- 1 -

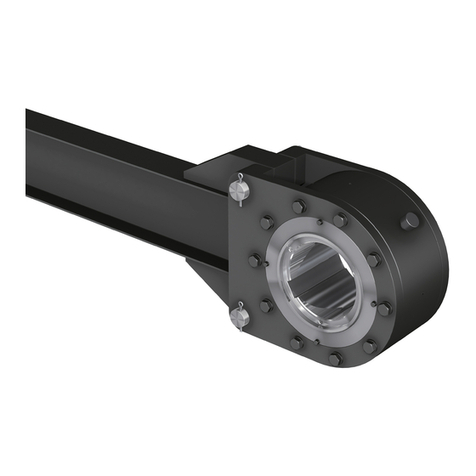

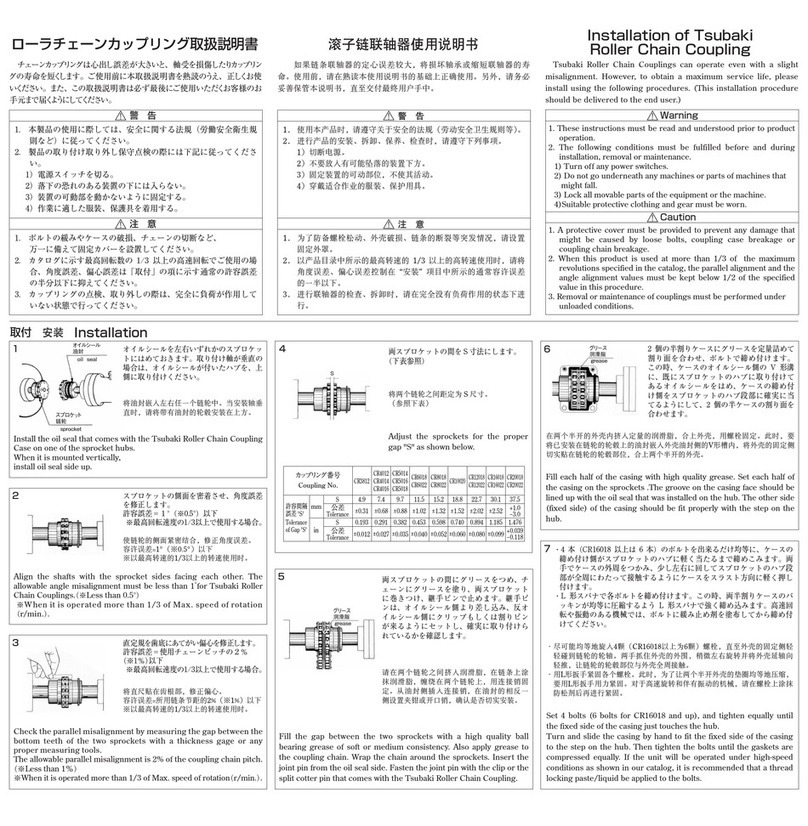

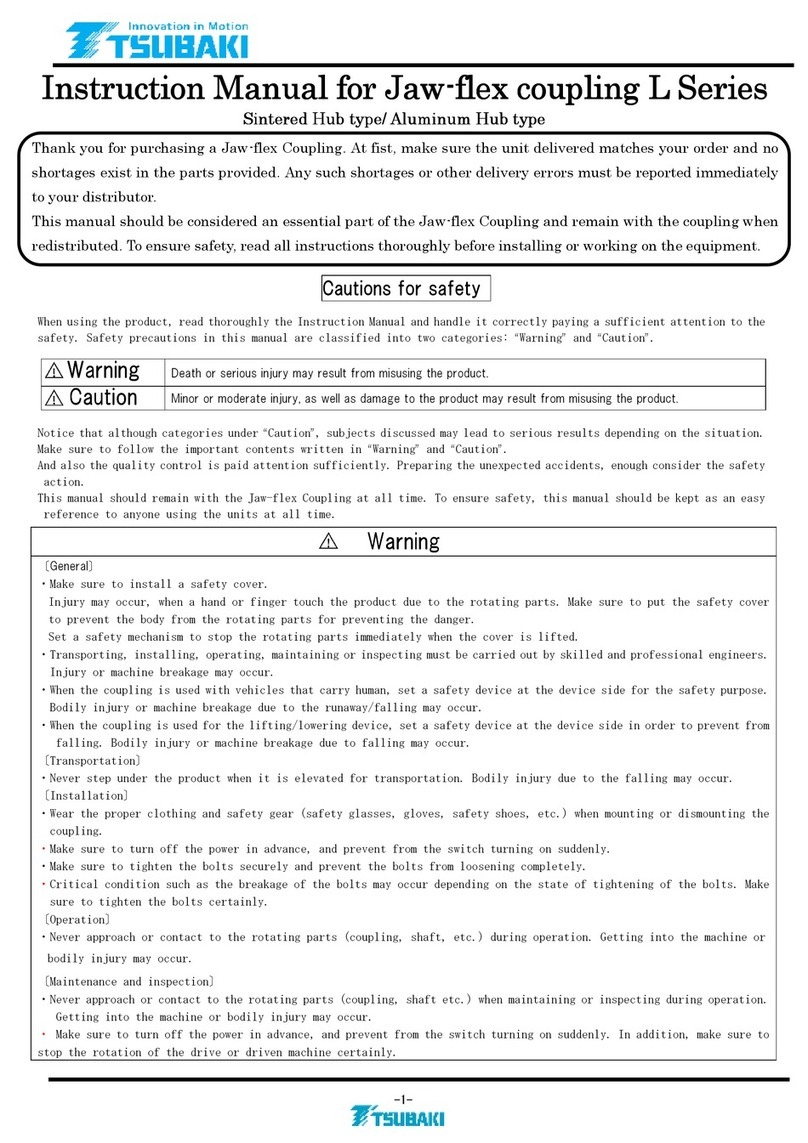

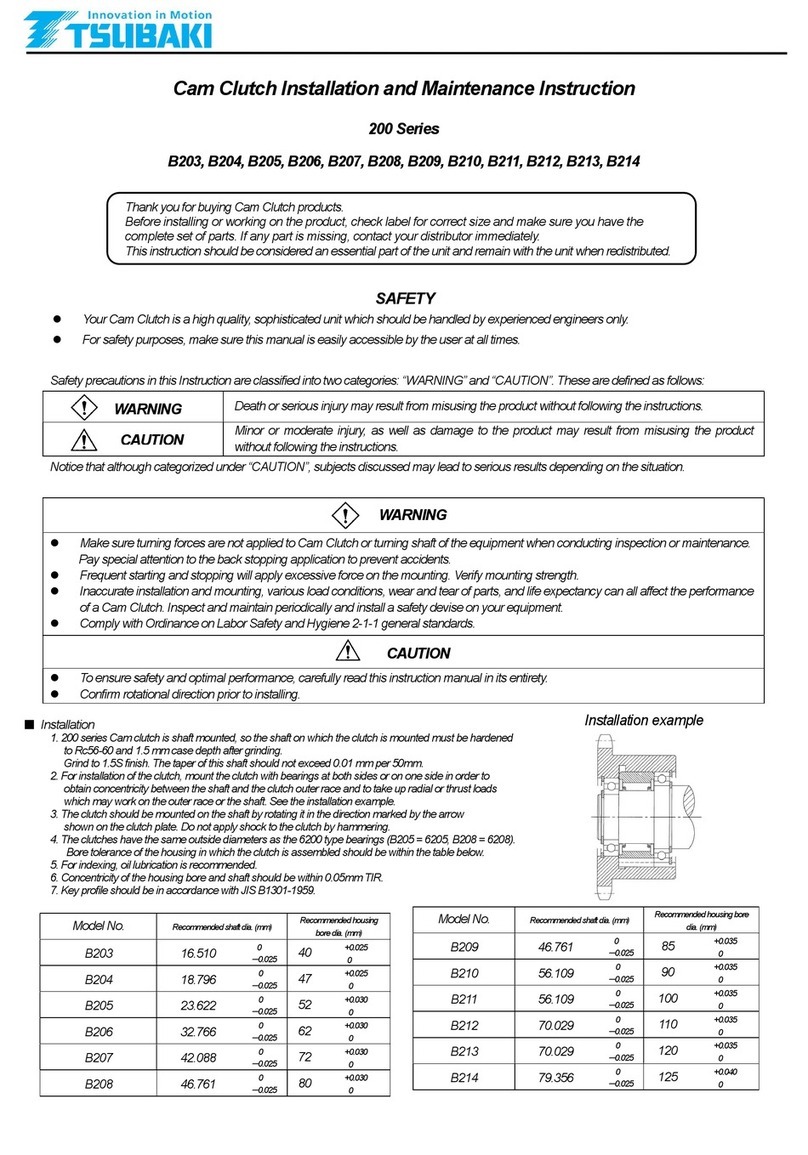

Cam Clutch Installation and Maintenance Instruction

MGUS Series / MIUS Series

MGUS300, MGUS400, MGUS500, MGUS600, MGUS700, MGUS750, MGUS800, MGUS900, MGUS1000

MIUS300, MIUS400, MIUS500, MIUS600, MIUS700, MIUS750, MIUS800, MIUS900, MIUS1000

Thank you for choosing Tsubaki E&M products.

Before installing or working on the product, confirm it is the correct size by checking its label and make sure you have the complete set of arts.

If any part is missing, contact your distributor immediately.

This manual should be considered an essential part of the unit and remain with the unit when redistributed.

SAFETY

1. Your Cam Clutch is a high quality, sophisticated unit which should be handled by experienced engineers only.

2. For safety purposes, make sure this manual is easily accessible by the user at all times.

3. To ensure safety and optimal performance,carefully read this instruction manual in its entirety.

Death or serious injury may result from misuse, improper installation and/or improper maintenance of

th

is product. Please refer to the detailed instructions provided in this manual for installation and

maintenance specifications.

USE CARE TO PREVENT INJURY

COMPLY WITH THE FOLLOWING TO

AVOID SERIOUS PERSONAL INJURY:

1. Guards must be provided on all chain and sprocket installations in

accordance with provisions of ANSI/ASME B15.1 -2000

“Safety Standards for Mechanical Power Transmission Apparatus,” and

ANSI/ASME B20.1 -2012 “Safety Standards for Conveyors and Related

Equipment,” or other applicable safety standards. When revisions of

these standards are published, the updated edition shall apply.

2. Always lock out the power switch before installing, removing, lubricating

or servicing a system which uses PTUC product.

3. When connecting or disconnecting PTUC products, eye protection is required.

Wear safety glasses, protective clothing, gloves and safety shoes.

4. Improper installation or mounting, as well as operating conditions and maintenance,

can affect the performance of a cam clutch. The cam clutch should be inspected regularly.

“PTUC is used by U.S. Tsubaki to designate “PowerTransmission Unit Components.”

PTUC products include Cam Clutch DISCO, POWER-LOCK

Ⓡ

, Shock Relay, Gearmotor,

HF Drive, Shock Damper, Power cylinderTM , Couplings, SCR variable speed motor and

other like products manufactured by/forTsubaki.