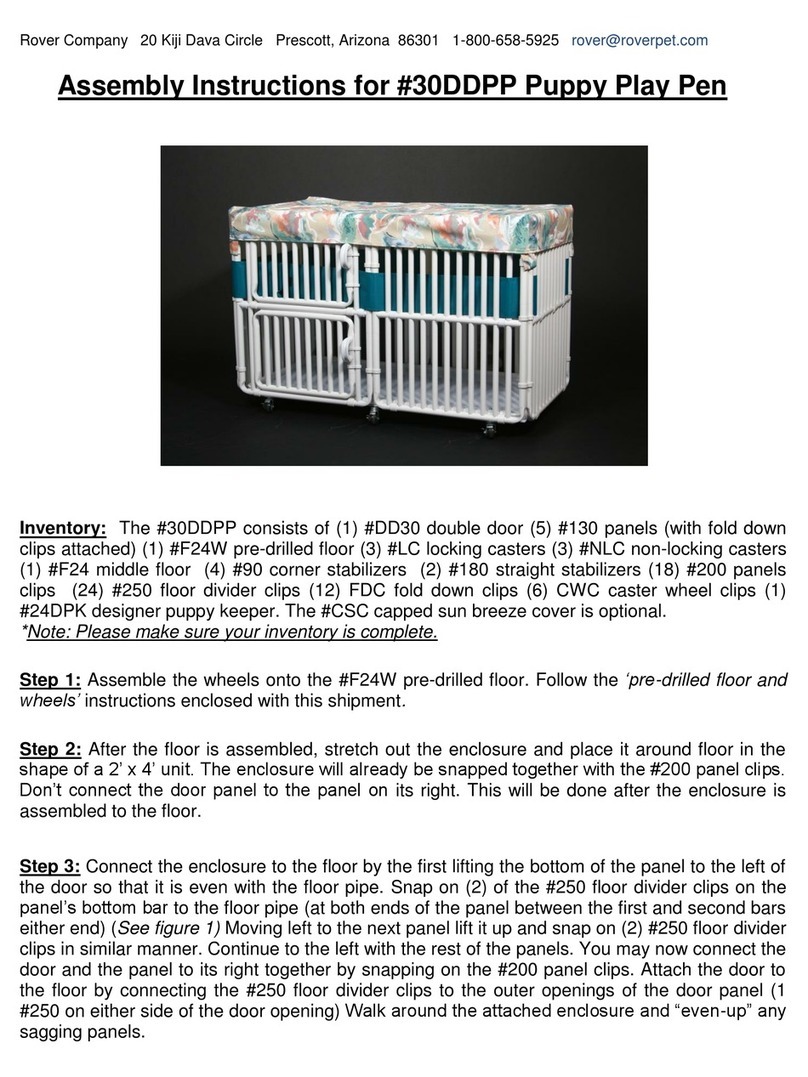

K9000 2.0 Twin Inspection and Acceptance on Delivery:

Inspect the K9000 2.0 Twin on arrival and prior to unwrapping to ensure there is no travel

damage. If there is any damage, please contact Tru Blu Dog Wash before accepting delivery.

The K9000 Twin Dog Wash is delivered in two parts with a total weight of approximately

350kg. The larger of the two parts weighs approximately 260kg and measures 2200mm in

length, 1850mm in height & 600mm in depth. The smaller of the two parts weighs

approximately 90kg and measures 1500mm in length, 1850mm in height & 600mm in depth.

Ensure a qualified operator of the unloading equipment is used to lift or move the Dog Wash.

Each of the two parts of the Dog Wash (Within Australia) are first bubble wrapped and then

wrapped in black plastic cargo wrap. They are secured to individual pallets with a tie down

strap over the cabinet and 6 screws (4 screws for the smaller part).

Position the Dog Wash while on the pallets near their final location. The larger section of the

Dog Wash goes to the left-hand side, with the highest point being the back of the Dog Wash.

Take caution removing the plastic and bubble wrap avoid using a knife as it may scratch the

stainless steel or decals. With a screw gun remove the screws from the feet and the tie down

straps.

A second inspection should be undertaken to ensure no damage has occurred during travel.

