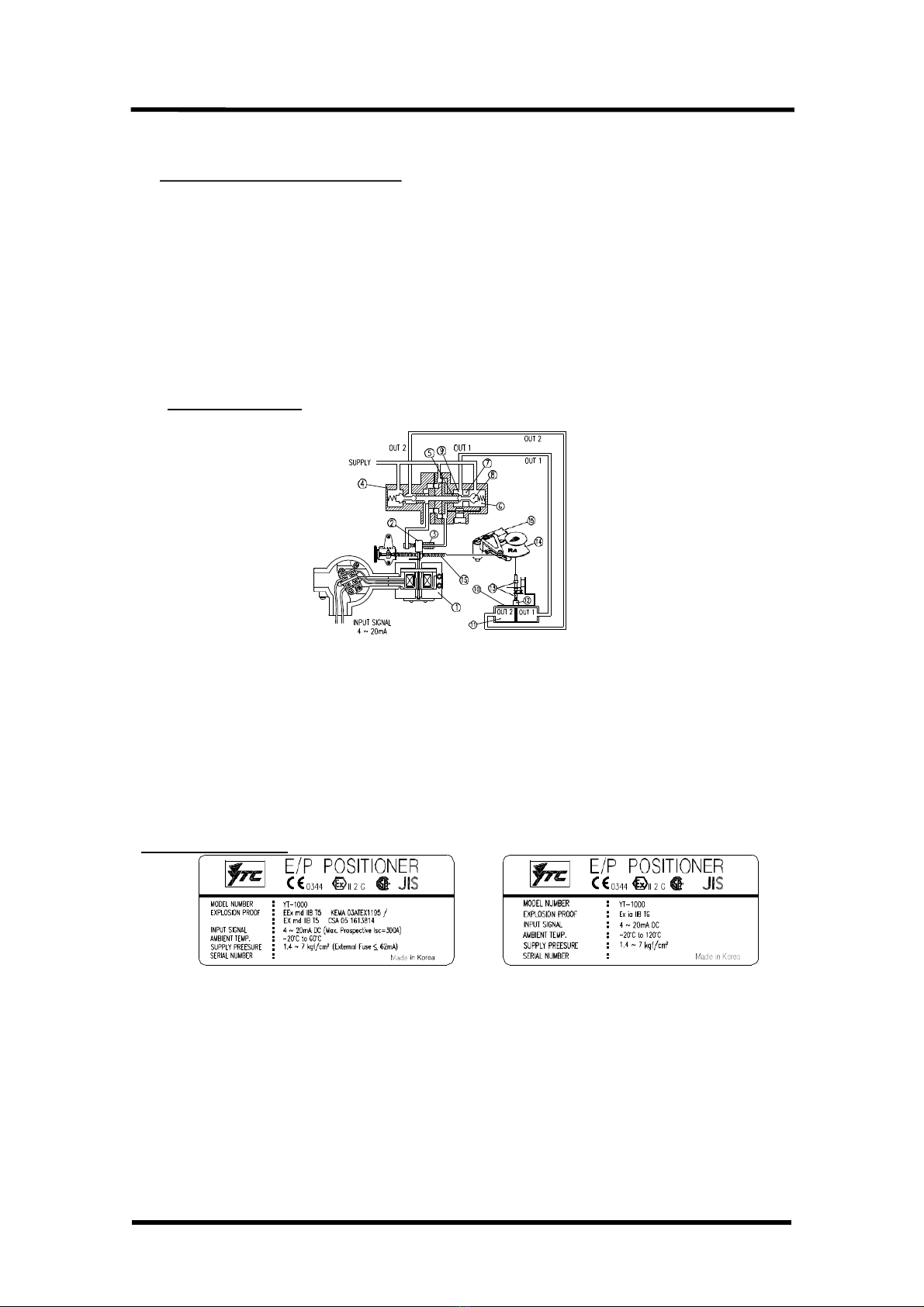

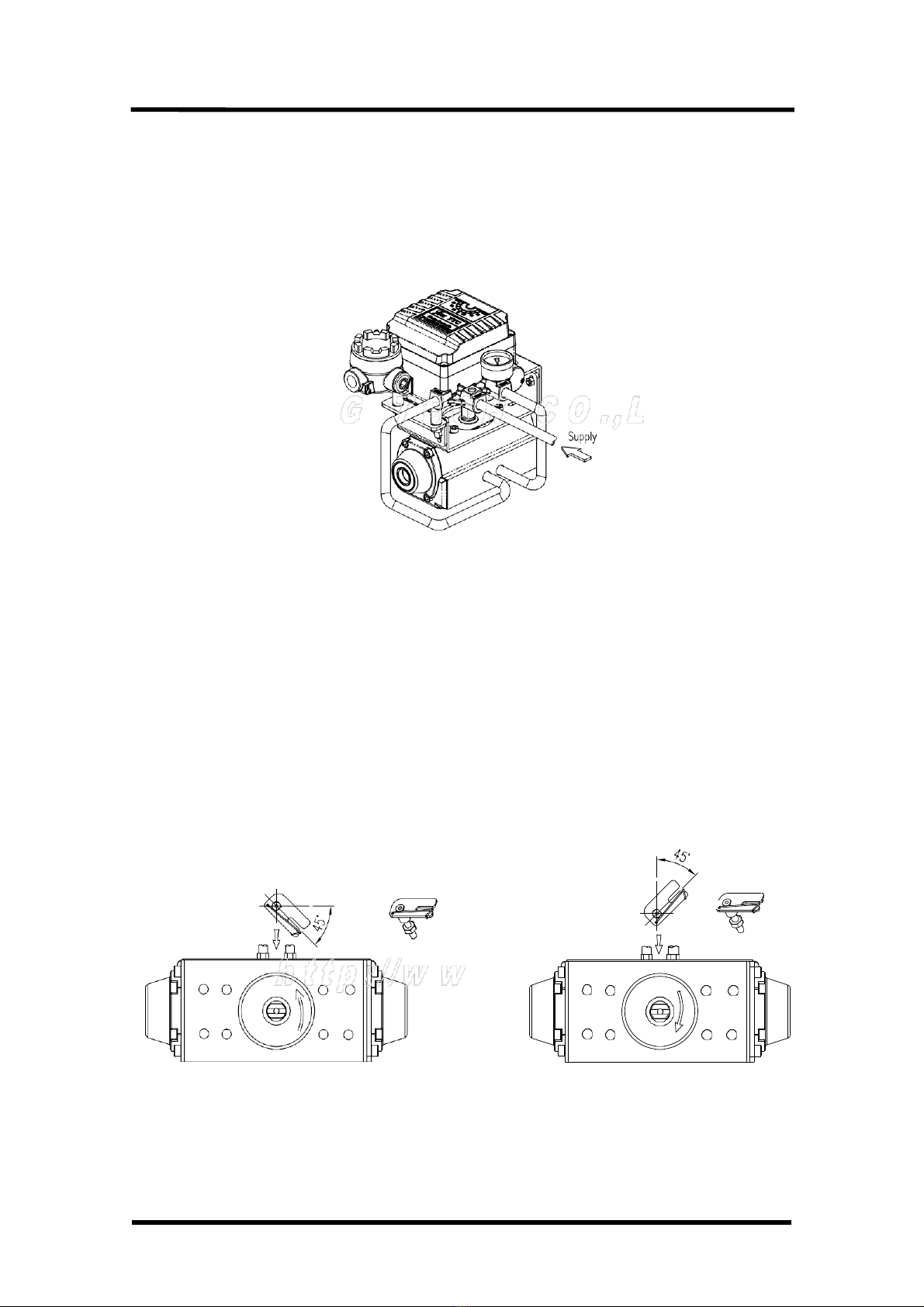

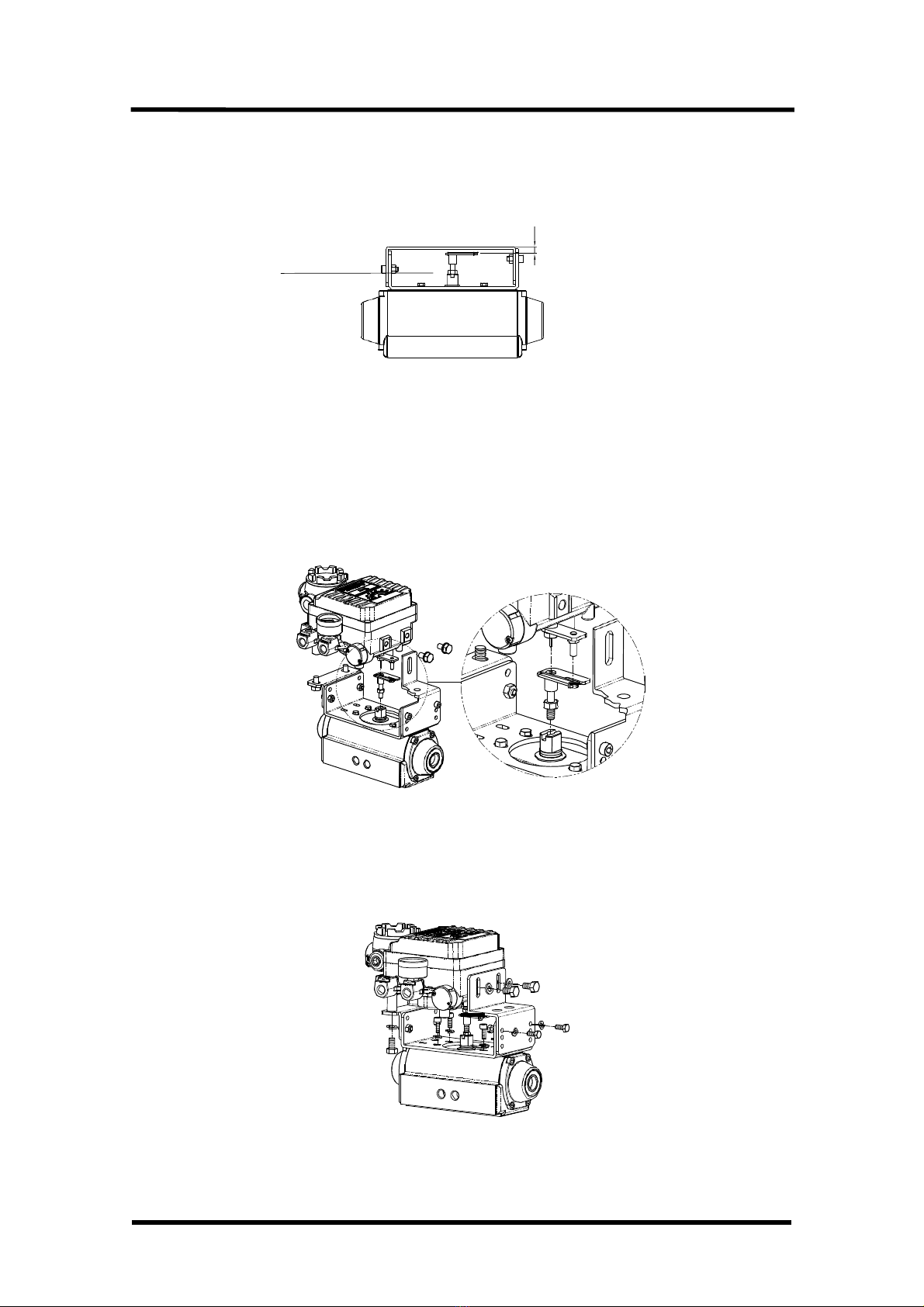

Electro-Pneumatic Positioners

Category U-EPR

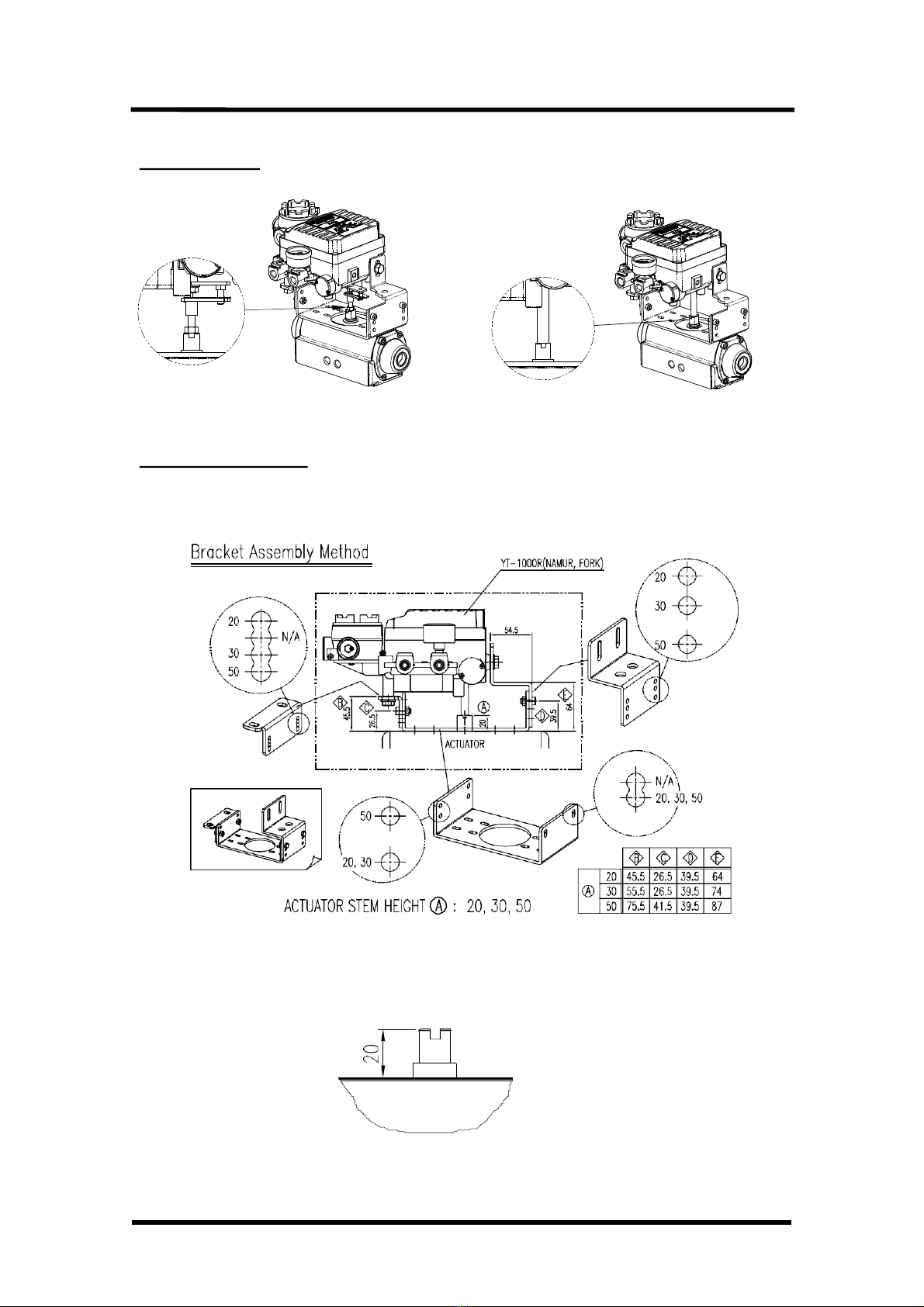

Single Double

Input Signal 4~20mA DC *1

Impedance 250±15Ω

