Tsubaki FLATVEYOR ZP User manual

Other Tsubaki Industrial Equipment manuals

Tsubaki

Tsubaki Mini M Series User manual

Tsubaki

Tsubaki PB Series User manual

Tsubaki

Tsubaki BSEU Series Technical specifications

Tsubaki

Tsubaki CR3812 User manual

Tsubaki

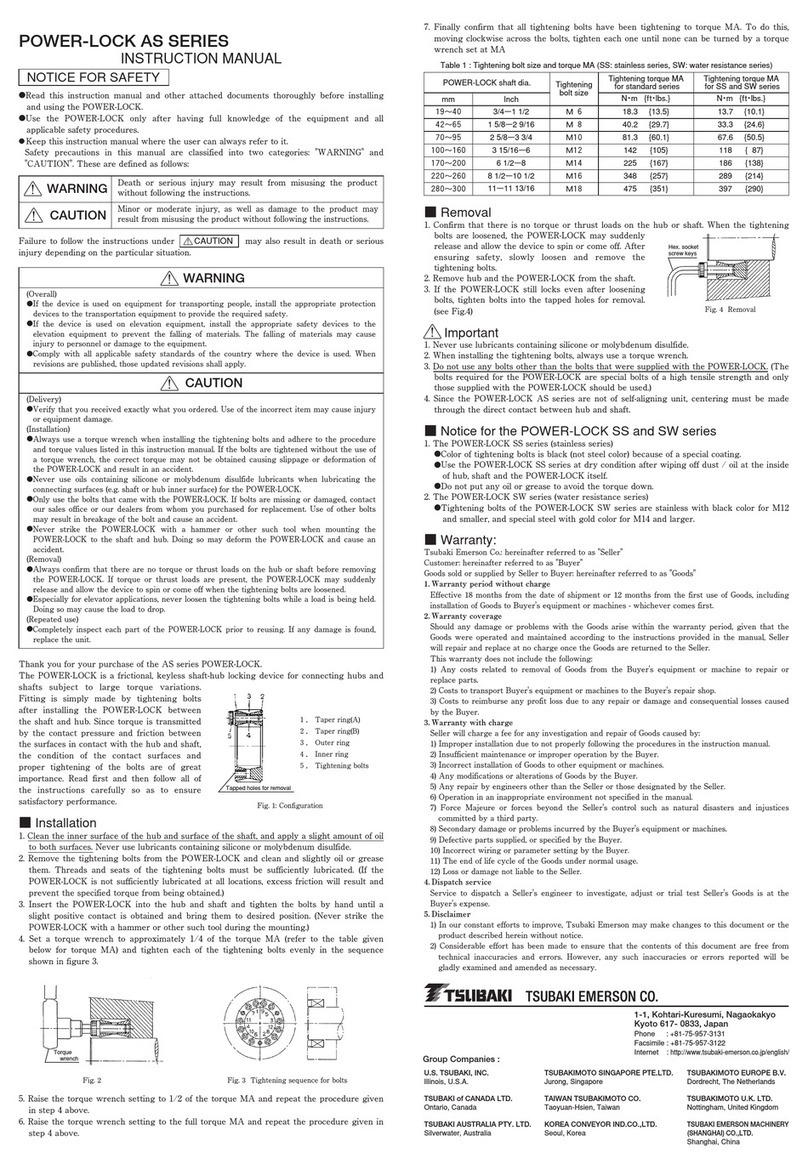

Tsubaki Power-Lock AS Series User manual

Tsubaki

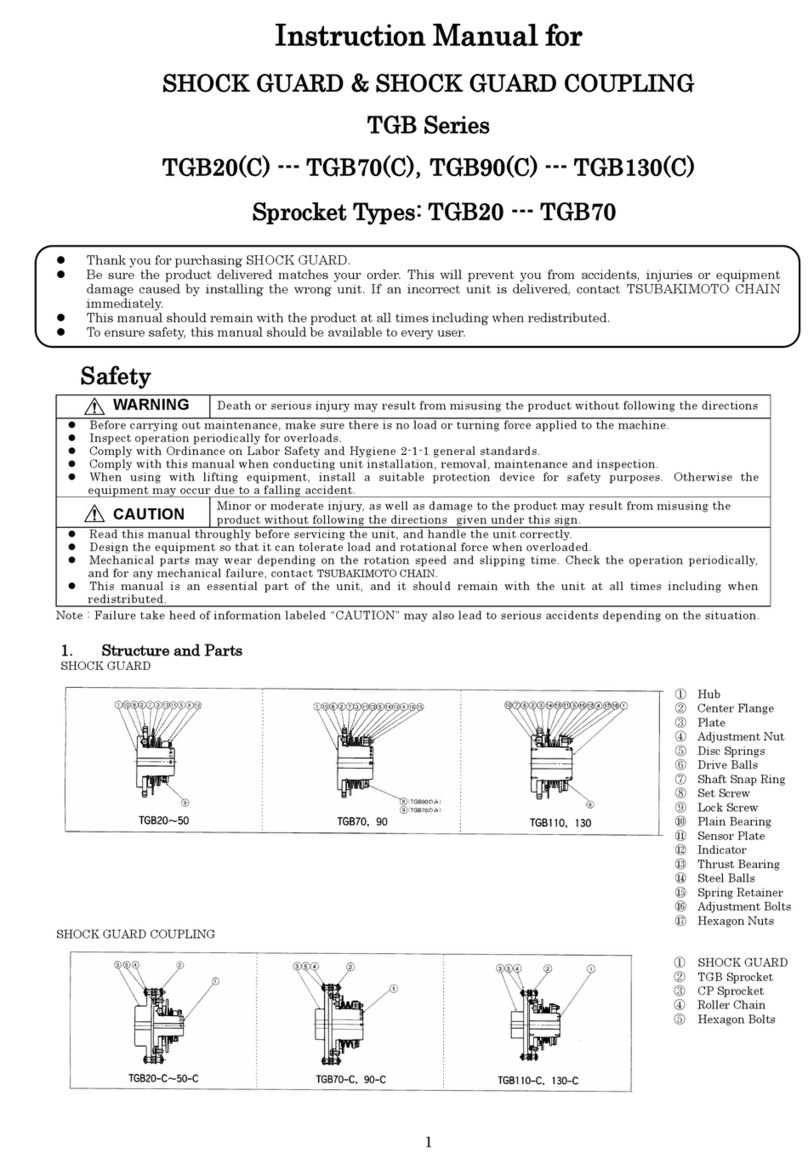

Tsubaki TGB Series User manual

Tsubaki

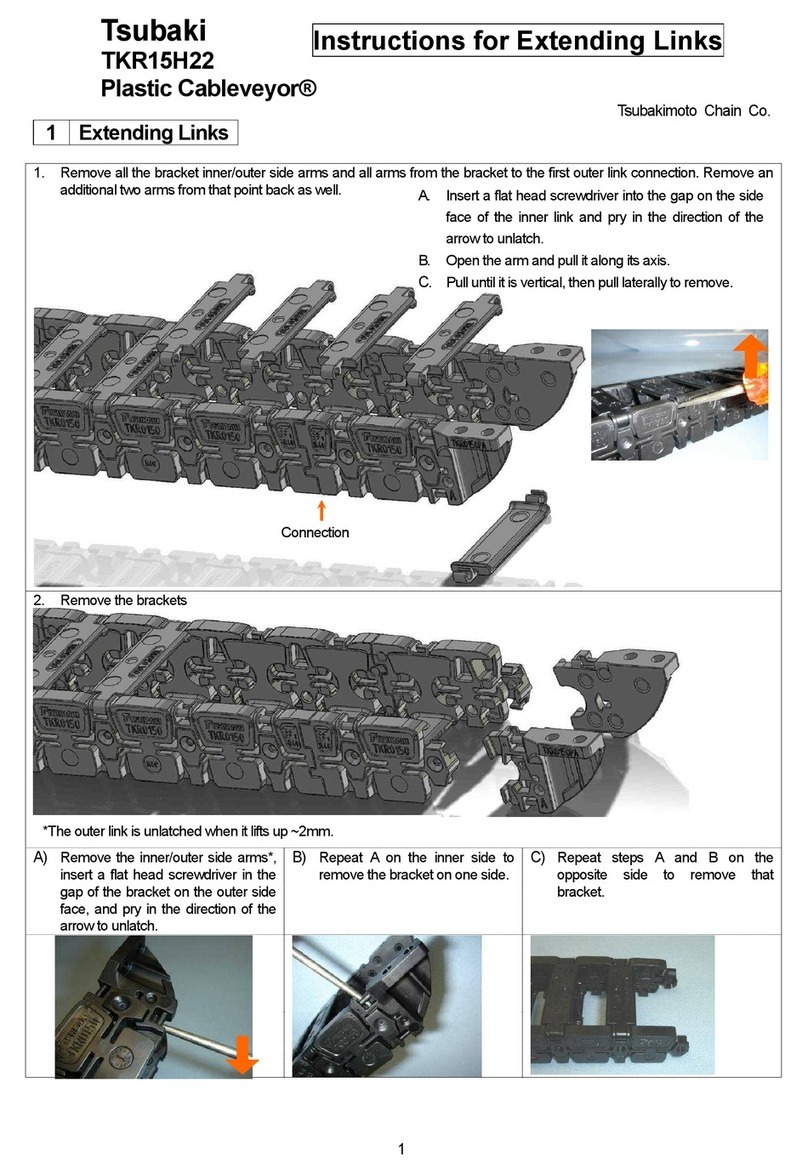

Tsubaki TKR15H22 User manual

