7.FinallyconfirmthatalltighteningboltshavebeentighteningtotorqueMA.Todothis,

movingclockwiseacrossthebolts,tighteneachoneuntilnonecanbeturnedbyatorque

wrenchsetatMA

■Removal

1.Confirmthatthereisnotorqueorthrustloadsonthehuborshaft.Whenthetightening

boltsareloosened,the POWER-LOCK maysuddenly

releaseandallowthedevicetospinorcomeoff.After

ensuring safety, slowly loosen and remove the

tighteningbolts.

2.RemovehubandthePOWER-LOCKfromtheshaft.

3. If the POWER-LOCK still locks even after loosening

bolts,tightenboltsintothetappedholesforremoval.

(seeFig.4)

Important

1.Neveruselubricantscontainingsiliconeormolybdenumdisulfide.

2.Wheninstallingthetighteningbolts,alwaysuseatorquewrench.

3.DonotuseanyboltsotherthantheboltsthatweresuppliedwiththePOWER-LOCK.(The

boltsrequiredforthePOWER-LOCKarespecialboltsofahightensilestrengthandonly

thosesuppliedwiththePOWER-LOCKshouldbeused.)

4.Sincethe POWER-LOCKASseriesare notofself-aligningunit, centeringmustbe made

throughthedirectcontactbetweenhubandshaft.

■NoticeforthePOWER-LOCKSSandSWseries

1.ThePOWER-LOCKSSseries(stainlessseries)

●Coloroftighteningboltsisblack(notsteelcolor)becauseofaspecialcoating.

●UsethePOWER-LOCKSSseriesatdryconditionafterwipingoffdust/oilattheinside

ofhub,shaftandthePOWER-LOCKitself.

●Donotputanyoilorgreasetoavoidthetorquedown.

2.ThePOWER-LOCKSWseries(waterresistanceseries)

●TighteningboltsofthePOWER-LOCKSWseriesarestainlesswithblackcolorforM12

andsmaller,andspecialsteelwithgoldcolorforM14andlarger.

■Warranty:

TsubakiEmersonCo.:hereinafterreferredtoas"Seller"

Customer:hereinafterreferredtoas"Buyer"

GoodssoldorsuppliedbySellertoBuyer:hereinafterreferredtoas"Goods"

1. Warrantyperiodwithoutcharge

Effective18monthsfromthedateofshipmentor12monthsfromthefirstuseofGoods,including

installationofGoodstoBuyer'sequipmentormachines-whichevercomesfirst.

2. Warrantycoverage

Shouldanydamage or problemswiththe Goodsarisewithin the warrantyperiod,given that the

Goodswereoperated and maintainedaccordingto theinstructionsprovidedin themanual,Seller

willrepairandreplaceatnochargeoncetheGoodsarereturnedtotheSeller.

Thiswarrantydoesnotincludethefollowing:

1) Any costs related to removal of Goods from the Buyer's equipment or machine to repair or

replaceparts.

2)CoststotransportBuyer'sequipmentormachinestotheBuyer'srepairshop.

3)Coststoreimburseanyprofitlossduetoanyrepairordamageandconsequentiallossescaused

bytheBuyer.

3. Warrantywithcharge

SellerwillchargeafeeforanyinvestigationandrepairofGoodscausedby:

1)Improperinstallationduetonotproperlyfollowingtheproceduresintheinstructionmanual.

2)InsufficientmaintenanceorimproperoperationbytheBuyer.

3)IncorrectinstallationofGoodstootherequipmentormachines.

4)AnymodificationsoralterationsofGoodsbytheBuyer.

5)AnyrepairbyengineersotherthantheSellerorthosedesignatedbytheSeller.

6)Operationinaninappropriateenvironmentnotspecifiedinthemanual.

7) Force Majeure or forces beyond the Seller's control such as natural disasters and injustices

committedbyathirdparty.

8)SecondarydamageorproblemsincurredbytheBuyer'sequipmentormachines.

9)Defectivepartssupplied,orspecifiedbytheBuyer.

10)IncorrectwiringorparametersettingbytheBuyer.

11)TheendoflifecycleoftheGoodsundernormalusage.

12)LossordamagenotliabletotheSeller.

4. Dispatchservice

Service to dispatch a Seller's engineer to investigate, adjust or trial test Seller's Goods is at the

Buyer'sexpense.

5. Disclaimer

1)Inourconstanteffortstoimprove,TsubakiEmersonmaymakechangestothisdocumentorthe

productdescribedhereinwithoutnotice.

2)Considerableefforthas been made to ensurethatthecontents of this document arefreefrom

technical inaccuracies and errors. However, any such inaccuracies or errors reported will be

gladlyexaminedandamendedasnecessary.

●Read this instruction manual and other attached documents thoroughly before installing

andusingthePOWER-LOCK.

●Use the POWER-LOCK only after having full knowledge of the equipment and all

applicablesafetyprocedures.

●Keepthisinstructionmanualwheretheusercanalwaysrefertoit.

Safety precautions in this manual are classified into two categories: "WARNING" and

"CAUTION".Thesearedefinedasfollows:

FailuretofollowtheinstructionsunderCAUTION mayalsoresultindeathorserious

injurydependingontheparticularsituation.

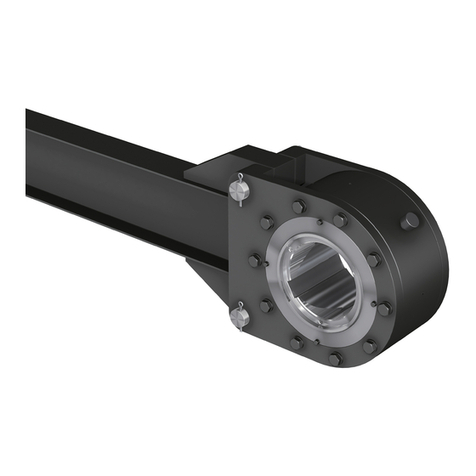

ThankyouforyourpurchaseoftheASseriesPOWER-LOCK.

ThePOWER-LOCKisafrictional,keylessshaft-hublockingdeviceforconnectinghubsand

shafts subject to large torque variations.

Fitting is simply made by tightening bolts

after installing the POWER-LOCK between

theshaftandhub.Sincetorqueistransmitted

by the contact pressure and friction between

thesurfacesincontactwiththehubandshaft,

the condition of the contact surfaces and

proper tightening of the bolts are of great

importance. Read first and then follow all of

the instructions carefully so as to ensure

satisfactoryperformance.

■Installation

1.Cleantheinnersurfaceofthehubandsurfaceoftheshaft,andapplyaslightamountofoil

tobothsurfaces.Neveruselubricantscontainingsiliconeormolybdenumdisulfide.

2.RemovethetighteningboltsfromthePOWER-LOCKandcleanandslightlyoilorgrease

them. Threads and seats of the tightening bolts must be sufficiently lubricated. (If the

POWER-LOCKisnotsufficientlylubricatedatalllocations,excessfrictionwillresultand

preventthespecifiedtorquefrombeingobtained.)

3. Insert the POWER-LOCK into the hub and shaft and tighten the bolts by hand until a

slight positive contact is obtained and bring them to desired position. (Never strike the

POWER-LOCKwithahammerorothersuchtoolduringthemounting.)

4. Set a torque wrench to approximately 1/4 of the torque MA (refer to the table given

below for torque MA) and tighten each of the tightening bolts evenly in the sequence

showninfigure3.

5.Raisethetorquewrenchsettingto1/2ofthetorqueMAandrepeattheproceduregiven

instep4above.

6.RaisethetorquewrenchsettingtothefulltorqueMAandrepeattheproceduregivenin

step4above.