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 7

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

1.1 K9000 2.0 Twin System Specifications

SYSTEM WITHOUT ON BOARD HOT WATER UNIT

Power 240V 25 AMP

WATER Inlet Pressure (Min)

40psi / 275kpa

Hot

½

” Ball valve

Cold

½

” Ball

valve

WATER Inlet Pressure (Max)

72psi / 500kpa

Hot

½

” Ball valve

Cold

½

” Ball valve

COLD WATER Inlet temperature

Minimum

5 Degrees Celsius

Maximum

30 Degrees Celsius

HOT WATER Inlet temperature Minimum 55 Degrees Celsius

Maximum

6

5

Degrees Celsius

Factory Set water temperature

35 Degrees Celsius at wash gun

WATER Maximum Operating Pressure

50psi / 350kpa

Factory set via water regulator

FILTRATION x2 Primary Stainless steel mesh filter

Secondary

Vinidex DBA Lic. No.

WMKA20071

Back Flow Prevention Device Connections to be protected by a “high hazard” backflow prevention device. i.e.

“RPZ” or Registered “Air-GAP” Recommended Watts 009M3-AUS RP 15 or

20mm AS2845.1 Lic WMKA1335

WASTE x2 50mm DIA Outlets as well as, a minor trade waste application to be made to the

local water regulator (Contact your local water authority trade waste division)

SYSTEM WITH ON BOARD HOT WATER UNIT

Power Unit 240V 25 AMP

Power Hot Water

Stiebel Eltron DHB

-

E 27 AU

415V 40 AMP

WATER Inlet Pressure (Min)

40psi / 275kpa

Cold ¾” Ball valve

WATER Inlet Pressure (Max)

72

psi /

5

00kpa

Cold ¾” Ball valve

COLD WATER Inlet temperature

Minimum

5 Degrees Celsius

Maximum

30 Degrees Celsius

Factory Set water temperature 35 Degrees Celsius at wash gun

WATER Maximum Operating Pressure

50psi / 350kpa

Factory set via water regulator

FILTRATION x2

Primary

Stainless steel mesh filter

Secondary

Vinidex DBA Lic. No. WMKA20071

Back Flow Prevention Device Connections to be protected by a “high hazard” backflow prevention device. i.e.

“RPZ” or Registered “Air-GAP” Recommended Watts 009M3-AUS RP 15 or

20mm AS2845.1 Lic WMKA1335

WASTE x2 50mm DIA Outlet as well as, a minor trade waste application to be made to the

local water regulator (Contact your local water authority trade waste division)

DIMENSIONS / WEIGHT

Dimensions

Length

3

7

00

mm / Height 1850mm / Depth 600mm

Weight

Left Hand Side 260

kg

–

Right Hand Side 90kg (Total weight 350kg)

APPROVALS

Risk assessment performed by IAPMO (NATA accredited laboratory)

IEC 61000-6-3:2006 Electromagnetic compatibility (EMC) – Part 6.3: Generic standards – Emission standard for residential,

commercial and light

-

industrial environments

AS/NZS 60335.2.75:2005 + Admt 2009 in relation to vending machines AS 60204.1:2005 ‘Safety of machinery – Electrical

equipment of machines, General Requirements’

IEC 61000-6-1: 2005 Electromagnetic compatibility (EMC) Generic standards. Immunity for residential, commercial and light-

industrial environments

.

ATS 5200.101:2005

–

Strength of

Assembly

EPA Registered Noise tested rating of 66dba @ 4 meters

USAGES

Water usage: 16 to 20 litres per minute, where both units in operation (40

-

50 litres per single dog wash)

Average power usage per wash cycle is .76kwh (dependent on hot water sourc

e)

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 8

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

2 Installation

The K9000 2.0 Twin Dog Wash (Dog Wash) can be installed either indoor or outdoor.

Caution should be taken when the Dog Wash has been delivered and is

being unloaded. The K9000 2.0 Twin Dog Wash is delivered in two parts with a total weight

of approximately 350kg. The larger of the two parts weighs approximately 260kg and

measures 2200mm in length, 1850mm in height & 600mm in depth. The smaller of the two

parts weighs approximately 90kg and measures 1500mm in length, 1850mm in height &

600mm in depth.

Ensure a qualified operator of the unloading equipment is used to lift or move the Dog Wash.

Inspect the Dog Wash when you receive it to ensure there is no damage. If there is any

damage, please contact Tru Blu Dog Wash before accepting it.

