levels of torque may distort the sprinkler inlet with conse-

quent leakage or impairment of the sprinkler.

The O-ring seal for pendent sprinklers must be installed

to prevent possible dripping of spray onto the fusible link,

due to clearance between the shield mounting hole and

the threaded end of the sprinkler.

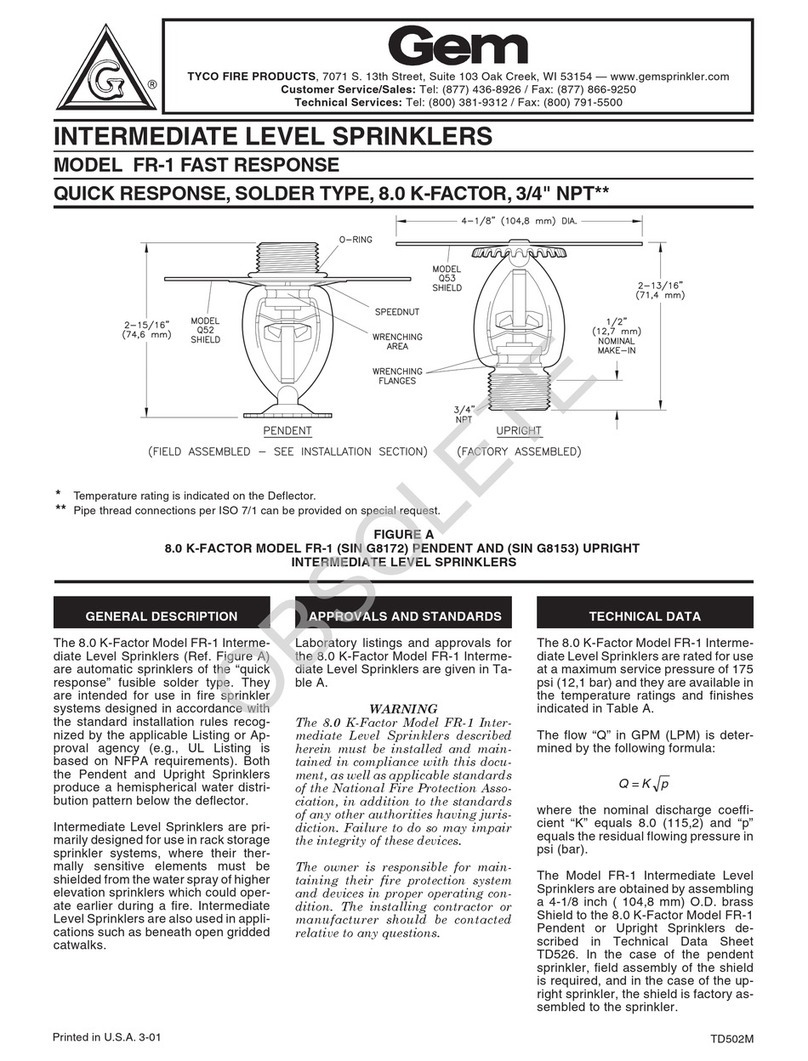

1. Upright sprinklers must be installed only in the upright

position and pendent sprinklers must be installed only in

the pendent position. The centerline of the sprinkler

must be vertical.

2. Upright sprinklers are shipped preassembled, and pen-

dent sprinklers are to be field assembled. Refer to Fig-

ure 1 or 2, as applicable, for proper orientation of parts

for the pendent sprinkler. The speednut is installed by ro-

tating it clockwise over the sprinkler pipe threads, and

the O-ring is rolled over the sprinkler pipe threads.

When properly installed, the O-ring and speednut will be

slightly compressed, thereby firmly holding the shield in

its proper position.

3. With pipe thread sealant applied to the pipe threads,

hand tighten the sprinkler into the sprinkler fitting.

Wrench tighten the Sprinkler using only the W-Type 11

Sprinkler Wrench (Ref. Figure 3). The wrench recess of

the W-Type 11 is to be applied to the sprinkler wrench-

ing area (Ref. Figure 1 or 2, as applicable).

CARE AND MAINTENANCE

The 5.6 and 8.0 K-Factor, SuperNova S120 Sprinklers

must be maintained and serviced in accordance with the

following instructions:

NOTE

Before closing a fire protection system main control valve

for maintenance work on the fire protection system which

it controls, permission to shut down the affected fire pro-

tection systems must be obtained from the proper authori-

ties and all personnel who may be affected by this action

must be notified.

Sprinklers which are found to be leaking or exhibiting vis-

ible signs of corrosion must be replaced.

