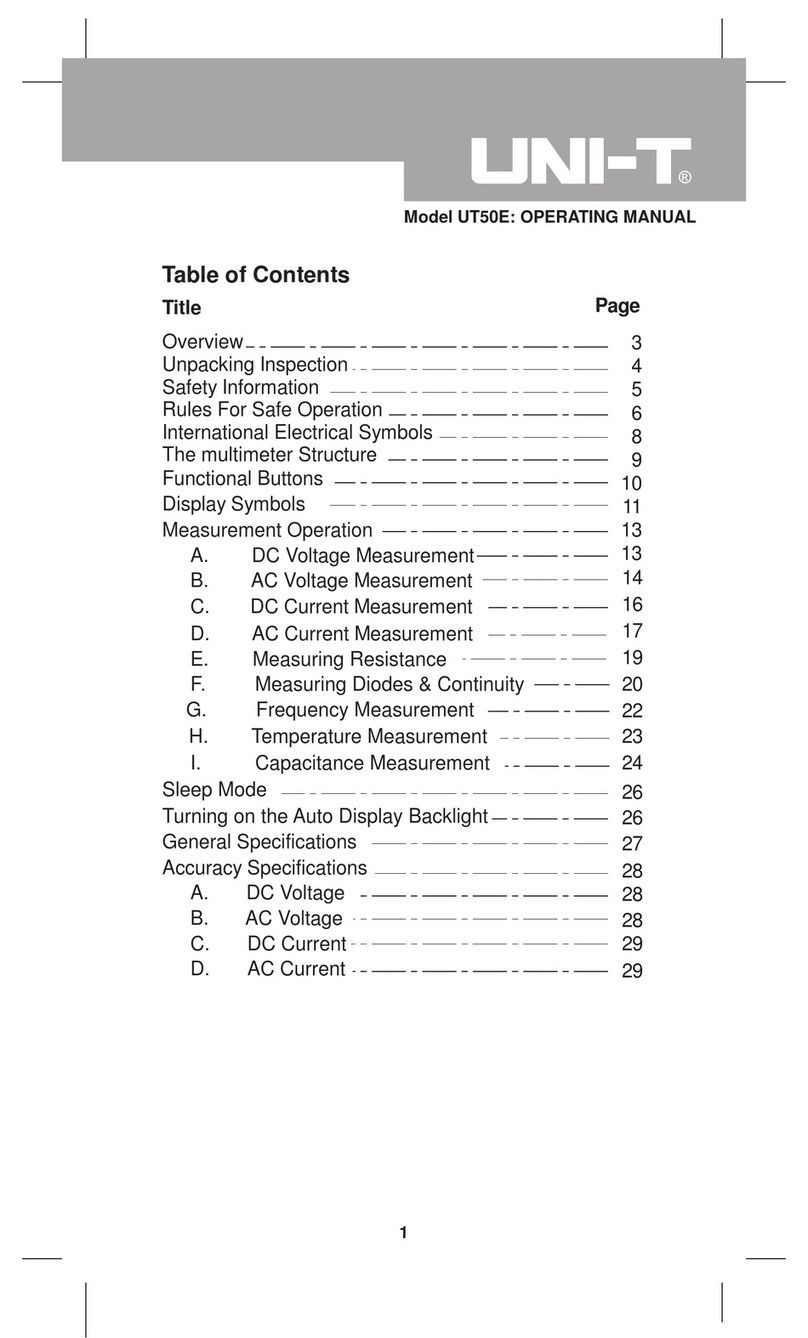

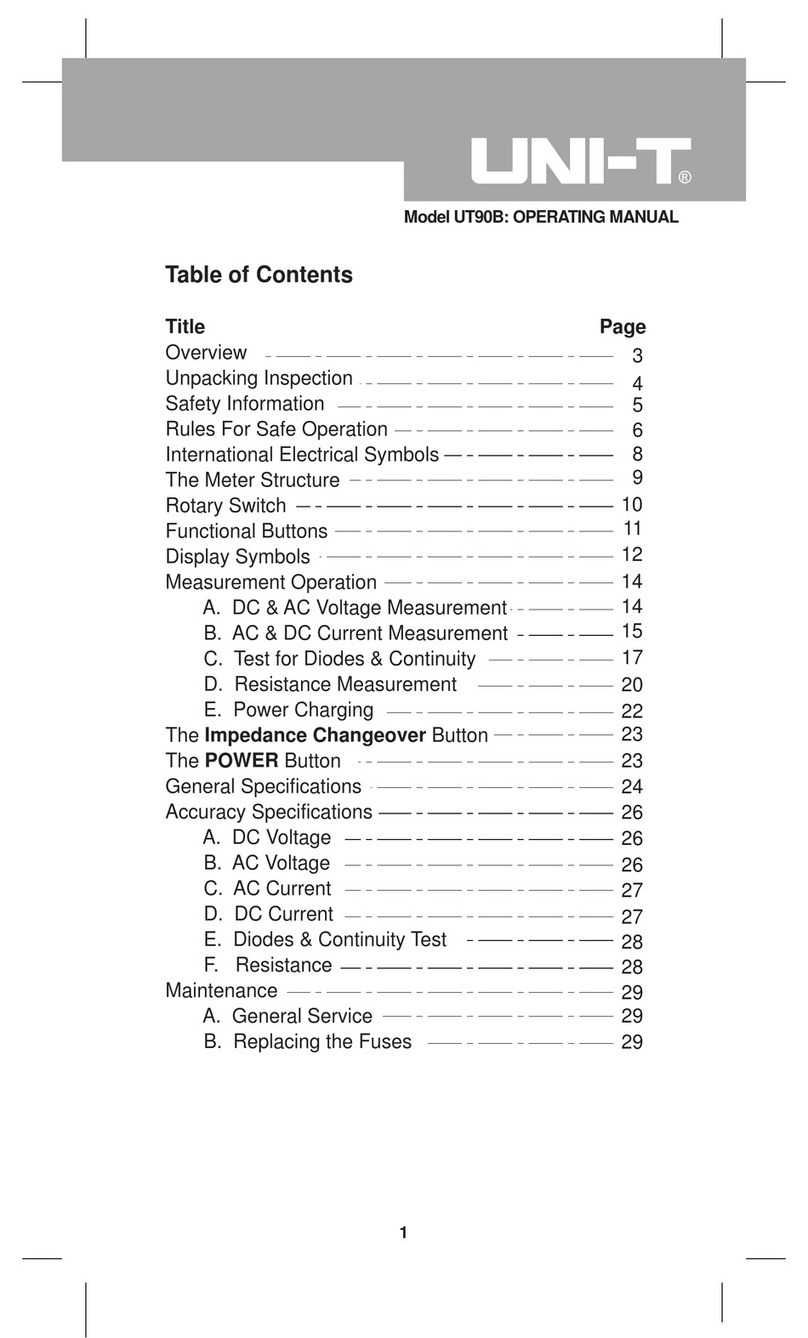

