TABLE OF CONTENT

1. FUNDAMENTAL OF THE SYSTEM ..........................................................................1

1.1. Overview.................................................................................................................1

2. ELECTRONICS..........................................................................................................5

2.1 Summary of Board Connectors.............................................................................5

2.2 Pin Configuration....................................................................................................8

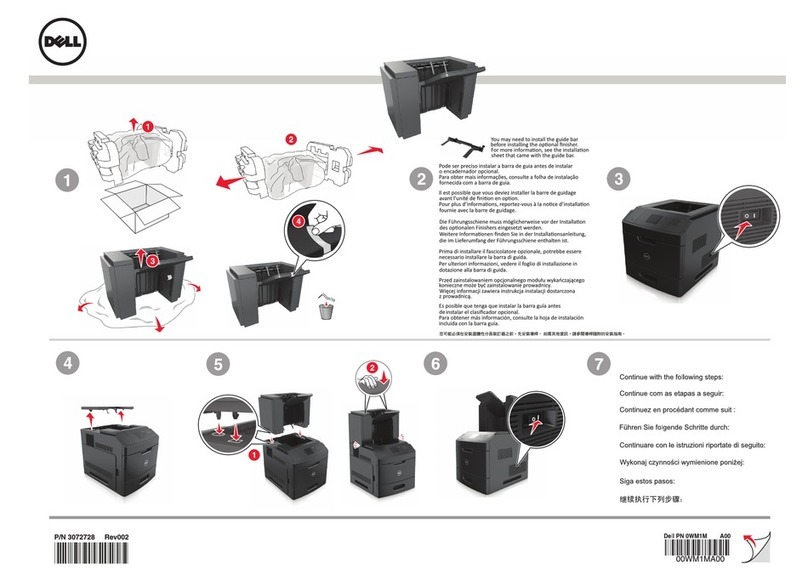

3. MECHANISM........................................................................................................... 11

3.1 Remove Covers.....................................................................................................11

3.2 Replacing the LCD Panel Module........................................................................13

3.3 Replacing the Power Supply Unit........................................................................14

3.4 Replacing Multi-interface Board..........................................................................15

3.5 Replacing the Main Board....................................................................................16

3.6 Replacing the Platen Roller Assembly................................................................17

3.7 Replacing the Stepping Motor.............................................................................18

3.8 Replacing the Printhead ASS'Y ...........................................................................19

3.9 Replacing the Gap and Black-mark Sensor Module..........................................21

3.10 Replacing the DC Motor.....................................................................................23

4. TROUBLESHOOTING............................................................................................. 25

4.1 Common Problems...............................................................................................25

5. MAINTENANCE.......................................................................................................29

UPDATE HISTORY......................................................................................................31