408- 1536

Hand Crimping Tools 46073 and 46074

3of 5Rev HTyco Electronics Corporation

The hand tool is inspected before being shipped from

the plant; however, it is recommended that the tool be

inspected immediately upon arrival to ensure that the

tool has not been damaged during shipment.

Wire ends should butt against wire stop; however,

application is acceptable if wire ends are flush with or

protrude beyond inside ends of wire barrels.

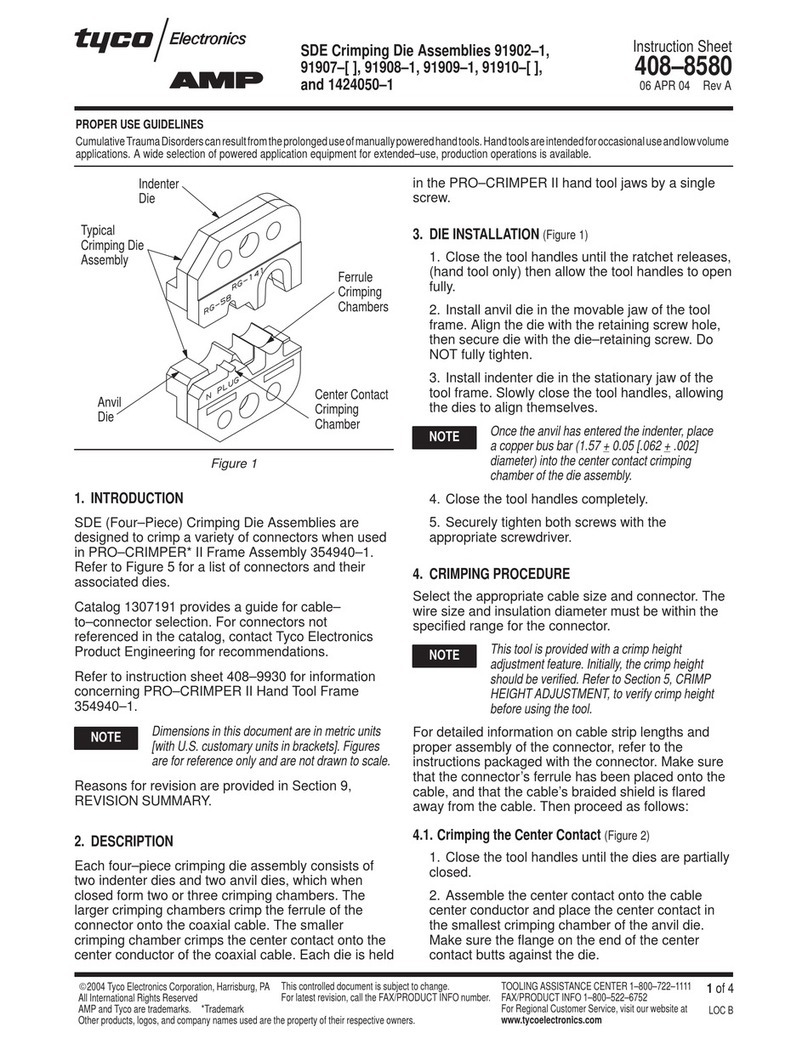

Observe crimped rings for splitting. split rings indicate

possible damaged dies or wire insulation diameter is too

large (refer to Figure 2). Conductor strands may fracture

if over--sized insulation diameter is used.

Figure 4

2

Reject

1

1

2

Crimping Inspection

Due to the precision design, it is important that

no parts of these tools be interchanged except

those replacement parts listed in Figure 7.

4.1. Daily Maintenance

1. Remove dust, moisture, and other contaminants

with a clean brush, or a soft, lint--free cloth. Do

NOT use objects that could damage the tool.

2. Make certain that the retaining pins are in place

and that they are secured with retaining rings.

3. All pins, pivot points, and bearing surfaces

should be protected with a thin coat of any good

SAE 20 motor oil. Do NOT oil excessively.

4. When the tool is not in use, keep handles closed

to prevent objects from becoming lodged in the

dies. Store the tool in a clean, dry area.

4.2. Lubrication

Lubricate all pins, pivot points, and bearing surfaces

with SAE 20 motor oil as follows:

Tool used in daily production—lubricate daily

Tool used daily (occasional)—lubricate weekly

Tool used weekly—lubricate monthly

Wipe excess oil from tool, particularly from crimping

area. Oil transferred from the crimping area onto

certain terminations may affect the electrical

characteristics of an application.

4.3. Periodic Inspection

1. Hand tool should be immersed (handles partially

closed) in a reliable commercial degreasing

compound to remove accumulated dirt, grease,

and foreign matter.

2. Close tool handles until ratchet releases and

then allow them to open freely. If they do not open

quickly and fully, the spring is defective and must

be replaced. See Section 5, REPLACEMENT AND

REPAIR.

3. Inspect head assembly for worn, cracked, or

broken dies. If damage is evident, see Section 5,

REPLACEMENT AND REPAIR, for information on

obtaining customer repair service.

A. Gaging the Crimping Chamber

This inspection requires the use of a plug gage

conforming to the dimensions provided in Figure 5.

Tyco Electronics does not manufacture or market

these gages. To gage the crimping chamber, proceed

as follows:

1. Remove traces of oil or dirt from the crimping

chamber and plug gage.

2. Close the tool handles until it is evident that the

dies have bottomed; then hold in this position. Do

NOT force the dies beyond initial contact.

3. Align the GO element with the wire barrel

crimping section. Push element straight into the

crimping chamber without using force. The GO

element must pass completely through the

crimping chamber. See Figure 6.

4. Align the NO--GO element and try to insert it

straight into the same crimping chamber. The

NO--GO element may start entry, but must not

pass completely through the crimping chamber.

SeeFigure6.

5. With dies bottomed, check insulation (ring)

crimping section using the appropriate plug gage in

same manner as Steps 3 and 4.

If the crimping chamber conforms to the gage

inspection, the tool is considered dimensionally

correct, and should be lubricated with a THIN coat of

any good SAE 20 motor oil. If not, refer to Section 5,

REPLACEMENT AND REPAIR, for information on

obtaining further evaluation and repair.

For additional information regarding the use of a plug

gage, refer to instruction sheet 408--7424.

NOTE

i