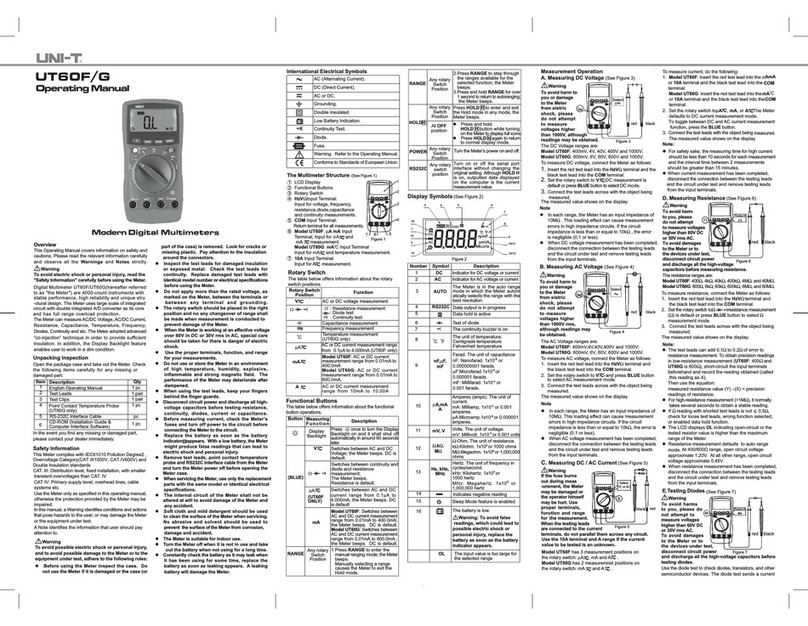

Overview

Warning

To avoid electric shock or personal injury, read the

Meter.