Each of the two parts of the Dog Wash (Within Australia) are first bubble wrapped and then

wrapped in black plastic cargo wrap. They are secured to individual pallets with a tie down

strap over the cabinet and 6 screws (4 screws for the smaller part).

Position the Dog Wash while on the pallets near their final location. The larger section of the

Dog Wash goes to the left-hand side, with the highest point being the back of the Dog Wash.

Take caution removing the plastic and bubble wrap avoid using a knife as it may scratch the

stainless steel or decals. With a screw gun remove the screws from the feet and the tie down

straps.

Inside the cabinet you will find an Install Pack, open and verify the parts against the check

list. There will also be an operator’s manual, product MSDS’s and product order forms in a

purpose built sleave within the cabinet.

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 9

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

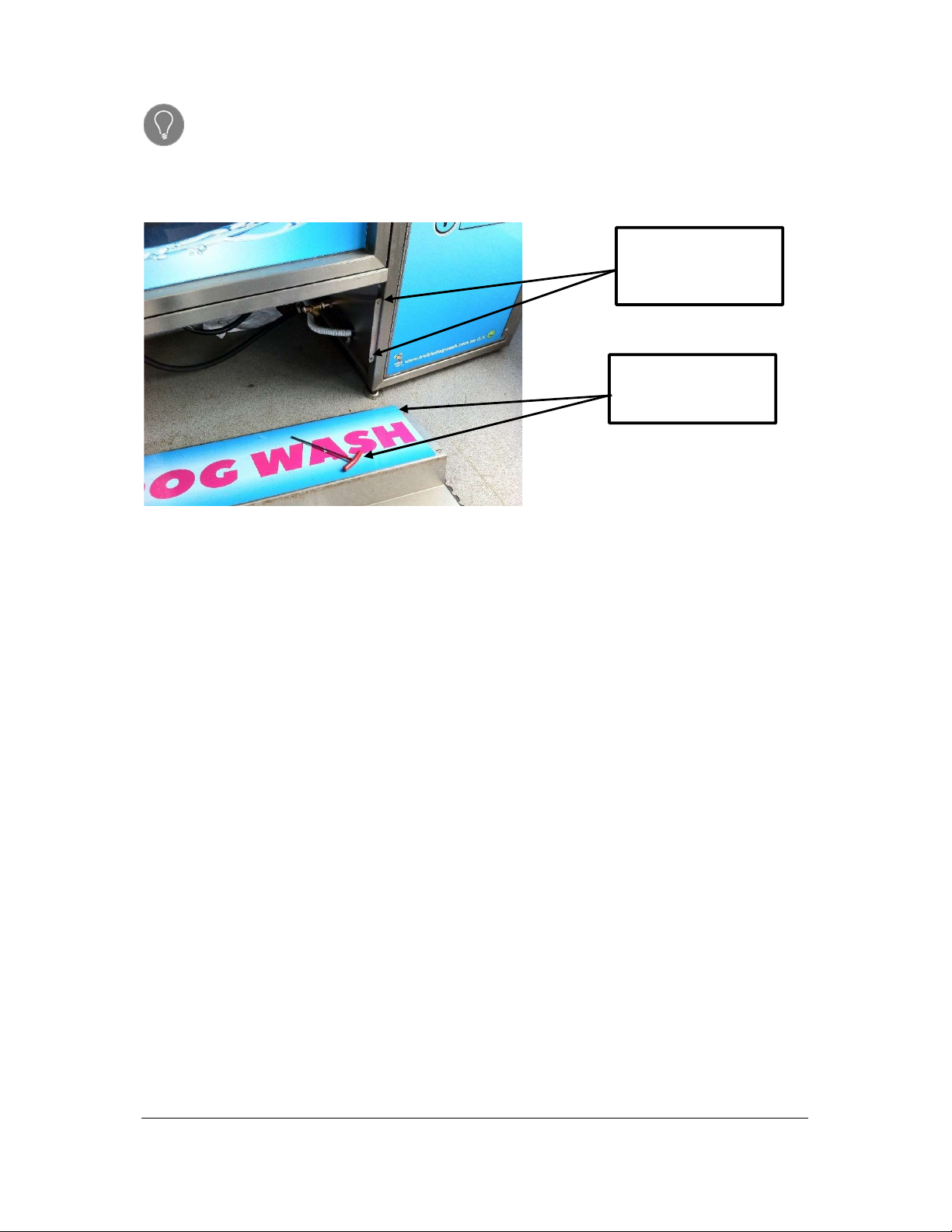

It is recommended that the front kicker plate be removed from the left-hand tub prior

to installation and handling as this will allow safer lifting and the required access during

installation. Care should be taken not to damage the plumbing fittings during lifting and

positioning of the unit.

