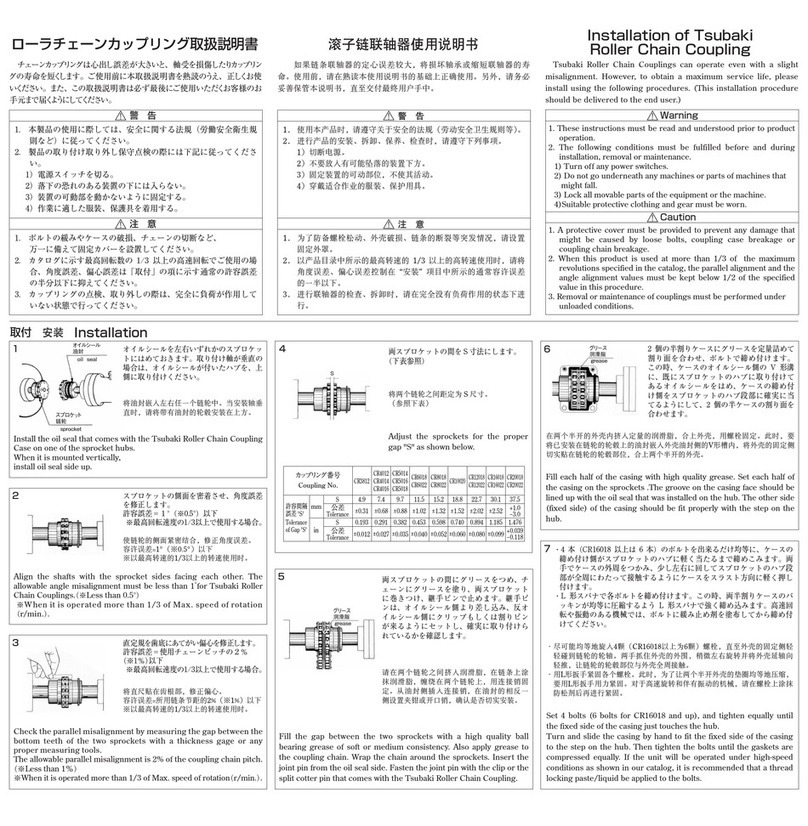

3

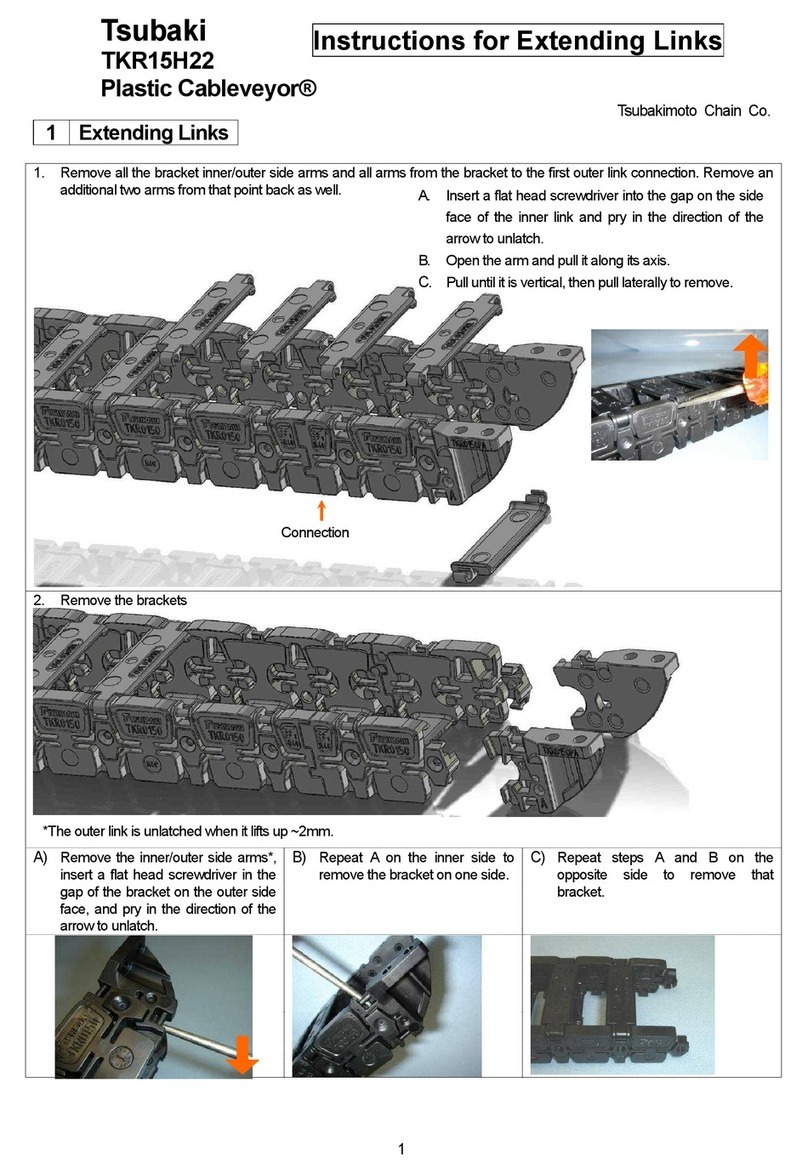

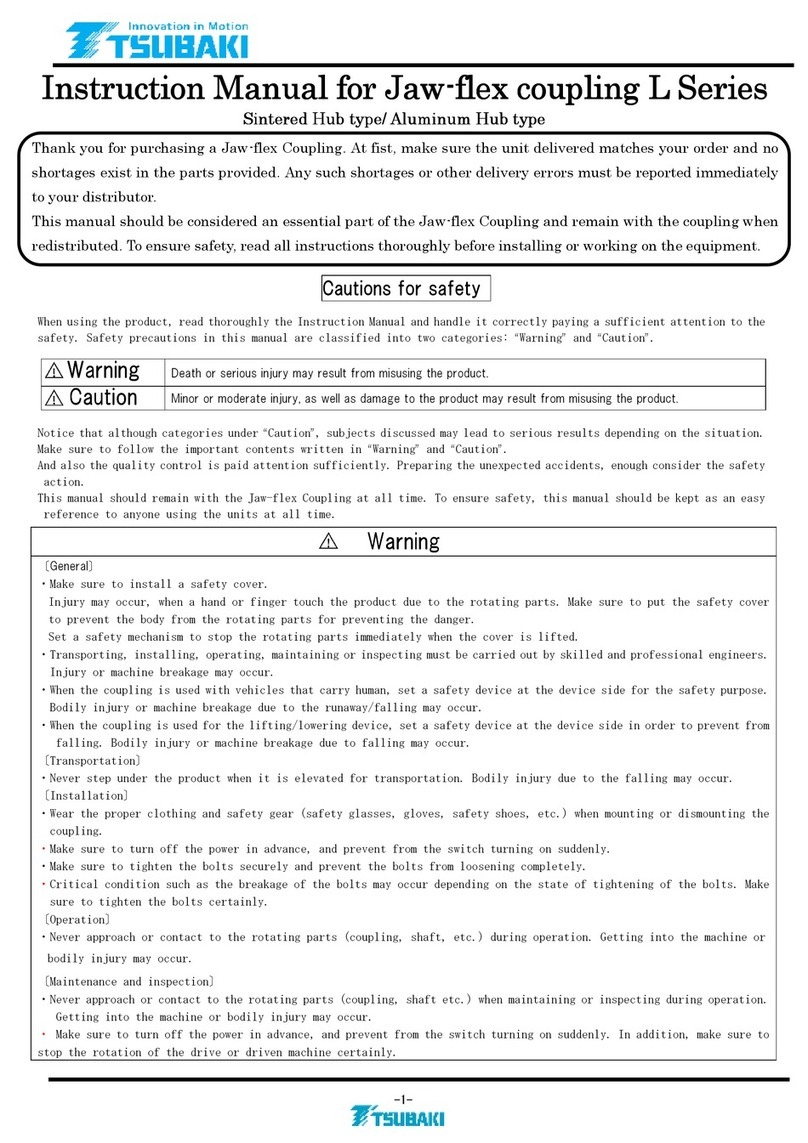

3. Disconnecting the Plastic Bracket

3-1. Find the set mark

Check that the triangular set mark on the end of

the bracket and the screwdriver mark printed on

the arm side of the bracket are aligned.

3-2. Disconnect the bracket

Insert a screwdriver into the groove between the

triangular mark and screwdriver mark on the

bracket. Pry open in the direction of the triangular

mark to release the lock. Release the lock on the

other side in the same way and remove the arm.

Flip the Cableveyor over and release the locks on

the opposite side.

