TSC TTP-384M User manual

THERMAL TRANSFER / DIRECT THERMAL

BAR CODE PRINTER

TTP-384M

USER’S

MANUAL

Contents

1. Introduction ............................................1

1.1 Product Introduction ...............................................................................1

1.2 Compliances ............................................................................................1

2. Operations Overview .....................................3

2.1 Unpacking and Inspection ......................................................................3

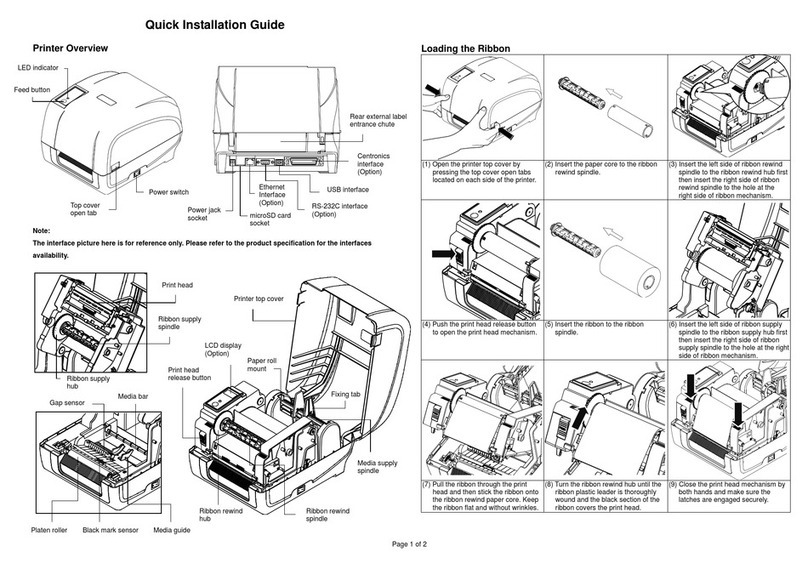

2.2 Printer Overview ......................................................................................4

2.2.1 Front View ......................................................................................4

2.2.2 Interior view....................................................................................5

2.2.3 Rear View........................................................................................6

2.3 Operator Controls....................................................................................8

2.3.1 Front Panel Display .......................................................................8

2.3.2 LED Indicators ...............................................................................8

2.3.3 Front Panel Keys ...........................................................................9

2.4 Setting Up the Printer..............................................................................9

2.5 Loading Ribbon......................................................................................10

2.6 Loading Media........................................................................................13

3. Menu Function .........................................15

3.1 Setup Menu Overview............................................................................16

3.1.1 Printer Setup ................................................................................17

3.1.2 Sensor...........................................................................................24

3.1.3 Serial Comm.................................................................................32

3.1.4 Ethernet........................................................................................35

3.2 File Manager...........................................................................................38

3.2.1 File List.........................................................................................38

3.2.2 Avail. Memory...............................................................................38

3.2.3 Del. All Files..................................................................................39

3.3 Diagnostics ............................................................................................40

3.3.1 Print Config. .................................................................................40

3.3.2 Dump Mode..................................................................................41

3.3.3 Rotate Cutter................................................................................42

3.4 Language................................................................................................42

3.5 Service....................................................................................................43

3.5.1 Initialization..................................................................................43

3.5.2 Mileage Info..................................................................................44

4. Diagnostic Tool.........................................45

i

ii

4.1 Start the Diagnostic Tool.......................................................................45

4.2 Printer Function (Calibrate sensor, Ethernet setup, RTC setup………)

.......................................................................................................................46

5. Troubleshooting ........................................47

5.1 Common Problems................................................................................47

5.2 Mechanism Fine Adjustment to Avoid Ribbon Wrinkles ....................51

6. Maintenance ...........................................53

Revise History ...........................................55

1. Introduction

1.1 Product Introduction

Thank you very much for purchasing TSC bar code printer.

This printer is designed with die-casting aluminum chassis and print mechanism, metal

cover with large clear media view window, which ensuring to work for the extreme and

heavy duty industrial environment and applications.

With back-lit graphic LCD display, printer status can be managed easier and operated

more user friendly. The moveable sensor design can accept wide range of label media.

All of the most frequently used bar code formats are included. Fonts and bar codes can

be printed in any one of the four directions. This printer is built-in the high quality, high

performance MONOTYPE IMAGING® True Type font engine and one CG Triumvirate

Bold Condensed smooth font. With flexible firmware design, user can also download the

True Type Font from PC into printer memory for printing labels. Besides the scalable

font, it also provides a choice of five different sizes of alphanumeric bitmap font, OCR-A

and OCR-B fonts. By integrating rich features, it is the most cost-effective and high

performance printer in its class!

1.2 Compliances

CE Class A:

EN55022:1998+A1:2000+A2:2003:

EN55024:1998+A1:2001+A2:2003:

EN 61000-4 SERIES REQULATIONS

ETSI EN 301 489-17:V1.2.1(2002-08)

FCC:

CFR 47, Part 15/CISPR 22 3RD EDITION:1997, Class A

L, CUL

-1 1st

1

04

U

UL 60950

TÜV/Safety:

200IEC60950-1:

EN 60950-1/A11:20

2

nweise

sorgfältig durch

brauch auf.