The kicker plate for the right-hand tub can be found in the tub, it will be wrapped for

protection during travel.

It is also recommended that the white film protecting the unit is not removed until after install

as this will help prevent any installation damage.

A 4mm allen key is used

to remove the kicker

plate.

The kicker plate allen

key bolt positions (2 at

each end)

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 10

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

2.1 Assembling the Dog Wash

You need to assemble the two parts of the K9000 2.0 Twin Dog Wash using the stainless

bolts, washers, nuts and industrial grade silicone which are supplied.

Make sure the assembly occurs as near as possible to the installation point, keeping in mind

you will need to work behind the dog wash to join the 2 sections together. Assembly will be

easier if the units are on an even surface as we need to align guides into the main cabinet

from the wash tub.

Prior to removing the timber framing from the right-hand side wash tub, you will need to place

some type of chock or support to take the weight and keep the parts aligned to make for

easy assembly.

When removing the timber framing you can discard the 2 of the 3 nuts, the bolts are used as

guides passing into the main cabinet. You will notice 2 washes attached to the timber frame

with a screw these are required in assembly. Now remove the four screws (2 with washes)

from the rear of the main cabinet and set these aside as they will be used to join the two

parts.

The photo left shows the timber framing as

shipped, only the nuts are removed with one

being re-used in assembly.

The picture on the right shows the shelf that

the wash tub sits upon as well as the 4 screws

that need to be removed and then re-instated

when the tub & cabinet joined.

The picture below shows the timber framing

removed and the chock/support holding the

part in alignment.

Shelf

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 11

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

Now that we have the two parts aligned and ready for joining, we need to use the silicone

supplied to water proof the join. The silicone is run down from the top rear of the cabinet and

along the bottom out to the front (along the seams). Refer to the below photo.

Silicone

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 12

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

The 3 guide bolts from the wash tub, two at the bottom and one at the top are used to guide

the tub into place. Once in position the right-hand tub will sit on the stainless-steel ledge and

the three back plates will align with the 4 pre-drilled holes in the main cabinet (these holes

had the 4 screws removed earlier).

Of the 3 guide bolts, only the front lower bolt is used to secure the tub to the cabinet. Using

the 2 washers and 1 of the 3 nuts removed from the timber frame attach the bolt to the

cabinet. Washers and nut go inside the cabinet.

Using the four screws and 2 washers removed from the back of the cabinet use these to

attach the back of the right-hand tub to the cabinet. The two screws without washers are top

and bottom, while the washers are used in the middle join.

Using 4 of the 5 supplied coach bolts, flat washers and nylon lock nuts (1 spare) attach the

base of the wash tub to the main cabinet.

Two

bottom

guide bolts

Top guide

bolt

Location of screws

joining the tub to the

cabinet, the two centre

screws have the washers.

Front guide

bolt to have

2 washers

and nut

fixed

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 13

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

Now that the K9000 2.0 Twin Dog Wash is assembled you need to silicone the inside of the

tub where it has been attached to the cabinet.

2.2 Levelling and Positioning the Dog Wash

The Dog Wash needs to be placed in a level horizontal position to operate correctly.

There are 6 adjustable feet and 2 mounting feet, place a level along the back of the Dog

Wash and adjust the feet according to get the Dog Wash Level, place the level along the top

of the cabinet running back to front to make sure it is not tilting forward or backwards.

ENSURE all doors open and close freely before securing the Dog Wash!

Once the Dog Wash is level, use the supplied spacer washes and anchor screws to secure

the Dog Wash to the ground.

Silicone

Base of tub

with 1 of

the 4 bolts

in place

Inside of cabinet

with 1 of the 4

washer & nylon lock

nuts in place

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 14

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

2.3 Connecting the Water Supply and Waste connection to the Dog Wash.

Before connecting the Dog Wash to Water and Waste ensure local regulations are

considered. Please refer to the installation manual for more detail.

