TW-SP245 MANUAL

state: 14.03.2019 page 2of 12

Table of contents

1. Important Information 2

2. Specification 3

3. Prepare before using 3

4. Maintenance 4

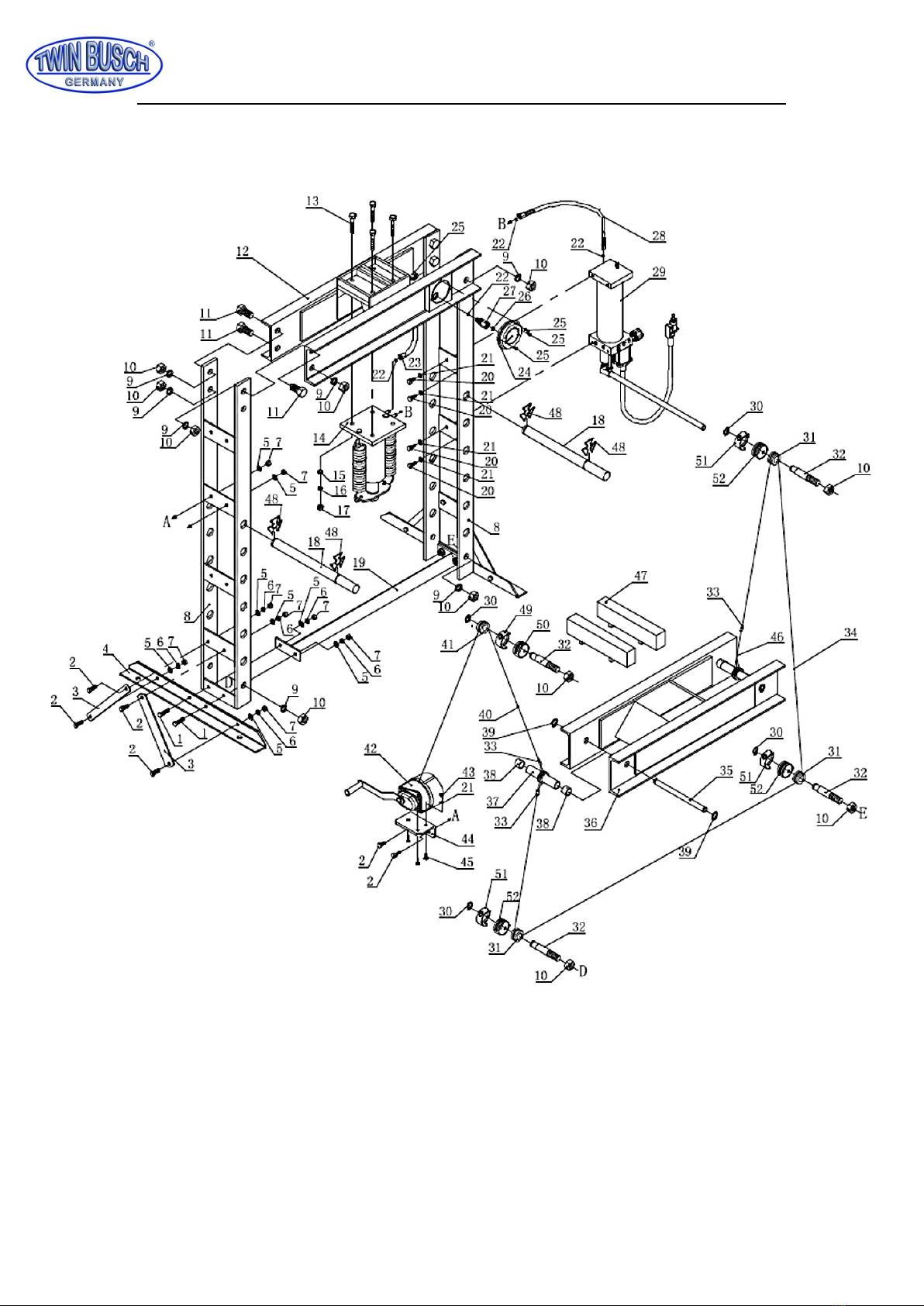

5. Spare parts 6

6. CE-certificate 11

Operation Manual

1. Important Information

1.1 Safety Information

1.1.1 Hazard Symbols Used in the Manuals

This manual includes the hazard symbols defined below when the operations or

maintenance job involves a potential danger. These symbols describe the level of danger

involved in performing a job on the tool and the precautions to take to avoid the hazard.

1.1.2 Safety Requirements

Important

Make sure to read, understand, and strictly follow all safety related instructions before

operation or maintenance of this equipment.

Intended Users

This manual is to be made available to all persons who are required to install, configure or

service equipment described herein, or any other associated operation.

Application Area

The machinery described is intended for machinery production and assembling spare parts.

It is used to press, size, assemble, rivet small parts in process and not for other use.

Personnel

Installation, operation and maintenance of the equipment should be carried out by qualified

personnel. A qualified person is someone who is technically competent and familiar with

all safety information and established safety practices with the installation process,

operation and maintenance of this equipment; and with all the hazards involved.