Trumpf TruLight 1000 User manual

Installation manual

TruLight™ 1000 examination light

English

en-GB

This page is left intentionally blank.

55000-00019_002_01 – 1695231 – 17/10/2018 3

Instructions for service personnel

Please read this installation manual very carefully and take into account the

safety instructions and the special requirements for installation.

This installation manual apply to:

Device versions TruLight™ 1000 lighting system:

• Version with light head as ceiling-mounted version.

• Version with light head as wall-mounted version.

• Version with light head as mobile pedestal version.

• Version with a light head on TRUMPF Medizin Systeme GmbH + Co. KG

ceiling-mounted supply unit.

55000-00019_002_01 – 1695231 – 17/10/2018 4

How to contact us

Manufacturer and distributor TRUMPF Medizin Systeme GmbH + Co. KG

Carl-Zeiss-Straße 7–9

07318 Saalfeld

Germany

Telephone: +49 3671 586-0

Fax: +49 3671 586-41165

info@trumpfmedical.com

www.trumpfmedical.com

Trumpf Medical will hereinafter be used as a synonym for TRUMPF Medizin Systeme

GmbH + Co. KG to improve readability.

Technical Customer Service Telephone: +49 (0)3671 586-41911

Fax: +49 (0)3671 586-41175

E-mail service.wwo@trumpfmedical.com

The contact details for the current sites of the technical customer service in the indi-

vidual countries are provided on the Internet at www.trumpfmedical.com.

In the following, Technical Customer Service will be used as a synonym for Trumpf

Medical Customer Service and for technicians of service operators authorised and

trained by Trumpf Medical.

55000-00019_002_01 – 1695231 – 17/10/2018 5

Validity

Other applicable documents

Designation Document number Material No.

Service Manual

TruLight 1000 DE

55000-00022 1867293

Spare Parts List

TruLight 1000 DE / EN

55000-00039 1857652

Instruction Manual

TruLight 1000 DE

55000-00012 1695232

55000-00019_002_01 – 1695231 – 17/10/2018 6

Notes relating to this documentation

Copyright and property rights

Copyright • All rights reserved. This installation manual is protected by copyright.

• Any use not currently regulated by law must be approved in writing by TRUMPF

Medizin Systeme GmbH + Co. KG, hereinafter referred to as Trumpf Medical.

• Trumpf Medical will assume no liability whatsoever arising from or connected

with the use of unapproved information by any person or company.

Modifications and translations

Modifications to the device • We constantly work on the further development of our products and reserve the

right to make changes to the scope of delivery in terms of form, equipment and

technology.

Changes to the installation manual • The content of the installation manual can be changed at any time without prior

notice.

• Please keep up to date on the current version of the instructions, e.g. using the

Trumpf Medical Online Information System (OIS) at regular intervals.

Translations • The German-language version of this Installation Manual shall be binding as

regards translations into foreign languages.

Trademarks

•TruLight

™ 1000 is a registered trademark of TRUMPF GmbH + Co. KG.

• All other brands listed in the installation manual are the exclusive property of the

respective manufacturer.

7

55000-00019_002_01 – 1695231 – 17/10/2018

Table of Content

1Important information for safe installation ....................................................................... 10

1.1 Details for identification of the device............................................................................................................ 10

1.2 Details for identification of the installation manual ....................................................................................... 10

1.3 Delivery ........................................................................................................................................................... 10

1.3.1 Transportation damage ......................................................................................................................................................10

1.3.2 Identifying the components based on serial numbers .......................................................................................................11

1.4 Required installation equipment .................................................................................................................... 11

1.5 Qualification of service staff ........................................................................................................................... 11

1.6 Ambient conditions for operation and storage .............................................................................................. 11

1.6.1 Ambient conditions for operation ......................................................................................................................................11

1.6.2 Ambient conditions for storage ..........................................................................................................................................11

1.7 Conformity ...................................................................................................................................................... 12

1.7.1 Identification.......................................................................................................................................................................12

1.7.2 Proper use...........................................................................................................................................................................12

1.7.3 Special features...................................................................................................................................................................12

1.7.4 Improper use.......................................................................................................................................................................12

1.8 Exclusion of liability......................................................................................................................................... 13

1.9 Documentation of the installation.................................................................................................................. 13

1.10 Disposal........................................................................................................................................................... 13

2On-site requirements ....................................................................................................... 14

2.1 Approval of wall and ceiling anchorage .......................................................................................................... 14

2.2 Fasteners and mounting methods .................................................................................................................. 14

2.3 On-site electrical installation .......................................................................................................................... 15

3Safety instructions ........................................................................................................... 16

3.1 Structure of the safety instructions in this installation manual...................................................................... 16

3.1.1 Indicating risk of injury .......................................................................................................................................................16

3.1.2 Indicating damage to property ...........................................................................................................................................16

3.1.3 Indicating additional information .......................................................................................................................................16

