8

Sel-0010.docx

Rev2

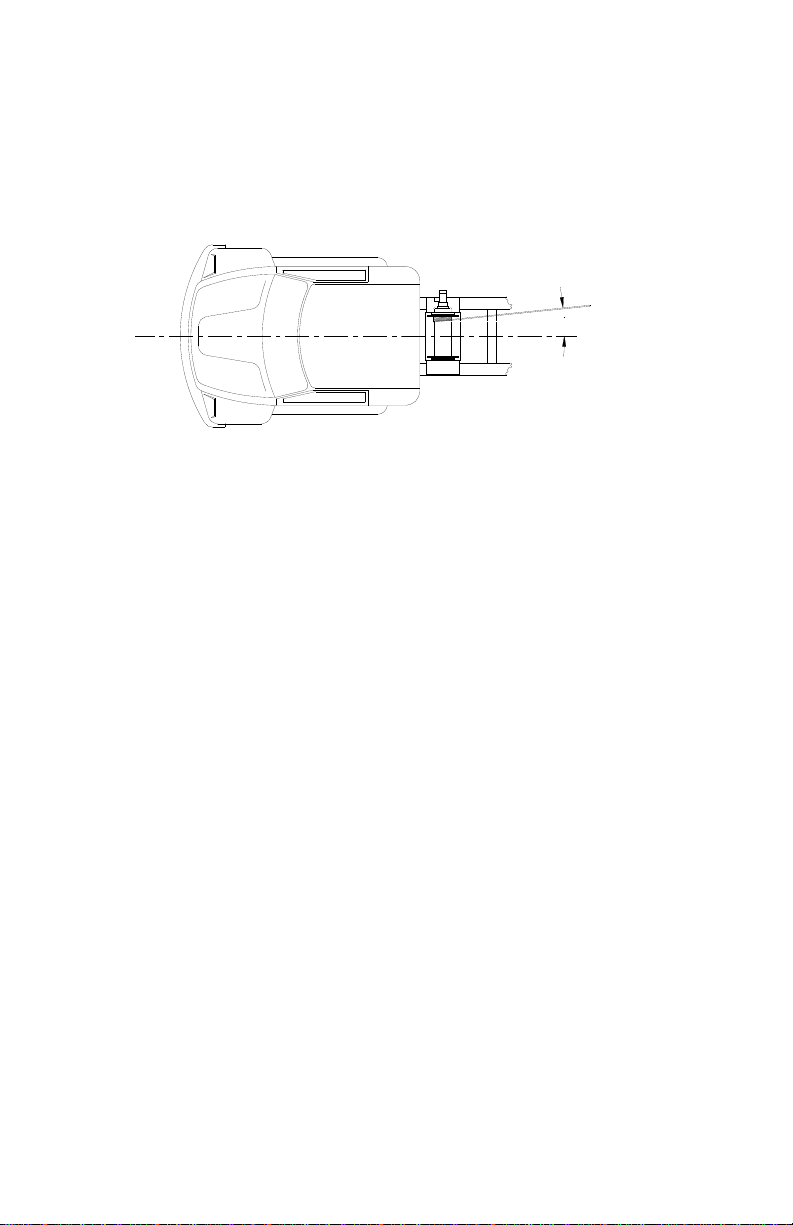

CABLE INSTALLATION

To install the cable wedge anchor, first consult the wire

rope manufacturer for recommendations on how to

prepare the end of the wire rope. Thread the prepared end

of wire rope through the smaller side of the opening of the

cable drum wedge pocket. Pull through enough cable to

loop it back around and insert the end back into the wedge

pocket to about 3/4 depth of the pocket. Install the wedge

in the loop then pull the slack out of the loop with the

working line. The wedge will slip into the pocket and

secure the wire rope into the drum.

To install the u-bolt clamp style of anchor, first prepare the

end of the cable as recommended by the wire rope

manufacturer. Pass the wire rope through the u-bolt so

that the end extends approximately 2x the diameter of the

cable. Tighten the clamp evenly until the wire rope begins

to deform slightly under the u-bolt and the cable is held

securely.