Automatic sprinklers must never be shipped or stored

where their temperature will exceed 100°F/38°C and they

must never be painted, plated, coated, or otherwise al-

tered after leaving the factory. Modified or over-heated

sprinklers must be replaced.

Care must be exercised to avoid damage - before, dur-

ing, and after installation. Sprinklers damaged by drop-

ping, striking, wrench twist/slippage, or the like, must be

replaced.

The owner is responsible for the inspection, testing, and

maintenance of their fire protection system and devices in

compliance with this document, as well as with the appli-

cable standards of the National Fire Protection Associa-

tion (e.g., NFPA 25), in addition to the standards of any

other authorities having jurisdiction. The installing contrac-

tor or sprinkler manufacturer should be contacted relative

to any questions.

It is recommended that automatic sprinkler systems be in-

spected, tested, and maintained by a qualified Inspection

Service.

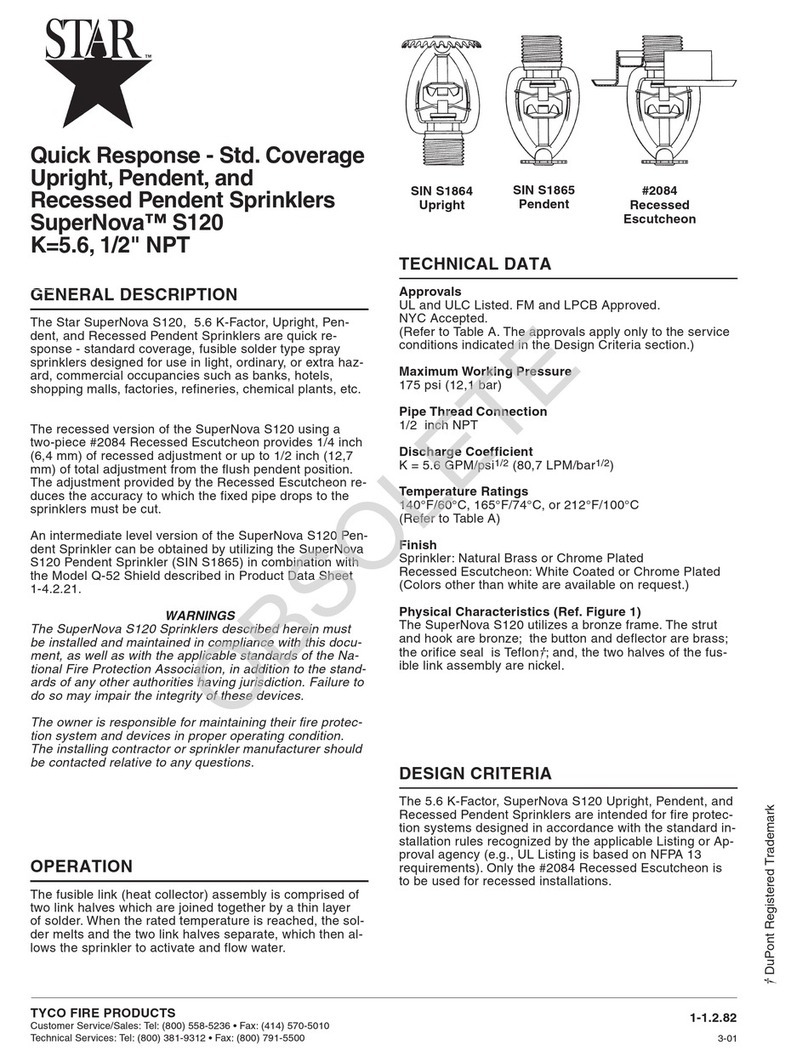

RECESS

WREN

H

ONLY USE

SUPERNOVA

SPKR" END FOR

"SMALL FRAME

#2849

FIGURE 3

W-TYPE 11 SPRINKLER WRENCH

STAR SPRINKLER

1-4.2.21 Page 3

SPRINKLER FINISH

Temperature

Rating

Frame

Color Code

Natural

Brass

Chrome

Plated

Natural

Brass

165°F/74°C

212°F/100°C

Plain

White

K = 5.6 Upright (S1991)

K = 8.0 Upright (S1993)

Notes:

1. Listed by Underwriters Laboratories, Inc. as Quick Response Sprinklers.

2. Listed by Underwriters’ Laboratories of Canada as Quick Response Sprinklers.

3. Approved by Factory Mutual Research Corporation as Quick Response Rack Storage Sprinklers.

TABLE A

LABORATORY LISTINGS AND APPROVALS

Chrome

Plated

1, 2, 3

1, 2, 3

K = 5.6 Pendent (S1865)

K = 8.0 Pendent (S1867)

1, 2, 3

1, 2, 3