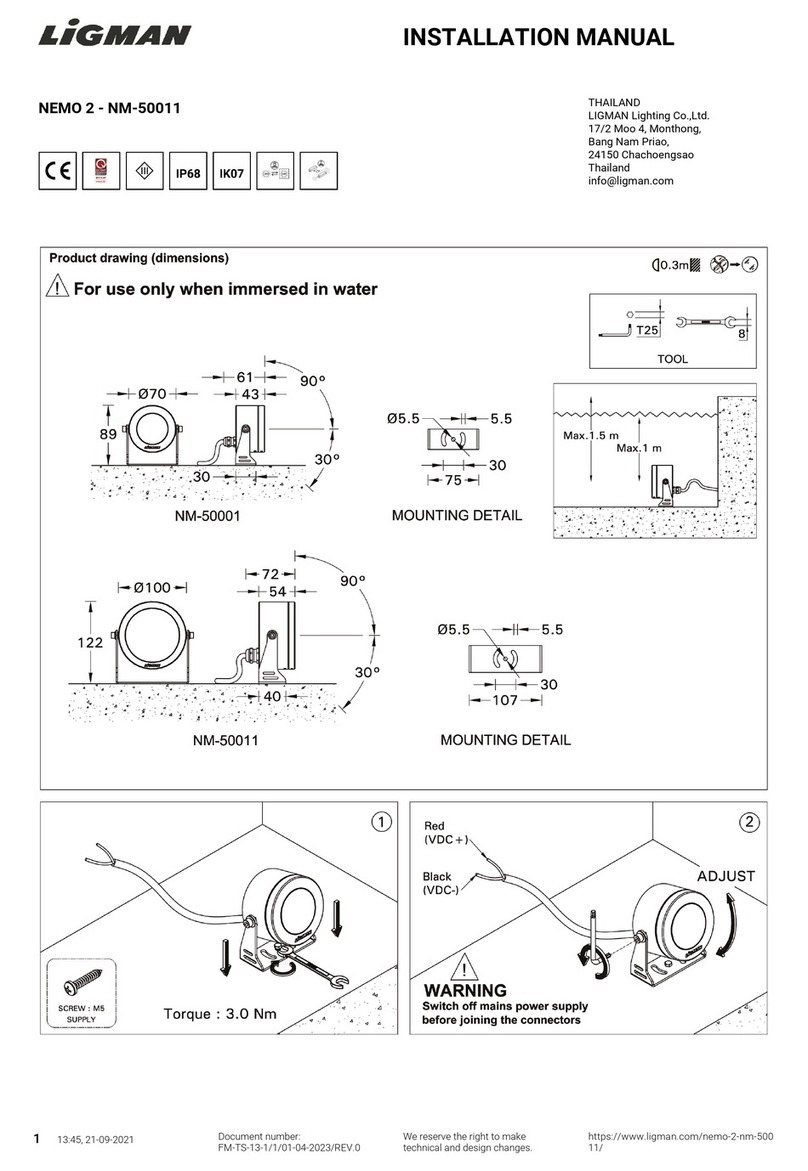

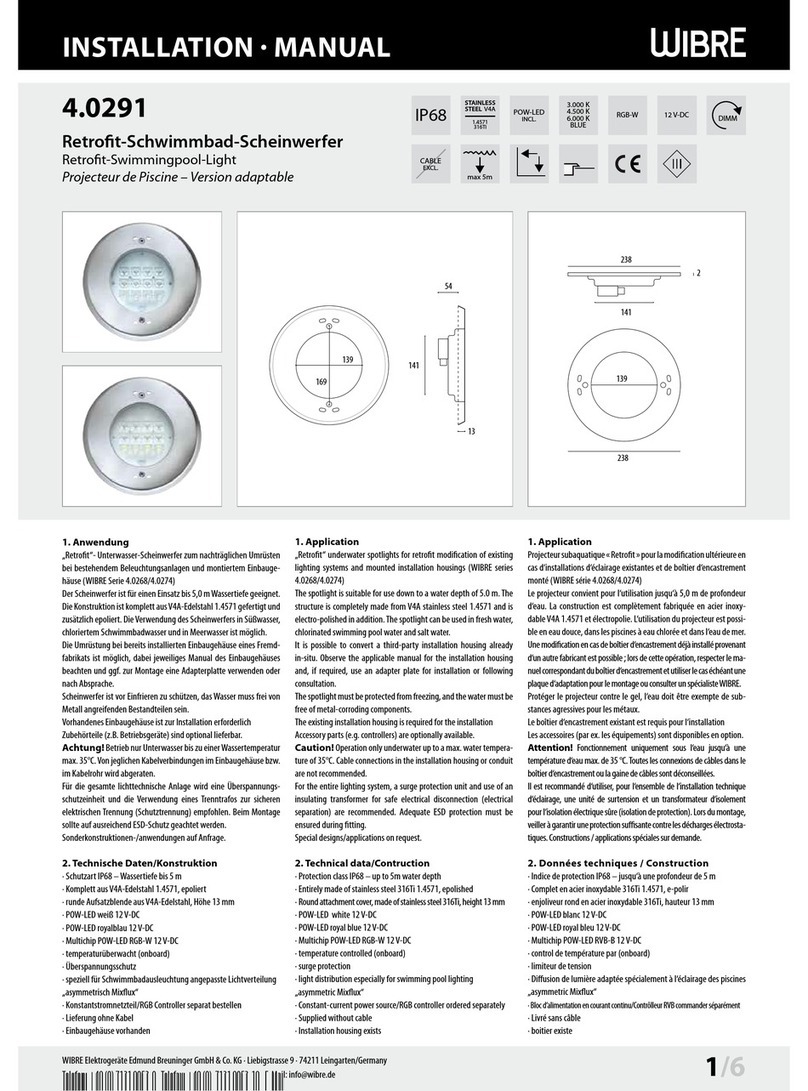

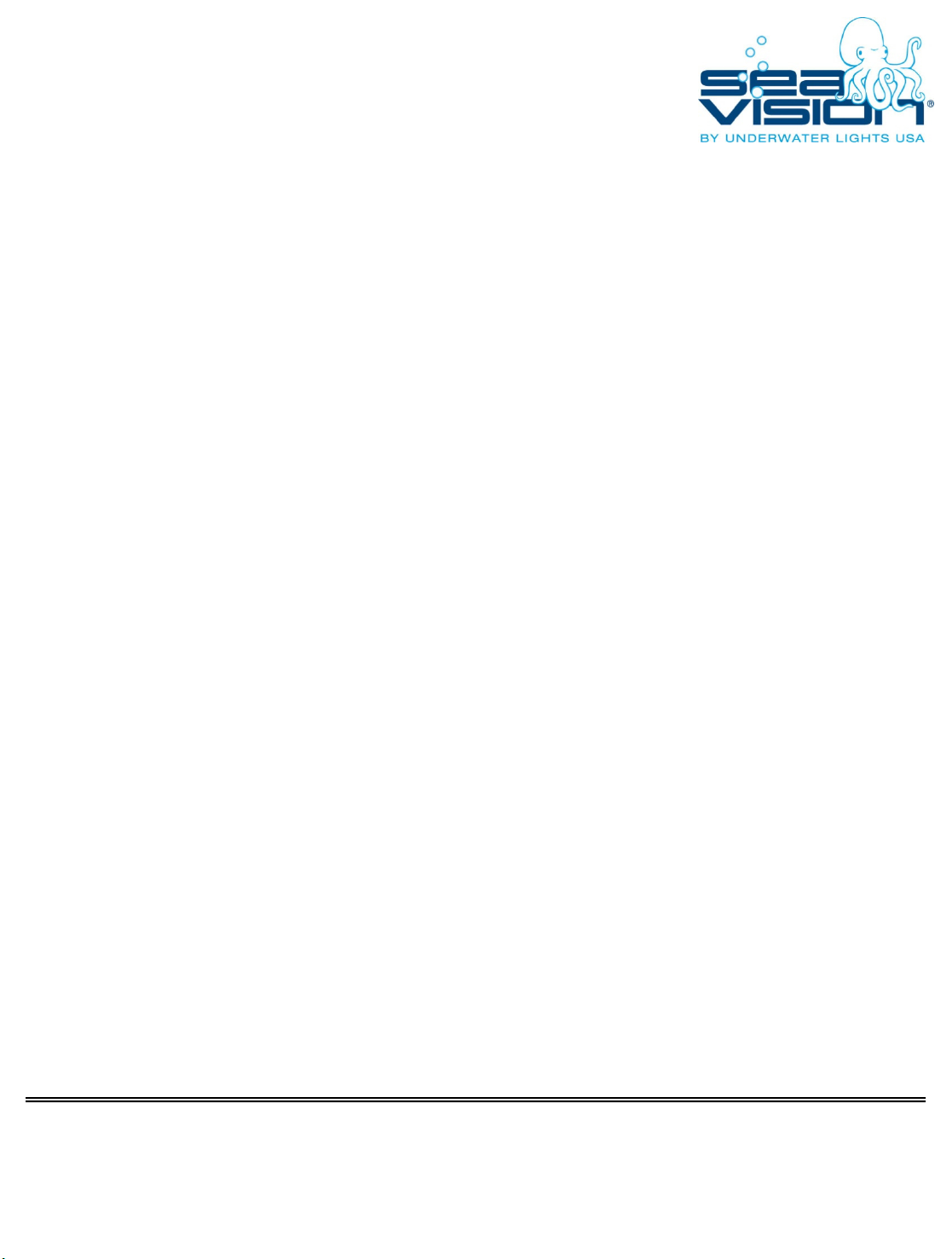

MODELS A13A11A13-10A16B, 120VAC/150W & A13A11A13-11A16B, 240VAC/150W

BALLOON PART DESCRIPTION

1 10001 MAIN BODY / COFFERDAM

2 10002 FRONT FLANGE

3 10003 GLASS RETAINING RING

4 10004 REFLECTOR TUBE

5 10005 REFLECTOR

6 10006 COMPRESSION RING

7 10007 LOCKING RING

8 10008 CONNECTING RING

9 10009 PROJECTOR LID

10 10010 GLASS

11 10011 GLASS GASKET

12 10012 CONNECTING RING GASKET

13 10013 REFLECTOR TUBE O-RING

14 10014 PROJECTOR LID O-RING

15 10015 FRONT FLANGE O-RING

16 10016 LAMP SOCKET

17 10034 LAMP, 150 WATT

18 10018 PORCELAIN TERMINAL BLOCK

19 10019 CABLE STRAIN RELIEF

20 10020 M6 x 1.0 x 14LG SST SHCS

21 10020 M6 x 1.0 x 14LG SST SHCS

22 10032 M4 x 0.7 x 16LG SST SHCS

23 10024 M6 x 1.0 x 25LG SST SET SCREW

24 10025 M6 x 1.0 SST HEX LOCKNUT

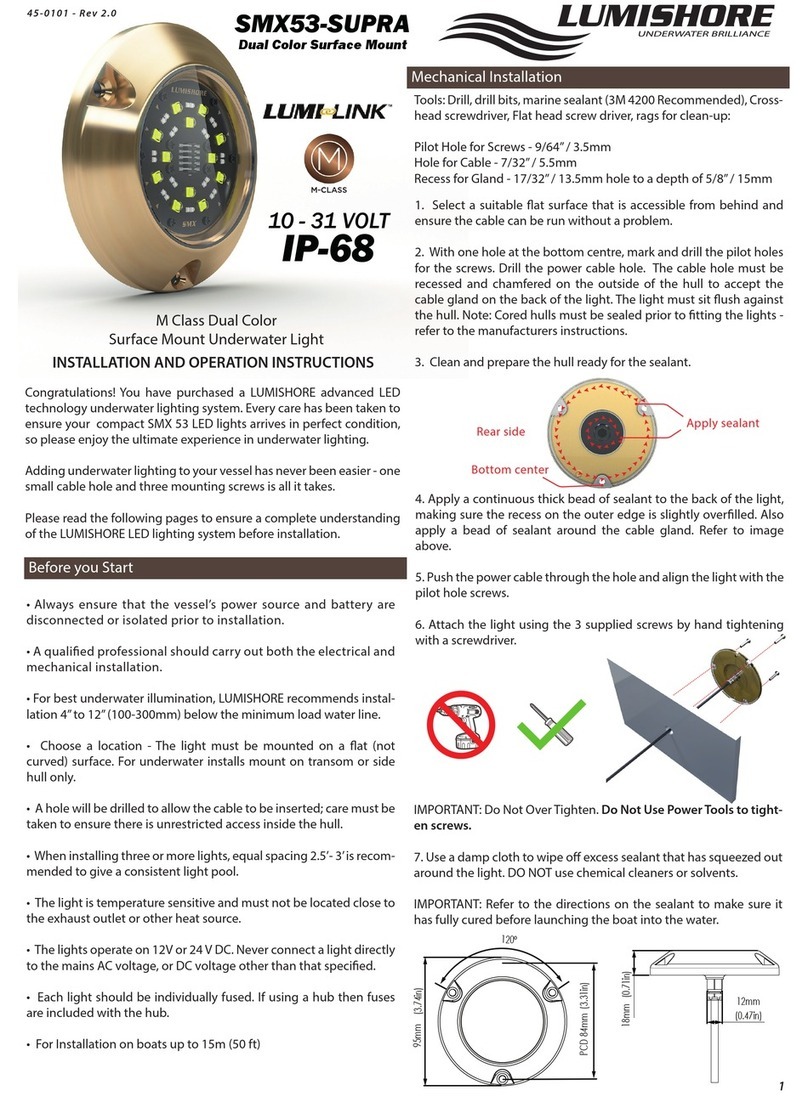

Installation:

To be installed by qualified personnel only at minimum 250-300mm (10-12”) below the light load water line using proper tools and materials. The