3.2 Additional symbols for safety instructions...................................................................................................... 16

3.3 Symbols on the device .................................................................................................................................... 16

3.4 Overview of the most important safety instructions...................................................................................... 17

4Identification of the lighting system.................................................................................. 20

4.1 Use of serial numbers and device labels......................................................................................................... 20

4.1.1 Markings on the ceiling-mounted version ..........................................................................................................................20

4.1.2 Markings on the wall-mounted version..............................................................................................................................20

4.1.3 Markings on the mobile stand version ...............................................................................................................................21

5Installation of ceiling version ............................................................................................ 22

5.1 Overview of assemblies for central axis.......................................................................................................... 22

5.1.1 Central axis assembly..........................................................................................................................................................22

5.1.2 Support arm system assembly............................................................................................................................................24

5.1.3 Light unit assembly .............................................................................................................................................................24

5.2 Power supply to the ceiling version ................................................................................................................ 24

5.3 Attachment of ceiling anchor plate to the slab ceiling ................................................................................... 25

5.3.1 Attachment of ceiling anchor plate with heavy-duty anchors............................................................................................25

5.4 Installation of ceiling pipe flange plate on the ceiling anchor plate ............................................................... 26

5.4.1 Installation with threaded rods ..........................................................................................................................................26

5.4.2 Assembly with hexagonal profiles ......................................................................................................................................27

5.5 Installation of ceiling pipe flange plate on the slab ceiling ............................................................................. 28

5.5.1 Attachment of ceiling pipe flange plate with heavy-duty anchors .....................................................................................28

Table of Content

8

55000-00019_002_01 – 1695231 – 17/10/2018

5.6 Connecting the on-site power supply ............................................................................................................. 29

5.6.1 Input voltage 100 V - 240 V.................................................................................................................................................29

5.7 Mount canopy................................................................................................................................................. 29

5.8 Installation of the support arm system on the central axis ............................................................................ 30

5.8.1 Preparing for the assembly.................................................................................................................................................30

5.8.2 Dismantling the circlip ........................................................................................................................................................30

5.8.3 Mounting the circlip............................................................................................................................................................32

5.8.4 Checking the secure fit of the circlip...................................................................................................................................33

5.8.5 Completing the installation.................................................................................................................................................34

5.9 Installation of the light unit on the support arm system ................................................................................ 35

5.10 Controlling driving movements....................................................................................................................... 36

5.10.1 Check levelling of the lighting system.................................................................................................................................36

5.10.2 Rotation / swivel ranges of the support arm system..........................................................................................................36

5.10.3 Rotation / swivel ranges of the light head..........................................................................................................................36

6Installation of wall version ............................................................................................... 37

6.1 Overview of assemblies of wall bearing.......................................................................................................... 37

6.1.1 Wall bearing assembly........................................................................................................................................................37

6.1.2 Support arm system assembly............................................................................................................................................37

6.1.3 Light unit assembly .............................................................................................................................................................37

6.2 Power supply to the wall version.................................................................................................................... 38

6.3 Fastening the wall bearing .............................................................................................................................. 39

6.4 Connecting the on-site power supply ............................................................................................................. 41

6.4.1 Input voltage 100 V - 240 V.................................................................................................................................................41

6.5 Installation of the support arm system on the wall bearing........................................................................... 43

6.5.1 Preparing for the assembly.................................................................................................................................................43

6.5.2 Dismantling the circlip ........................................................................................................................................................43

6.5.3 Mounting the circlip............................................................................................................................................................45

6.5.4 Checking the secure fit of the circlip...................................................................................................................................46

6.5.5 Completing the installation.................................................................................................................................................47

6.6 Installation of the light unit on the support arm system ................................................................................ 48

6.7 Controlling the driving movements ................................................................................................................ 49

6.7.1 Check levelling of the lighting system.................................................................................................................................49

6.7.2 Rotation / swivel ranges of the support arm system..........................................................................................................49

6.7.3 Rotation / swivel ranges of the light head..........................................................................................................................49

7Assembly of mobile stand version ..................................................................................... 50

7.1 Overview of assemblies .................................................................................................................................. 50

7.1.1 Stand base assembly...........................................................................................................................................................50

7.1.2 Stand pipe assembly ...........................................................................................................................................................50

7.1.3 Spring arm assembly...........................................................................................................................................................50

7.1.4 Light unit assembly .............................................................................................................................................................50

7.2 Power supply of the stand version.................................................................................................................. 51

7.3 Assembling the stand base ............................................................................................................................. 52

7.4 Assembling the stand rod ............................................................................................................................... 53

7.5 Assembly of the spring arm on the stand rod................................................................................................. 54

7.5.1 Preparing for the assembly.................................................................................................................................................54

7.5.2 Dismantling the circlip ........................................................................................................................................................54

7.5.3 Mounting the circlip............................................................................................................................................................56

7.5.4 Checking the secure fit of the circlip...................................................................................................................................57

