TRU-BLU K9000 Mini User manual

i

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

K9000 Mini

Operators Manual

© Copyright 2016, Tru Blu Dog Wash, All rights reserved. K9000® is a registered trademark

of Tru Blu Dog Wash.

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx Page ii

© Tru Blu Dog Wash 2016

© Copyright 2016, Tru Blu Dog Wash, All rights reserved. K9000® is a registered trademark

of Tru Blu Dog Wash.

All requests and enquiries regarding the use of, and availability of this manual are to be

directed to:

Tru Blu Dog Wash

Factory No. 1

34 Caramut Road

Warrnambool

Victoria 3280

Australia

Tel: +61 (0)3 5562 9088

Fax: +61 (0)3 5562 9022

Email: [email protected]m.au

Website: www.trubludogwash.com.au

www.findadogwash.com

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx Page iii

© Tru Blu Dog Wash 2016

Explanation of symbols used in this manual

Warning

Tip

Important - Take note

Regulatory Compliance Mark

Date

Summary of Changes

Sections Changed/Added

Author/s

Version

14/08/2017

1

st

Edition

All as new model

Phil Worrell

V

1.0

13/12/2018

New EJ pump exploded view 4.1.4 Phil Worrell V2.0

08/04/2019

New How to videos added

11.2

Phil Worrell

22/05/2019 How to open coin mech &

added error codes

5.1.4, 5.1.5 & 5.1.6 Phil Worrell V3.0

Version

3.0

Status

Published

Date

27

/05/2019

Author/s

Phil Worrell

Build Approver

Tim Darmanin

Sales Approver

Sarah Clausen

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx Page iv

© Tru Blu Dog Wash 2016

Table of Contents

1 K9000 Mini Inspection and Acceptance on Delivery: ...................................................... 1

1.1 K9000 Mini System Specifications ........................................................................... 2

2 Installation ...................................................................................................................... 3

2.1 Levelling and Positioning the K9000 Mini ................................................................ 3

2.2 Connecting the Water Supply and Waste connection to the K9000 Mini. ................. 4

2.2.1 Connecting the Water Supply ........................................................................... 4

2.2.2 Hot Water Breaker ........................................................................................... 5

2.2.3 Connecting the Waste ...................................................................................... 6

2.3 Connecting the Power – For Your Electrician .......................................................... 7

2.4 Completing the Installation ...................................................................................... 8

3 Commissioning the Unit.................................................................................................. 8

4 Main Board Components ................................................................................................ 9

4.1 K9000 Mini Main Board with Iwaki EJ Series Pumps ............................................... 9

4.1.1 Control Module ................................................................................................10

4.1.2 Product Dosing Pump Factory Settings (Iwaki EJ Series Pumps) ...................11

4.1.3 Bleeding Product Dosing Pumps (Iwaki - EJ Series Pumps) ...........................12

4.1.4 Iwaki Dosing Pump – EJ Series Exploded View ..............................................13

4.2 Approved Products .................................................................................................14

5 Cash Box Components .................................................................................................15

5.1 SP Coin Acceptor ...................................................................................................16

5.1.1 SP On Board Programming (OBP) Instructions ...............................................17

5.1.2 Coin Acceptor Removal ...................................................................................19

5.1.3 Coin Acceptor Cleaning ...................................................................................19

5.1.4 Coin Acceptor Error Messages ........................................................................20

5.1.4.1 Coin Acceptor Error Message Table.........................................................20

5.1.4.2 Coin Acceptor Error Processes ................................................................21

6 Temperature Valve ........................................................................................................23

6.1 Temperature Adjustment ........................................................................................23

7 Dryer .............................................................................................................................24

7.1 Non-Heated Dryer Details ......................................................................................24

8 Override Key (Wash down Key) ....................................................................................25

9 Floor Lifting Tool ...........................................................................................................26

10 Operator Maintenance ...............................................................................................27

10.1 Maintenance Schedule ...........................................................................................27

10.2 External Maintenance Items ...................................................................................29

10.3 Rotary Dial Maintenance ........................................................................................29

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx Page v

© Tru Blu Dog Wash 2016

10.4 Dryer Maintenance .................................................................................................30

10.5 Cleaning .................................................................................................................31

11 General Information ...................................................................................................34

11.1 Canine parvovirus ..................................................................................................34

11.2 Instruction “How to” Videos ....................................................................................34

12 MSDS Attachments ...................................................................................................35

12.1 Material Safety Data Sheet (MSDS) Fido’s Everyday Shampoo .............................35

12.2 Material Safety Data Sheet (MSDS) Fido’s Crème Conditioner ..............................35

12.3 Material Safety Data Sheet (MSDS) Fido’s Fre-Itch Rinse Concentrate .................35

12.4 Material Safety Data Sheet (MSDS) Fido’s Hydrobath Flush ..................................35

13 Maintenance Record ..................................................................................................36