"Safety Information" carefully before using the

Unpacking Inspection

Open the package case and take out the Meter. Check

the following items carefully for any missing or

damaged part:

In the event you find any missing or damaged part,

please contact your dealer immediately.

1 English Operating Manual 1 pc

2 Test Lead 1 pair

3 Multi-Purpose Socket 1 pc

4 Test Clip

5 Holster

6 9V Battery (NEDA 1604, 6F22 or 009P) 1 pc

1 pair

1 pc

Item Description Qty

Safety Information

This Meter complies with the standard IEC61010:

Pollution Degree 2; Overvoltage Category; (CAT. II 1000V,

CAT. III 600V) and Double Insulation;

CAT. II: Local level, appliance, PORTABLE EQUIPMENT

etc., with smaller transient voltage overvoltages than

CAT. III

CAT. III: Distribution level, fixed installation, with smaller

transient overvoltages than CAT. IV

Use the Meter only as specified in this operating manual,

otherwise the protection provided by the Meter may be

impaired.

In this manual, a Warning identifies conditions and

actions that pose hazards to the user, or may damage

the Meter or the equipment under test.

ANote identifies the information that user should pay

attention to.

Warning

To avoid possible electric shock or personal injury,

and to avoid possible damage to the Meter or to the

equipment under test, adhere to the following rules:

zBefore using the Meter inspect the case. Do not

use the Meter if it is damaged or the case (or part

of the case) is removed. Look for cracks or missing

plastic. Pay attention to the insulation around the

connectors.

zInspect the test leads for damaged insulation or

exposed metal. Check the test leads for continuity.

Replace damaged test leads with identical model

number or electrical specifications before using

the Meter.

zDo not apply more than the rated voltage, as

marked on the Meter, between the terminals or

between any terminal and grounding.

zThe rotary switch should be placed in the right

position and no any changeover of range shall

be made during measurement is conducted to

prevent damage of the Meter.

zWhen the Meter working at an effective voltage

over 60V in DC or 30V rms in AC, special care

should be taken for there is danger of electric

shock.

zUse the proper terminals, function, and range for

your measurements.

zIf the value to be measured is unknown, use the

maximum measurement position and reduce the

range stop by step until a satisfactory reading is

obtained.

zDo not use or store the Meter in an environment

of high temperature, humidity, explosive, inflammable

and strong magnetic field. The performance of

the Meter may deteriorate after dampened.

zWhen using the test leads, keep your fingers

behind the finger guards.

zDisconnect circuit power and discharge all high

-voltage capacitors before testing resistance,

continuity, diodes, capacitance or current.

zBefore measuring current, check the Meter's fuses

and turn off power to the circuit before connecting

the Meter to the circuit.

zReplace the battery as soon as the battery indicator

appears. With a low battery, the Meter might

produce false readings that can lead to electric

shock and personal injury.

zRemove test leads and multi-purpose socket from

the Meter and turn the Meter power off before

opening the Meter case.

zWhen servicing the Meter, use the replacement parts

with the same model or identical electrical specifica

-tions.

zTo avoid any damage to the meter or any accident,

do not alter the internal circuit of the Meter randomly.

zSoft cloth and mild detergent should be used to

clean the surface of the Meter when servicing. No

abrasive and solvent should be used to prevent

the surface of the Meter from corrosion, damage

and accident.

zThe Meter is suitable for indoor use.

zTurn the Meter power off when it is not in use

and take out the battery when not using for a long

time.

zConstantly check the battery as it may leak when

it has been using for some time, replace the battery

as soon as leaking appears. A leaking battery will

damage the Meter.