7.5.5 Completing the installation.................................................................................................................................................57

7.6 Connecting the internal power supply............................................................................................................ 58

7.7 Installation of the light unit on the spring arm ............................................................................................... 59

Table of Content

9

55000-00019_002_01 – 1695231 – 17/10/2018

7.8 Controlling the driving movements ................................................................................................................ 60

7.8.1 Rotation / swivel ranges of the spring arm.........................................................................................................................60

7.8.2 Rotation / swivel ranges of the light head..........................................................................................................................60

8Functional testing and instruction..................................................................................... 61

8.1 Functional test of the lighting system............................................................................................................. 61

8.2 Handover of the lighting system ..................................................................................................................... 62

9Adjustments ....................................................................................................................63

9.1 Adjusting the spring force on the spring arm ................................................................................................. 63

9.2 Adjusting the brake force of the quarter bracket ........................................................................................... 64

9.3 Replacing the internal equipment fuse of the mobile stand version..............................................................65

10 Consumables ................................................................................................................... 66

11 Technical data.................................................................................................................. 67

11.1 Device data ..................................................................................................................................................... 67

11.2 EMC information............................................................................................................................................. 68

12 Attachment .....................................................................................................................73

12.1 Contents of attachment .................................................................................................................................. 73

12.1.1 Circuit plan for ceiling version 100 V - 240 V / #1699488...................................................................................................74

12.1.2 Circuit diagram for mobile version 100 V - 240 V cable connection / #1699646 ...............................................................76

12.1.3 Circuit diagram for wall version 100 V - 240 V fixed connection / #1699647.....................................................................78

12.1.4 Drawing of switch cabinet TL 1000, 230V / #1698267 .......................................................................................................79

12.1.5 Borehole template for ceiling anchor plate, ceiling pipe flange plate / #1690273 ............................................................80

12.1.6 Borehole template for wall bearing / #4058120 ................................................................................................................81

55000-00019_002_01 – 1695231 – 17/10/2018 10

1 Important information for safe installation

1.1 Details for identification of the device

This installation manual is intended solely for devices that are shown on the device

label with the following information:

Device identification

1.2 Details for identification of the installation manual

Up-to-dateness of this installation manual To indicate the updated status of the installation manual, all pages are marked with a

7-figure identification number and the status:

Marking of the installation manual – Material no.: 1695231

– Date of publication: 17/10/2018

– Document number: 55000-00019_002_01

This marking is binding for the validity of the installation manual and must not be

removed irrespective of the type of publication (in printed or electronic form, in full

or excerpted).

1.3 Delivery

Before installation, check the delivery for completeness and for any possible

transportation damage. Unpack to check the delivery of all components. The

components can be identified by means of the order number of the delivery note and

the order-specific dimension sheet. Always store the delivery note with the main

components (light head or support arm system).

1.3.1 Transportation damage

Damage claims Claims for damage cannot be accepted unless Trumpf Medical is notified without

delay. In the event of damage during transport or missing components, please send

Trumpf Medical a report containing the following information:

Accompanying documents • Damage report giving details of damage or defects using the: Service Advice

Form (F60.M028)

• Main serial number of the lighting system or the serial numbers of the damaged

components

• Order number (shown on the delivery note and / or the order-specific dimension

sheet)

• Name and address of the customer

•Consignee

Address for returns In the event of a return, use the original packaging if possible.

Address returns to:

TRUMPF Medizin Systeme GmbH + Co. KG

Carl-Zeiss-Straße 7–9

07318 Saalfeld

Germany

Descriptor/rating Type Material no.

TruLight™ 1000 TruLight™ 1000 pre-assembly set 4058051

TruLight™ 1000 TruLight™ 1000 ceiling 4058110

TruLight™ 1000 TruLight™ 1000 wall 4058120

TruLight™ 1000 TruLight™ 1000 mobile 4058130

TruLight™ 1000 TruLight™ 1000 pendant 4058140

11

1 Important information for safe installation

55000-00019_002_01 – 1695231 – 17/10/2018

1.3.2 Identifying the components based on serial numbers

Serial numbers The components of the lighting system are marked by serial numbers:

• The serial numbers specify the components of a specific lighting system uniquely

in such a way that they cannot be confused.

• The components of a lighting system are listed in the delivery note of the

packaging by serial number.

• An overview of the serial number marking points on the device can be found in

Chapter 4.1, P. 20.

1.4 Required installation equipment

The following equipment is required to install the lighting system:

• Two ladders of the required length

• Standard drilling equipment

or

• HILTI DD-EC 1 core drill

– with the corresponding drill bit

• Drilling templates

– Ceiling mount: (#1704432)

– Wall attachment: (#4058120)

•Level

• Torque spanner

• Calibrated lux meter

•Multimeter

• Standard toolkit

Tool List The tool list (TMS900we, 2009-12-21) contains a list of all the available special tools

with material numbers and can be downloaded from the Trumpf Medical Online

Information System (OIS).