1

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

1

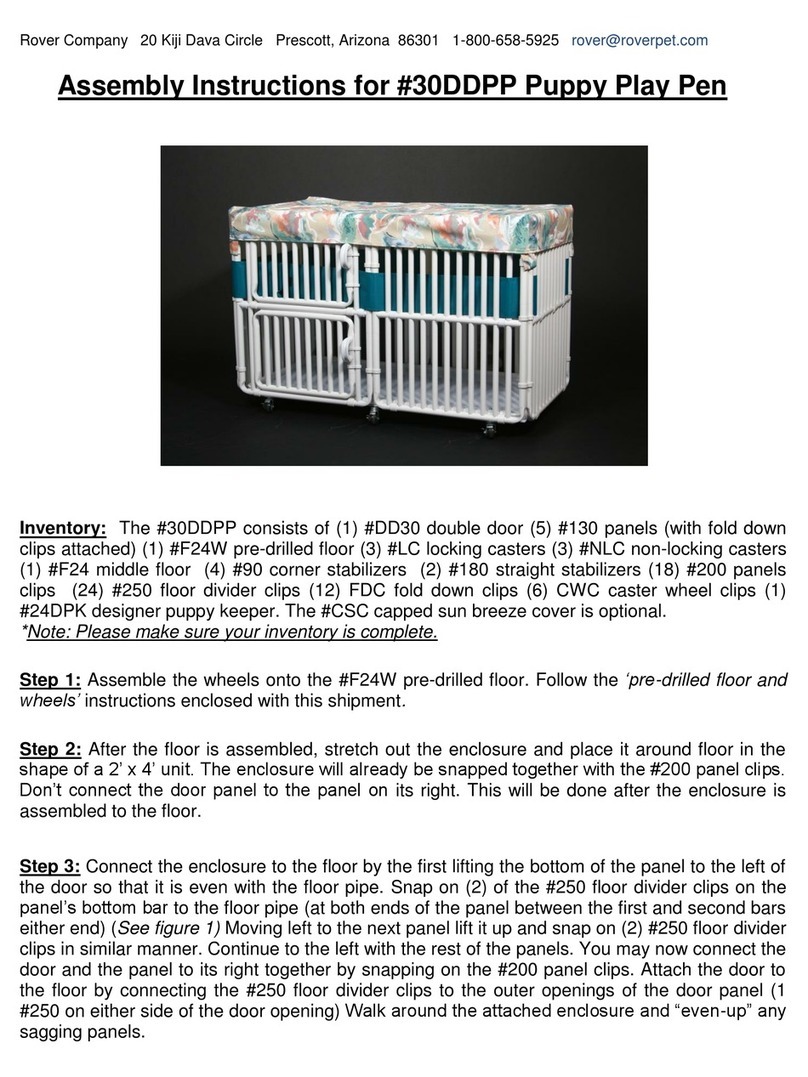

K9000 Mini Inspection and Acceptance on Delivery:

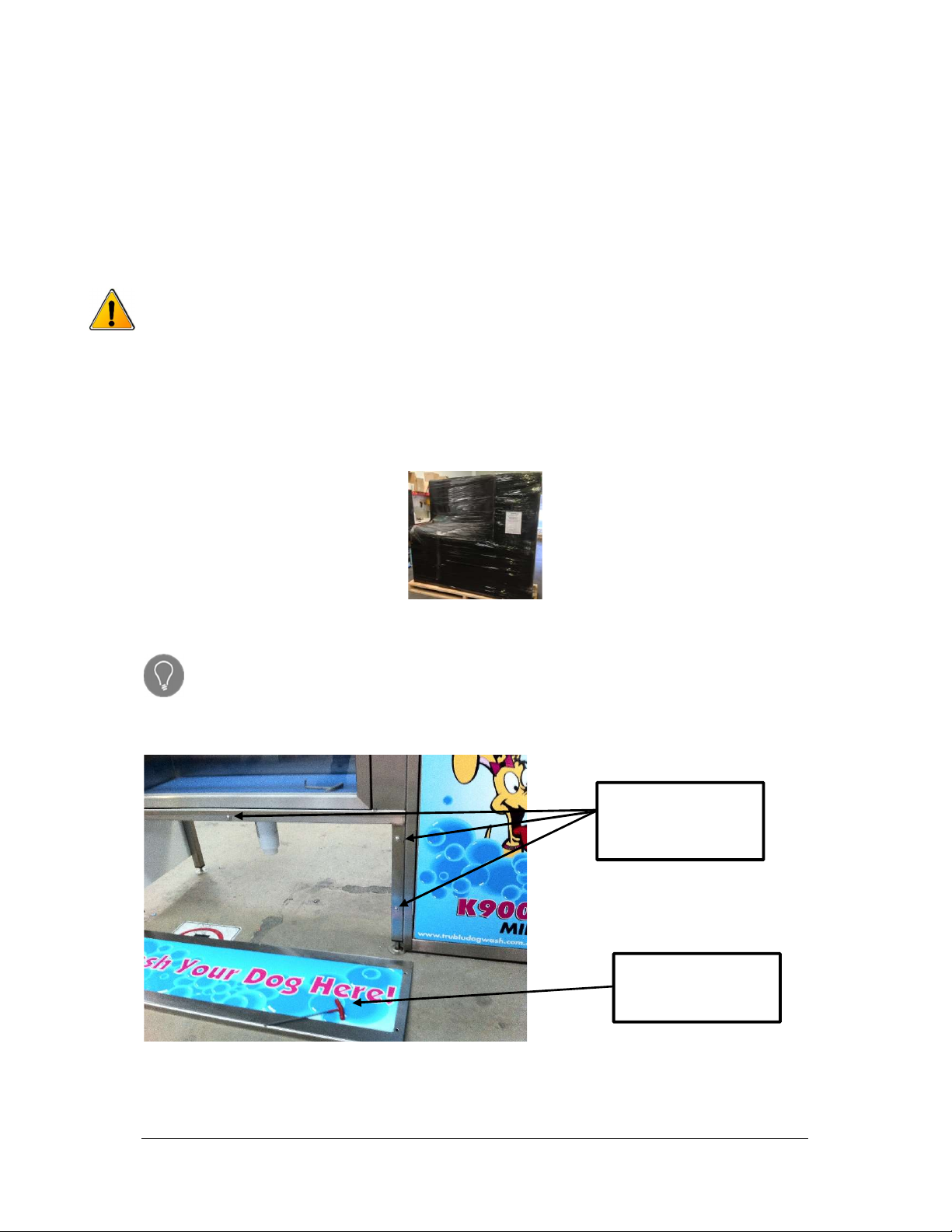

Inspect the K9000 Mini Dog Wash (K9000 Mini) on arrival and prior to unwrapping to ensure

there is no travel damage. If there is any damage, please contact Tru Blu Dog Wash before

accepting delivery.

Caution should be taken when the K9000 Mini has been delivered and is

being unloaded. The K9000 Mini weighs approx. 170kg. Ensure a qualified operator of the

unloading equipment is used to lift or move the K9000 Mini Dog Wash.

The K9000 Mini (Within Australia) is first bubble wrapped and then wrapped in black plastic

cargo wrap. It is secured to the pallet with a tie down strap over the cabinet and 6 screws.

Position the K9000 Mini while on the pallet near its final location. Take caution removing the

plastic and bubble wrap avoid using a knife as it may scratch the stainless steel or decals.

With a screw gun remove the screws from the feet and the tie down strap.

A second inspection should be undertaken to ensure no damage has occurred during travel.

