1

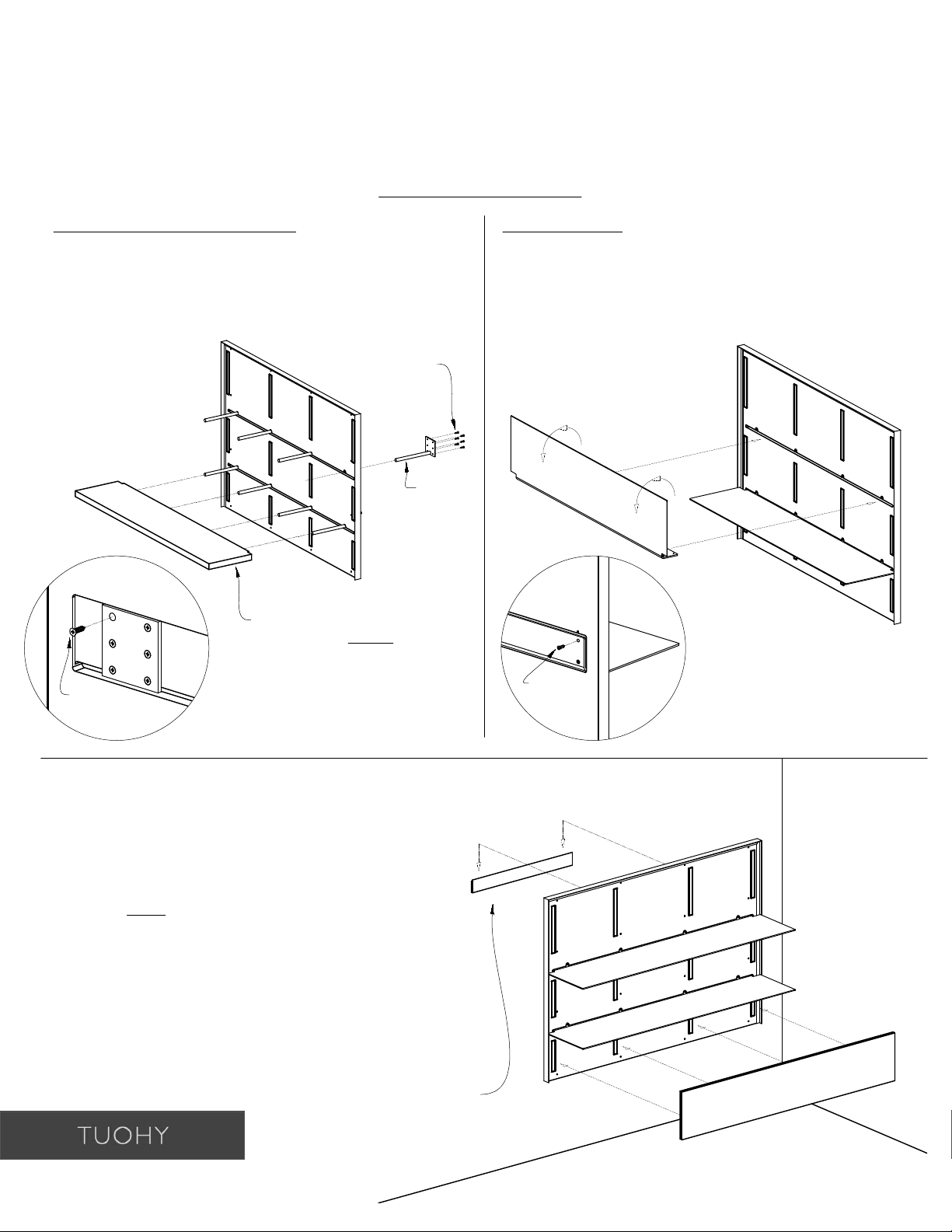

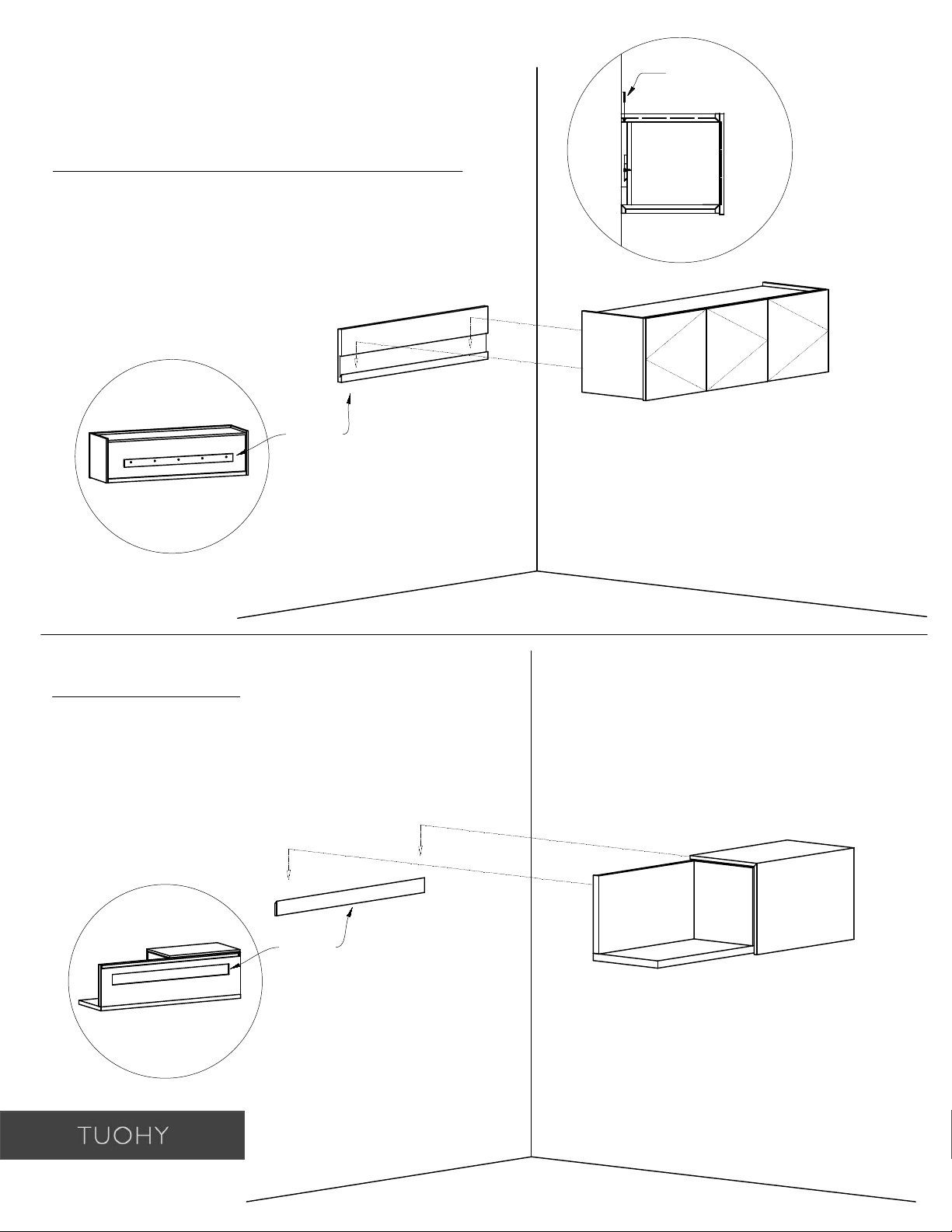

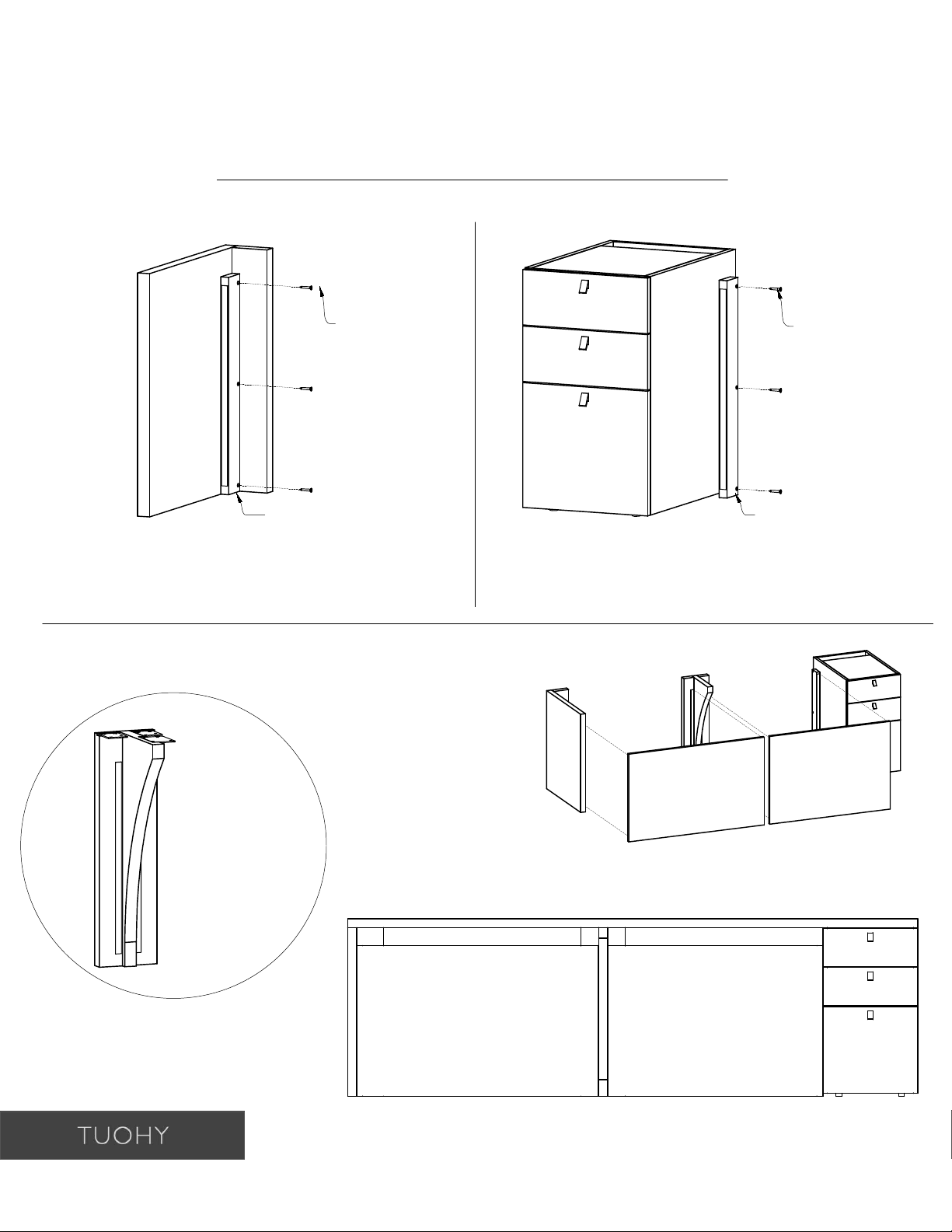

