Page 6

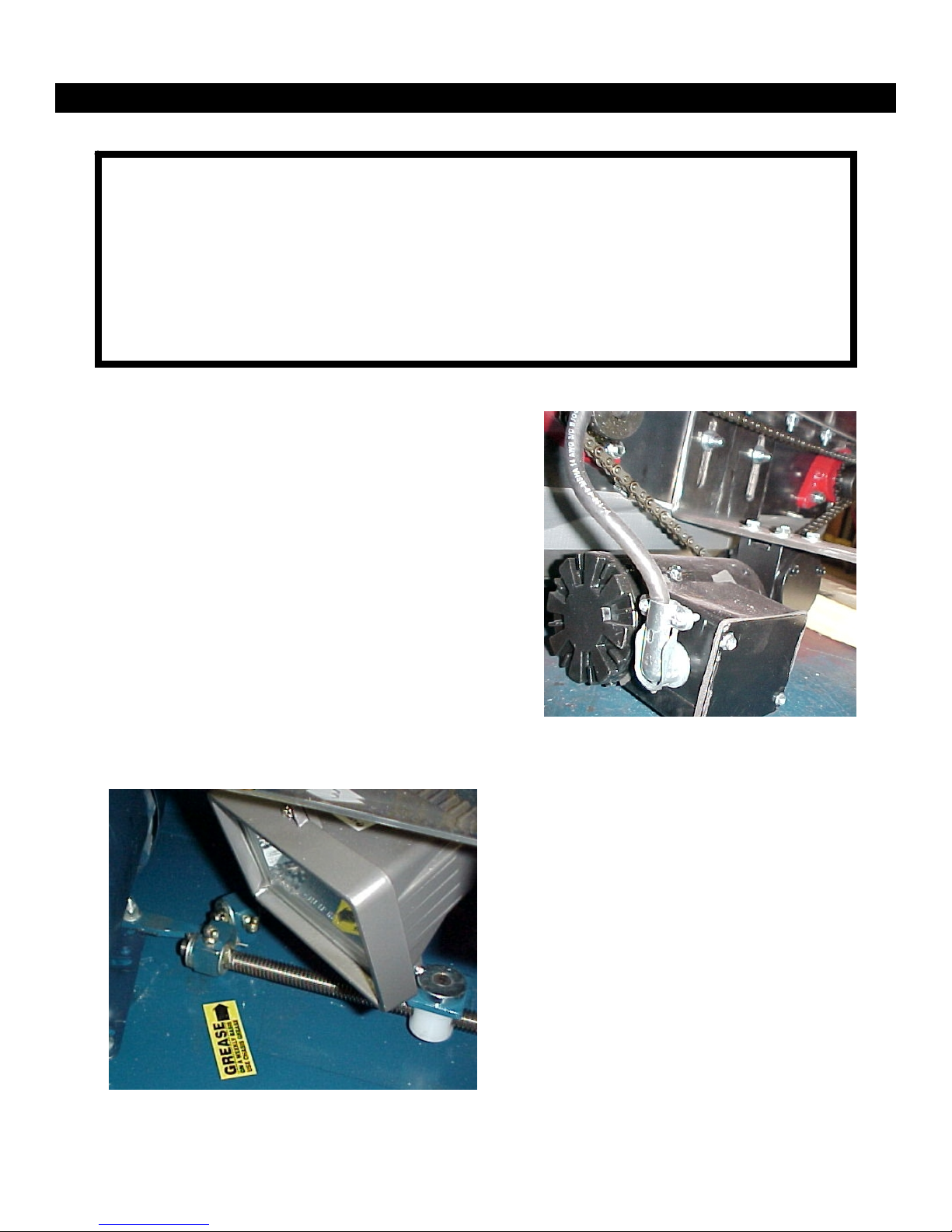

Fig. 6 shows the gear motor used to

drive the rubber coated rollers. Adjust

chain tension using the slots in the

mounting plate and the 3/8 bolts and

hardware.

Optimum chain tension is ±1/8 inch

maximum deflection between the roller

driven gear sprockets.

It is preferred to use dry spray graphite

(not oil) on chain and sprocket drive

train. Fig. 6

At right are two grease zerks.

Lubricate each location.

Use chassis grease on all zerks.