. Verwenden Sie Keine

nschlußsteckdose soll nahe dem Gerät angebraucht und leicht zugänglich

Gerät ist vor Feuchtigkeit zu schűtzen.

ren Stand zu achten. Ein Kippen oder

etz die Anschlußwerte.

40℃betieben

Wichtige Sicherheits-Hi

1.Bitte lesen Sie Diese Hinweis

2.Heben Sie diese Anleitung fűr den späteren Ge

3.Vor jedem Reinigen ist das Gerät vom Stromentz zu trennen

Flűssig-oder Aerosolreiniger. Am besten eignet sich ein angefeuchtetes Tuch zur

Reinigung.

4.Die Netza

sein.

5.Das

6.Bei der Aufstellung des Gerätes ist auf siche

Fallen könnte Beschädigungen hervorrufen.

7.Beáchten Sie beim Anschluß an das stromn

8. Dieses das Gerät kann bis zu einer Außentemperatur von maximal

werden.

CAUTION

1. HAZARDOUS MOVING PARTS IN CUTTER MODULE. KEEP FINGER AND OTHER BODY

3. TIONS.

PARTS AWAY.

2. THE MAIN BOARD INCLUDES REAL TIME CLOCK FEATURE HAS LITHIUM BATTERY

CR2032 INSTALLED. RISK OF EXPLOSION IF BATTERY IS REPLACED BYAN

INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO THE MANUFACTURER INSTRUC

2. Operations Overview

2.1 Unpacking and Inspection

This printer has been specially packaged to withstand damage during shipping.

Please carefully inspect the packaging and printer upon receiving the bar code printer.

Please retain the packaging materials in case you need to reship the printer.

Unpacking the printer, the following items are included in the carton.

One printer unit

One Windows labeling software/Windows driver CD disk

One quick installation guide

One power cord

One USB interface cable

One ribbon take up paper core

If any parts are missing, please contact the Customer Service Department of your

purchased reseller or distributor.

3

2.2 Printer Overview

2.2.1 Front View

1

2

3

6

4 5

1. LED indicators

2. LCD display

3. Front panel buttons

4. Paper exit chute

5. Printer cover

6. Cutter module (Optional)

4

2.2.2 Interior view

7

1

8

2

3

5

1. Ribbon rewind spindle

2. Printhead

3. Ribbon sensor

4. Media sensor

5. Platen roller

6. Printhead release lever

7. Ribbon supply spindle

8. Label rollguard

9. Label supply spindle

10. Media guide bar

11. Label guide

5

9

4

10

6 11

2.2.3 Rear View

1

6

1. Fan-fold paper entrance chute

2. Centronics interface

3. USB interface

4. RS-232C interface

5. Power jack socket

*6. SD card slot

7. Ethernet interface

8. PS/2 interface

9. Power switch

* Recommended SD card specification.

SD card spec SD card capacity Approved SD card manufacturer

V1.0, V1.1 128 MB SanDisk, Transcend

V1.0, V1.1 256 MB SanDisk, Transcend, Panasonic

V1.0, V1.1 512 MB SanDisk, Transcend, Panasonic

V1.0, V1.1 1 GB SanDisk, Transcend, Panasonic

V2.0 SDHC CLASS 4 4 GB

V2.0 SDHC CLASS 6 4 GB SanDisk, Transcend, Panasonic

V1.0, V1.1 microSD 128 MB Transcend, Panasonic

8

7

6

9

4

5

2

3

7

V1.0, V1.1 microSD 256 MB Transcend, Panasonic

V1.0, V1.1 microSD 512 MB Panasonic

V1.0, V1.1 microSD 1 GB Transcend, Panasonic

V2.0 SDHC CLASS 4 microSD 4 GB Panasonic

V2.0 SDHC CLASS 6 microSD 4 GB Transcend

V1.0, V1.1 miniSD 128 MB Transcend, Panasonic

V1.0, V1.1 miniSD 256 MB Transcend, Panasonic

V1.0, V1.1 miniSD 512 MB Transcend, Panasonic

V1.0, V1.1 miniSD 1 GB Transcend, Panasonic

V2.0 SDHC CLASS 4 miniSD 4 GB Transcend

V2.0 SDHC CLASS 6 miniSD 4 GB

- The DOS FAT file system is supported for the SD card.

- Folders/files stored in the SD card should be in the 8.3 filename format

- The miniSD/microSD card to SD card slot adapter is required.

2.3 Operator Controls

2.3.1 Front Panel Display

LED indicators

LCD display

Front

p

anel buttons

2.3.2 LED Indicators

LED Status Indication

Off Printer power off

On Printer power on

On Printer is ready

Printer is paused

Blinking Printer is downloading data

Off Printer is ready

On Carriage open OR Cutter error

Blinking No paper, Paper jam OR "No ribbon

8

2.3.3 Front Panel Keys

Keys Function

1. Enter the menu system

2. Once in the menu system, return to previous menu. If at menu root,

exits the menu system.

Pauses or resumes printing

Advance one label

Scroll up the menu options

Scroll down the menu options

Select the currently highlighted option

2.4 Setting Up the Printer

1. Place the printer on a flat, secure surface.

2. Make sure the power switch is off.

3. Connect the printer to the computer with the provided USB cable.

4. Plug the power cord into the AC power cord socket at the rear of the printer, and

then plug the power cord into a properly grounded power outlet.

9

2.5 Loading Ribbon

1. Lift printer cover open.

2. Push the printhead release lever to open the printhead mechanism.

Printhead

release lever

3. Install the ribbon onto the ribbon supply spindle.

Note: Make sure the ribbon is set at the center of the spindle.

4. Install the paper core onto the ribbon rewind spindle.

Note: Make sure the paper core is set at the center of the spindle.

10

5. Thread the ribbon through the ribbon sensor slot and printhead.

11

5. Stick ribbon onto ribbon rewind paper core, keeping the ribbon flat and wrinkle-free.

6. Wind the ribbon rewind spindle clockwise roughly 3~5 circles until ribbon is smooth,

properly stretched and wrinkle-free.

Ribbon

Ribbon

sensor

7. Close the printhead mechanism, making sure the latches are engaged properly.

zLoading path for ribbon

12

2.6 Loading Media

1. Lift printer cover open.

2. Push the printhead release lever to open the printhead mechanism.

Printhead

release lever

3. Remove ONE label rollguard.

4. Place media roll on label supply spindle.

5. Replace label rollguide.

Note: Make sure the media is set at the center of spindle.

Label

rollguides

6. Pull the leading edge of the label forward through the media guide bar past media

sensor, and place the leading edge onto the platen roller.

13

14

Media sensor Media guide bar

Label guide

7. Adjust the label guide to fit label width.

8. Close printhead mechanism, making sure the latches are engaged properly.

9. Using the front display panel, set media sensor type and calibrate the selected

sensor.

Note: Re-calibrate the gap/black-mark sensors when changing media.

zLoading path for roll labels

3. Menu Function

Main Menu Overview

Russian

Polish

Spanish

Exit

↓

↓

↓

Main Menu

Setup F ile Manager Diagnostics Language Serv ice Exit

↓↓↓ ↓↓

Printer Setup File List Print Config. English

Mileage Info.

↓↓↓ ↓

Initialization

↓

↓

Sensor

Avail

.

Memory

↓↓↓ ↓

Dump Mode Chinese(TC)

↓↓↓ ↓

Serial Comm. Del. All Files Rotate Cutter Chinese(SC) Exit

*Ethernet Exit

↓↓

Japanese

Exit

Exit

German

↓

↓

Italian

↓

French

Notice:

* Ethernet function is available on the LCD display when Ethernet card is installed.

15

3.1 Setup Menu Overview

Exit

↓

Stop Bit(s)

Exit

↓

Exit Data Bits

↓↓↓

Exit

Calibration Parity Configure

↓

↓↓↓

ZPL2

Status Baud Rate Status

↓↓↓

Setup

ExitSensor Serial Comm. Ethernet

↓

↓

Printer Setup

TSPL2

Notice:

* Ethernet function is available on the LCD display when Ethernet card is installed.

16

3.1.1 Printer Setup

Printer Setup

Speed Density Direction Print Mode Offset Shift Y Reference X Code Pag

e

Country

+000~-00

0

TSPL2

↓

Exit

↓↓ ↓↓↓

Shift X Reference

Y

000~999

↓

000~9994 0 0 +000~-

↓↓ ↓

USA 001

BRI 002

+000~-00

0

51 1BatchMode

62 GER 003

73 CutterMode

DAN 032

FRE 031

95

84

Exit

10 6

11 7

ITA 033

SPA 034

SWE 036

12 8 SWI 038

9

10

437 039

042

850 041

11

04412

852

13

860

14

15

863 045

865 046

857 047

1252 048

061

1250 049

055

1254

1253

1251

1255

1256

1257

358

1258

Exit

8859-1

8859-2

8859-3

8859-4

8859-5

8859-6

8859-7

8859-8

8859-9

8859-10

8859-15

950

936

932

351

None

Peeler Mode

Cutter

949

17

Other manuals for TTP-384M

1

Table of contents

Other TSC Printer manuals

TSC

TSC TA300 Series User manual

TSC

TSC PRINTRONIX ML240 Series User manual

TSC

TSC TDM-20 User manual

TSC

TSC TX200 Series User manual

TSC

TSC TTP-225 Series User manual

TSC

TSC Alpha-3R User manual

TSC

TSC PEX-1120 Series User manual

TSC

TSC Alpha-2R Series User manual

TSC

TSC TTP-248M User manual

TSC

TSC TTP-247 User manual