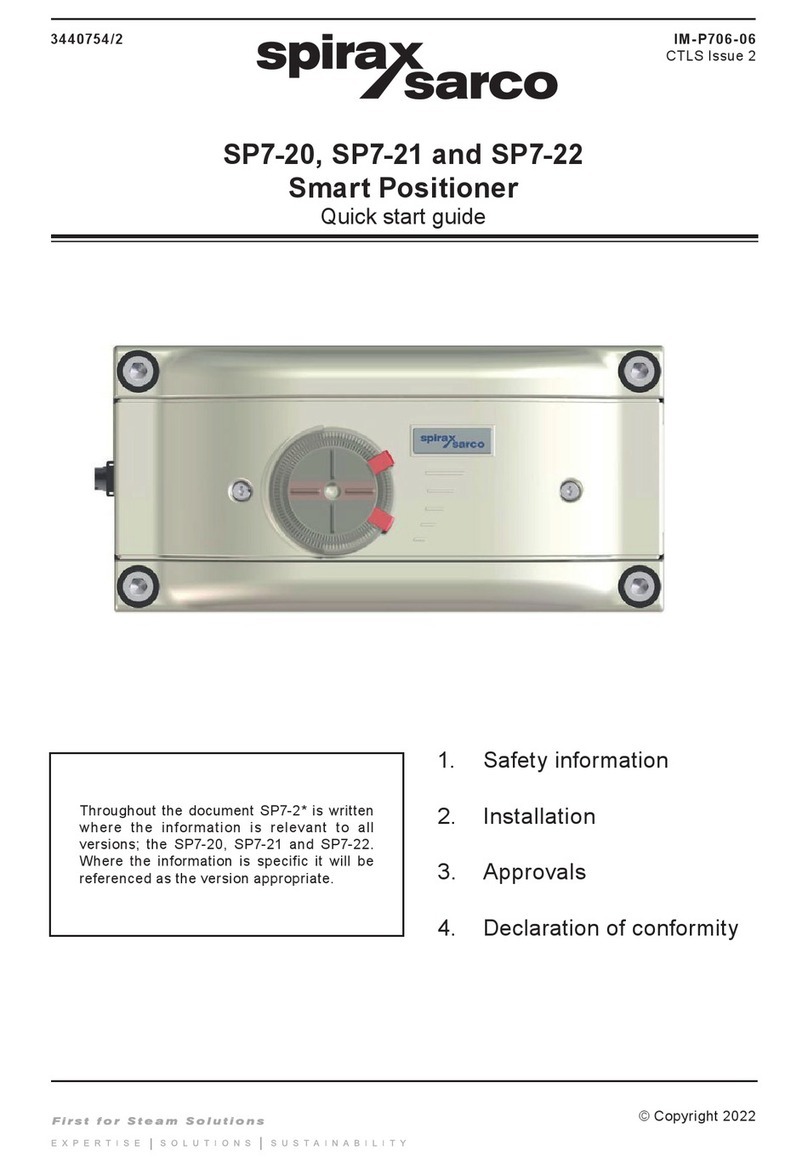

IM-P343-46 CTLS Issue 32

1. Safety information

Safe operation of these products can only be guaranteed if they are properly

installed, commissioned, used and maintained by qualified personnel

(see Section 1.11) in compliance with the operating instructions. General

installation and safety instructions for pipeline and plant construction, as well

as the proper use of tools and safety equipment must also be complied with.

WARNING: The maximum process fluid temperature must be suitable for

use if the unit is to be used in any potential explosive atmosphere. For the

device maintenance in a potentially explosive atmosphere, we recommend

the usage of tools which do not produce and / or propagate sparks.

1.1 Intended use

Referring to the Installation and Maintenance Instructions, product markings and

Technical Information Sheet, check that the product is suitable for the intended

use / application. These products comply with the requirements of the Directive

2014/34/EU (ATEX) for the use of equipments in potentially explosive atmospheres.

1.2 Access

Ensure safe access and if necessary a safe working platform (suitably guarded)

before attempting to work on the product. Arrange suitable lifting gear if required.

1.3 Lighting

Ensure adequate lighting, particularly where detailed or intricate work is required.

1.4 Hazardous liquids or gases in the pipeline

Consider what is in the pipeline or what may have been in the pipeline at some

previous time. Consider: flammable materials, substances hazardous to health,

extremes of temperature.

1.5 Hazardous environment around the product

Consider: explosion risk areas, lack of oxygen (e.g. tanks, pits), dangerous gases,

extremes of temperature, hot surfaces, fire hazard (e.g. during welding), excessive

noise, moving machinery. The positioner suitable for installation in Zone 1 or

Zone 2 ( Gas ) Zone 21 or Zone 22 ( Dust ) according to the Atex rating reported

in the following. The positioner shall not be used in zone 0.

1.6 The system

Consider the effect on the complete system of the work proposed. Will any proposed

action (e.g. closing isolation valves, electrical isolation) put any other part of the

system or any personnel at risk?

Dangers might include isolation of vents or protective devices or the rendering

ineffective of controls or alarms. Ensure isolation valves are opened and closed

progressively to avoid system shocks.

1.7 Pressure systems

Ensure that any pressure is isolated and safely vented to atmospheric pressure.

Consider double isolation (double block and bleed) and the locking or labelling of

closed valves. Do not assume that the system has depressurised even when the

pressure gauge indicates zero.

1.8 Temperature

Allow time for temperature to normalise after isolation to avoid the danger of burns.

X