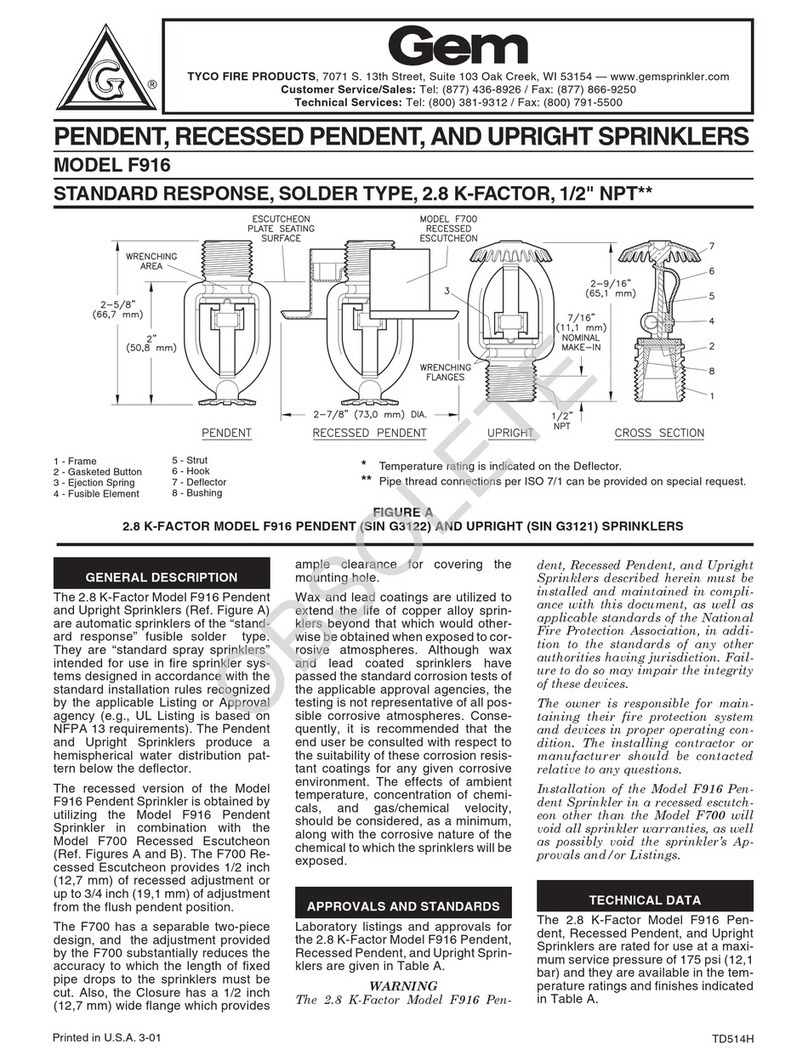

Table 1 - LF Horizontal Sidewall and Recessed Horizontal

Sidewall Sprinkler Design Requirements for

NFPA 13D & NFPA 13R Occupancies

Minimum Design Flow (Pressure)

Coverage Multiple Deflector Temperature

Area Single Sprinkler Sprinklers Distance

*12' x 12' 14 GPM/16.0 psi 11 GPM/9.9 psi 4" - 12" 155°F/68°C

(3,7 m x 3,7 m) (53,1 lpm / 1,1 bar) (41,7 lpm / 0,7 bar)

175°F/79°C

*14' x 14' 14 GPM/16.0 psi 12 GPM/11.8 psi 4" - 12" 155°F/68°C

(4,3 m x 4,3 m) (53,1 lpm / 1,1 bar) (45,5 lpm / 0,8 bar)

175°F/79°C

*16' x 16' 16 GPM/20.9 psi 13 GPM/13.8 psi 4" - 6" 155°F/68°C

(4,9 m x 4,9 m) (60,6 lpm / 1,4 bar) (49,3 lpm / 1,0 bar)

175°F/79°C

‡16' x 16' 19 GPM/29.5 psi 18 GPM/26.4 psi 6" - 12" 155°F/68°C

(4,9 m x 4,9 m) (72 lpm / 2,0 bar) (68,2 lpm / 1,8 bar)

‡16' x 18' 19 GPM/29.5 psi 18 GPM/26.4 psi 4" - 12" 155°F/68°C

(4,9 m x 5,5 m) (72 lpm / 2,0 bar) (68,2 lpm / 1,8 bar)

* These flows and pressures are applicable for Smooth, Flat, Ceilings with

a Max. 8:12 Slope.

‡ These flows and pressures are applicable for Smooth, Flat, Ceilings with

a Max. 2:12 Slope.

Design

Criteria

Installation

The Central Model LF Horizontal Sidewall

Sprinklers must be installed in accordance

with the following instructions:

NOTES

Do not install any bulb type sprinkler if the

bulb is cracked or there is a loss of liquid

from the bulb. With the sprinkler held

horizontally, a small air bubble with an

approximate diameter of 1/16 inch should

be present.

