TYWRD2S Datasheet

Hangzhou Tuya Information Technology Co., Ltd. 4 V2.0.0

Contents

1. Product Overview ............................................................................................................1

1.1 Features..................................................................................................................1

1.2 Applications ............................................................................................................2

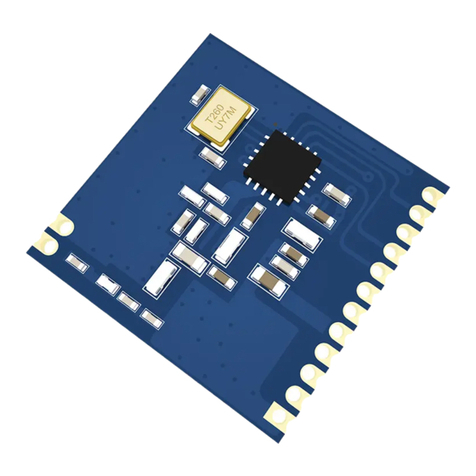

2 Module Interfaces.............................................................................................................6

2.1 Dimensions and Footprint ......................................................................................6

2.2 Interface Pin Definition...........................................................................................6

2.3 Test Pin Definition...................................................................................................8

3 Electrical Parameters........................................................................................................8

3.1 Absolute Electrical Parameters..............................................................................8

3.2 Electrical Conditions...............................................................................................9

3.3 TYWRD2S RX Power Consumption....................................................................10

3.4 Working Current ...................................................................................................10

4 RF Features....................................................................................................................10

4.1 Basic RF Features................................................................................................10

4.2 TYWRD2S Output Power.....................................................................................11

4.3 TYWRD2S RX Sensitivity.....................................................................................11

5 Antenna Information........................................................................................................12

5.1 Antenna Type........................................................................................................12

5.2 Antenna Interference Reduction...........................................................................12

5.3 Antenna Connector Specifications.......................................................................13

6 Packaging Information and Production Instructions.......................................................13

6.1 Mechanical Dimensions .......................................................................................13

6.2 Recommended PCB Encapsulation.....................................................................14

6.3 Production Instructions.........................................................................................14

6.4 Recommended Oven Temperature Curve ...........................................................16