International Electrical Symbols

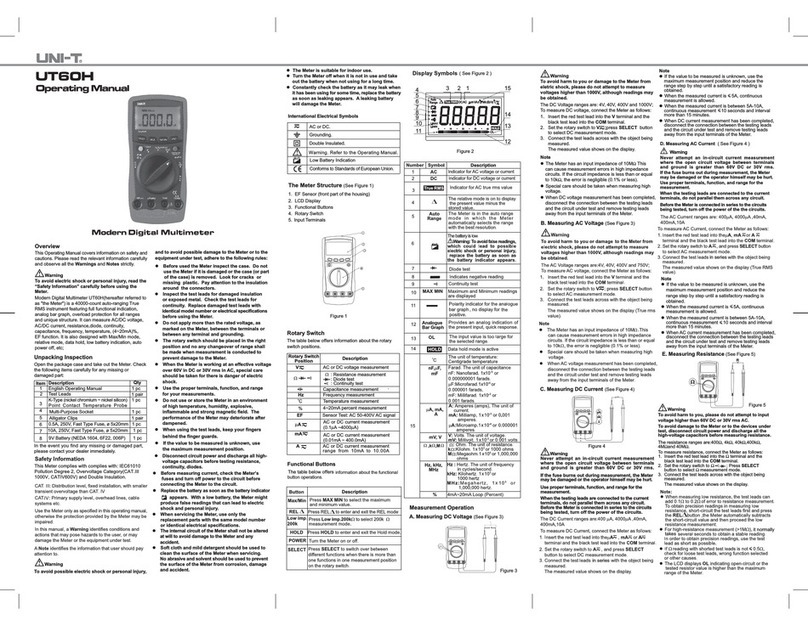

A. Measuring DC and AC Voltage(See Figure 3)

AC (Alternating Current).

DC (Direct Current).

Grounding.

Double Insulated.

Low Battery Indication.

Warning. Refer to the Operating Manual.

Conforms to Standards of European Union.

Diode.

AC or DC.

Fuse.

Continuity Test.

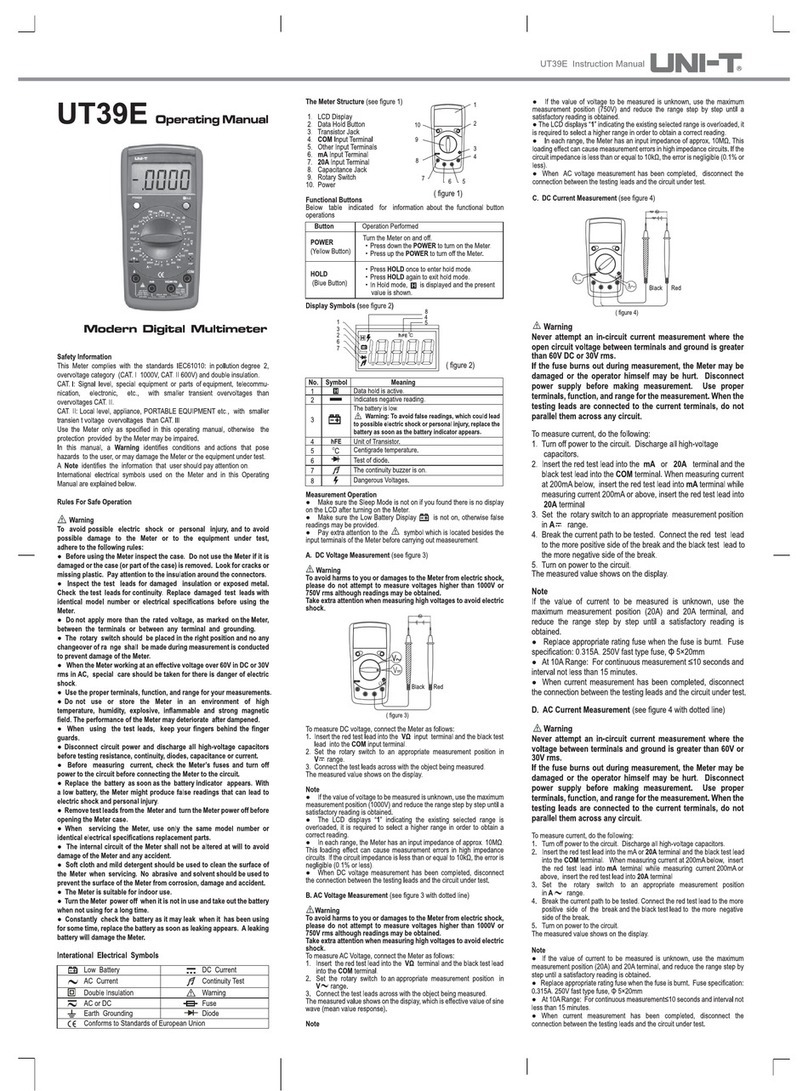

The Meter Structure (See Figure 1)

1 LCD Display

2POWER

3HOLD Button.

4 Rotary Switch

5COM Input Terminal

620A Input Terminal

7mA Input Terminal

8 Other Input Terminal. ( Figure 1)

Functional Buttons

Below table indicated for information about the functional

button operations

HOLD

(Blue

Button)

POWER

(Yellow

Button)

Turn the Meter on and off.

zPress down the POWER to turn on the

Meter.

zPress up the POWER to turn off the

Meter.

zPress HOLD once to enter hold mode.

zPress HOLD again to exit hold mode.

zIn Hold mode, is displayed and the

present value is shown.

Rotary Switch

Below table indicated for information about the

rotary switch positions.

DC voltage measurement.

AC voltage measurement.

Transistor Test

AC Current Measurement

DC Current Measurement

Fcx Capacitance Test

HLx Inductance Test

Diode test

Continuity test

Resistance measurement.

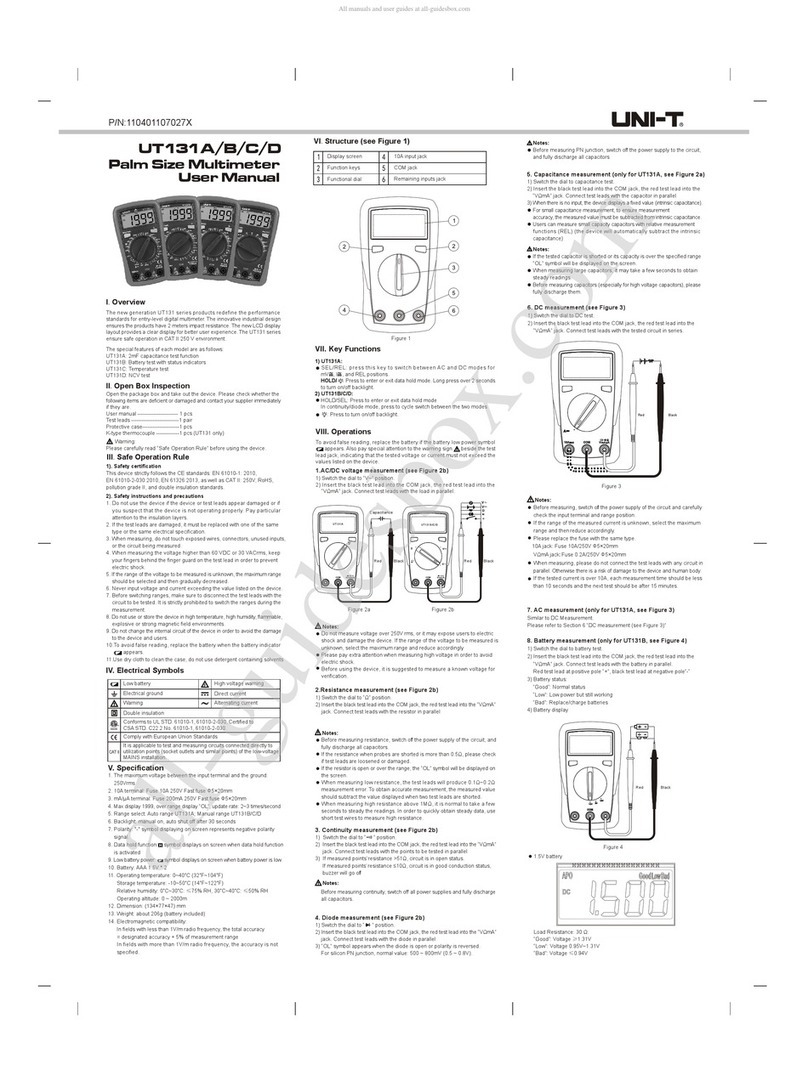

Display Symbols (See Figure 2)

( Figure 2)

No. Symbol Description

1

The battery is low.

Warning: To avoid false

readings, replace the battery as

soon as the battery indicator

appears.

4Indicates negative reading.

5Test of diode.

6The continuity buzzer is on.

7Date hold is active.

8

Indicator for AC voltage or current.

The displayed value is the mean

value.

3AC

Connect

Terminal

Indicator of connecting test leads

into different input terminals.

2Warning Symbol.

mA, A A: Amperes (amps). The unit of

current.

mA: Milliamp. 1 x 10-3 or 0.001

amperes.

V: Volts. The unit of voltage.

mV: Millivolt. 1 x 10-3 or 0.001 volts.

9hFE The Unit of Transistor Test

10-15

mH, H

H: Henry. The unit of Inductance.

mH: Millihenry. 1 x 10-3 or 0.001

henry.

( Figure 3)

Black Red

The DC Voltage ranges are: 200mV, 20V, 200V and 1000V.