Caution: Use a flat-head screwdriver with a narrow tip.

Forcefully inserting a broad tipped screwdriver may cause

Cableveyor breakage.

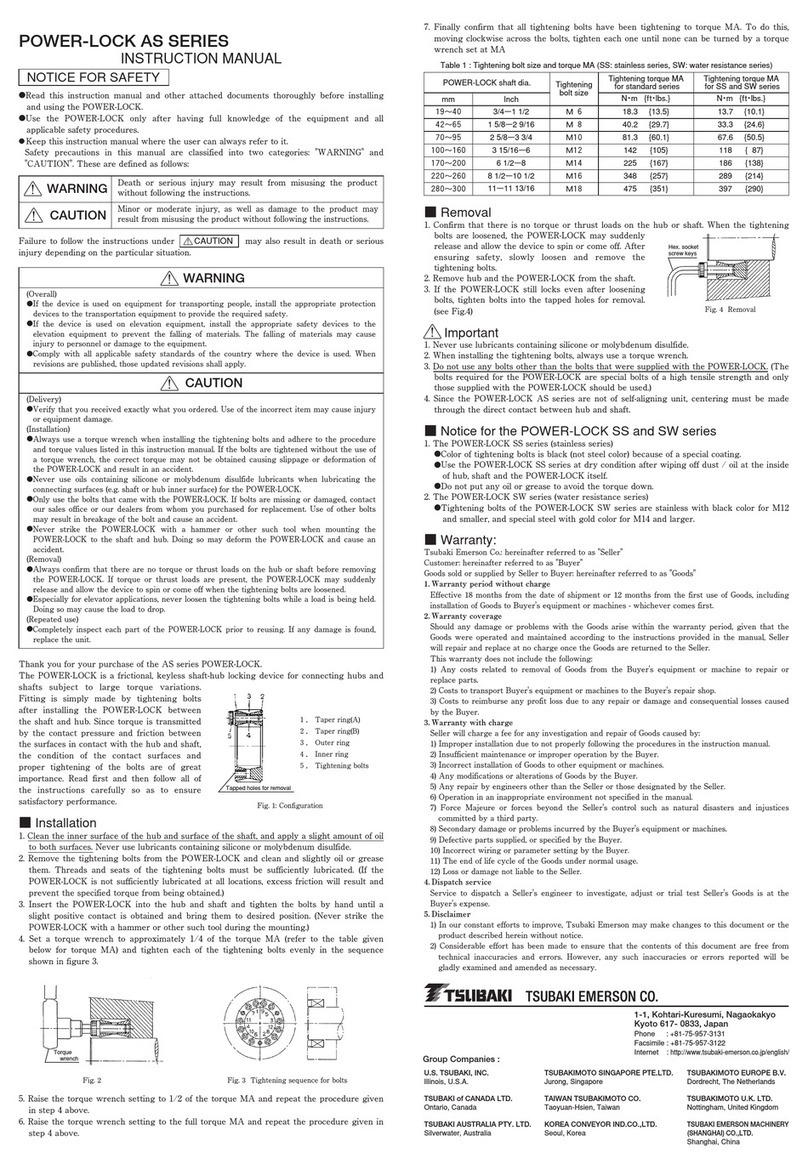

3-3. Bracket assembly

Insert the projection on the opposite side of the

screwdriver mark on the bracket arm diagonally into

the groove on the bracket. When you do so, the

screwdriver mark and the triangular mark on the

bracket will align in the same direction. (The arm

shape in the opposite direction differs and the arm will

not insert.) With both left and right sides properly

inserted into the grooves, push the arm down in the

direction of the screwdriver mark until you hear a click.

If you cannot push the arm in by hand, tap it in lightly

with a plastic hammer.

3-4. Points on fastening the bolts on both ends of the plastic bracket.

1) There is a risk of breakage if there is any unevenness on the surface where the plastic bracket will be attached.

Ensure the attachment face is as smooth and level as possible.

2) Be careful so as not to over-tighten the plastic bracket attachment bolts and cause breakage. Always insert a washer

between the bolt and the plastic bracket for brackets with straight holes.

3) The plastic brackets are made of resin with a high elastic deformation. Conduct regular inspections to ensure that

bolts have not loosed.

Recommended M8 bolt fastening torque: 3.9N

m (0.4kg

m)

Triangular

mark

Screwdriver mar

Use a screwdriver with a 4.5mm or

smaller ti

.