Contents

1. Introduction..........................................................................................................1

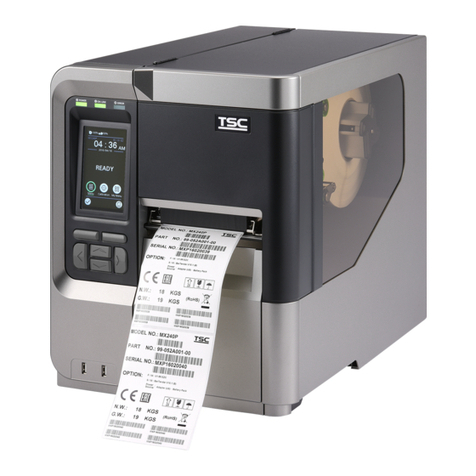

1.1 Product Introduction ..................................................................................... 1

1.2 Product Features........................................................................................... 2

1.2.1 Printer Standard Features .................................................................. 2

1.2.2 Printer Optional Features ................................................................... 3

1.3 General Specifications.................................................................................. 4

1.4 Print Specifications........................................................................................4

1.5 Ribbon Specifications....................................................................................4

1.6 Media Specifications ......................................................................................5

2. Operations Overview ...........................................................................................6

2.1 Unpacking and Inspection ............................................................................ 6

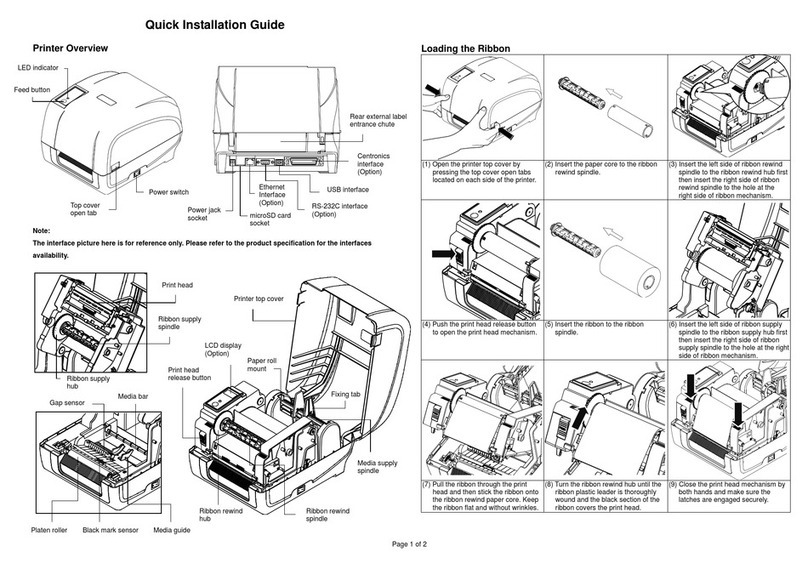

2.2 Printer Overview ............................................................................................ 7

2.2.1 Front View............................................................................................ 7

2.2.2 Interior View ........................................................................................8

2.2.3 Rear View.............................................................................................9

3. Setup...................................................................................................................10

3.1 Setting up the Printer .................................................................................. 10

3.2 Loading the Ribbon..................................................................................... 11

3.3 Loading the Media....................................................................................... 14

3.3.1 Loading the Roll Labels.................................................................... 14

3.3.2 External Label Roll Mount Installation (Option).............................. 17

4. LED and Button Functions ...............................................................................18

4.1 LED Indicator ............................................................................................... 19

4.2 Regular Button Functions........................................................................... 19

4.3 Power-on Utilities ........................................................................................ 19

4.3.1 Gap/Black Mark Sensor Calibration................................................. 20

4.3.2 Gap/Black Mark Calibration, Self-test and Dump Mode.................. 21

4.3.3 Printer Initialization........................................................................... 24

4.3.4 Set Black Mark Sensor as Media Sensor and Calibrate the Black

Mark Sensor................................................................................................... 25

4.3.5 Set Gap Sensor as Media Sensor and Calibrate the Gap Sensor .. 25

4.3.6 Skip AUTO.BAS................................................................................. 26

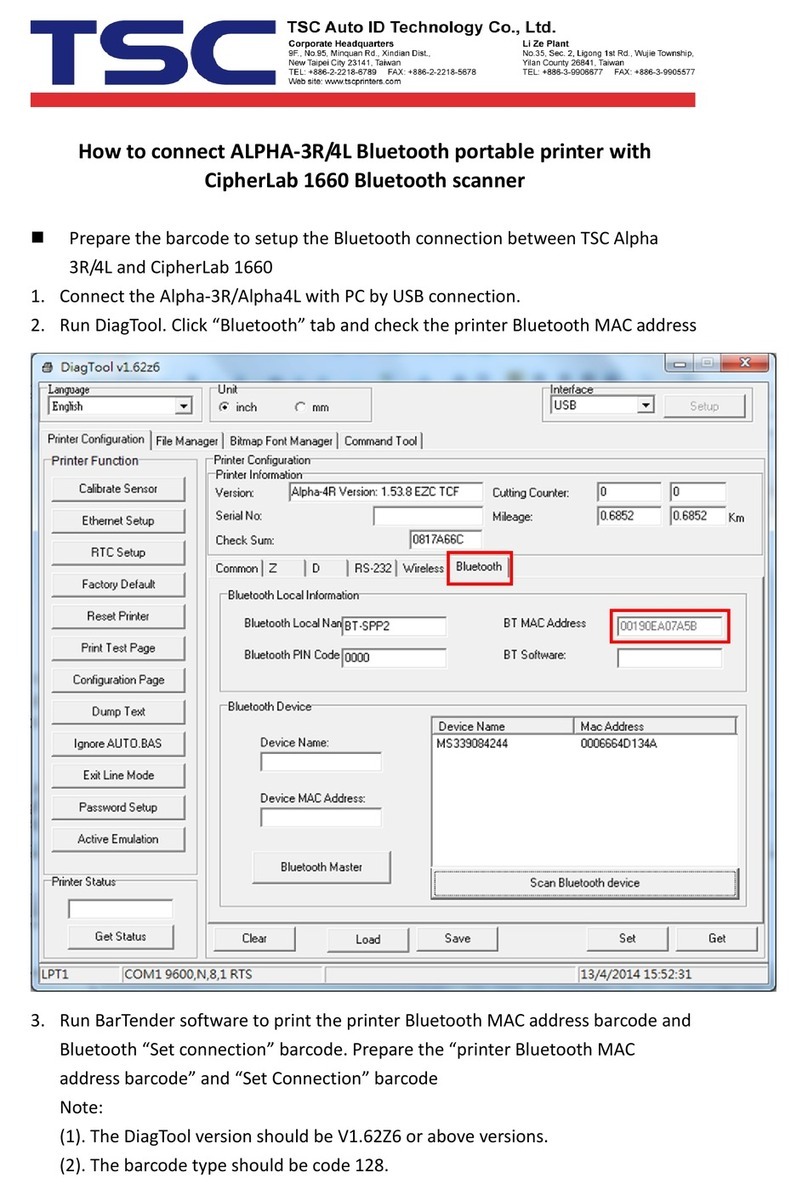

5. Diagnostic Tool..................................................................................................27

5.1 Start the Diagnostic Tool ............................................................................ 27

5.2 Printer Function........................................................................................... 28