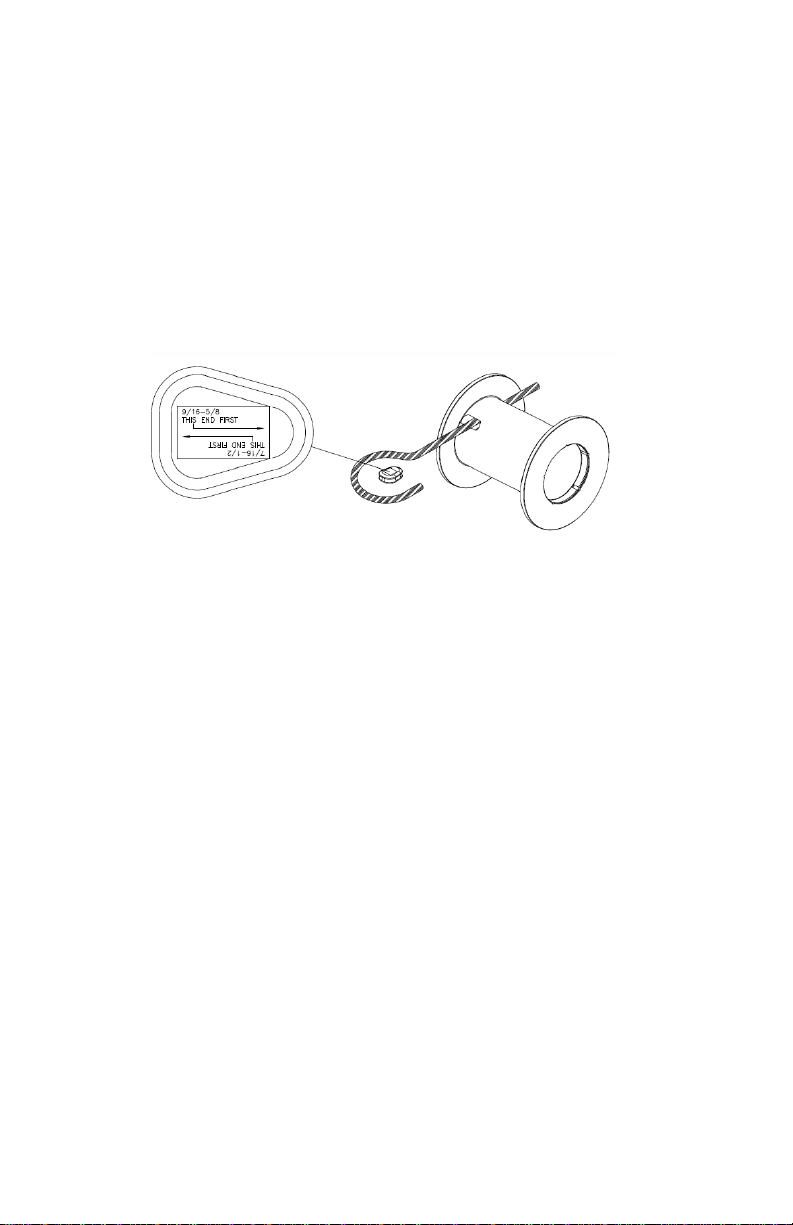

When using the ferrule wedge anchor the cable must be 6

strand. First, make sure the cable end is cut clean and

square. Insert the cable through the ferrule and spread

the strands to insert the wedge halves over the core of the

wire rope. Position individual strands into proper grooves

around the wedge halves and tap the wedges until they

are flush with the strand ends. Slide the ferrule back over

the wedge and drive the wedge into the ferrule with a

hammer and short pipe which fits inside the strands and

over the core.

WARNING: CABLE ANCHORS ON TULSA WINCHES

ARE NOT DESIGNED TO HOLD THE RATED LOAD OF

THE WINCH. YOU MUST KEEP AT LEAST 5 WRAPS

OF CABLE ON THE DRUM TO INSURE THAT THE

CABLE DOES NOT COME LOOSE.