AV15 INSTALLATIONMANUAL | TruSteelAutoVap15 Installation Instructions | v. 1.3

2 / 43

Table of contents

INTRODUCTION ................................................................................................ 3

ABOUT AUTOVAP15 ...................................................................................... 3

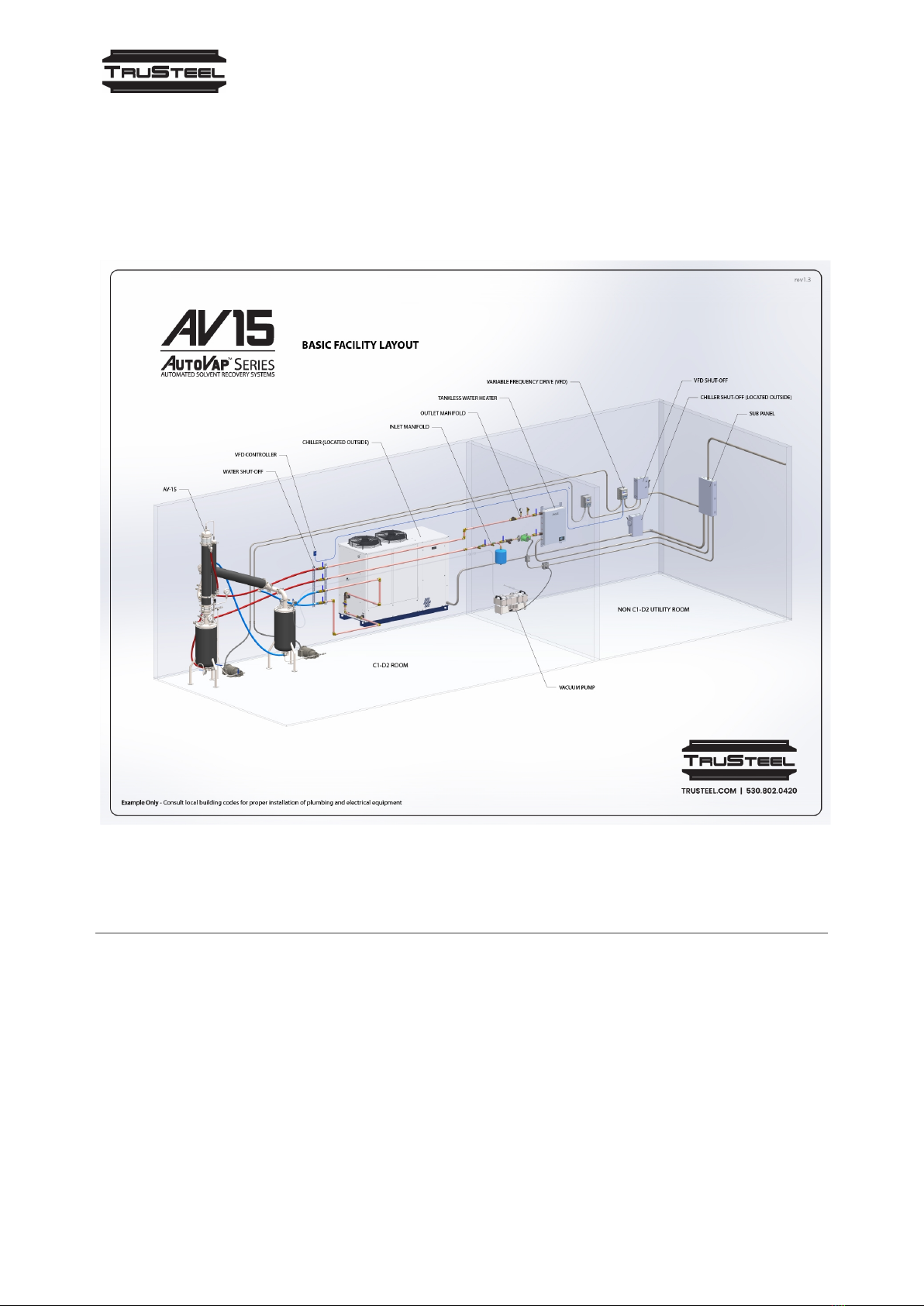

FACILITY LAYOUT ........................................................................................ 4

CHECKLISTS ..................................................................................................... 5

EQUIPMENT MANIFEST .................................................................................. 6

AV15 REQUIREMENT CHECKLIST .................................................................... 8

EQUIPMENT SPECIFICATIONS .......................................................................... 10

WATER HEATER ......................................................................................... 10