1.5 Qualification of service staff

Professional qualifications The device may only be installed, maintained and repaired by the Trumpf Medical

Customer Service unit or by authorised Trumpf Medical Service partners.

1.6 Ambient conditions for operation and storage

Various ambient conditions apply to the operation and temporary storage of the

device.

1.6.1 Ambient conditions for operation

• Ambient temperature: 10 °C to 40 °C

• Relative humidity: 30% to 75%

• Air pressure: 700 hPa to 1060 hPa

• Operating height: max. 3000 m above sea level

1.6.2 Ambient conditions for storage

• Ambient temperature: -15 °C to +60 +°C

• Relative humidity: 5% to 95%

• Air pressure: 500 hPa to 1060 hPa

12

1 Important information for safe installation

55000-00019_002_01 – 1695231 – 17/10/2018

1.7 Conformity

1.7.1 Identification

Conformity The manufacturer declares that this product conforms to the fundamental

requirements according to MDD Appendix I and documents the same by means of

the CE and UL marking.

CE mark: This device is a Class I medical device as defined by the European Medical

Device Directive (MDD).

UL mark UL mark: device tested by Underwriter Laboratories Inc. for the USA and Canada with

regard to shock and fire hazard and also mechanical endangerment.

1.7.2 Proper use

Proper use Lighting unit for the local illumination of the patient’s body to support diagnoses or

treatments which may be interrupted in case of light failure without hazard to the

patient.

Working range • The working range lies at a distance between 70 and 150 cm to the area being

examined.

• The device is suitable for continuous operation.

• Each use beyond the aforementioned conditions is considered to fall outside the

scope of proper use. Only the user or operator will be liable for any loss or

damage arising as a result.

1.7.3 Special features

High light intensity To ensure good visibility, the light head has a high light intensity.

Overlap of the light fields • Visible light also generates heat in the examination area due to physical effects.

The light intensity must be reduced when perfusion is reduced or the tissue starts

to dry out.

Examinations in the field of vision • For examinations in the facial area with unprotected and open eyes, high levels of

local light intensities may lead to damage to eyesight. The patient's eyes must be

closed or protected as necessary (e.g. with safety goggles with an optical density

of at least 2 or designed according to protection level 6 EN169).

1.7.4 Improper use

Improper use The examination light is not intended for use in operating theatres.

• Additional load on the light support is not permitted.

• The device may not be exposed to severe vibration.

Restriction • The device is not suitable for operation in areas at risk of explosions

• The device is not suitable for use in rooms or areas in which inflammable

mixtures of anaesthetics with air or oxygen or laughing gas (N20) are used.

• The device should not be used in the vicinity of strong magnetic fields.

• Mixtures of combustible anaesthetic vapours with oxygen or laughing gas may

arise in the vicinity of the device in such a high concentration that ignition could

occur under certain circumstances. The danger area is formed in accordance with

EN 11197 in an area between 5 cm and 25 cm from the point of outflow or escape

of the gas.

/ AMD1: 2012;

/ AMD1: 2013;

2014;

13

1 Important information for safe installation

55000-00019_002_01 – 1695231 – 17/10/2018

1.8 Exclusion of liability

Exclusion of liability The Trumpf Medical warranty for the product requires that:

• the device is used exclusively for the proper use and is operated and maintained

in accordance with the provisions of this installation manual

• only original spare parts or accessories approved by Trumpf Medical are used

• no modifications are made to the device

• inspections and maintenance work are carried out at the time intervals specified

• an initial commissioning is carried out and the device is released for operation

with a handover declaration

1.9 Documentation of the installation

Installation must be performed with the use of an installation report (TK_IS_200).

Download the specified report in electronic format via the online information system,

complete it and hand it over to the Technical Customer Services unit of TRUMPF

Medizin Systeme GmbH & Co. KG.

The installation reports contain all the important test and installation steps and the

documentation required for handover of the device.

The following must be observed when documenting the installation reports:

• Documentation about the serial number of the installed components, stating the

assembly site.

The serialisation structure prescribed during delivery must be adhered to during

installation. If serial equipment other than that prescribed by the manufacturer

is to be installed, this must be noted on the various installation reports.

• The handover of the lighting system for operation must be confirmed by the

operator.

The lighting system must be handed over to the operator following

commissioning and testing by the service staff of the installer. The operator must

be instructed in the functional check and visual inspection, the adjustment work

and in cleaning and caring for the lighting system in accordance with the valid

installation manual.

1.10 Disposal

The device must be disposed of in accordance with the requirements of directive

WEEE II 2012 / 19 / EU and relevant national regulations at a suitable waste disposal

point for the recycling of electrical and electronic devices.

RoHS conformity • The device meets the requirements of Directive 2011/65/EU RoHS (restriction of

the use of certain hazardous substances in electrical and electronic devices).

