TABLE OF CONTENT

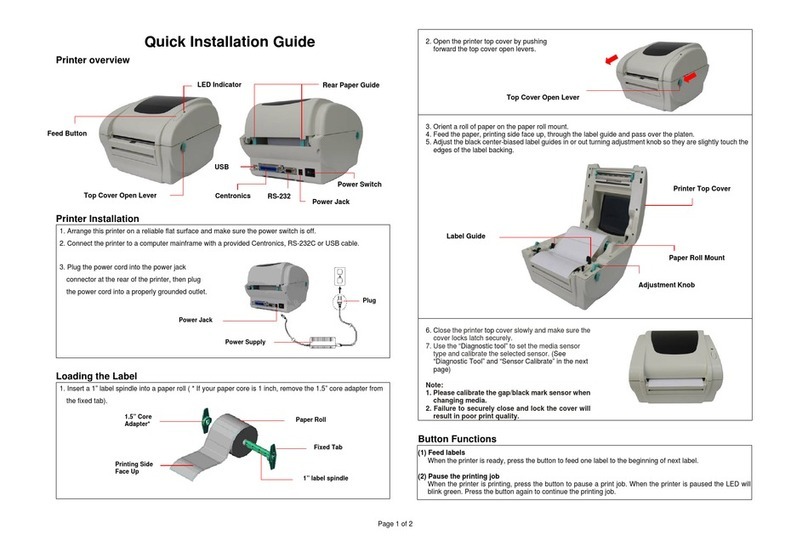

1. OVERVIEW................................................................................................................1

1.1 Front View ...............................................................................................................1

1.2 Interior View ............................................................................................................2

1.3 Rear View.................................................................................................................1

2. ELECTRONICS..........................................................................................................3

2.1 Summary of Board Connectors.............................................................................3

2.2 Pin Configuration....................................................................................................7

3. MECHANISM.............................................................................................................9

3.1 Replacing the Print Engine Mechanism................................................................9

3.2 Replacing the Main Board....................................................................................12

3.3 Replacing the Gap Sensor Module......................................................................13

3.4 Replacing the Black-mark Sensor Module .........................................................14

3.5 Replacing the Stepping Motor.............................................................................15

3.6 Replacing the Platen Roller Assembly................................................................16

3.7 Replacing the Print Head Module........................................................................18

3.8 Replacing the Key Module (LCD Module/Option) ..............................................20

3.9 Replacing the DC Motor Module..........................................................................21

3.10 Peel-off Module Installation (Option) ................................................................22

3.11 Cutter Module Installation (Option)...................................................................24

4. TROUBLESHOOTING.............................................................................................26

4.1 LED Status.............................................................................................................26

4.2 Print Quality ..........................................................................................................27

5. MAINTENANCE.......................................................................................................30

UPDATE HISTORY......................................................................................................32