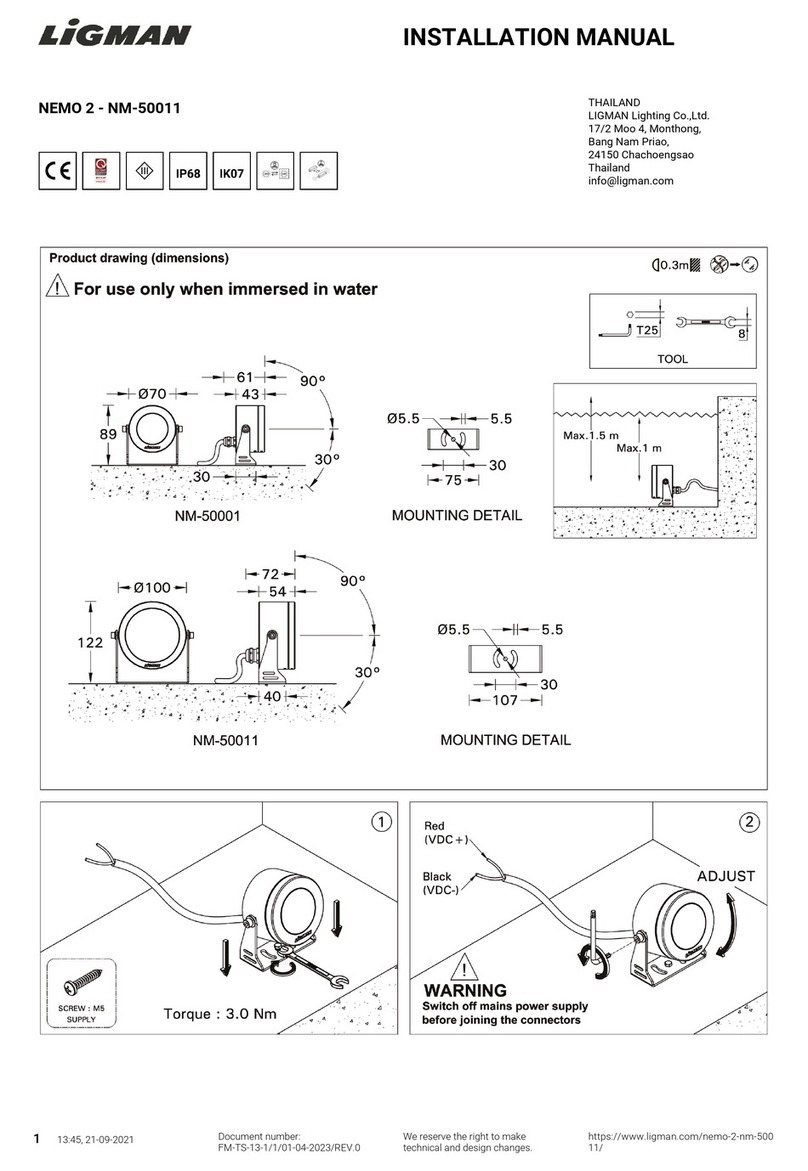

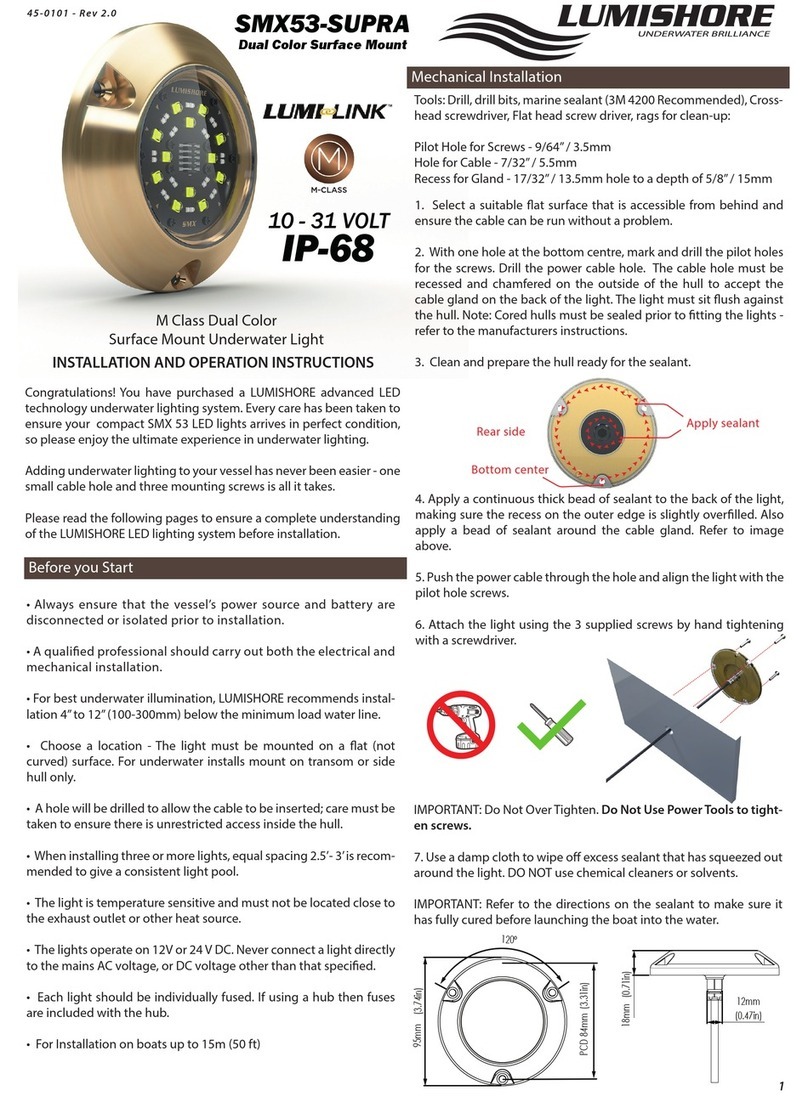