2.3.1 Connecting the Water Supply

Flush the pipes prior to connecting to the DOG WASH. Maximum allowable inlet water

pressure is 72psi (0.5mpa / 500kpa).

The picture at left shows the hot and cold-water entry points for a K9000 2.0 Twin without an

on-board hot water unit. While the picture on the right shows the water entry point for a

K9000 2.0 Twin with an on-board hot water unit.

Cold water

connection

Hot water

connection

Cold water

connection

HW unit

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 15

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

2.3.2 Adjusting the Water Pressure

Once connected the regulator can be adjusted to ensure the Dog Wash has water

pressure of 50 psi (0.35mpa / 345kpa). Ensure that the waste has been connected

prior to testing, refer section 2.3.2

The below pictures show the pressure gauge for each tub and pressure regulator for the dog

wash (both tubs). You will also see a water pressure setting sticker confirming the settings.

The pressure is increased by turning the screw clockwise or decreased by turning the screw

counter clockwise.

Increase

Decrease

Pressure

Gauges

Pressure

Regulator

Pressure

Setting

Sticker

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 16

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

2.3.3 Hot Water

Hot water can be sourced from the site or the dog wash can include an on-board hot water

service.

2.3.3.1 Site Supplied Hot Water

Shown below is a K9000 2.0 Twin that was installed at a site that supplied HOT water, and

as such the unit did not require to have an on-board hot water service.

*Please consult with Tru Blu Dog Wash to ensure your existing hot water supply is adequate.

Hot Water Cold Water

Approximately

150 to 200mm

above ground

level – needs

to fit below

bottom of dog

wash

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 17

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

2.3.3.2 On Board Instantaneous Hot Water Unit

Below left is a photo of the water fittings for the hot water unit leading in and out of the

service. The picture on the right is the actual Stiebel Eltron DHB-E 27 AU hot water unit

which is fitted inside the dog wash cabinet, bottom left.

2.3.3.2.1 Initial Start Up of the Stiebel Eltron DHB-E 27 AU Hot Water Unit

The initial start-up of the Stiebel Eltron should be conducted by an electrician referencing the

Stiebel AU Operation and Installation guide.

The below is an extract showing how to activate the safety pressure limiter for flow pressure

using the reset button. For detailed instructions refer to the Stiebel Eltron AU Operation and

Installation guide.

Power is to be turned off

Turn water on

Hot Water

Temperature

Knob

Water

from

mains

Hot

water

out of

HW

Unit

Hot water from

HW unit to dog

wash

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 18

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

Take the front cover of the Stiebel Eltron to expose the

reset button.

Pictured left is the Stiebel Eltron with the cover removed.

The close up below is highlighted to assist locating the

reset button.

The below is a close up of the reset button.

Activate the safety pressure limiter

for flow pressure by firmly pressing

in the reset button (the appliance is

delivered with the safety pressure

limiter disabled).

Picture left shows the reset button

being pressed down using a small

screw driver

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 19

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

Re-Fit the Stiebel Eltron cover and secure with supplied screw.

Power can now be turned on.

For detailed instructions refer to the Stiebel Eltron AU Operation and Installation guide

supplied with the K9000 dog wash.

Push the temperature selector plug

into the "set temperature" PCB.

The plug is already attached to the

cover it needs to be “plugged” into the

base.

Picture left shows the reset button

being pressed down using a small

screw driver

Z:\Build\K9000 2.0 Twin\K9000 2.0 Twin Operators Manual July 2019 v1.0.docx Page 20