Tsubaki

Tsubaki NES Series User manual

Tsubaki

Tsubaki MZEU Series Technical specifications

Tsubaki

Tsubaki MZ Series Technical specifications

Tsubaki

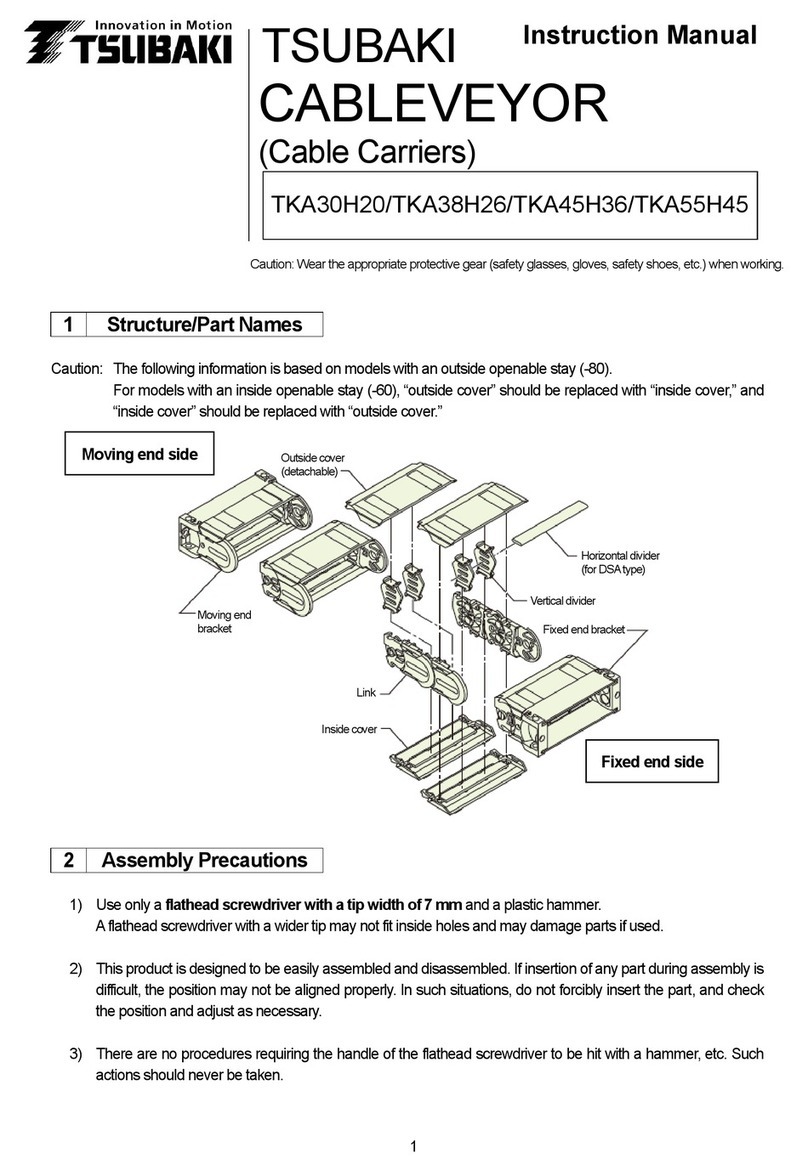

Tsubaki TKA30H20 User manual

Tsubaki