It is recommended that the front kicker plate be removed prior to installation and

handling as this will allow safer lifting and the required access during installation. Care

should be taken not to damage the plumbing fittings during lifting and positioning of the unit.

It is also recommended that the white film protecting the unit is not removed until after install

as this will help prevent any installation damage.

A 4mm allen key is used

to remove the kicker

plate.

The kicker plate allen

key bolt positions (2 at

each end and 1 top

centre)

2

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

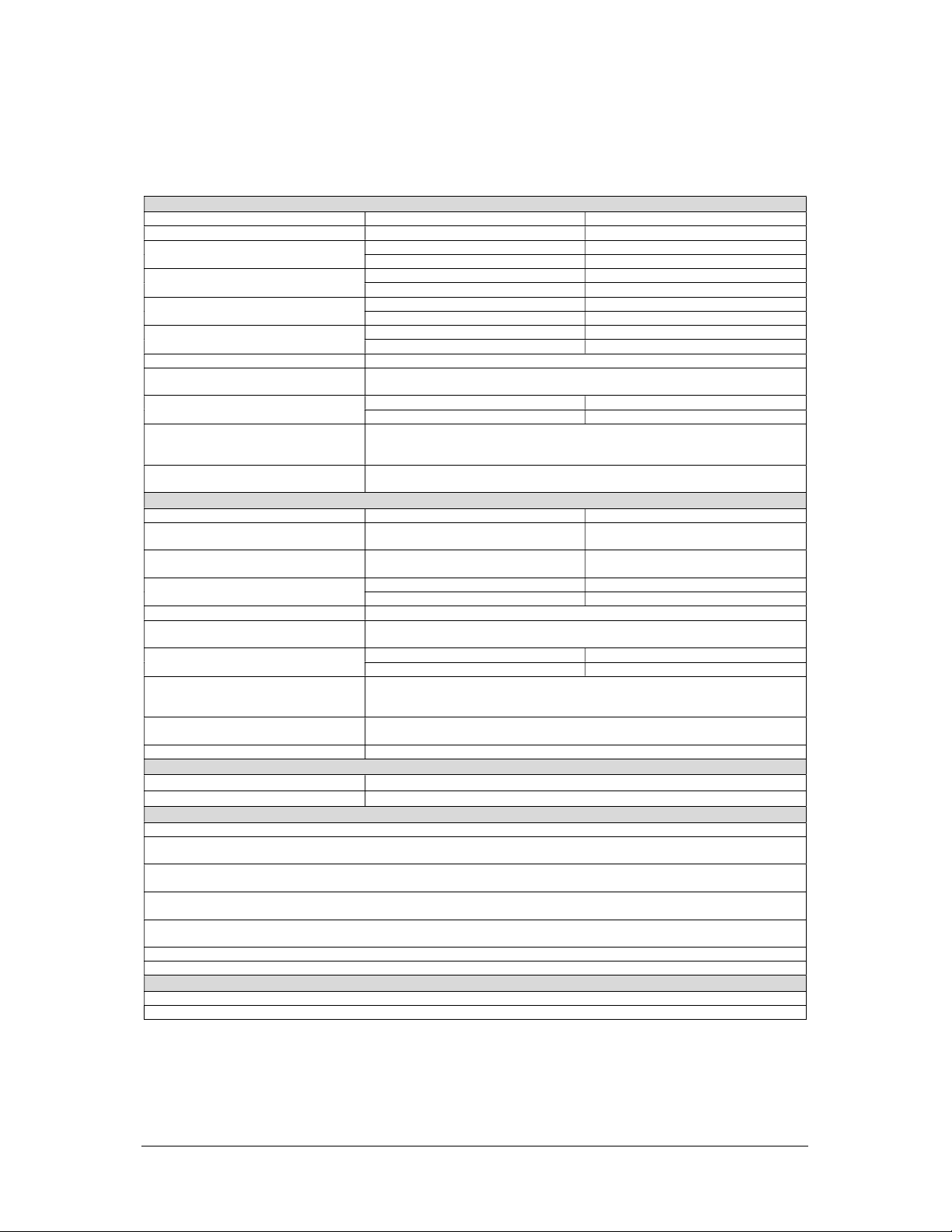

1.1 K9000 Mini System Specifications

SYSTEM WITHOUT ON BOARD HOT WATER UNIT

Power

240V

15 AMP (with heated dryer)

Power

240V

10 AMP (without heated dryer)

WATER Inlet Pressure (Min)

40psi / 275kpa

Hot

½” Ball valve

Cold

½” Ball valve

WATER Inlet Pressure (Max)

72psi / 500kpa

Hot

½” Ball valve

Cold ½” Ball valve

COLD WATER Inlet temperature

Minimum

5 Degrees Celsius

Maximum

30 Degrees Celsius

HOT WATER Inlet temperature

Minimum

55 Degrees Celsius

Maximum

6

5 Degrees Celsius

Factory Set water temperature

35 Degrees Celsius at wash gun

WATER Maximum Operating Pressure

50psi / 350kpa

Factory set via water regulator

FILTRATION

Primary

Stainless steel mesh

filter

Secondary

Vinidex DBA Lic. No. WMKA20071

Back Flow Prevention Device Connections to be protected by a “high hazard” backflow prevention device. i.e.

“RPZ” or Registered “Air-GAP” Recommended Watts 009M3-AUS RP 15 or

20mm AS2845.1 Lic

WMKA1335

WASTE 50mm DIA Outlet as well as, a minor trade waste application to be made to the

local water regulator (Contact your local water authority trade waste division)

SYSTEM WITH ON BOARD HOT WATER UNIT

Power

240V

25

AMP

WATER Inlet Pressure (Min)

40psi / 275kpa

Cold ½” Ball valve

WATER Inlet Pressure (Max)

72

psi /

5

00kpa

Cold ½” Ball valve

COLD WATER Inlet temperature Minimum 5 Degrees Celsius

Maximum

30 Degrees Celsius

Factory Set water temperature

35

Degrees Celsius at wash gun

WATER Maximum Operating Pressure

50psi / 350kpa

Factory set via water regulator

FILTRATION Primary Stainless steel mesh filter

Secondary

Vinidex DBA Lic. No. WMKA20071

Back Flow Prevention Device Connections to be protected by a “high hazard” backflow prevention device. i.e.