A leak tight 1/2 inch NPT sprinkler joint

should be obtained with a torque of 7 to 14

ft.lbs. (9,5 to 19,0 Nm). A maximum of 21

ft.lbs. (28,5 Nm) of torque is to be used to

install 1/2 inch NPT sprinklers. Higher

levels of torque may distort the sprinkler

Model LF Horizontal Sidewall and

Recessed Horizontal Sidewall Sprinklers

are UL, C-UL Listed and NYC Approved

(MEA 323-98-E) for use in accordance

with current NFPA standards for use on

wet pipe sprinkler systems. These

sprinklers have been investigated for use

under smooth flat horizontal ceilings with

slopes up to 2 inches per foot, at spacings

up to 16 feet by 18 feet, using the design

requirements found in Table 1. These

sprinklers have also been investigated for

use under smooth flat sloping ceilings with

slopes up to 8 inches per foot, at spacings

up to 16 feet by 16 feet, using the design

requirements found in Table 1 as well as

the sloped ceiling "Specific Application

Design Criteria" found in Figure 1.

The Recessed Horizontal Sidewall

Sprinklers are only listed with the Series

BV Res./QR Recessed Escutcheon

Assembly.

The minimum required single and multiple

sprinkler flow rates for systems designed

to NFPA 13D or NFPA 13R occupancies

are given in Table 1. The single sprinkler

flow rate is the minimum required

discharge from the most hydraulically

demanding single sprinkler and, the

multiple sprinkler flow rate is the minimum

required discharge from each of the total

number of "design sprinklers" as specified

in NFPA 13D or NFPA 13R.

TIA 99-1 (Tentative Interim Ammendment)

with an effective date of May 22, 2000

states that the minimum required

discharge from each of the "design

sprinklers" for systems designed to NFPA

13 must be calculated based on delivering

a minimum design density of 0.1 gpm/sq.

ft. for each of the listed coverage areas

shown in Table 1. Consult the authority

having jurisdiction regarding the

application of this TIA to the currently

adopted NFPA 13.

Model LF Residential Horizontal Sidewall

and Recessed Horizontal Sidewall

Sprinklers must be installed using the

obstruction and minimum distance

between sprinkler criteria for extended

coverage sidewall sprinklers found the

current edition of NFPA 13.

NOTES

Residential Fire Sprinkler Systems

should only be designed and installed

by those competent and completely

familiar with automatic sprinkler

system design, installation procedures,

and techniques.

The sprinkler must be secured in

position by firmly fastening the

sprinkler system piping to the

structure. If the sprinkler is not

properly secured in position, reaction

forces resulting from sprinkler

operation could alter its orientation and

its water distribution pattern. The

sprinkler escutcheon cannot be used

to hold the sprinkler in position.

Several criteria may apply to the

installation and usage of each

sprinkler. Consequently, it is

recommended that the sprinkler

system designer review and develop a

working understanding of the

complete list of criteria prior to

initiating the design of the sprinkler

system.

Questions concerning sprinkler

installation and usage criteria, which

are not covered by the following

instructions, should be submitted to

Central Sprinkler. Include sketches

and technical details as appropriate.

In some instances, the requirements of

this document may concern

specifications which are more

stringent and which take precedence

over those specified in NFPA 13, NFPA

13D, NFPA 13R, or by the authority

having jurisdiction.

inlet with consequent leakage or impair-

ment of the sprinkler.

Step 1. The sprinkler must only be

installed in the sidewall position with the

centerline of the sprinkler parallel to the

ceiling and perpendicular to the wall. The

top of the deflector is to be positioned

towards the ceiling.

Step 2. After installing the BV Res./QR

Recessed Support Cup (or other accept-

able escutcheon, as applicable) over the

sprinkler pipe threads and with pipe thread

sealant applied to the pipe threads, hand

tighten the sprinkler into the sprinkler

fitting.

Step 3. Wrench tighten the sprinkler using

only a BV Sprinkler Wrench (1099). The

wrench recess of the BV Sprinkler Wrench

is to be applied to the sprinkler wrench

flats (Ref Figure 3).

Step 4. For Recessed Sidewall Sprinkler

Applications, a Protective Cap is available

which helps to prevent damage to the

sprinkler during ceiling/wall installation

and/or during application of the finish

coating of the ceiling/wall. Place the

Protective Cap over the Recessed

Support Cup and push it sideways until it

bottoms out against the sprinkler deflector.

NOTE

As long as the Protective Cap remains in

place, the system is considered to be "Out

of Service"

Step 5. After the ceiling/wall has been

completed , remove and discard the

Protective Cap. If the Sprinkler has been

damaged, replace the entire Sprinkler

assembly. Do not attempt to modify or

repair a damaged sprinkler.

Step 6. Push the outer ring of the

Recessed Escutcheon over the Re-

cessed Support Cup. If the Recessed

Escutcheon cannot be engaged with the

Support Cup or the Recessed Escutcheon

cannot be engaged sufficiently to contact

the wall, the Sprinkler Fitting must be

repositioned.