7

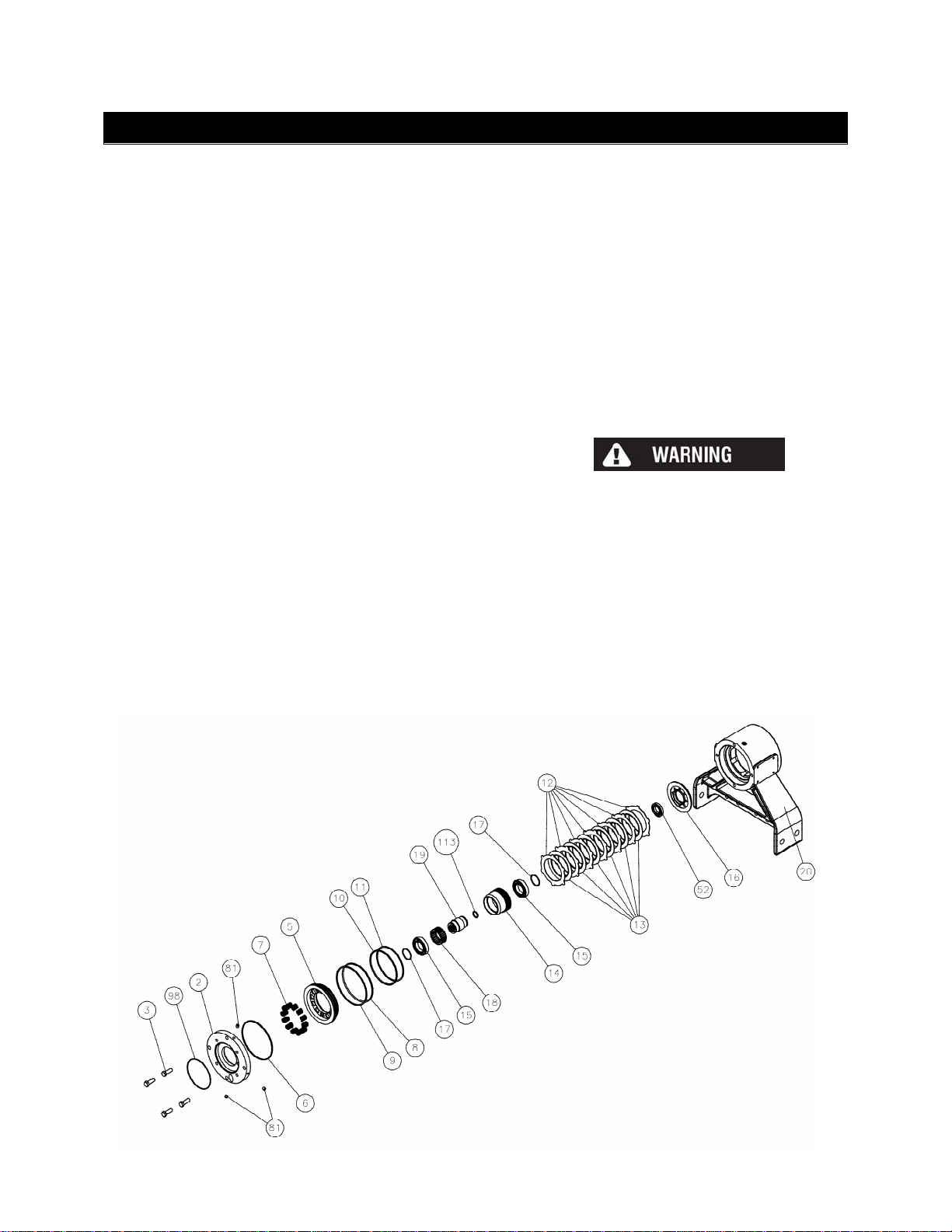

B. BRAKE SECTION DISASSEMBLY

1. Evenly remove the four cap screws (3) that

hold the brake cover (2) in place. Spring

pressure will raise the cover up as the cap

screws are loosened. Carefully remove the

cover (2) from the brake housing (20).

Inspect the o-ring (6) on cover for damage.

2. Remove the springs (7) from the piston (5)

and check the free height. Each spring

should measure at least 1.240 inches with

no force on them.

3. Remove the piston (5) by installing two

pieces of 3/8”-16NC all thread into the two

holes in the top of the piston and run in

evenly until the piston is clear of the

housing. An alternate way of removing the

piston is to use shop air to slowly pressurize

the brake cavity to remove the piston from

the brake housing (20).

4. Inspect the o-rings (8, 10) and back up rings

(9, 11) on the piston, replace if necessary.

Grasp the brake driver/clutch assembly

(assembled items 14, 15, 17, 18, 19, 113)

and remove it from the brake housing.

5. Remove the stator plates (12) and friction

discs (13) from the brake housing and check

them for excessive wear. Replace the parts

if necessary. Be sure to check the top stator

plate for scoring caused by the removal of

the piston and polish if needed. Friction

discs should measure no less than .055-in.

thickness and stator plates should measure

no less than .068-in thickness.

6. To disassemble the brake driver/clutch

assembly, remove the retaining ring (17)

from either end of the driver. Then, remove

the brake driver (14) and bearing (15) from

the input driver (19). Next, remove the

sprag clutch (18). Finally, remove the

retaining ring (17) from the other end of the

driver, then remove the second bearing (52)

from the input driver.

Notice the direction of lock-up

on the clutch for re-assembly.

Inspect the input driver and brake driver for

wear, replace if necessary.

7. Remove the bearing housing (16) and

inspect the bearing (52).

8. If the bushing or seal in the brake housing

needs to be replaced, follow the drum

section disassembly and reassembly

sections of this manual prior to reassembly

of the brake..