“RPZ” or Registered “Air-GAP” Recommended Watts 009M3-AUS RP 15 or

20mm AS2845.1 Lic WMKA1335

WASTE 50mm DIA Outlet as well as, a minor trade waste application to be made to the

local water reg

ulator (Contact your local water authority trade waste division)

Tundish

Required for hot water relief pipe

DIMENSIONS / WEIGHT

Dimensions Length 1650mm / Height 1750mm / Depth 550mm

Weight

K9000

Mini

-

170

kg

APPROVALS

Risk assessment

performed by IAPMO (NATA accredited laboratory)

CE conformity with the following European Union Directives: EMC Directive 2004/108/EC & Low Voltage Directive

2006/95/EC

IEC 61000-6-3:2006 Electromagnetic compatibility (EMC) – Part 6.3: Generic standards – Emission standard for residential,

commercial and light

-

industrial environments

AS/NZS 60335.2.75:2005 + Admt 2009 in relation to vending machines AS 60204.1:2005 ‘Safety of machinery – Electrical

equipment of machines, General Requirements’

IEC 61000-6-1: 2005 Electromagnetic compatibility (EMC) Generic standards. Immunity for residential, commercial and light-

industrial environments

.

ATS 5200.101:2005

–

Strength of Assembly

EPA Registered Noise tested rating of 66dba @ 4 meters

USAGES

Water

usage: 8 to 12 litres per minute (40

-

60 litres per single dog wash)

Average power usage per wash cycle is .76kwh (dependent on hot water source)

3

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

2 Installation

The K9000 Mini Dog Wash can be installed either indoor or outdoor.

2.1 Levelling and Positioning the K9000 Mini

The K9000 Mini needs to be placed in a level horizontal position to operate correctly.

There are 8 adjustable feet, place a level along the back of the K9000 Mini and adjust the

feet according to get the K9000 Mini Level, place the level along the top of the cabinet

running back to front to make sure it is not tilting forward or backwards.

There are 2 different types of adjustable feet, four* exposed that are adjusted by hand

turning the actual feet and four* inside the cabinet floor that have rubber grommet covers,

you will need to remove the rubber grommets and adjust these with a large flat head screw

driver.

*Note: depending on the model the number of adjustable feet numbers will vary. It will be

either 4 hand adjusted with 2 requiring a screw driver or 2 hand adjusted with 4 requiring a

screw driver.

ENSURE all doors open and close freely before securing the K9000 Mini!

Once the K9000 Mini is level, use the anchor screws supplied to bolt the K9000 Mini to the

floor/surface.

The picture left shows the

location and how to adjust the

feet within the cabinet.

Note: The hot water unit will

need to be moved forward to

allow access to the internal

feet adjusted with the large

flat head screw driver. It does

not need to be removed.

4

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

2.2 Connecting the Water Supply and Waste connection to the K9000 Mini.

Before connecting the K9000 Mini to water and waste ensure local regulations are

considered. Some sites may require an additional back flow prevention device. Local

regulations may also require sites to use copper pipes for waste.

2.2.1 Connecting the Water Supply

Flush the pipes prior to connecting to the K9000 Mini.

Maximum allowable inlet water pressure is 450kpa. (72 Psi / 0.5 Mpa)

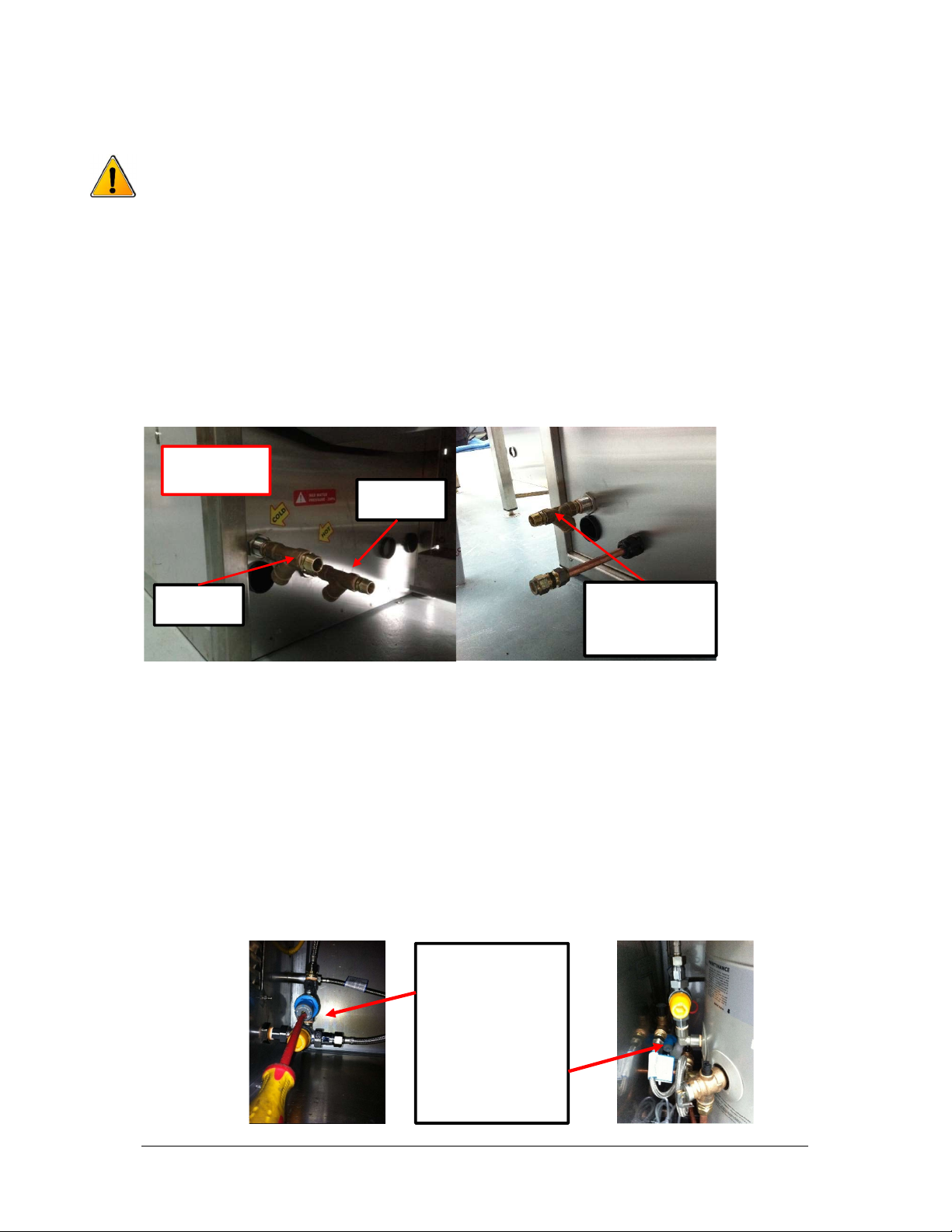

The picture at left shows the hot and cold-water entry points for a K9000 Mini without an on-

board hot water unit. While the picture on the right shows the water entry point for a K9000

Mini with an on-board hot water unit.