Tsubaki Backstop BS-F Series User manual

Tsubaki

Tsubaki EW Series User manual

Tsubaki

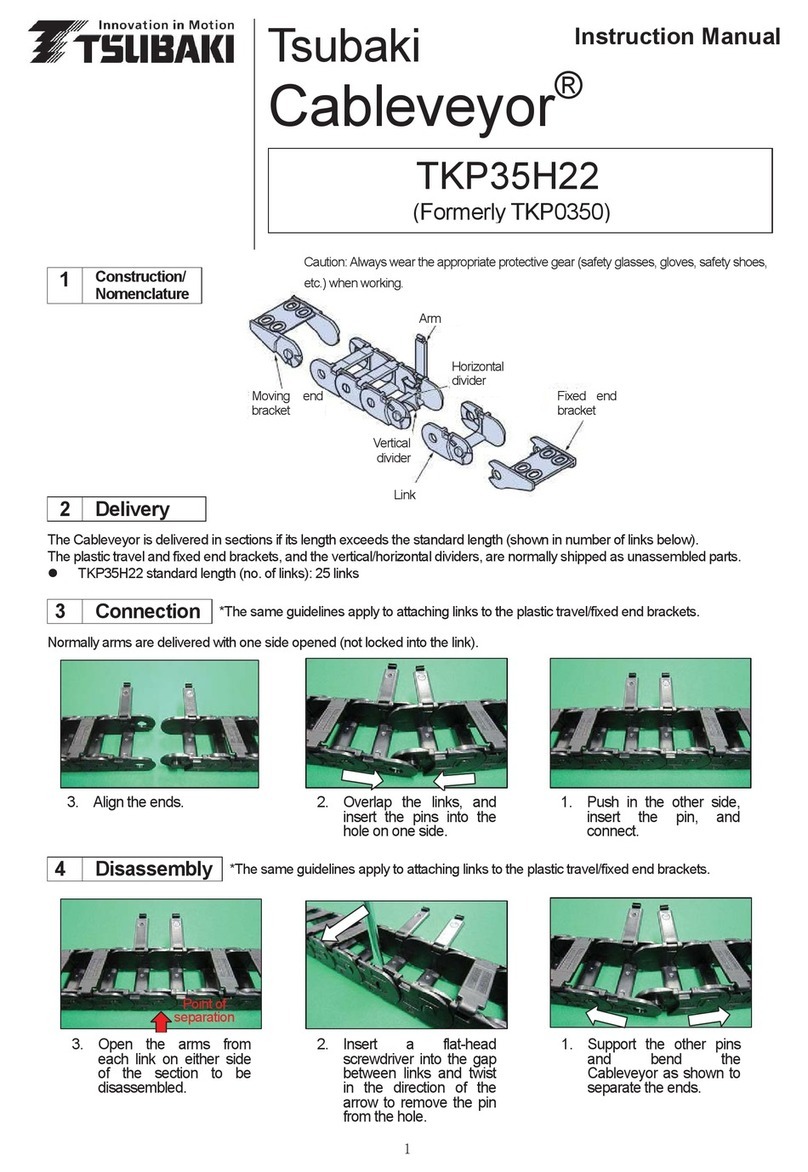

Tsubaki Cableveyor TKP35H22 User manual

Tsubaki

Tsubaki OLDHAM COUPLING User manual

Tsubaki

Tsubaki BB Series User manual

Tsubaki