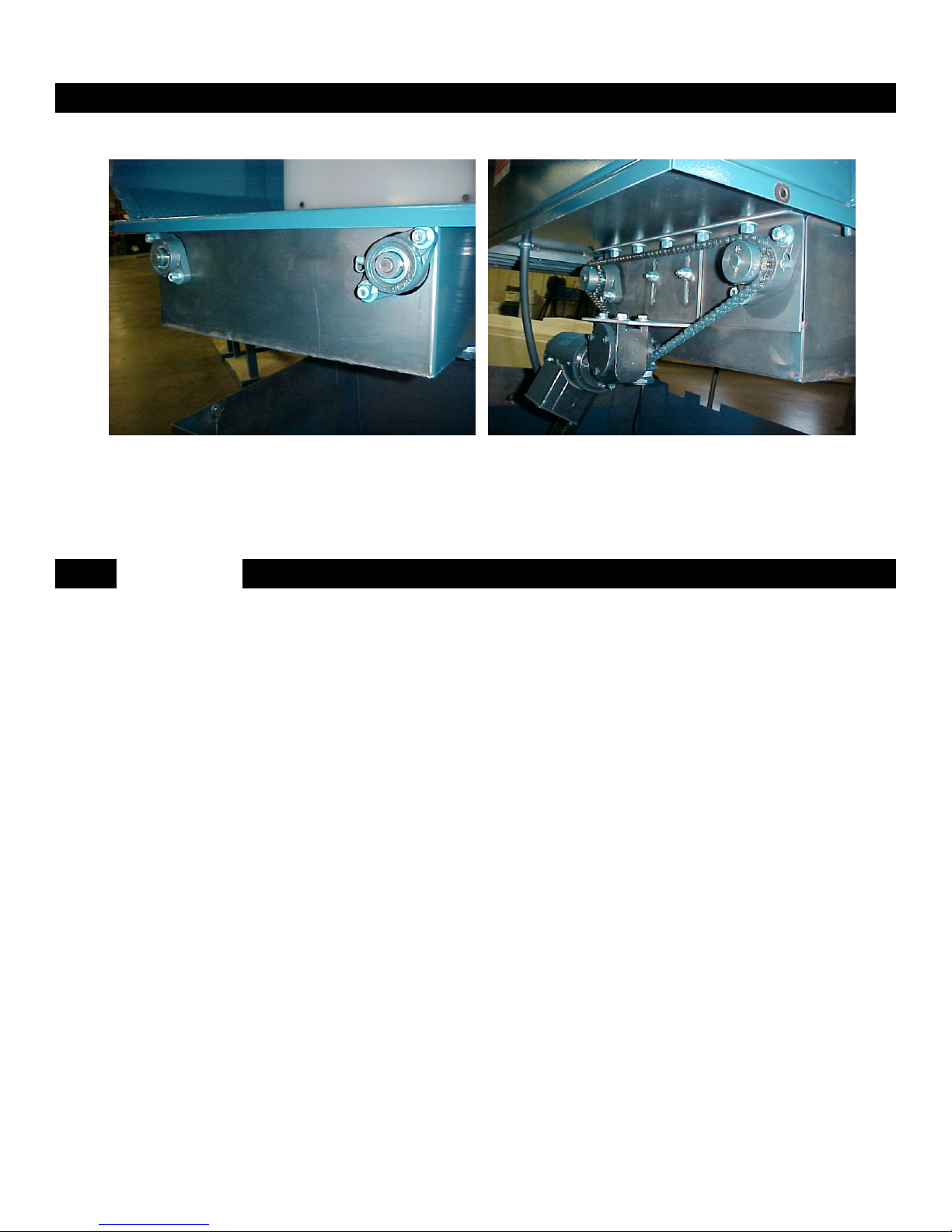

To replace the halogen light bulb

(TSI PN12170-1) unscrew the lens

frame and remove bulb. Make sure

unit is unplugged from electric power

source to do this.

Fig. 7

Caution

When removing top half of unit from lower section use caution not to place

hands or limbs between the two halves. Use blocks of wood or some other

item to brace each half before servicing or providing maintenance.

To replace each section be careful not to cut or pinch electric cords,

vacuum hose or other unit parts otherwise associated to the unit.