Once connected the regulator can be adjusted to ensure the K9000 Mini has water pressure

of between 20 & 30 psi when the pressure gun is in use and between 40 & 50 psi when

pressure gun is not being utilised.

To verify the pressure when the gun is not being utilised you need to view the gauge at the

moment the pressure gun is turned off as it will give a true indication of the psi prior to

resetting to the hold psi of approximately 40.

The psi verification can be done with the override key and a wash setting of stop or

with money/token and the rinse setting selected.

If adjustment required, you will need adjust the regulator. The regulator is adjusted using a

screw driver, where pressure needs to be increased turn the screw anticlockwise and to

decrease pressure turn in a clockwise direction.

Cold water

connection

Cold water

connection

Hot water system

on board

Hot water

connection

Site Supplied

Hot Water

The picture left shows

regulator being

adjusted in a mini with

no hot water system

on board.

The picture right

shows the regulator

position in a mini with

a hot water system on

board.

5

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

2.2.2 Hot Water Breaker

After the water is connected the hot water tap is to be turned on and the hot water system

filled and bled.

Once the hot water system is filled the hot water circuit breaker located in the control

box is to be turned on. The power must be isolated prior to removing the cover from

the Control Module refer to section 4 Main Board Components.

Hot water tap to be

turned on

Bleeding the hot water

system by pulling the

pressure valve until

water runs. (Top valve

only)

6

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

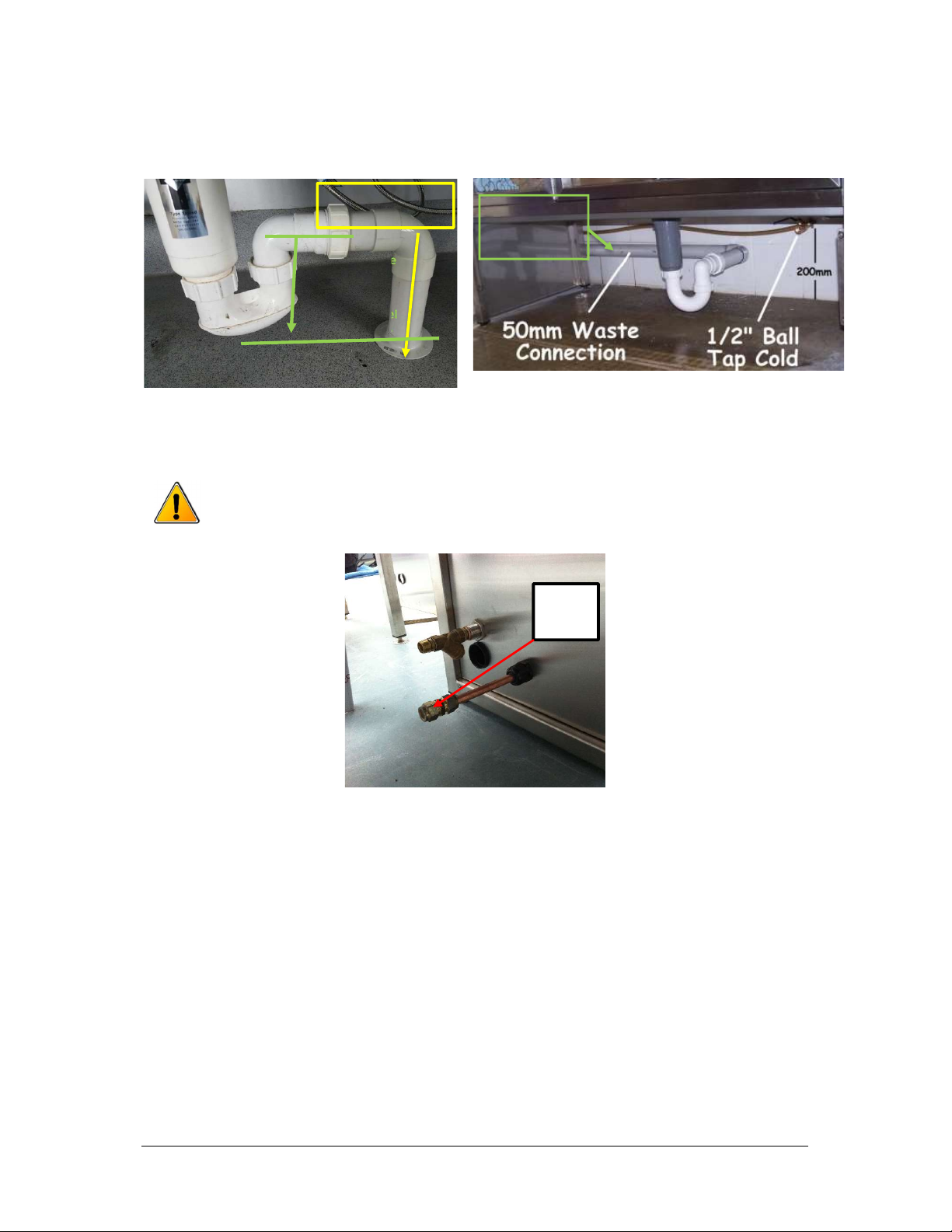

2.2.3 Connecting the Waste

Connect the 50mm waste using the P-trap (supplied in the install kit)

The copper waste pipe connected to the hot water unit relief valves needs to be run into a

waste point or tundish (not supplied). The same waste point as the P-trap can be utilised.