55000-00019_002_01 – 1695231 – 17/10/2018 14

2 On-site requirements

Care must be taken to ensure that the ceiling and wall anchorage of the lighting

system takes into account all the circumstances that apply to each individual case,

that the approval of the relevant building authorities has been obtained and that all

installation work is carried out in accordance with the regulations and using suitable

tools.

2.1 Approval of wall and ceiling anchorage

Declaration of acceptance by the structural

engineer

The condition and sustainability of the mounting structure must be inspected by a

structural engineer and confirmed in a certificate. This verification of the structural

calculation for the load-bearing capacity must be done prior to installation and must

be available.

Aborted holes If drilling of a hole has been aborted, for example, by drilling into the reinforcement,

the structural engineer in charge must be involved since adequate structural load

distribution may be endangered.

Observe and follow construction

provisions

The respectively valid national and regional construction provisions must be

complied with.

2.2 Fasteners and mounting methods

Fasteners are not part of the scope of delivery. The selection of fasteners is the

responsibility of the structural examination and approval of the responsible building

authority.

Ceiling anchoring

Reinforced concrete ceiling, class C20/25 The following fasteners are recommended for well-constructed reinforced concrete

ceilings of class C20/25 (or better quality):

• Four ceiling anchors of the type: HILTI

• Approval document: ETA-98/0001 (European Technical Approval)

• Type: HST M10x90

Strength of the slab ceiling The minimum component thickness of the slab ceiling to use ceiling anchors must be

120 mm. In case of lower slab ceiling thicknesses, different fasteners are usually

proposed in the order-specific dimension sheet.

Manufacturer processing regulations The processing regulations of the fastener manufacturers must be taken into

account. The ceiling anchor plate / wall pipe flange plate must lie flush on the fixing

substrate for correct load distribution.

Observe and follow construction

provisions

The respectively valid national and regional construction provisions must be

complied with.