minimum hull thickness is 10mm (0.4”) and maximum (for sufficient light cooling) is 90mm (3.5”) with an access area of at least 75mm (3”) left

behind the light for lamp servicing and general ventilation.

After selecting a flat surface, cut a 100mm (4”) diameter hole through the vessel hull in the desired location. Caution! Check that no electrical

wiring, fuel lines, oil lines, water lines etc., pass near or through the intended hole location.

For light disassembly remove six nuts (24), remove Projector Lid (9), carefully disconnect ground wire, remove Connecting Ring (8), remove

LockingRing(7)andremoveCompressionRing(6)fromMainBody(1). Warning! Do not rotate Connecting Ring (8) while attached to

Projector Lid (9) or ground wire damage will occur! Carefully coat Main Body (1), Front Flange (2) and inner surface of hull hole with 3M

5200 Marine Adhesive or equivalent. Caution! Avoid placing excess adhesive on Main Body (1) threads. Note: Exposed inner hole surface must be

properly sealed before light installation to prevent potential water intrusion into the hull proper. Holding Front Flange (2), push Main Body (1)

through hull hole, slide Compression Ring (6) over Main Body (1) and then tighten Locking Ring (7) hand tight. Note: Ensure that the tips of all six

fasteners (21) are NOT touching Compression Ring (6). After the 3M 5200 Marine Adhesive is fully cured, tighten six fasteners (21) to 9 Nm (7

ft/lbs) using a 5mm allen wrench.

Upon making proper electrical connections (see ballast manual), reverse aforementioned light disassembly procedure and tighten six nuts (24) in a

criss-cross pattern to 2 Nm (1.5 ft/lbs). Note: Apply anti-seize compound to Connecting Ring (8) internal threads. Upon completing light

installation, it is highly recommended that Front Flange (2) be coated with antifouling paint. Also, hand tighten 4mm set screw located in Locking

Ring (7), then connect wire lead from 4mm screw provided on Locking Ring (7) to the vessels grounding and cathodic protection system.

Serviceable Parts:

For Lamp replacement remove six nuts (24), remove Projector Lid (9), carefully pull Lamp (17) out of Lamp Socket (16), push new Lamp (17) into

Lamp Socket (16), install Projector Lid (9) and tighten six nuts (24) in a criss-cross pattern to 2 Nm (1.5 ft/lbs). Caution! Ensure that the new lamp

is clean and free of dust, dirt, grease, oil, water and finger prints.

For glass replacement remove six nuts (24), remove Projector Lid (9), carefully disconnect ground wire, remove Connecting Ring (8), remove

Reflector Tube (4), remove Glass Retaining Ring (3), remove six fasteners (20) and remove Glass Gasket (11). Upon thoroughly cleaning all

surfaces, reverse said procedure to assemble and tighten six nuts (24) in a criss-cross pattern to 2 Nm (1.5 ft/lbs). Note: Six fasteners (20) are

tightened in a criss-cross pattern to 9 Nm (7 ft/lbs) using a 5mm allen wrench.

SV10 Light 120VAC/150W

240VAC/150W

Underwater Lights Europe Sarl

16, rue Rouaze

06400 Cannes, France

Phone: 33-(0)-4-97-21-02-96

Fax: 33-(0)-4-97-21-10-96

Internet: www.seavision.com

Underwater Lights USA, LLC

3406 SW 26th Terrace, C-6/7

Fort Lauderdale, FL 33312USA

Phone: 1-954-760-4447

Fax: 1-954-525-3261

Internet: www.seavision.com