Before connecting to the waste point or tundish ensure local regulations are

considered as some sites may require copper pipe.

If unsure with any of the above steps please phone (03) 5562 9088 for assistance.

The approximate

measure for a

K9000 Mini is

300mm (pipe

centre) on a level

ground service.

Waste

plumbed away

to waste point

Waste

point

Waste plumbed

directly into ground

7

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

2.3 Connecting the Power – For Your Electrician

Shown on the right is the main electrical

cable inside the dog wash. It enters

through the gland at the bottom of the

dog wash close to the ground.

Run the power cable in 20mm flexible

conduit as there is a socket already

installed into the bottom of the main

circuit breaker box shown.

Shown below is a photo taken from the

rear of the dog wash of the main

electrical cable enter point to the dog

wash cabinet.

Once you run the cable and conduit to

this point, and then leave another

800mm for the termination inside the dog

wash.

Term

inate Here

800mm

20mm Flex

Conduit

Electrical Cable Entry

Point of Dog Wash

20mm Flex

Conduit

Expansion Valve

outlet if hot water

system on board

OR

Site Hot Water Inlet

Cold Water

Inlet

8

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

2.4 Completing the Installation

Now that the K9000 Mini has been installed you can now refit the front kicker plate removed

earlier to allow the installation to proceed and peel the protective white film from the unit.

You are now ready to commission the K9000 Mini.

Please ensure that the hot water breaker has been turned on refer section 2.2.2.

3 Commissioning the Unit

The K9000 Mini is delivered with sufficient product for approximately 100 washes and it is

recommended that commissioning the unit occurs after installation.

Commissioning the unit requires the following tests to be undertaken;

Override key wash (refer section 8)

Insert Coins

Insert Notes (if applicable)

Insert Tokens (if applicable)

During the tests check the following;

water pressure gauge: when pressure gun is being utilised the pressure range should

be between 20 & 30 psi and when gun is off the psi should be in the range 40 to 50

psi. Refer section 2.2.1 re regulation of water pressure.

water temperature, should be cool at a 40cm distance from the wash gun, refer

section 6.1 for water temperature adjustment.

9

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

4 Main Board Components

4.1 K9000 Mini Main Board with Iwaki EJ Series Pumps

Product

Injectors x

2

Product Dosing Pumps

(Iwaki) EJ Series x 2

Dryer Unit

Pressure

Switch

Rinse Solenoid

Control Module

Pressure Gauge

Product Dosing

Pumps (Iwaki) EJ

CE Isolator Switch

Hot water breaker is left in the off position

from Factory. Ensure hot water system has been filled

with water before switching on.

Circuit Breakers

Located Behind this

cover

10

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

4.1.1 Control Module

The Control Module contains the fuses, transformer, relays etc.

The cover from the Control Module should never be removed unless the power is

disconnected.

The below picture has the main components of the Control Module labelled. It should be

noted that there is a red LED light on each of the 3 fuses and if this is lit then the fuse has

blown.

11

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

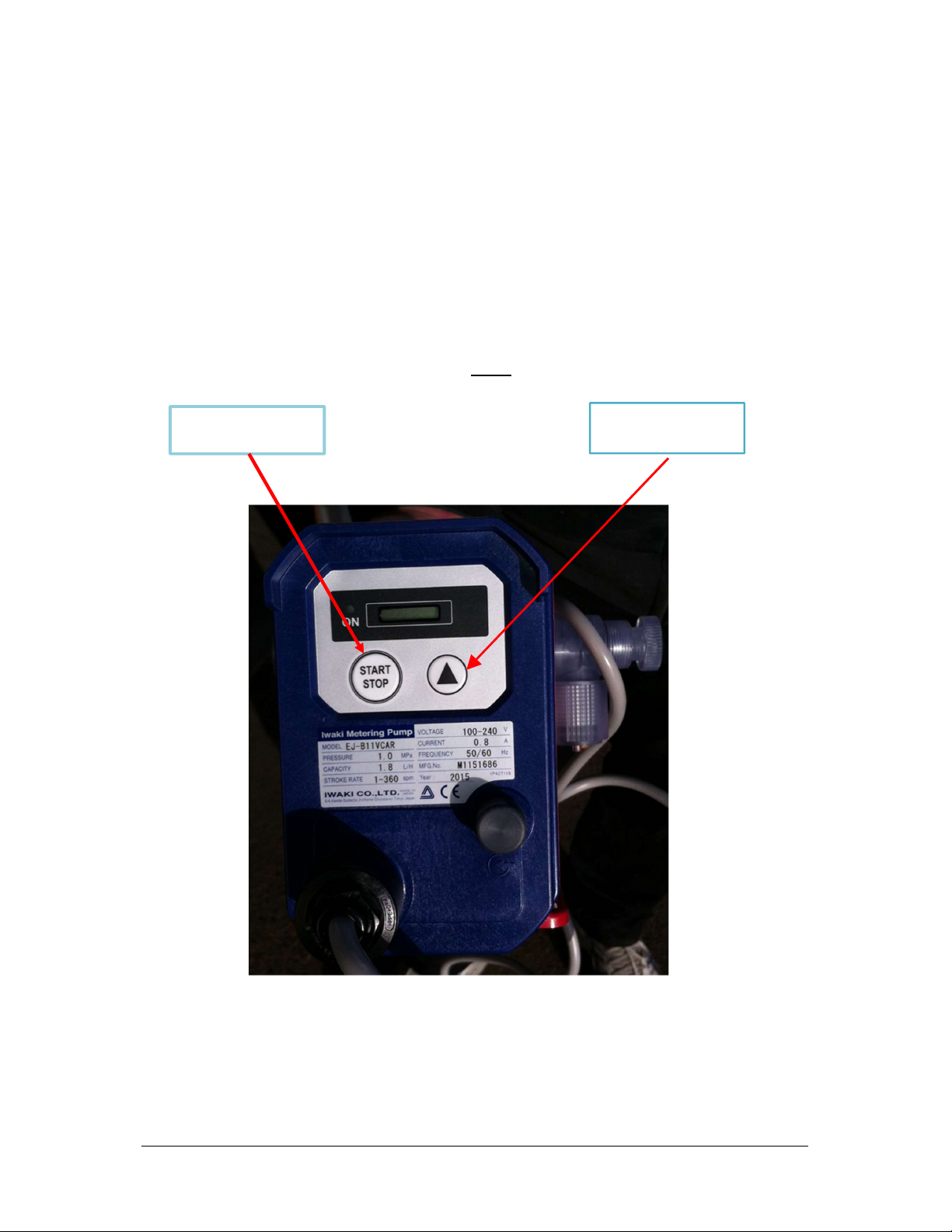

4.1.2 Product Dosing Pump Factory Settings (Iwaki EJ Series Pumps)

Settings are guidelines/recommendations for Fido’s or other approved high-quality

concentrated products:

Shampoo: 200 SPM*

Condition rinse: 180 SPM*

*Note: Strokes Per Minute

To adjust settings, depress the up arrow* to the recommended SPM rate, as detailed above.