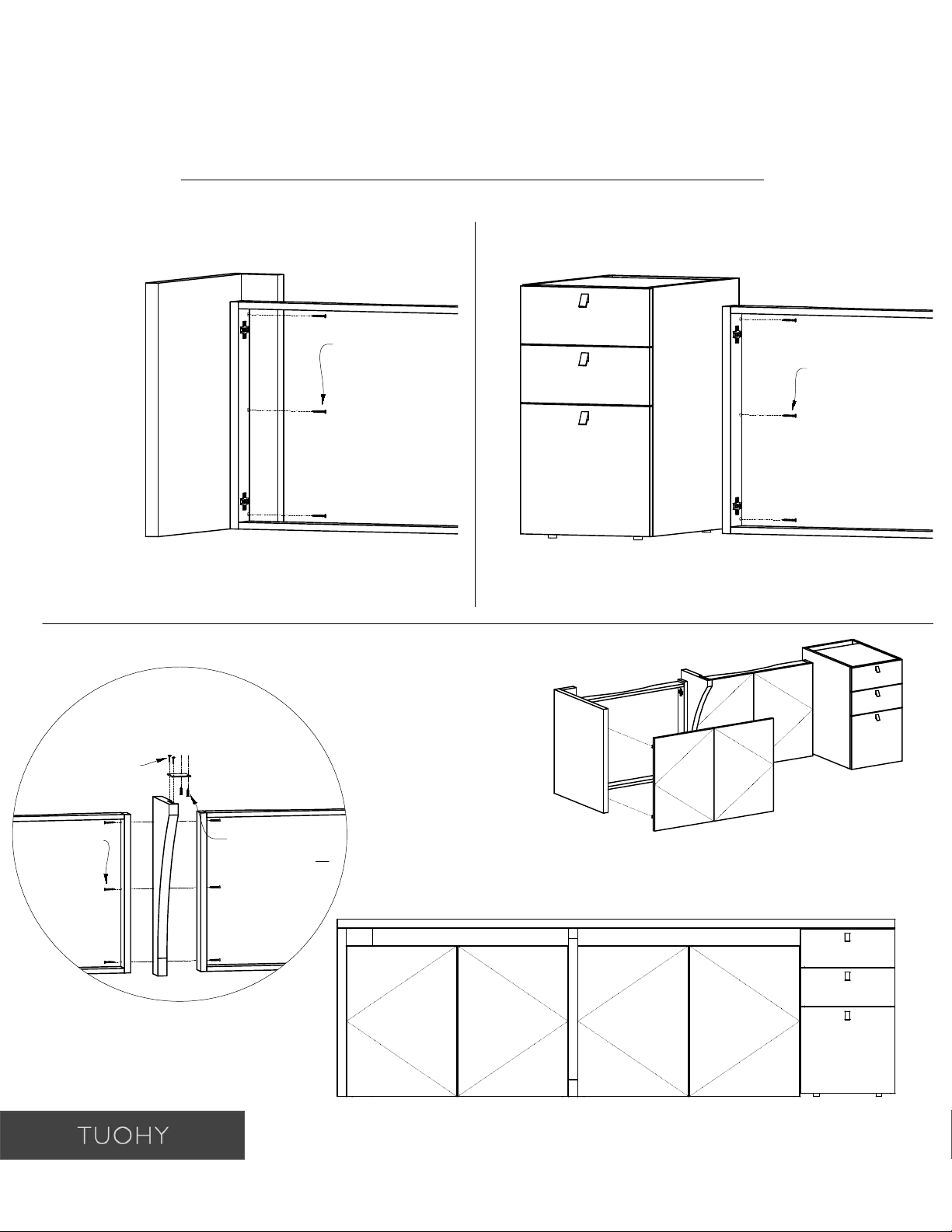

WALL PANELS & SHELVING

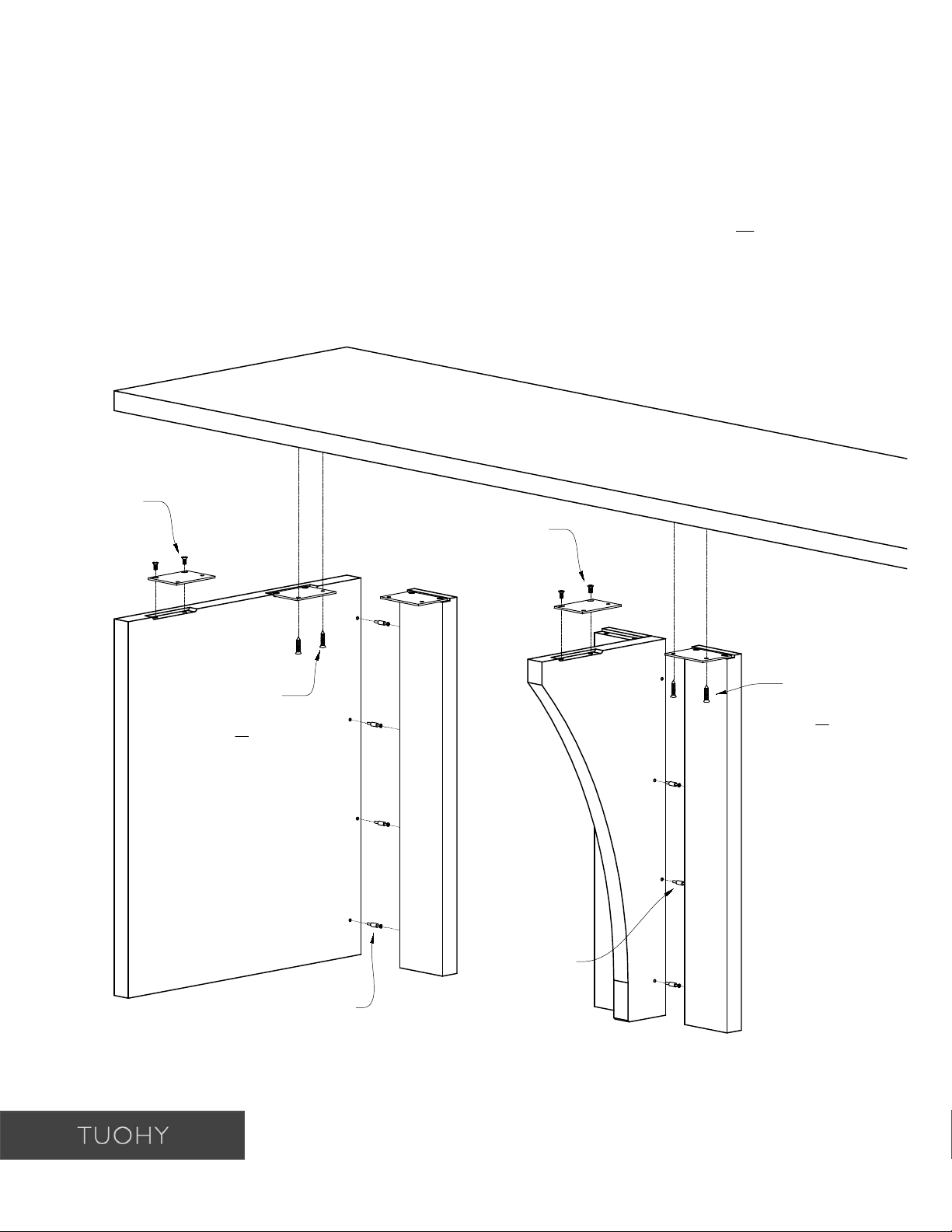

** Wall panel wood shelving support posts and 1/4" metal shelves

must be installed in wall panel prior to securing wall panel to wall.

Wall Panel Shelving

1. Attach french cleat to wall.

** To be used as installation aid only.

(Installer responsible for attachment hardware)

2. Secure wall panel to wall.

** Do NOT rely on french cleat only!

** Panel must be secured to wall throughout

panel using the pre-drilled holes to obtain

maximum shelf weight.

Toggle fasteners are recommended.