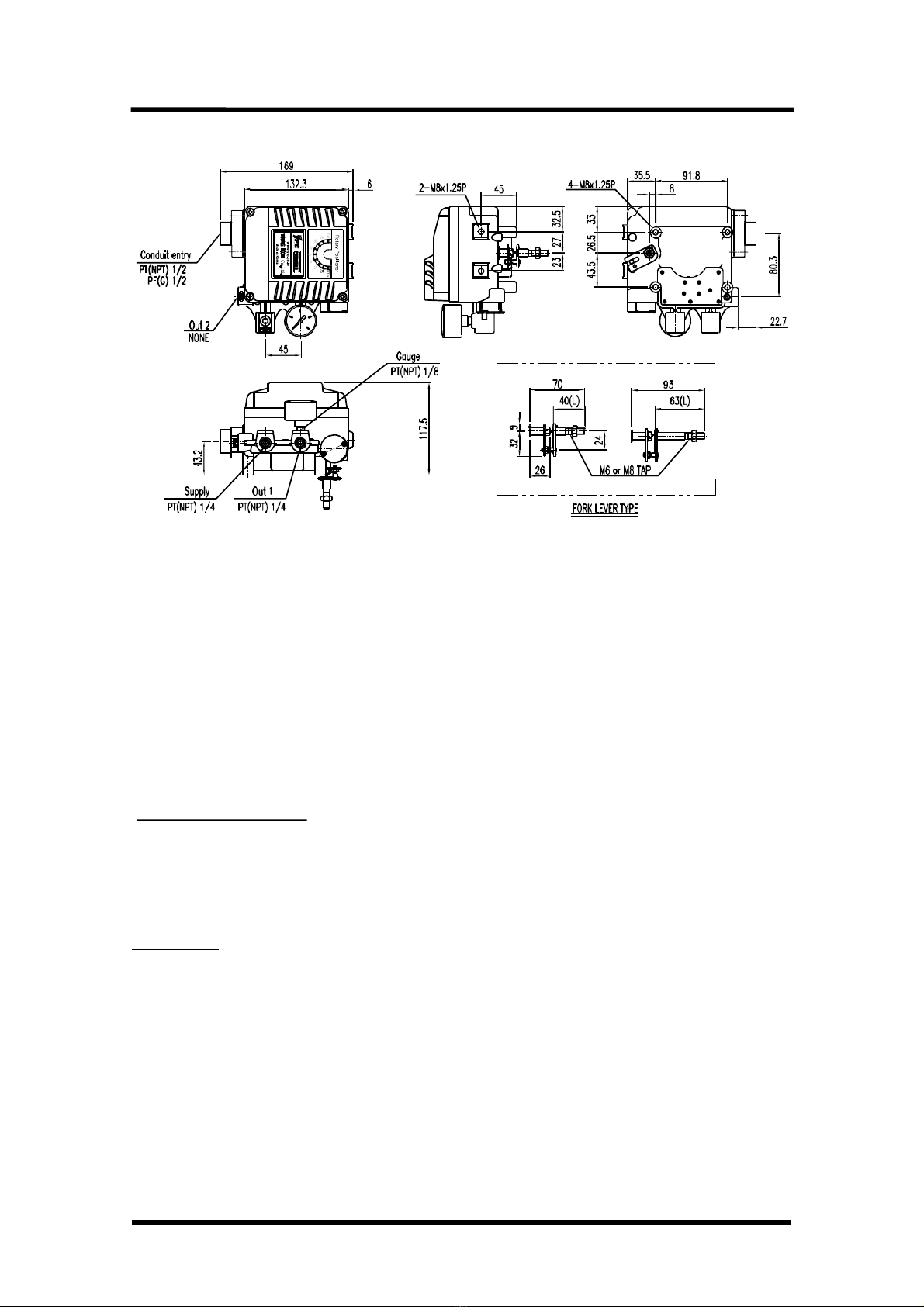

Supply Pressure 1.4~7.0kgf/cm2(20~100 psi)

Stroke 0~900 *2

Air Connection PT(NPT) 1/4

Gauge Connection PT(NPT) 1/8

Conduit Entry PF 1/2 or G 1/2

Explosion Proof *3

Domestic: ExdmIIBT5, ExdmIICT5, ExiaIIBT6

ATEX: EExmdIIBT5, JIS : ExsdIIBT5

CSA : ExmdIIBT5, NEPSI : ExiaIICT6

Protection IP66

Ambient

Temperat

ure

Operating Standard:-20∼70℃,

Low: -40∼70℃High: -20∼120℃

Explosion -20~60℃(T5), -20~40℃(T6)

Linearity ±1.0% F.S

Hysteresis 1.0% F.S

Sensitivity ±0.2% F.S ±0.5% F.S

Repeatability ±0.5% F.S

Air Consumption 3LPM (Sup=1.4kgf/cm2,20psi)

Flow Capacity 80LPM (Sup=1.4kgf/cm2,20psi)

Material Aluminum Diecasting

Weight 2.7kg(6.1lb)

- 5-

Specification

*Tested under ambient temperature of 20℃, absolutepressureof 760mmHg, and humidityof 65%.

Please contact us formoredetailed specification.

*1: For 1/2 Split Control,it can be applied by adjustingzero andspan.

*2: For inquiryregarding strokes under 10mm or above 150mm,

* U-EPR has differenttypes of explosionproofcertificates. Please make sure to check explosionproof

grade.