*Note: The pump must be in operation when making an adjustment. The arrow will only increase the

SPM, so to reduce the rate you must fully increase the rate to 360, release the Stroke Rate button and

repress it. This will reset the SPM to 1, you can then increase to the required SPM rate. Once the

required rate is reached press the start/stop button twice to save the required rate.

‘Stroke Rate’

Button

‘Start / Stop’

Button

12

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

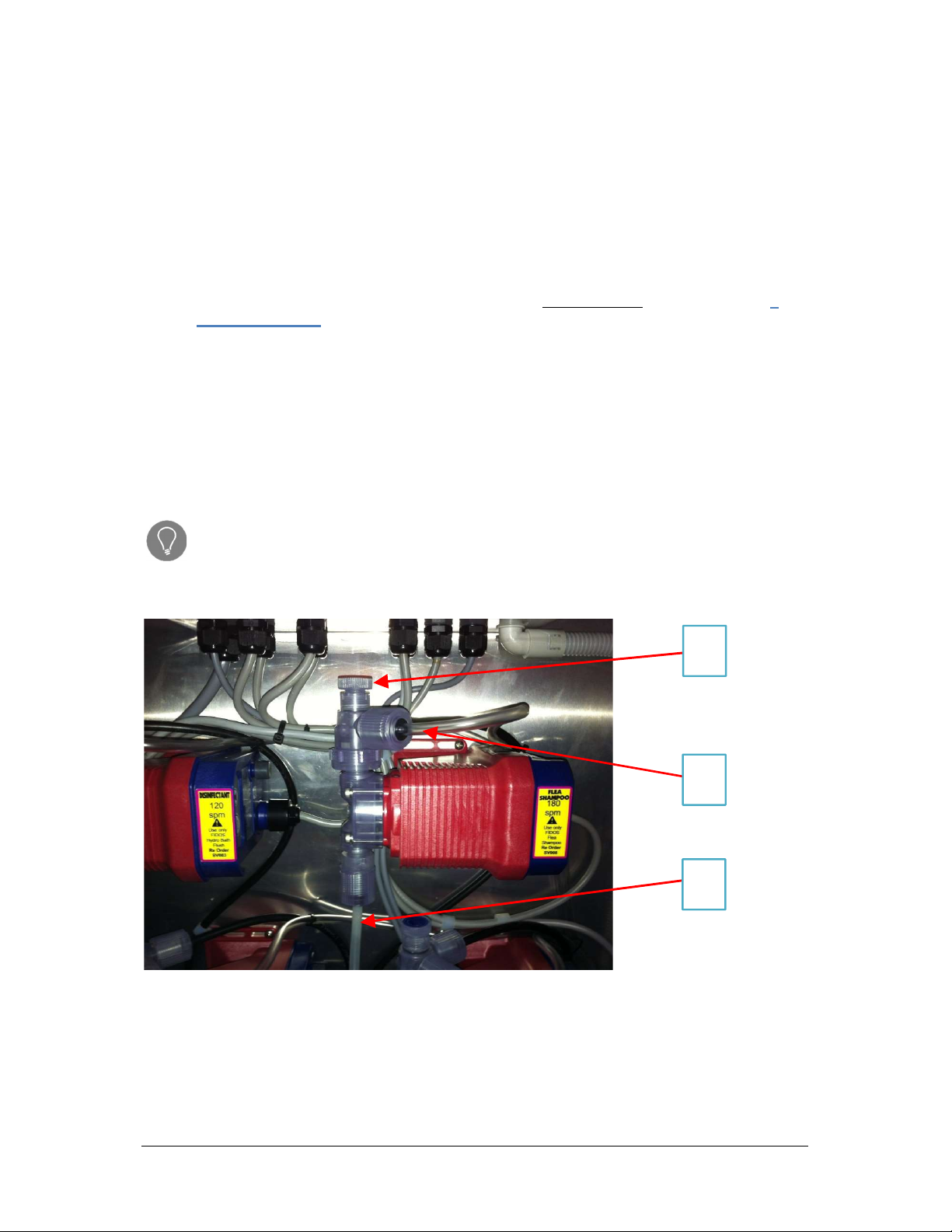

4.1.3 Bleeding Product Dosing Pumps (Iwaki - EJ Series Pumps)

The need to bleed product dosing pump will arise when products have run out or in some

case when products have been replaced and air has become trapped in the tube.

Bleeding procedure:

1. Select the product you wish to bleed by turning the rotary switch e.g.: shampoo

2. Release bleeder valve (item A below) by turning anti-clockwise as shown below; 3

turns maximum.

3. Once product reaches the clear waste tube (item B below) re-tighten the bleeder

valve by turning clock-wise;

4. After process is complete visually inspect the suction line for air pockets-if air pockets

are present repeat process.

NOTE: After pump has been bled, there will be a distinctive change in the sound of the pump

(pump will sound quieter).

If there are problems bleeding heavier concentrates rattle the suction line (item C

below), and/or squeeze it to assist with shifting the product up into the pump head.