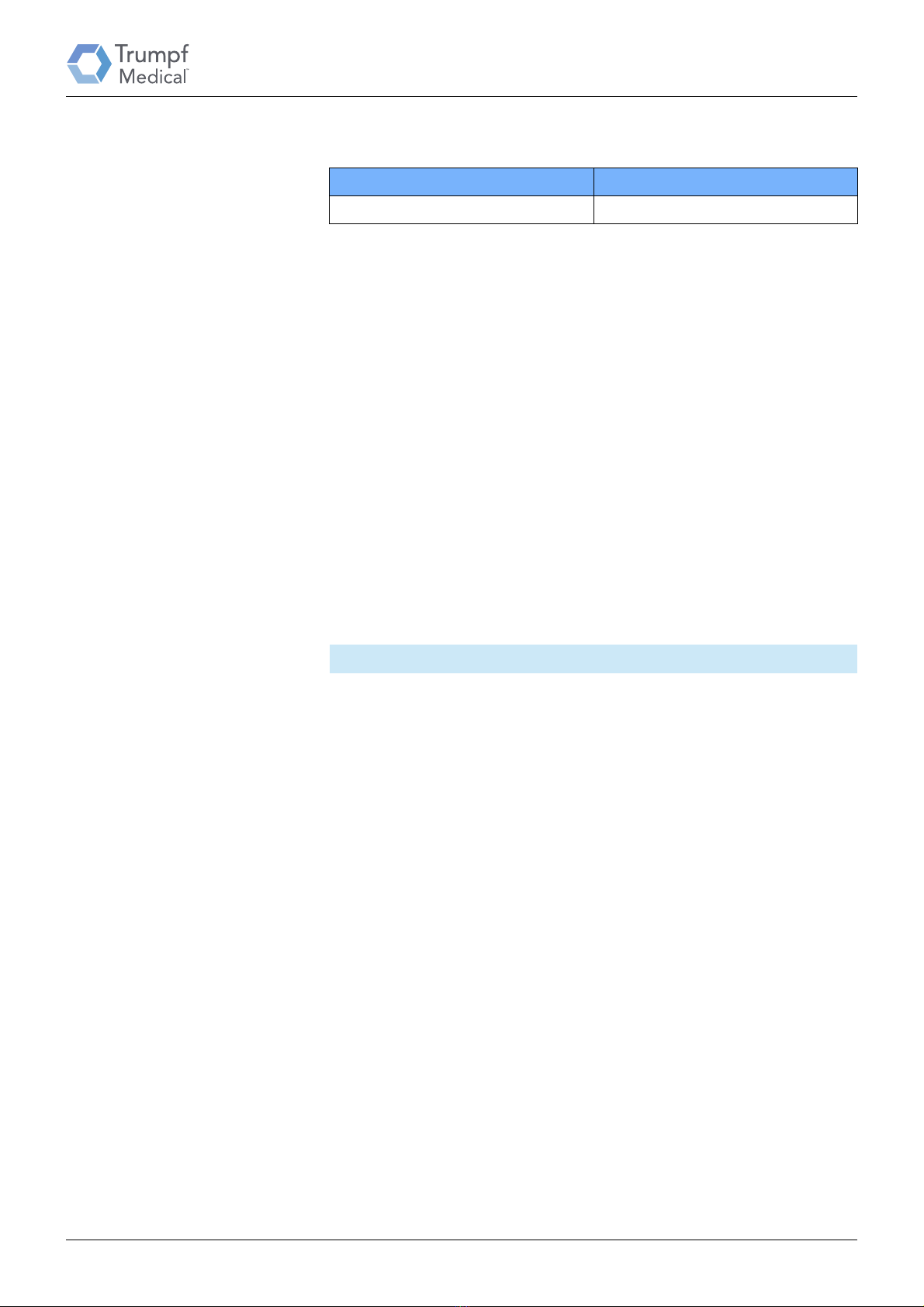

Load data for ceiling anchorage:

Reinforced concrete wall, class C20/25 The following fasteners are recommended for well-constructed reinforced concrete

walls of class C20/25 (or better quality):

• Two heavy-duty anchors of the type: HILTI

• Approval certificate no. ETA-98/0001

• Type: HST M10x90

Lightweight construction walls In case of lightweight construction walls that cannot be subjected to loads, it is

necessary to insert a metal construction. The suitability of the metal construction

provided by the customer must be confirmed in writing and documented by the

customer (operator or representative commissioned and authorised by the operator,

e.g. planners, architects, etc.).

Weight force Bending moment

350 N 70 Nm

15

2 On-site requirements

55000-00019_002_01 – 1695231 – 17/10/2018

Load data for wall anchorage:

2.3 On-site electrical installation

The on-site electrical connections must be made in accordance with the TruLight™

1000 planning rules by a specialised company appointed by the customer. The

following requirements must be complied with:

Execution by a specialised electrical

company

• Planning, execution and testing of the electrical installation must be performed

on-site by professional and specialised electrical designers and state-licensed

electrical specialised companies.

Country-specific regulations • If it is required by the regulations applicable in the respective country that the

device be connected to the power supply by authorised electricians, then this

subsequent procedure must be carried out.

All-pin disconnecting device for the power

supply

• It must be possible to disconnect all pins of the power supply lines from the

mains power supply by a device provided on-site.

• The series terminals must be freely accessible for installation of the device and

for carrying out the prescribed electrical safety tests.

• The electrical installations for the room in question must meet the requirements

of the nationally applicable regulations.

• For the Federal Republic of Germany, DIN VDE 0100 Part 710 applies.

• For the USA, the requirements of NFPA 70 and NFPA 99 apply

Electrical fuses for ME devices

For ME devices with permanent connections, the device used for

electrical insulation of the circuits must have a lock that can be set to the

off position to disconnect the circuits from the mains supply. A mains

supply switch, when used as an electrical insulation device, must meet

the requirements of IEC 61058-1.

If ME devices are not permanently installed and do not have a mains

switch, a suitable plug device for disconnecting the ME device from the

mains will meet the requirements.

Weight force Bending moment

70 N 70 Nm

NOTE

55000-00019_002_01 – 1695231 – 17/10/2018 16

3 Safety instructions

3.1 Structure of the safety instructions in this installation

manual

In this installation manual, important information is marked by graphic symbols or

signal words.

3.1.1 Indicating risk of injury

Signal words such as DANGER, WARNING or CAUTION indicate the severity of the

hazard. Various triangle symbols are used to add visual emphasis.

DANGER indicates an immediately dangerous situation in which non-compliance can

cause death or serious injury.

WARNING indicates a potentially dangerous situation in which non-compliance may

cause death or serious injuries.

+CAUTION indicates a potentially dangerous situation in which non-compliance may

cause minor injuries.

3.1.2 Indicating damage to property

ATTENTION indicates a potentially dangerous situation, which, –unless avoided,– can

lead to damage to property.

3.1.3 Indicating additional information

NOTE provides you with additional information and helpful tips for safe and efficient

use of the device.

3.2 Additional symbols for safety instructions

Gas explosion: warns of explosive ignition of gas mixtures

Electric shock: indicates an electric shock hazard which could cause serious injury or

even death

The spring arm may bounce up: warns of the spring arm jumping up while

dismantling the light head / flat screen

Lighting system falling down: warns of a sudden downwards movement of the light

system when it is exposed to additional loads

Damage to surfaces: warns against damage to surfaces caused by unsuitable

cleaning agents and disinfectants

3.3 Symbols on the device

CE conformity mark: certifies the conformity of the device with the European

product directive (Medical Device Directive (MDD).

DANGER

WARNING

CAUTION

ATTENTION

NOTE

17

3 Safety instructions

55000-00019_002_01 – 1695231 – 17/10/2018

Follow the Instruction Manual: refers to the instruction manual

UL mark: device has been tested by Underwriter Laboratories Inc. for the USA and

Canada. UL / cUL classification regarding electric shock, fire hazard and mechanical

hazard only in accordance with ANSI / AMI ES60601-1: 2005/AMD1: 2012,

IEC 60601-2-41:2009/AMD1:2013, CAN/CSA-C22.2 No. 60601-1: 2014, UL 60601-1,

CAN/CSA-C22.2 No. 601.1.