The AC Voltage ranges are: 2V, 200V and 1000V

To measure DC&AC Voltage, connect the Meter as follows:

1. Insert the red test lead into theV input terminal

and the black test lead into the COM input terminal.

2. Set the rotary switch to an appropriate measurement

position in V or V range.

3. Connect the test leads parallel across with the object

to be measured.

The measured value shows on the display.

Note

zIf the value of voltage to be measured is unknown,

use the maximum measurement position (1000V)

and reduce the range step by step until a satisfactory

reading is obtained.

zThe LCD displays

range is overloaded, it is required to select a higher

range in order to obtain a correct reading.

zIn each range, the Meter has an input impedance of

approx. 10M This loading effect can cause

measurement errors in high impedance circuits. If the

circuit impedance is less than or equal to 10 k ,the

error is negligible (0.1% or less).

zWhen voltage measurement has been completed

disconnect the connection between the testing leads

and the circuit under test, and remove the testing

leads away from the input terminal of the Meter.

B. Measuring DC and AC Current (See Figure 4)

( Figure 4)

Black Red

"1" indicating the existing selected

Warning

Never attempt an in-circuit current measurement

where the open circuit voltage between terminals

and ground is greater than 60V DC or 30V rms.

If the fuse burns out during measurement, the Meter

may be damaged or the operator himself may be hurt.

Use proper terminals, function, and range for the

measurement. When the testing leads are connected

to the current terminals, do not parallel them across

any circuit.

The DC Current ranges : 2mA, 200mA and 20A

The AC Current ranges : 2mA, 200mA and 20A

To measure current, do the following:

1. Turn off power to the circuit. Discharge all high-voltage

capacitors.

2. Insert the red test lead into the 20A or mA input

terminal and the black test lead into the COM terminal.

When you measure current below 200mA, please insert

the red test lead into the mA input terminal. When you

measure 200mA or above, insert the red test lead into

the 20A input terminal.

3. Set the rotary switch to an appropriate measurement

position in A or A range.

4. Break the current path to be tested. Connect the red

test lead in serial to the more positive side of the break

and the black test lead to the more negative side of

the break.

5. Turn on power to the circuit.

The measured value shows on the display.

( Figure 5)

Black Red

C. Measuring Resistance (See Figure 5)

Warning

To avoid damages to the Meter or to the devices under

test, disconnect circuit power and discharge all the

high-voltage capacitors before measuring resistance.

Note

zIf the value of current to be measured is unknown,

use the maximum measurement position, and reduce

the range step by step until a satisfactory reading is

obtained.

zFor safety sake, the measuring time for high current

should be less than 10 seconds and the interval time

between 2 measurements should be greater than 15

minutes

zWhen current measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test, and remove the testing leads

away from the input terminal of the Meter

1. Insert the red test lead into the V input terminal and

the black test lead into the COM terminal.

2. Set the rotary switch to an appropriate measurement

position in range.

3. Connect the test leads with the object being measured

in parallel.

The measured value shows on the display.

Note

The test leads can add 0.1 to 0.3 of error to the low

UHVLVWDQFHUDQJHȍPHDVXUHPHQW

To obtain accurate readings in low-resistance, short-circuit

the input terminals beforehand and record the reading

obtained (called this reading as X). (X) is the additional

resistance from the test lead.

Then use the equation:

measured resistance value (Y) - (X) = accurate readings

of resistance.

zFor high resistance (>1M ), it is normal taking several

seconds to obtain a stable reading..

zWhen there is no input, for example in open circuit

condition, the Meter displays "1".

zWhen resistance measurement has been completed,

disconnect the connection between the testing leads

and the circuit under test, and remove the testing leads

away from the input terminal of the Meter.

D. Testing Diodes and Continuity (See Figure 6)

Warning

To avoid damage to the Meter or to the equipment

under test, disconnect circuit power and discharge

all high-voltage capacitors before measuring diodes.

To avoid harms to you, never attempt to input

( Figure 6)

Black Red

Digital Multimeter Model UT58D is a 2000-count hand

-held instrument with remarkable features: ex-large

LCD, steady operations, overload protection for all

ranges and unique structure. It is designed with large

-scale integrated circuits and dual integral A/D converter

as the core, which offers 28 measuring ranges and can

measure AC/DC voltage, AC/DC current, resistance,

capacitance, inductance, transistor, diode and continuity.

It is also equipped with data hold, full icon display and

sleep mode functions,etc;

Description

Measurement Operation