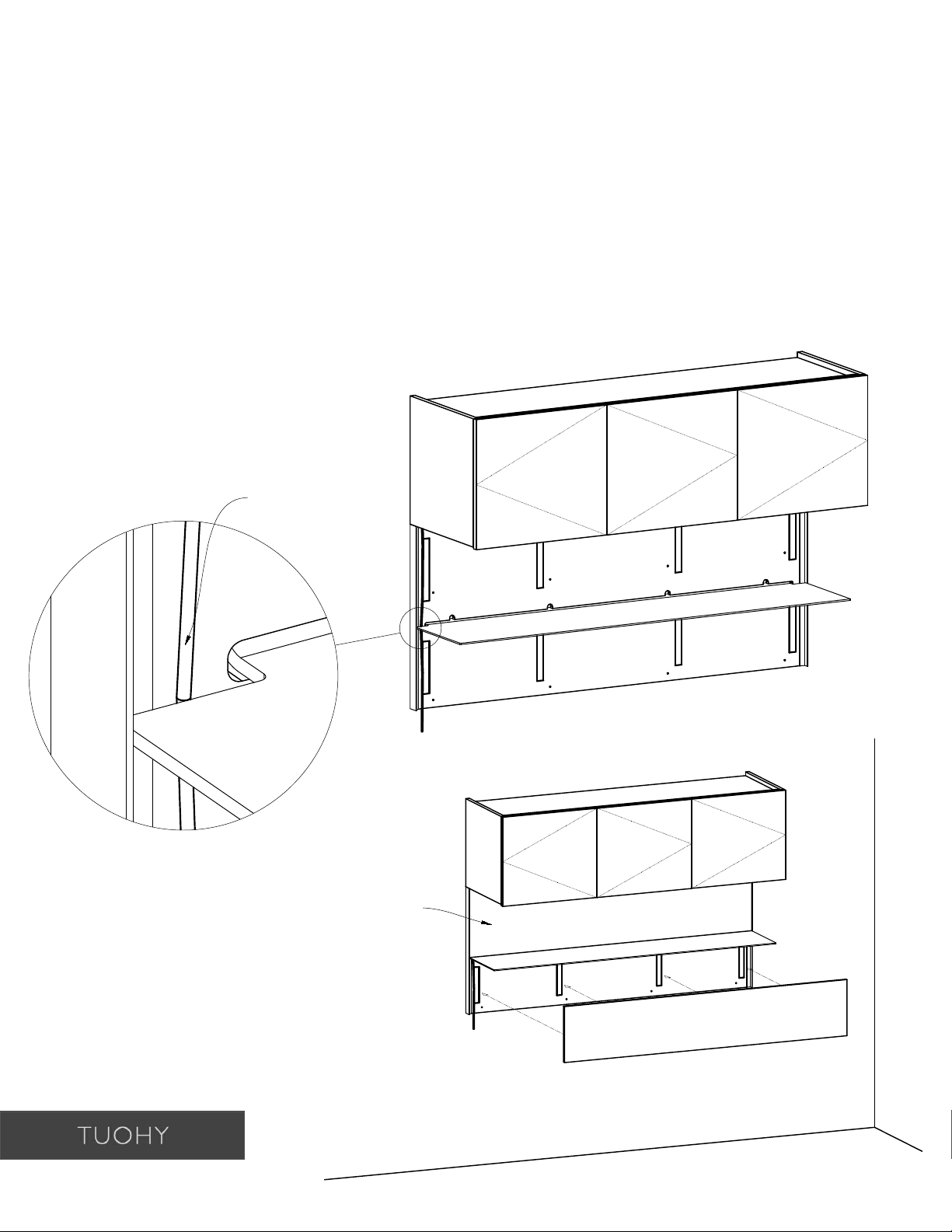

3. Fasten cover panels to secured wall panel

using pre-installed Velcro strips.

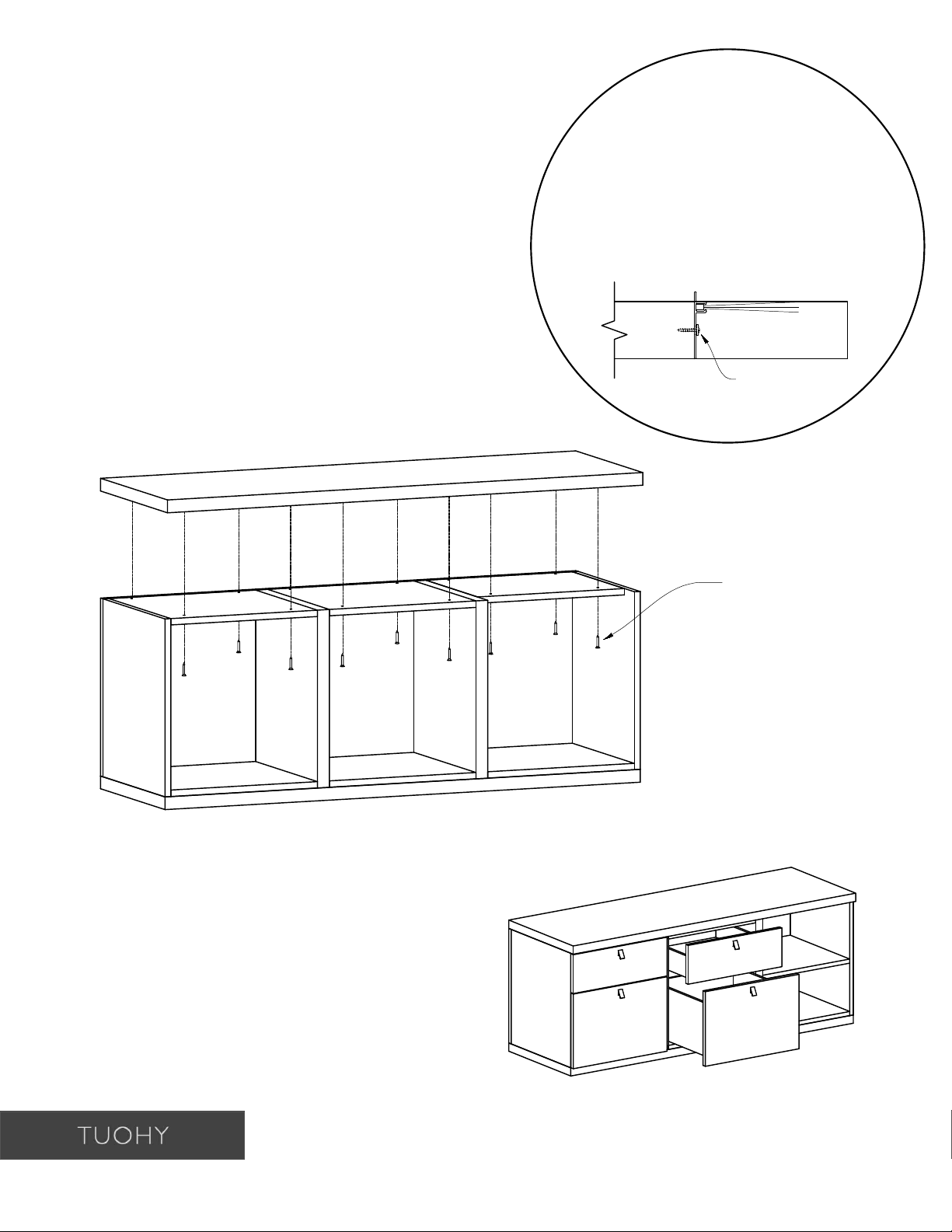

Wood Shelving Support Posts:

1. Insert wood shelving support posts into

allotted holes through back of wall panel.

2. Attach using #8 x 3/4" Flat Head Screws

from back side of wall panel.

French cleat to be installed

as installation aid only.

(Installer responsible for

attachment hardware)

#8 x 3/4"

Flat Head

Screws

Wood

Shelving

Support

Post

Metal Shelving:

1. Insert metal shelving into slot through front of

wall panel and rotate down at the same time.

2. Attach shelf by screwing #8 x 3/4" Flat Head

Screws through back of shelf into back of wall

panel.

#8 x 3/4"

Flat Head

Screws

(Back View

of Wall

Panel)

** Slide wood shelves onto

support posts AFTER wall

panel is attached to wall.

(See below for wall panel to

wall attachment).

#8 x 3/4"

Flat Head

Screws

(Back View

of Wall

Panel)