3.4 Overview of the most important safety instructions

Requirements for the installation site

Gas explosion

The lighting system is not suitable for use in an environment

in which flammable mixtures of anaesthetics with oxygen or

laughing gas in a high concentration are used. Mixtures of combustible

anaesthetic vapours with oxygen or laughing gas may arise in the vicinity

of the device in a sufficiently high concentration that ignition may occur

under certain circumstances.

The danger area is formed in accordance with EN 11197 in an area

between 5 cm and 25 cm from the point of outflow or escape of the gas.

Strong magnetic fields

The support arm systems of the lighting systems must not be used in the

vicinity of strong magnetic fields.

BF / CF Class application components

No BF or CF Class application components in accordance with IEC 60601-1

may be directly connected to the support arm systems of the lighting

system.

Risks posed by electric shock

Switch off the on-site power supply

Touching a live equipment component may lead to fatal

electrical shock:

• Switch off all pins of the on-site power supply for all installation

work and secure them against being switched on again.

• Pull out the mains plug of the mobile stand version and secure it

against being plugged in again.

Check the electronic components

Check the state of the electrical components and insulations.

• Damaged parts or supply lines may not be used for assembly.

DANGER

DANGER

18

3 Safety instructions

55000-00019_002_01 – 1695231 – 17/10/2018

Load restriction

Crashing of the lighting system

The loading of the support arm system is restricted to the

max. load. of 30 Nm.

• No additional attachments may be installed on the support arm

system, except for the light head.

• Do not place any additional weight on the support arm system.

Swivel movement of the light head

Risk of injury due to uncontrolled swivel movement

Uncontrolled movement of the spring arm may result when

the spring force of the spring arm is not correctly adjusted.

Risk of jamming

When swivelling the light head, the distance between the

quarter bracket and the light head changes:

• Do not insert your fingers between the quarter bracket and the light

head when rotating the light head.

• Only grasp the light head with the sterilisable handle.

Cleaning and disinfection

Switch off the power supply

Touching live components may result in an electric shock.

• Disconnect all phases from the device before cleaning or

disinfection.

• Do not place any objects in the equipment openings.

Improperly used cleaning agents or disinfectants can pose a risk

for patients or damage products

If the instructions listed below are not observed or fulfilled, this can

damage the varnish or

coating of the device. Paint particles can come off and fall into open

wounds, which can represent a risk of contamination or infection for the

patients. Furthermore, it would render any claim for damages void!

• Only use wipe-over disinfection as a disinfection procedure.

• To clean or disinfect the device, the cloth for wiping must be moist

and not wet.

• Dispense cleaning agents and disinfectants such that no liquid can

enter through joints or openings of the examination light or parts of

the support arm system.

WARNING

WARNING

WARNING

19

3 Safety instructions

55000-00019_002_01 – 1695231 – 17/10/2018

• Use the surface disinfectant only at the concentration specified by

the manufacturer.

• Only use disinfectants approved by the manufacturer for use with

the following materials:

• Polycarbonate (PC), polyamide (PA), acrylonitrile butadiene styrene

copolymer (ABS), polystyrene (PS), polyurethane (PUR),

polyphenylsulfone (PPSU), polyvinyl chloride (PVC), polybutylene

terephthalate (PBT) and silicone.

• Due to the risk of surface damage:

– Do not use sharp, pointed or abrasive objects,

– Do not use abrasive substances or agents which can remove material,

– Do not use solvents, benzene, paint thinners, alkaline cleaning agents or

cleaning agents containing acids or aldehydes,

– Do not use agents with glycol derivatives, phenols, phenol derivatives or

quaternary compounds,

– To prevent paint or corrosion damage, only use agents that do not contain

chlorides or halides.

• In the event of an increased layer formation of surface disinfectant,

thorough cleaning must be performed.

• It is imperative to observe the hygiene instructions of the operator.

See the TruLight™ 1000 Examination Light instruction manual for detailed information

about cleaning and disinfection.

Commissioning

Initial commissioning prior to use

The lighting system must be handed to the user in a tested state after

initial operation before it can be used in routine medical procedures.

• The initial operation includes functional and safety checks on the

entire lighting system.

• Handover must be documented by a handover declaration.

System components

Identification of the system units

The components of the lighting system are pre-configured and pre-

assembled for a system according to the order-specific dimension sheet.

• In case of unclear assignment of components, you must consult

Trumpf Medical or the appropriate authorised partner of Trumpf

Medical.

