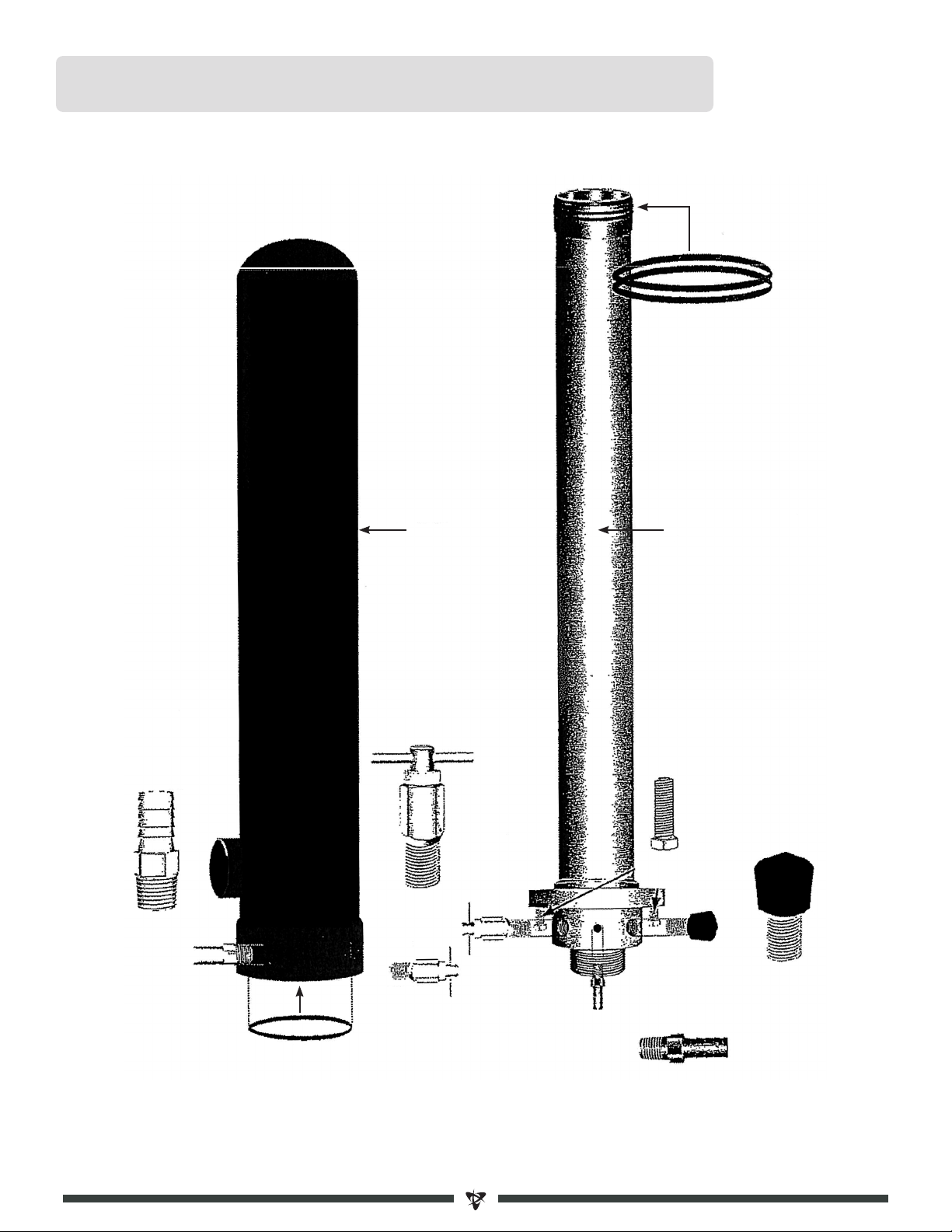

STEP 1 SUPERCOOLER

Assemble the cooler according to the manufacturer’s instructions. Once the

cooler is assembled, measure where it will best fit on your applicator and

bolt it down. Run the supplied wiring harnesses to the tractor. Keep in mind

where the applicator folds up.

STEP 2 SPLITTER

Thread the 1 ¼"x 6" pipe nipple into the 1 ¼" tee coming off of the cooler. The

splitter should be level and facing upright. If you want to mount the splitter

remotely, use the John Blue Splitter Stand.

STEP 3 MANIFOLDS

Thread the manifolds onto the manifold stands using the 1" nipple and a 1" tee.

Then thread in the hosebarbs. Once the manifolds are assembled they can be

attached to your applicator. Mount the pressure gauges so you can see them

from the tractor cab (if possible). When running lines, keep in mind how many

folds your applicator has, and where it folds up.

STEP 4 HOSE FROM SPLITTER TO MANIFOLDS

Cut a piece of hose to fit between the splitter and the furthest manifold.

According to the manifold assembly instructions, all other hoses should be

cut the same length as your longest hose. Failing to do so will distribute NH3

unevenly to each manifold, which will result in streaking.

SETTING UP AN NH3 KIT

2

Q. Can I plug my manifold ports?

A. Yes. If you have a John Blue Impellicone or Continental MVD manifold you can plug unused manifold outlets.

Be sure to plug an even amount of outlets per manifold if possible. Space plugs evenly on manifold to

ensure even distribution.

FAQ