Hex.socket

screwkeys

Torque

wrench

Tappedholesforremoval

CAUTION

WARNING

POWER-LOCKASSERIES

INSTRUCTIONMANUAL

NOTICEFORSAFETY

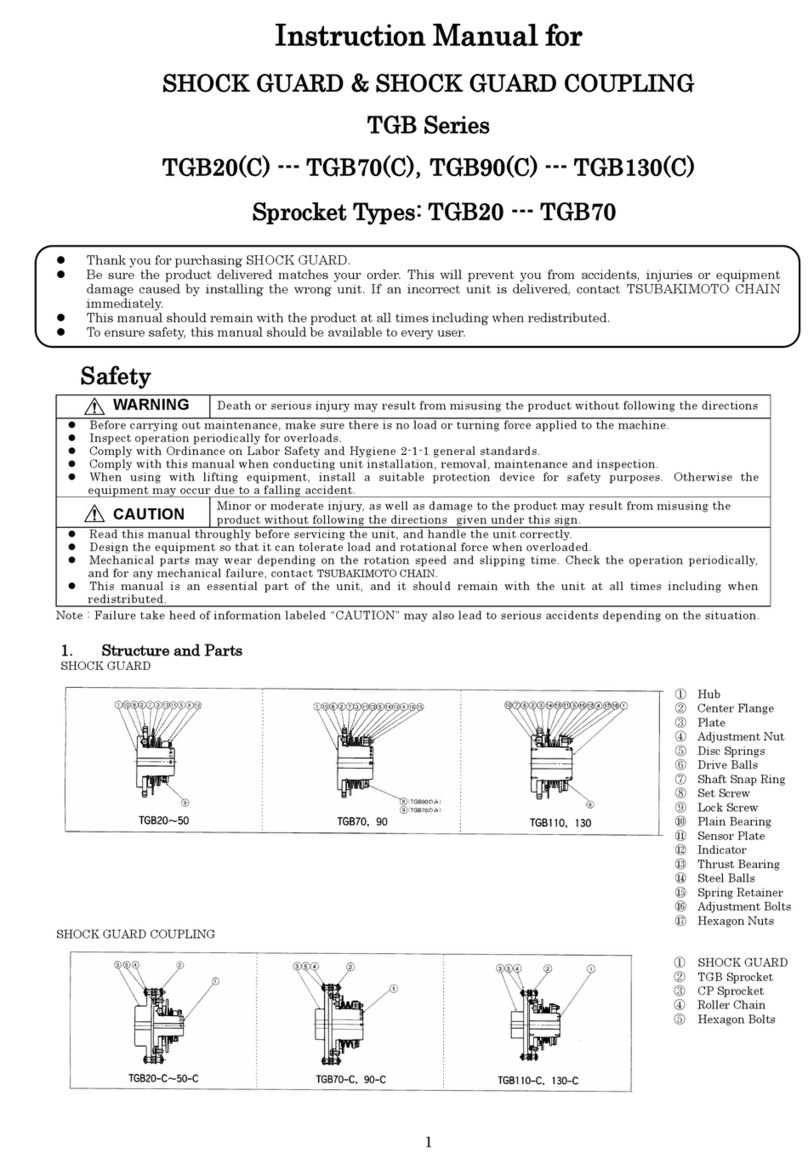

1.Taperring(A)

2.Taperring(B)