CAUTION

NOTE

55000-00019_002_01 – 1695231 – 17/10/2018 20

4 Identification of the lighting system

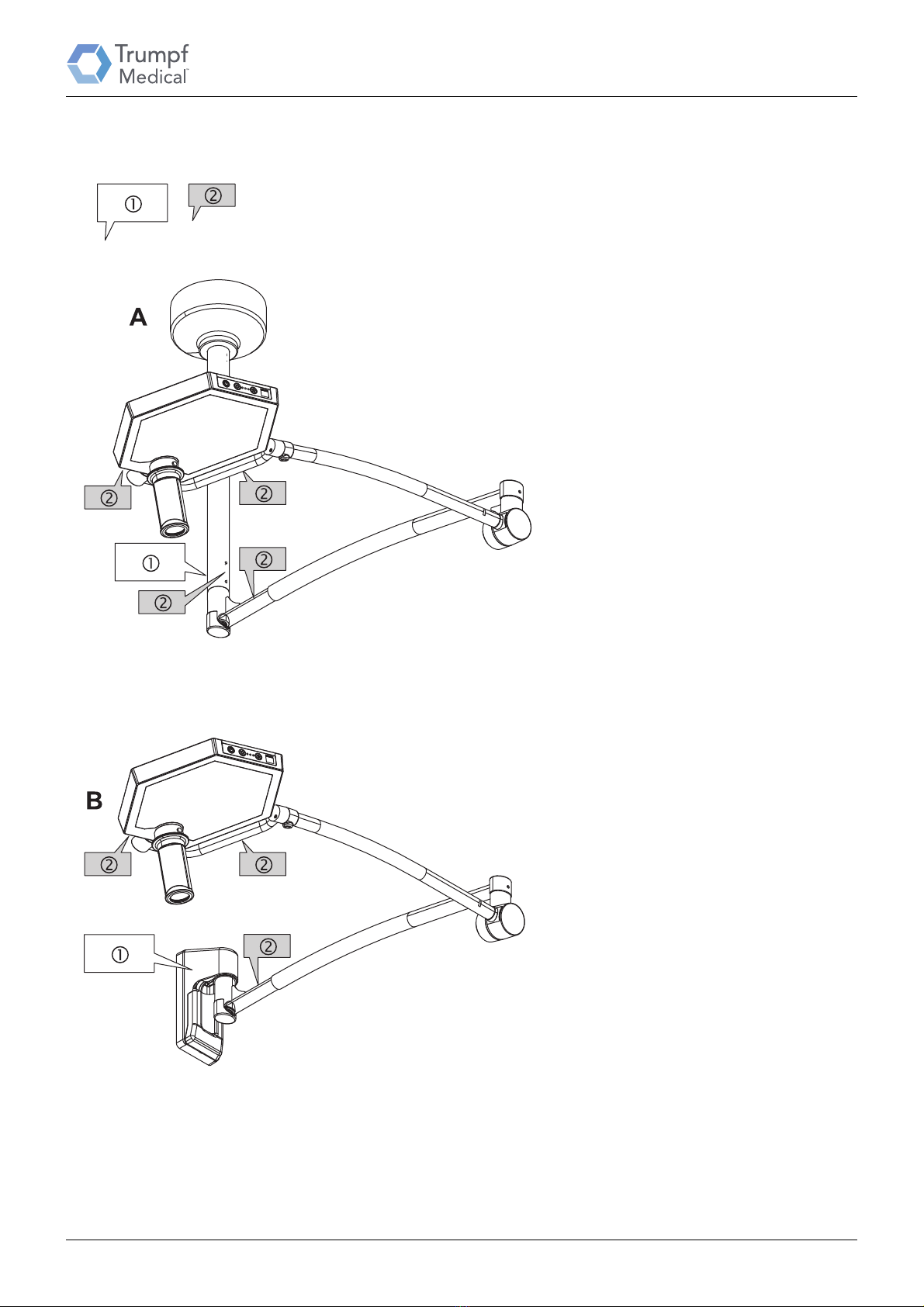

Figure 1 4.1 Use of serial numbers and

device labels

A lighting system is identified by its device

label and serial numbers.

• The device label 1 contains the specific

device data and also the main serial

number.

• The main serial number characterises an

entire device in an order-specific manner.

The main serial number also enables

components which do not have a serial

number themselves to be identified by

Trumpf Medical Customer Service,

permitting the correct spare parts to be

supplied.

• The serial numbers 2 identify the

individual components of a device.

4.1.1 Markings on the ceiling-

mounted version

A: Ceiling-mounted version

• The device label 1 with the main serial

number on the ceiling conduit.

• Serial numbers 2 of the individual

components are provided at:

–Light head

–Quarter bracket

– Ceiling conduit

– Boom with spring arm

4.1.2 Markings on the wall-mounted

version

B: Wall-mounted version

• The device label 1 with the main serial

number on the cover of the wall support.

• Serial numbers 2 of the individual

components are provided at:

–Light head

–Quarter bracket

– Boom with spring arm

This manual suits for next models

3

Table of contents

Other Trumpf Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual