............ www.truemfg.com ............

True Food Service Equipment, Inc.

66

INSTALLATION / OPERATION INSTRUCTIONS

LOCATING

REMOTE UNITS (This section applies to remotes only!)

• Remotecabinetsmustbeorderedasremote.We

donotrecommendconvertingfromastandard

selfcontainedtoremotesystem.

• Allremotecabinetsmustbehardwired.

• Nocastorsavailable.

• Allremotecabinetscomestandardusing404A

refrigerant.

• Allremoteunitscomestandardwith

expansionvalve,liquidlinesolenoid,heated

condensatepan,anddefrosttimerwhen

applicable.

• ContactTRUETechnicalServiceforBTU

requirements.

• Nowiringnecessarybetweencabinetand

condensingunit.

• Allremotecondensingunitspurchasedfrom

TRUEare208/230voltssinglephase.

If you have any questions regarding this section, please

call TRUE at 1-(800)-325-6152.

A. Setunitinitsfinallocation.Besurethereisadequate

ventilationinyourroom.Underextremeheat

conditions,(100°F+,38°C+),youmaywanttoinstall

anexhaustfan.

WARNING

Warranty is void if ventilation is insufficient.

B. ProperlevelingofyourTRUEcooleriscriticalto

operatingsuccess(fornon-mobilemodels).Effective

condensateremovalanddooroperationwillbe

effectedbyleveling.

C. Thecoolershouldbeleveledfronttobackandside

tosidewithalevel.

D. Ensurethatthedrainhoseorhosesarepositionedin

thepan.

E. Freeplugandcordfrominsidethelowerrearofthe

cooler(donotplugin).

F. Theunitshouldbeplacedcloseenoughtothe

electricalsupplysothatextensioncordsarenever

used.

WARNING

Cabinet warranties are void if OEM power cord is tampered

with. TRUE will not warranty any units that are connected to

an extension cord.

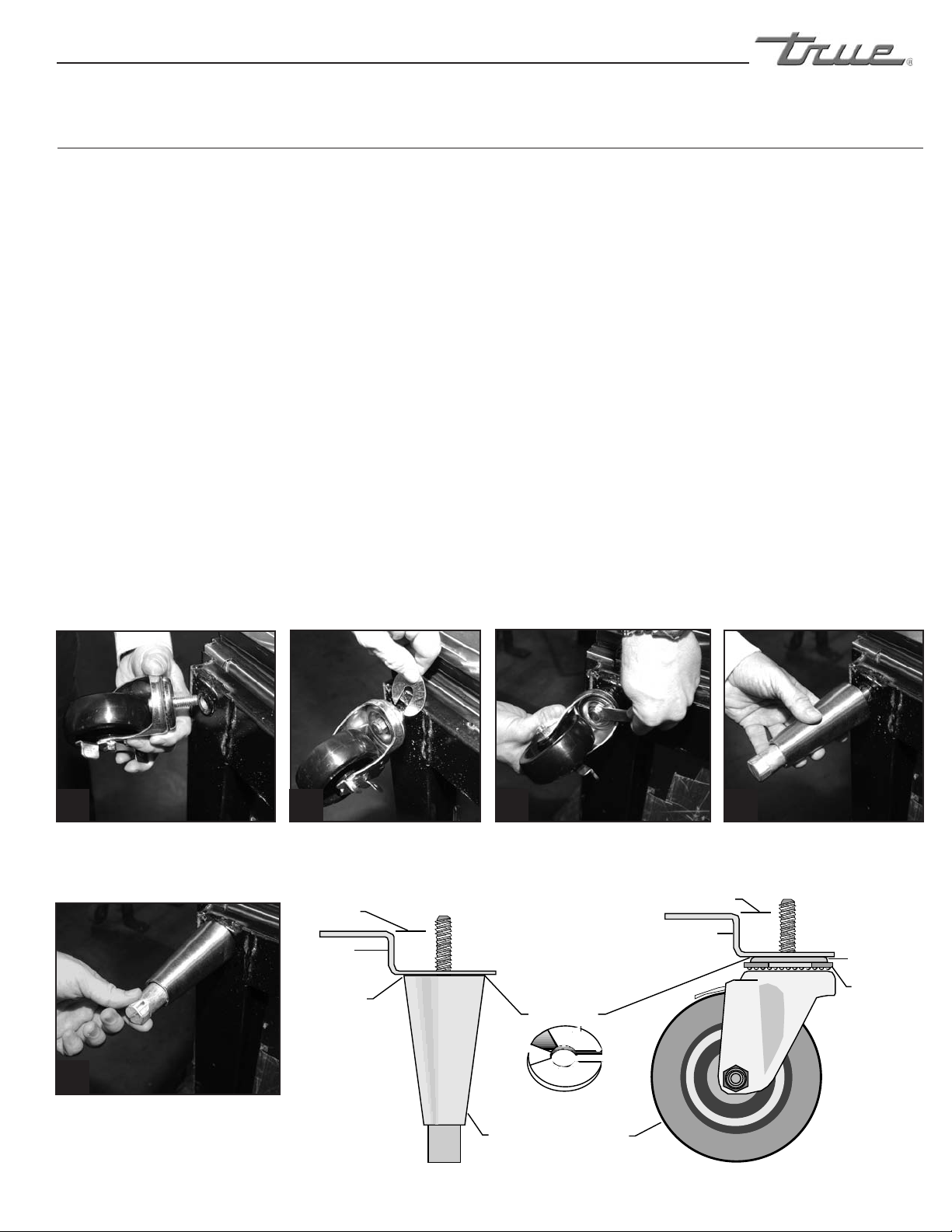

LEVELING

P

NEPCO/CENTRALAB

1227-5

REMOVECOVERMAKEPOWERCONNECTION

A. Removelouverfromthefrontofcabinetandbackguard

(ifapplicable)fromrearofcabinet(seepage29).

B. Skidboltsarelocatedineachof4cornersinsidecabinet

bottom.(SeephotoA).

C. Removeskidbolts.(SeephotoB).

D. Cutstrapsifapplicable.(SeephotoC).

E. Carefullyliftcabinetoffofskid. Removing skid from bottom of

cabinet.

AB

C

CLEARANCES (For proper cabinet operation, clearance guidelines should be followed)

Refrigerators – 1” at the rear, 0” at the sides, and open at the top (GDM-5, -6, -7, -9 = 1” at the rear, 1” at the sides,

and open at the top).

Freezers – 3” at the rear, 0” at the sides, and open at the top.

WARNING: Be sure there is adequate ventilation in your room. Under extreme heat conditions, (100°F+, 38°C+), you may

want to install an exhaust fan.