Last edited 16/11/2016

© Tru Blu Dog Wash 2016

2.3.4 Connecting the Waste

2.3.4.1 Existing Sites

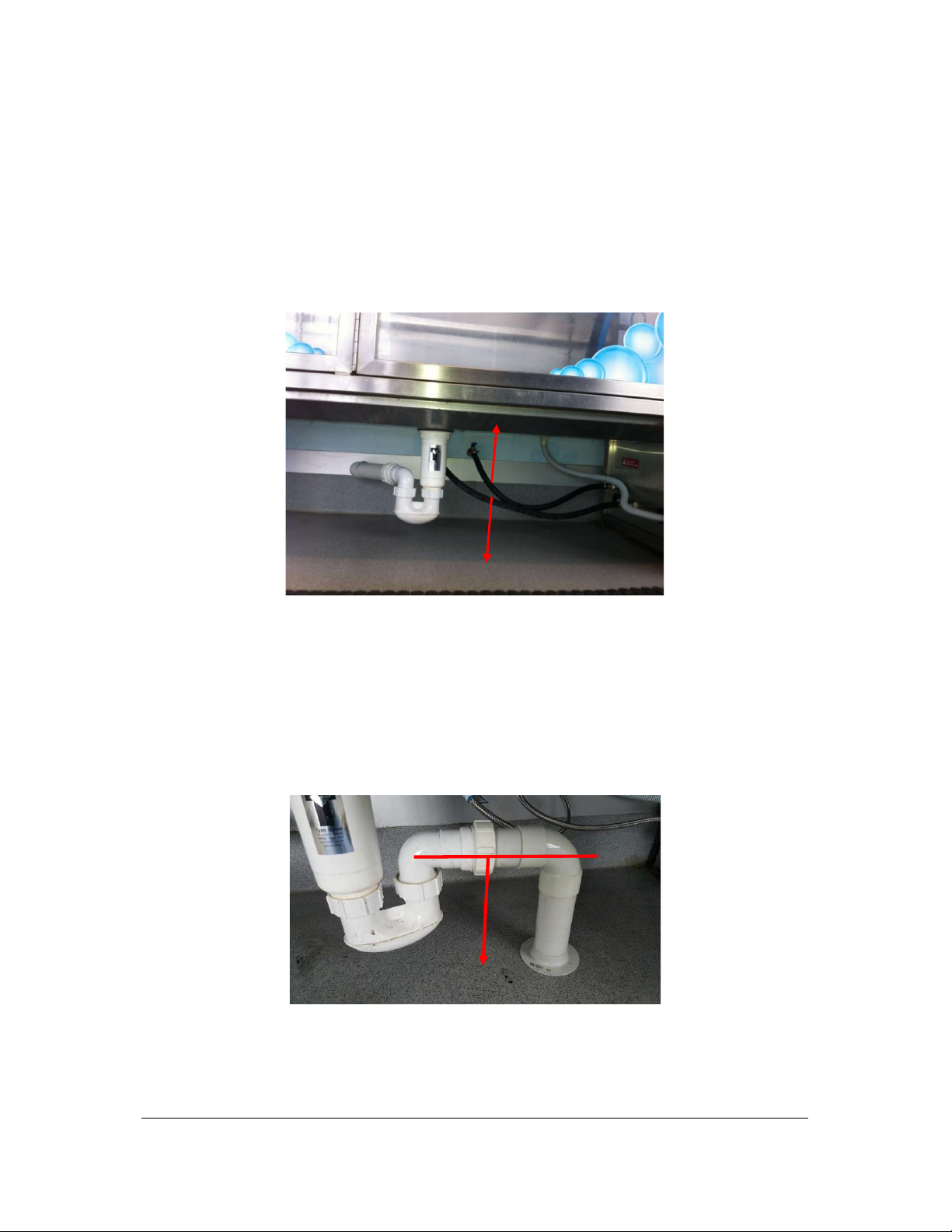

Shown below is a K9000 2.0 Twin that has been installed into an existing room. The two

50mm connection points were run through the back wall to an existing waste point (Note:

only 1 of the 2 waste points shown in photo). Other possibilities are to run the two 50mm

connection points along the walls to an existing waste point/s.

The connections are made to the 50mm waste using the two P-traps supplied in the install

kit.

2.3.4.2 New Sites

Shown below is a K9000 2.0 Twin that has been installed at a new site were the site has

allowed for the waste points as part of construction (Note: only 1 of the 2 waste points shown

in photo). Note, new sites may also utilise external waste points, and run the connections

through or along the walls.

The connections are made to the 50mm waste using the two P-traps supplied in the install

kit.

The approximate

measure for a Dog

Wash is 230mm

(pipe centre) on a

level ground service.

370mm

Other manuals for K9000 2.0

2

This manual suits for next models

1

Table of contents

Other TRU-BLU Pet Care Product manuals