3.Outerring

4.Innerring

5.Tighteningbolts

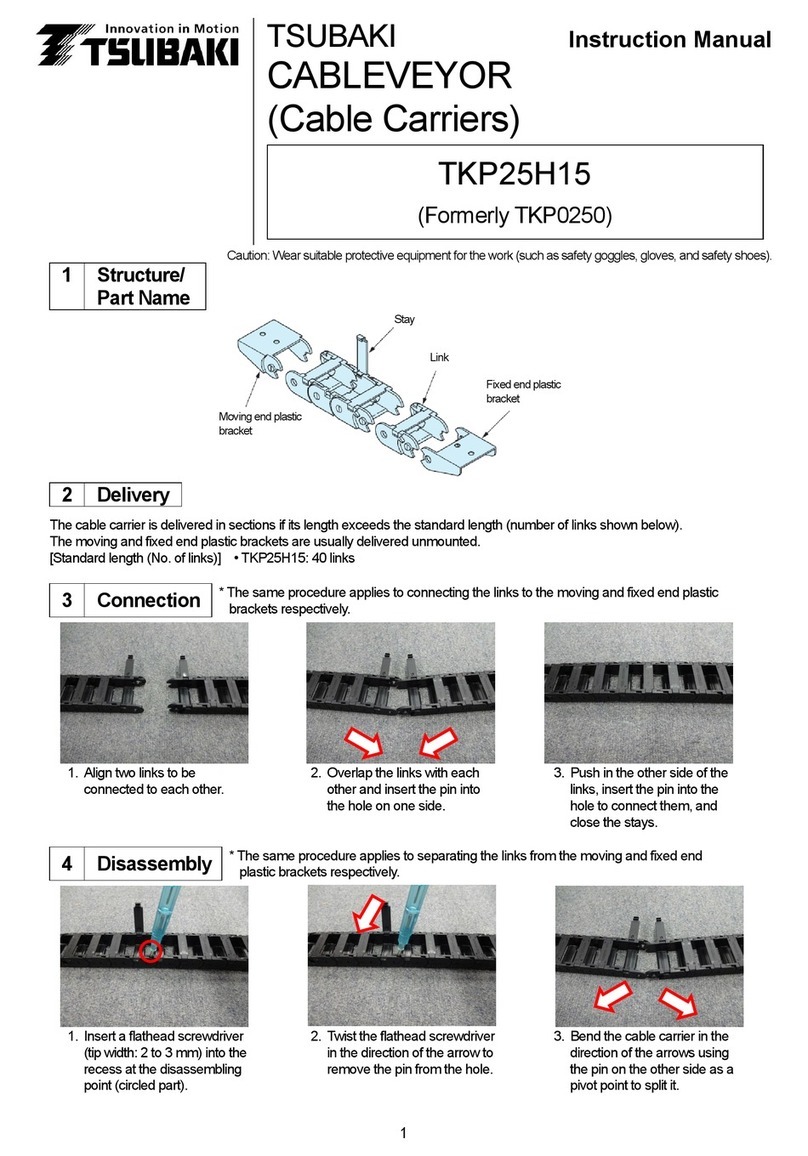

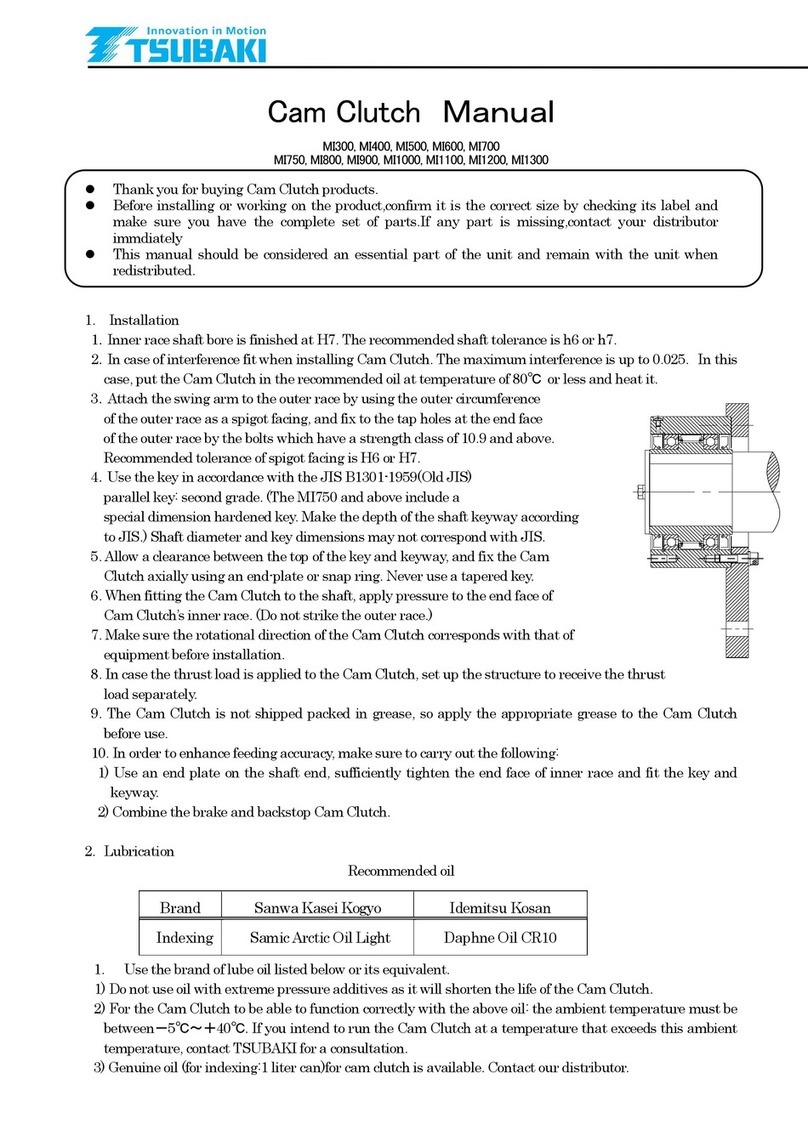

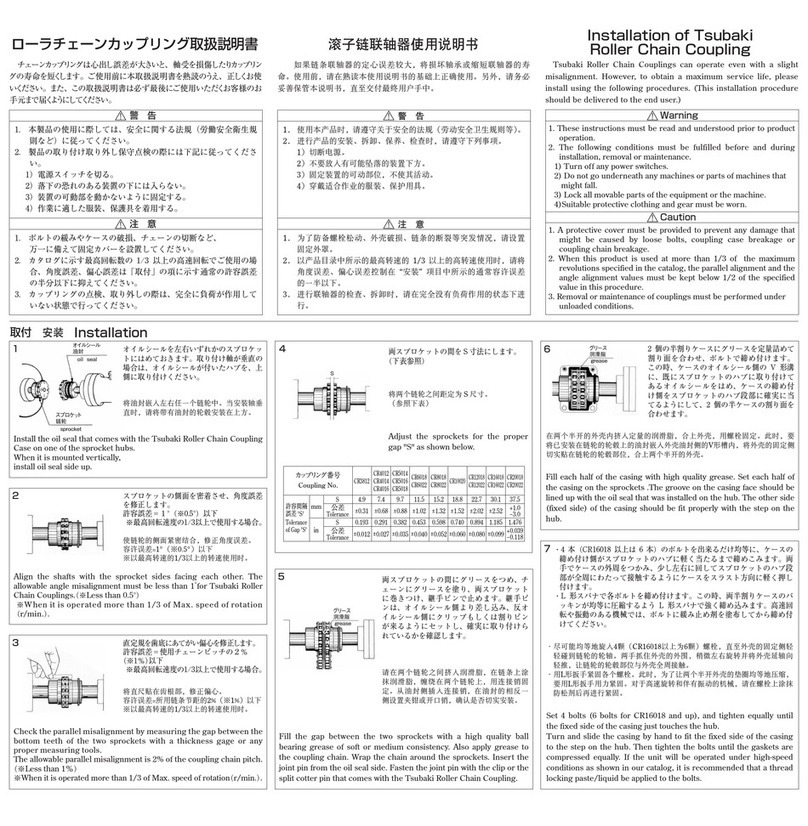

Fig.1:Configuration

Fig.2 Fig.3Tighteningsequenceforbolts

Fig.4Removal

(Overall)

●If the device is used on equipment for transporting people, install the appropriate protection

devicestothetransportationequipmenttoprovidetherequiredsafety.

●If the device is used on elevation equipment, install the appropriate safety devices to the

elevation equipment to prevent the falling of materials. The falling of materials may cause

injurytopersonnelordamagetotheequipment.