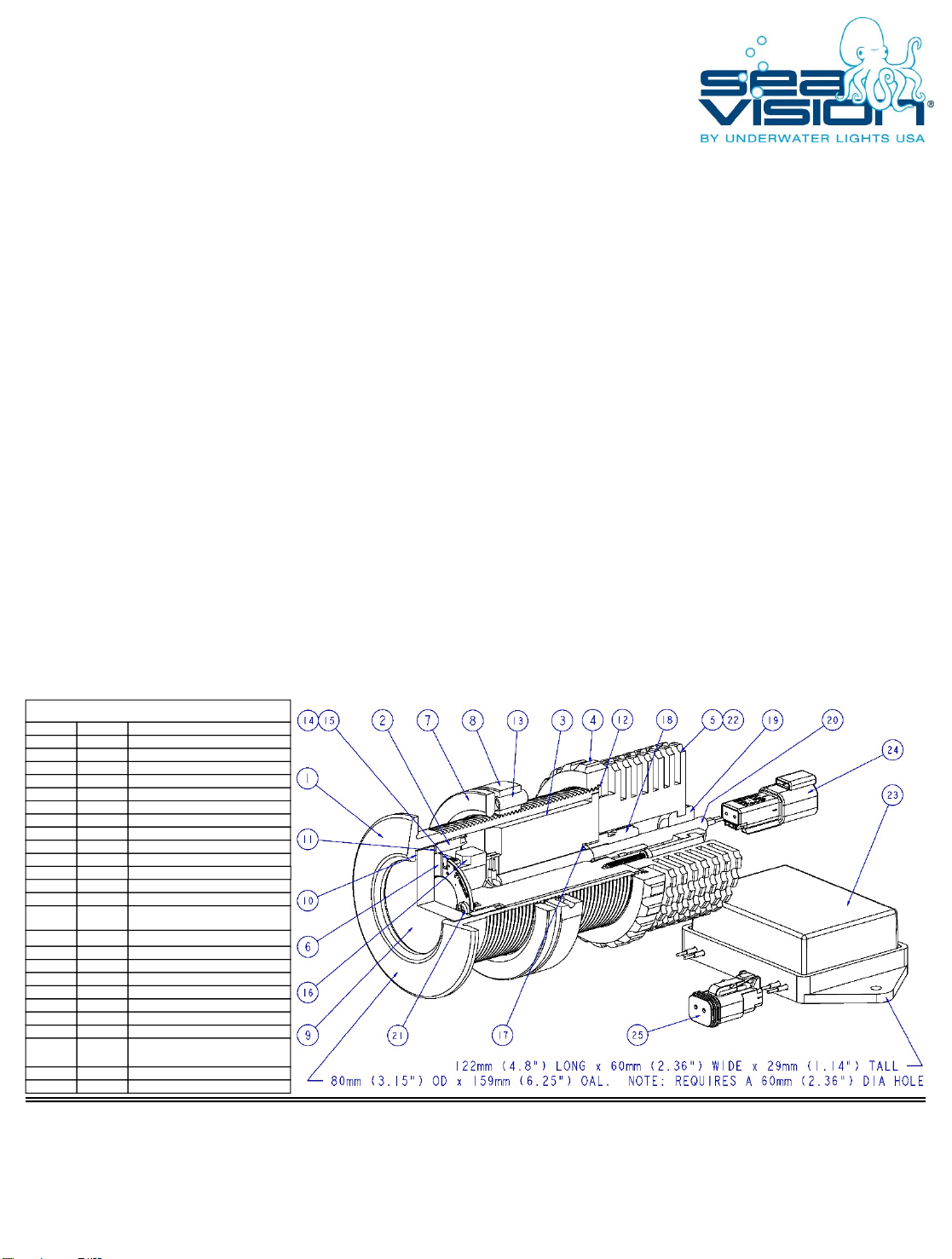

Installation:

This light should be installed at least 152mm (6”) below the water line by qualified/approved personnel using proper tools and

materials. The minimum hull thickness is 8mm (0.31”) and maximum (for sufficient heat dissipation) is 73mm (2.87”) with an

access area of at least 100mm (3.9”) left behind the light for LED array servicing and general ventilation.

After selecting a flat surface, cut a 60mm (2-3/8”) diameter hole through the vessel hull in the desired location. Caution! Check

that no electrical wiring, fuel lines, oil lines, water lines etc., pass near or through the intended hole location.

Remove numbers (4) [with attached (5)], (7) + (8) from the light. Carefully coat the Flanged Main Body (1) and inner surface of

above cut hole with 3M 5200 Marine Adhesive or equivalent. Caution! Avoid placing adhesive on flanged main body threads. Note:

Exposed inner hole surface must be properly sealed before light installation to prevent potential water intrusion into the hull proper.

Holding the Flanged Main Body (1), push the light through the hole, slide the Compression Ring (7) over the Flanged Main Body (1)

and then tighten the Locking Ring (8) hand tight. Note: Ensure that the tips of all three set screws (13) are NOT touching the

Compression ring (7). After the 3M 5200 Marine Adhesive is fully cured, tighten the three set screws (13) to 7 Nm (5 ft/bs) using a

3mm allen wrench.

Insert the Projector Mount (3) in the Flanged Main Body (1) and hand tighten Projector Lid (4) [with attached (5)]. Upon

completing light installation, it is highly recommended that the Flanged Main Body (1) face be coated with antifouling paint and a

wire lead be connected from the Locking Ring (8) M4 x 0.7 tapped hole to the vessels grounding and cathodic protection system.

Securely mount the LED Driver (23) as high as possible away from the light and point electrical wires downwards. Connect loose

LED driver RED wire lead to a switched and fused power source utilizing supplied fuse, connect loose LED driver BLACK wire lead to

a good ground. Plug LED driver (25) output connector to LED light input connector (24).

Caution! Directly connecting power source to light without using the LED driver will permanently damage the light.

Serviceable Parts:

The SV20 LED Underwater Light is field serviceable and most of the parts are replaceable. However, numbers (9), (10) + (11) are

not field serviceable on this light. Please contact our technical support staff to discuss your individual needs.

Underwater Lights Europe Sarl

16, rue Rouaze

06400 Cannes, France

Phone: 33-(0)-4-97-21-02-96

Fax: 33-(0)-4-97-21-10-96

Internet: www.seavision.com

Underwater Lights USA, LLC

3406 SW 26th Terrace, C-6/7

Fort Lauderdale, FL 33312USA

Phone: 1-954-760-4447

Fax: 1-954-525-3261 Internet:

www.seavision.com Email:

Thru-Hull Mount, LED Array

SV20 LED

Underwater Light

WHITE MODELS A11A11B41-13G32C-36, 12VDC & A11A11B41-14G32C-36, 24VDC

BLUE MODELS A11A11B49-13G32C-36, 12VDC & A11A11B49-14G32C-36, 24VDC

CABLE STRAIN RELIEF2011018

STRAIN RELIEF O-RING2010917

THERMOSWITCH2010816

WHITE LED ARRAY

BLUE LED ARRAY

20106

20121

14

M6 x 1.0 x 16LG SST SET SCREW2002113

PROJECTOR LID GASKET2001612

OUTER GLASS GASKET2004610

GLASS200459

LOCKING RING200118

COMPRESSION RING200107

LED SHIELD201056

PROJECTOR CAP201045

PROJECTOR LID201034

PROJECTOR MOUNT201013

GLASS RETAINING COLLAR200422

FLANGED MAIN BODY200391

DESCRIPTIONPARTBALLOON

12VDC LED DRIVER COMPLETE

24VDC LED DRIVER COMPLETE

20116

20117

23

RUBBER GROMMET2011119

INNER GLASS GASKET2004811

LED ARRAY CONNECTOR2010715

ELECTRICAL CABLE2011220

M3 x 0.5 x 5LG SST PPHS2011321

M3 x 0.5 x 20LG SST SHCS2011422

RECEPTACLE ASSEMBLY, 2-WAY2011824

PLUG ASSEMBLY, 2-WAY2011925