Tsubaki Cableveyor TKP68H46 User manual

Tsubaki

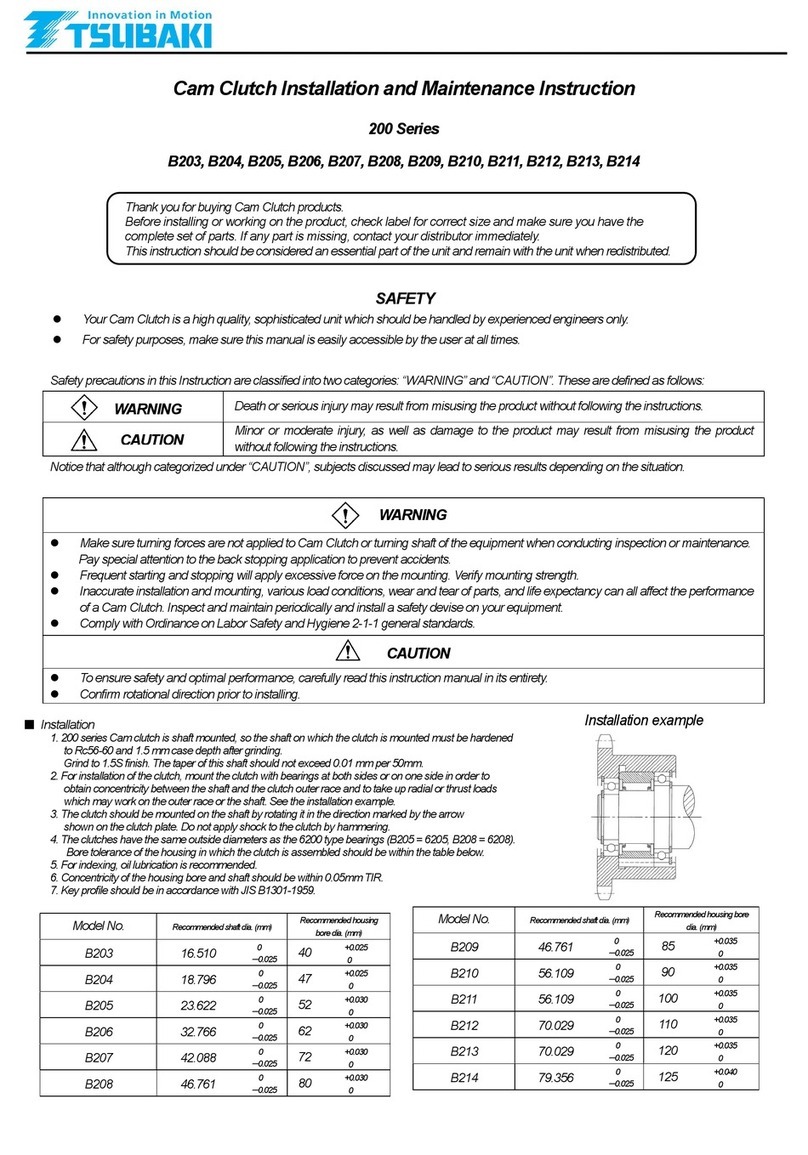

Tsubaki 200 Series Technical specifications

Tsubaki

Tsubaki TGB Series User manual

Tsubaki

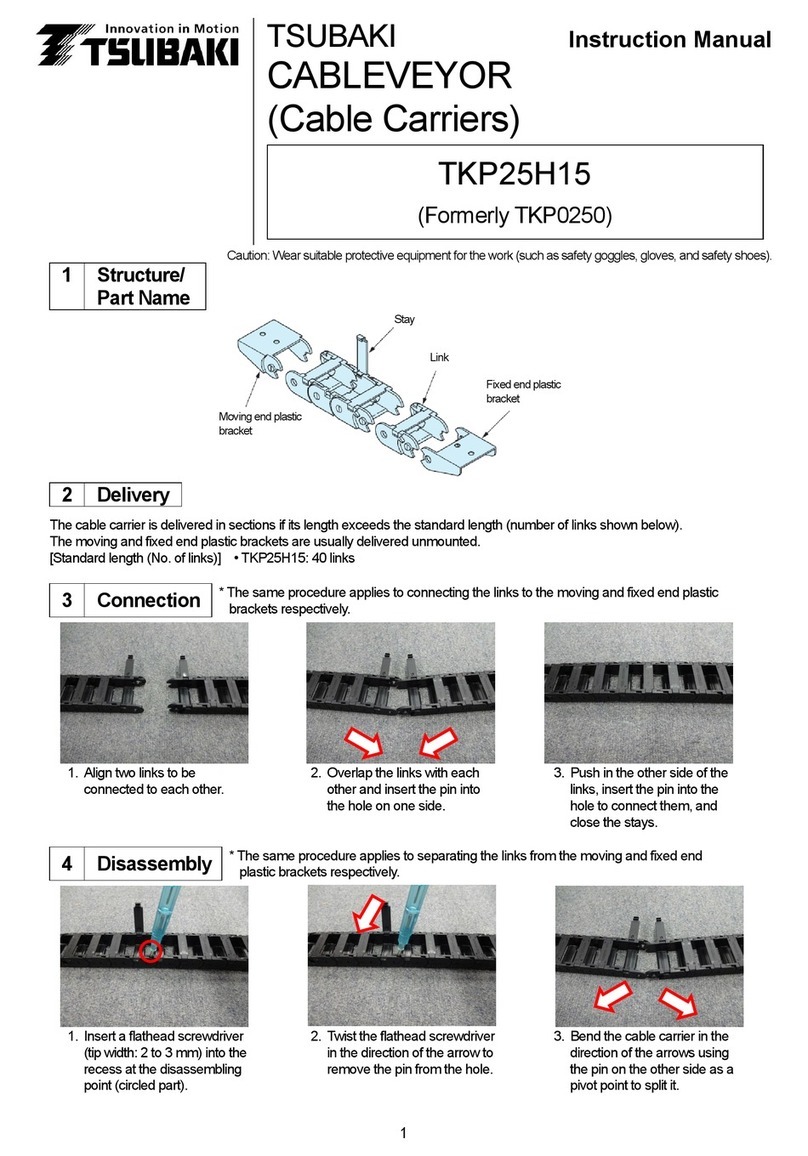

Tsubaki TKP25H15 User manual