●Comply with all applicable safety standards of the country where the device is used. When

revisionsarepublished,thoseupdatedrevisionsshallapply.

(Delivery)

●Verifythatyoureceivedexactlywhatyouordered.Useoftheincorrectitemmaycauseinjury

orequipmentdamage.

(Installation)

●Alwaysuseatorquewrenchwheninstallingthetighteningboltsandadheretotheprocedure

andtorquevalueslistedinthisinstructionmanual.Iftheboltsaretightenedwithouttheuseof

atorquewrench,the correct torque maynotbeobtained causing slippage ordeformationof

thePOWER-LOCKandresultinanaccident.

●Never use oils containing silicone or molybdenum disulfide lubricants when lubricating the

connectingsurfaces(e.g.shaftorhubinnersurface)forthePOWER-LOCK.

●OnlyusetheboltsthatcamewiththePOWER-LOCK.Ifboltsaremissingordamaged,contact

oursalesoffice orour dealersfromwhom youpurchasedfor replacement.Useof otherbolts

mayresultinbreakageoftheboltandcauseanaccident.

●Never strike the POWER-LOCK with a hammer or other such tool when mounting the

POWER-LOCKtotheshaft and hub. Doing so maydeformthePOWER-LOCK and cause an

accident.

(Removal)

●Alwaysconfirmthattherearenotorqueorthrustloadsonthehuborshaftbeforeremoving

the POWER-LOCK. If torque or thrust loads are present, the POWER-LOCK may suddenly

releaseandallowthedevicetospinorcomeoffwhenthetighteningboltsareloosened.

●Especiallyforelevatorapplications,neverloosenthetighteningboltswhilealoadisbeingheld.

Doingsomaycausetheloadtodrop.

(Repeateduse)

●Completelyinspecteachpart of thePOWER-LOCKpriorto reusing. If anydamageis found,

replacetheunit.

Death or serious injury may result from misusing the product

withoutfollowingtheinstructions.

Minor or moderate injury, as well as damage to the product may

resultfrommisusingtheproductwithoutfollowingtheinstructions.

CAUTION

WARNING

19〜40

42〜65

70〜95

100〜160

170〜200

220〜260

280〜300

M6

M8

M10

M12

M14

M16

M18

18.3{13.5}

40.2{29.7}

81.3{60.1}

142{105}

225{167}

348{257}

475{351}

13.7{10.1}

33.3{24.6}

67.6{50.5}

118{87}

186{138}

289{214}

397{290}

mm

3/4−11/2

15/8−29/16

25/8−33/4

315/16−6

61/2−8

81/2−101/2

11−1113/16

Inch

Tightening

boltsize

TighteningtorqueMA

forstandardseries

N・m{ft・lbs.} N・m{ft・lbs.}

TighteningtorqueMA

forSSandSWseries

Table1:TighteningboltsizeandtorqueMA(SS:stainlessseries,SW:waterresistanceseries)

POWER-LOCKshaftdia.

GroupCompanies:

U.S.TSUBAKI,INC.

Illinois,U.S.A.

TSUBAKIofCANADALTD.

Ontario,Canada

TSUBAKIAUSTRALIAPTY.LTD.

Silverwater,Australia

TSUBAKIMOTOSINGAPOREPTE.LTD.

Jurong,Singapore

TAIWANTSUBAKIMOTOCO.

Taoyuan-Hsien,Taiwan

KOREACONVEYORIND.CO.,LTD.

Seoul,Korea

TSUBAKIMOTOEUROPEB.V.

Dordrecht,TheNetherlands

TSUBAKIMOTOU.K.LTD.

Nottingham,UnitedKingdom

TSUBAKIEMERSONMACHINERY

(SHANGHAI)CO.,LTD.

Shanghai,China

1-1,Kohtari-Kuresumi,Nagaokakyo

Kyoto617-0833,Japan

Phone:+81-75-957-3131

Facsimile:+81-75-957-3122

Internet:

http://www.tsubaki-emerson.co.jp/english/