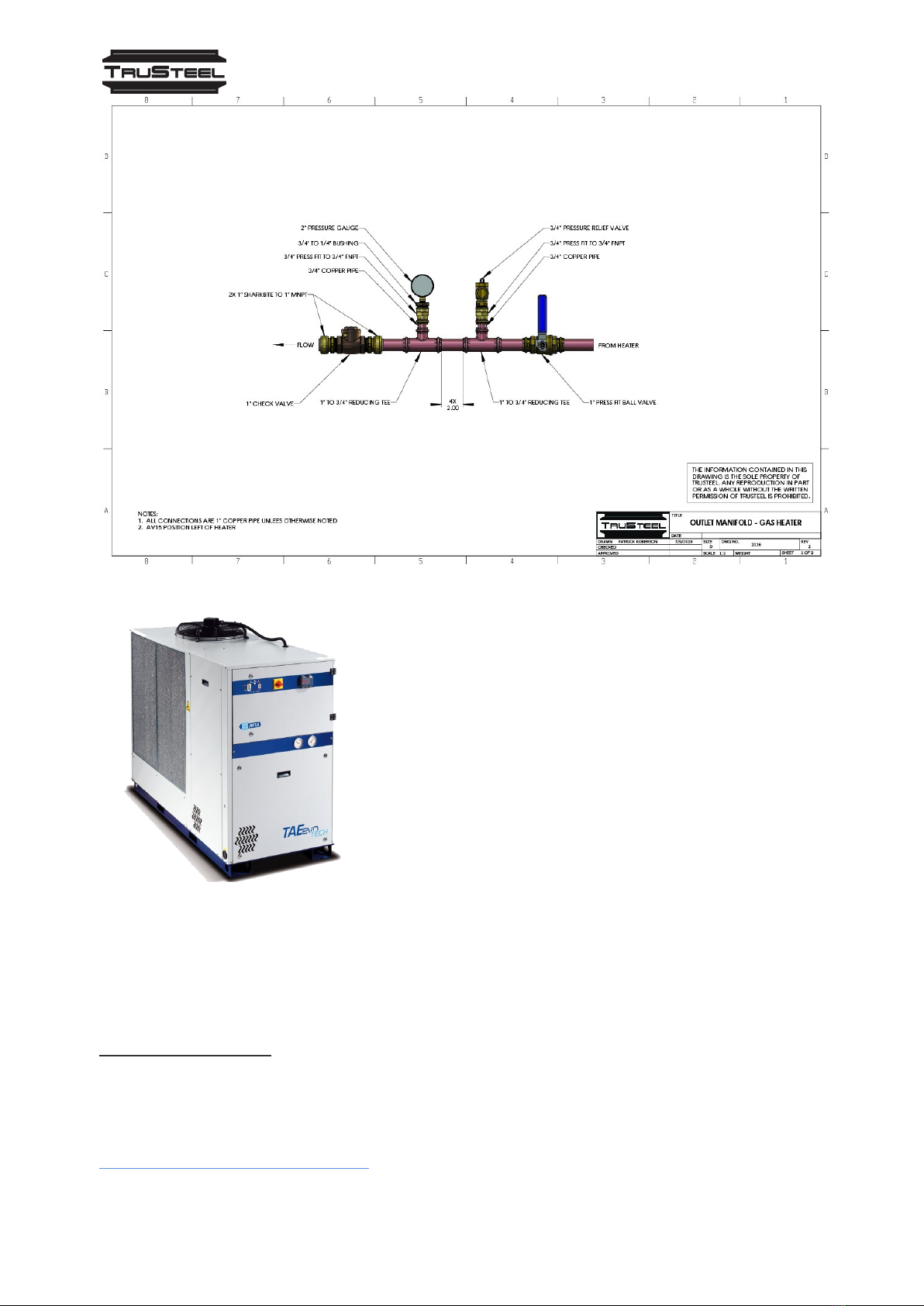

WATER HEATER MANIFOLD ..................................................................... 13

CHILLER ..................................................................................................... 15

VACUUM PUMP ............................................................................................ 16

PUMPS (VFD'S) ............................................................................................ 17

REQUIRED COMMODITIES ............................................................................... 19

AUTOVAP15 INSTALLATION & STARTUP INSTRUCTIONS .................................. 20

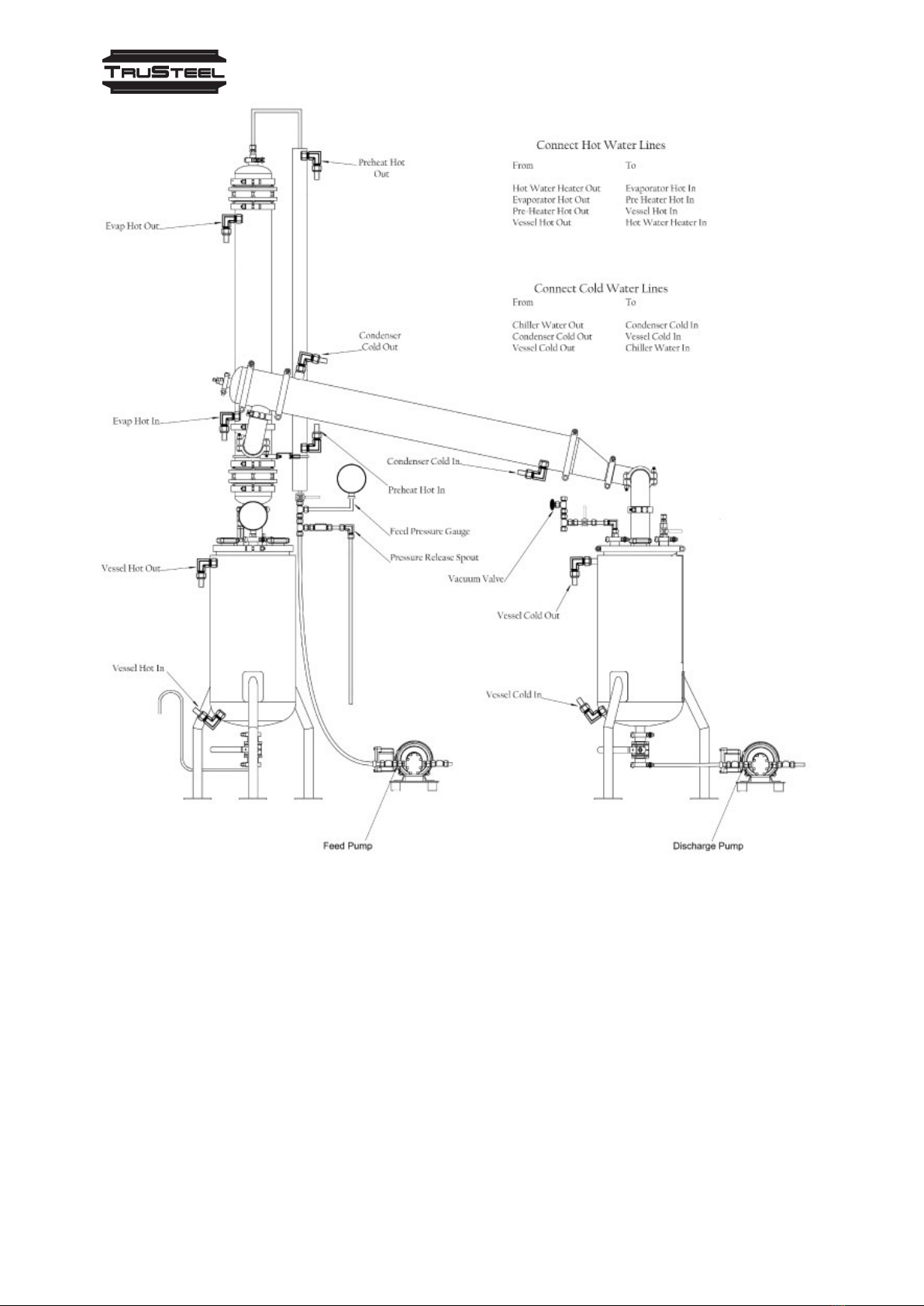

AUTOVAP15 ASSEMBLY ............................................................................... 20

UNBOXING .............................................................................................. 22

ASSEMBLY .............................................................................................. 26

CHILLER FILL & STARTUP ............................................................................ 32

SYSTEM REQUIREMENTS ......................................................................... 32

FILL CHILLER .......................................................................................... 32

Troubleshooting ................................................................................... 33

Alarm Reset Procedure ..................................................................... 33

b1AC Set Point ................................................................................ 34

ALc1 ALARM ON START-UP .............................................................. 35

Contact MTA ............................................................................................ 35

HEATING SYSTEM FILL & STARTUP .............................................................. 36

Prepare Equipment ................................................................................... 36