A

B

C

13

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

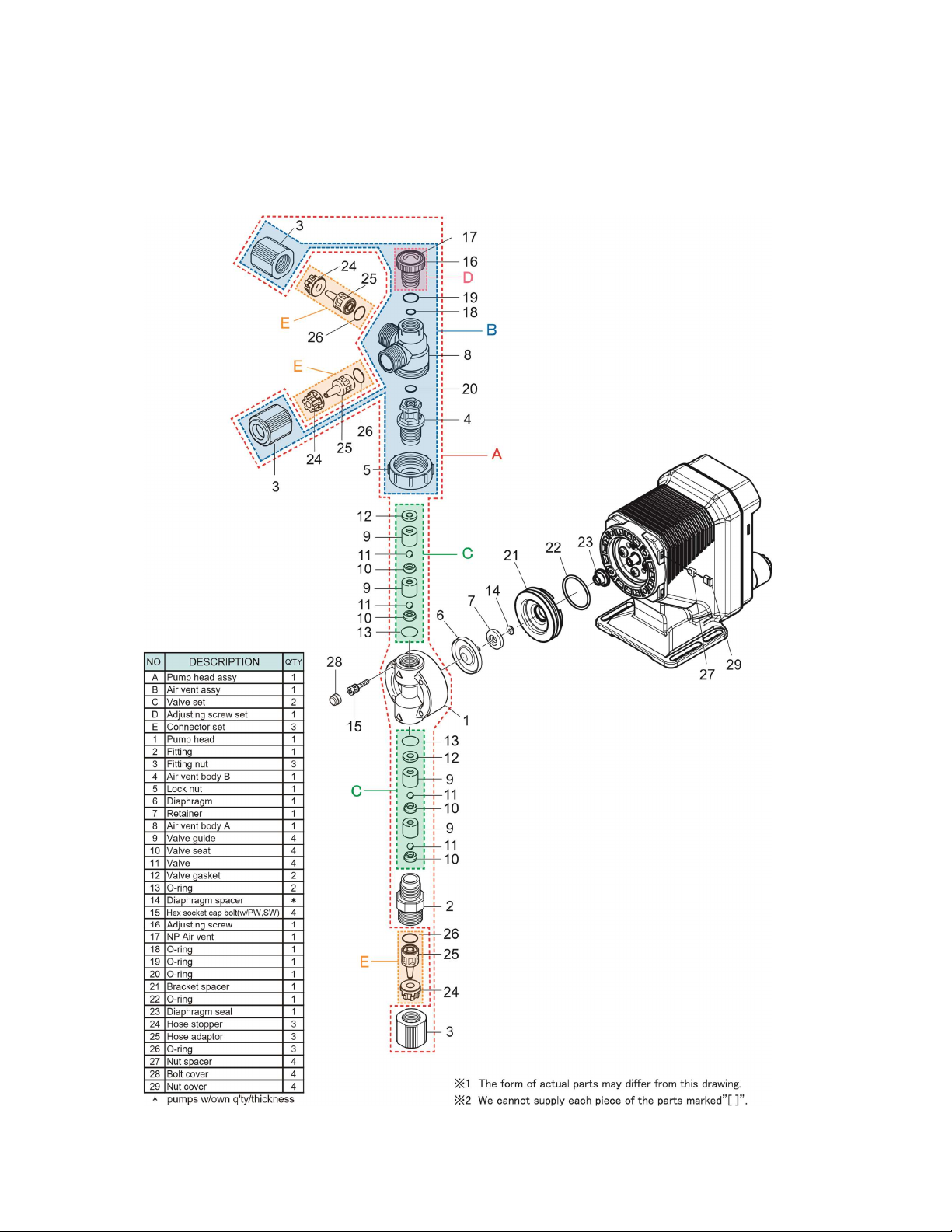

4.1.4 Iwaki Dosing Pump – EJ Series Exploded View

The pump in the diagram below is completely dismantled. Do not dismantle the pump

beyond the extent shown in this instruction manual.

14

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

4.2 Approved Products

The Australian Pesticides and Veterinary Medicines Authority (APVMA) contact details

are:

Office: 18 Wormald Street, Symonston, ACT, 2609, Australia

Office hours: 9.00am - 5.00pm Mon - Fri EST

Mailing address: APVMA, PO Box 6182, Kingston, ACT, 2604, Australia

Email: contact@apvma.gov.au

Phone: +61 2 6210 4701

Web: www.apvma.gov.au

Q: How do I check the current registration status of a chemical product?

A: Your supplier can check the registration status of chemicals, or you can access the

information on the database of all registered agricultural and veterinary products

in Australia from the Public Chemical Registration Information System – PUBCRIS,

accessed through the APVMA website.

Q: How do I know if a product has been registered?

A: The APVMA (known before March 2003 as the NRA) allocates a unique

registration number which is printed on the bottom of the product label. The

APVMA uses this approval number to verify the registration status of products. The

words "NRA Approval No." always appears in front of the number. The last four

digits tell you when the product was last assessed by the APVMA. However, some

older chemical products may not have an NRA number. In this case, ask your

supplier to check that the product you want is registered.

Approved Fido’s products

1. K9000 Shampoo (Registration not req’d) 2. Conditioner (Registration not req’d)

FIDOS K9000 Clear Bottled Every Day Shampoo FIDOS K9000 CLEAR Bottled Crème Conditioner

MSDS (see MSDS attached) MSDS (see MSDS attached)

3. Flea & Tick (APVMA No. 37433) 4. Disinfectant (APVMA No. 57855)

FIDO F Rinse Concentrate Fido Hydro Bath Flush

MSDS (see MSDS attached) MSDS (see MSDS attached)

The use of non-approved products may be harmful to the dog. Damage may also be caused

to the Tru Blu dog wash equipment and possible voiding of the units’ warranty.

The only products that are approved for use in the Tru Blu K9L Dog Wash

are Fido’s products produced in Australia by Mavlab Pty Ltd

(www.mavlab.com.au) and those registered as a “veterinary chemical

product” by the Australian Pesticides and Veterinary Medicines Authority

(APVMA) for use on dogs.

15

Z:\Build\K9000 Mini\K9000 Mini Operators Manual May 2019 v3.0.docx

© Tru Blu Dog Wash 2016

5 Cash Box Components

The below picture has the major components of the cash box labelled;

Warning Beeper (time running out, more coins required)

Override lock

Coin Acceptor

Rotary Switch

Interface board

Warning

Beeper

Interface Board

Rotary

Switch

Coin

Acceptor

Override

Key

Other manuals for K9000 Mini

1

Table of contents

Other TRU-BLU Pet Care Product manuals