Prepare To Fill PreHeater (Use Port #1) ...................................................... 37

Fill the System ......................................................................................... 38

Allow Pressure To Rise In System .............................................................. 39

Power On Heater and Recirculating Pump and check system for leaks ............ 39

Adjust Pressure On System (To compensate for heat expansion) ................... 41

Contact Hubbell Support ........................................................................... 41

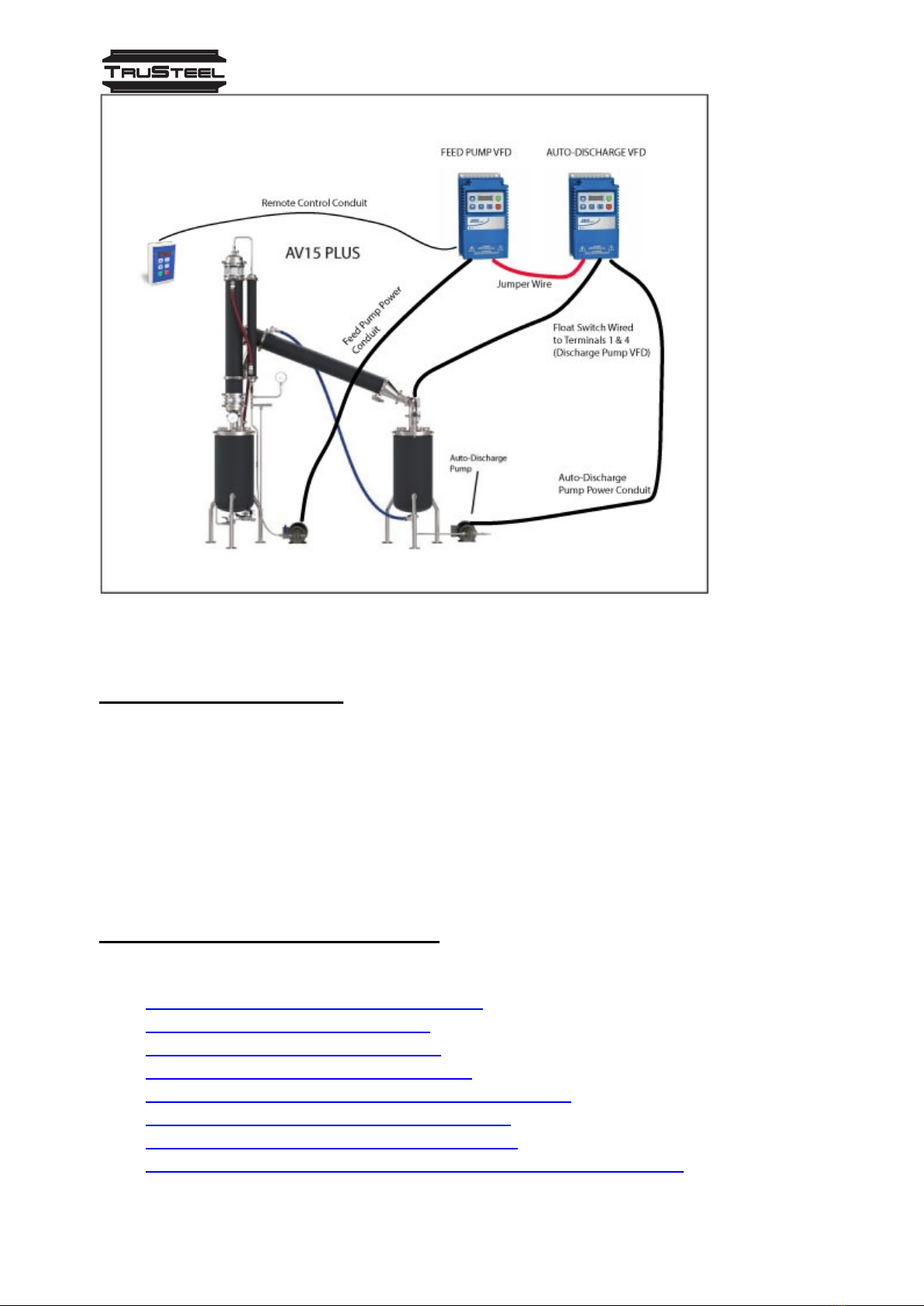

AUTODISCHARGE VFD WIRING .................................................................... 41

SCHEDULE ON-SITE TRAINING AND IQ/OQ ...................................................... 43