CAUTION! To prevent generator burnout, never run the locomotive without smoke

fluid in the smoke generator. If no smoke is in the generator, switch smoke genera-

tion to the OFF position. For more info, see smoke generator operation instructions.

SMOKE GENERATOR

The locomotive contains two smoke units which produce ”diesel

exhaust” through the two stacks on the top side of the cab body. The

smoke generators require the periodic addition of smoke fluid in order to

operate properly. When doing so make sure the switch marked “smoke”

in the front of the locomotive (see control box switch operation above) is

in the OFF position. Remove both stacks from the top of the locomotive,

and add 10-20 drops of USA Trains smoke fluid (USA Trains Part #R50001) to

BOTH smoke generator holes. Never overfill the smoke generator and

promptly wipe up any excess smoke fluid that may have spilled onto any

painted surfaces. Place both smoke stacks back on the top of the loco-

motive. Turn the smoke unit switch to the ON position and begin opera-

tion. Smoke production will begin when the fluid becomes heated. It may

take longer to generate the smoke if the unit is full. By following these

directions the smoke generator will provide hours of enjoyment and

enhance the realistic operation of your NW-2 locomotive.

CAUTION! NEVER RUN THE UNIT WITHOUT SMOKE FLUID UNLESS THE SMOKE SWITCH IS IN

THE OFF POSITION. THIS WILL PREVENT THE SMOKE GENERATOR FROM BURNING OUT!

NOTE: It is not uncommon for the front stack to smoke more than the rear

stack due to the draft created by movement of the locomotive

POWER PLUGS

Each locomotive is equiped with two recepticles to power sound or

lights only. Do not interconnect any two locomotives together using these

plugs or damage to one or both units will occur.

POWER REQUIREMENTS

The locomotive is designed to operate on direct current (DC) with out-

puts of 0-22 volts.

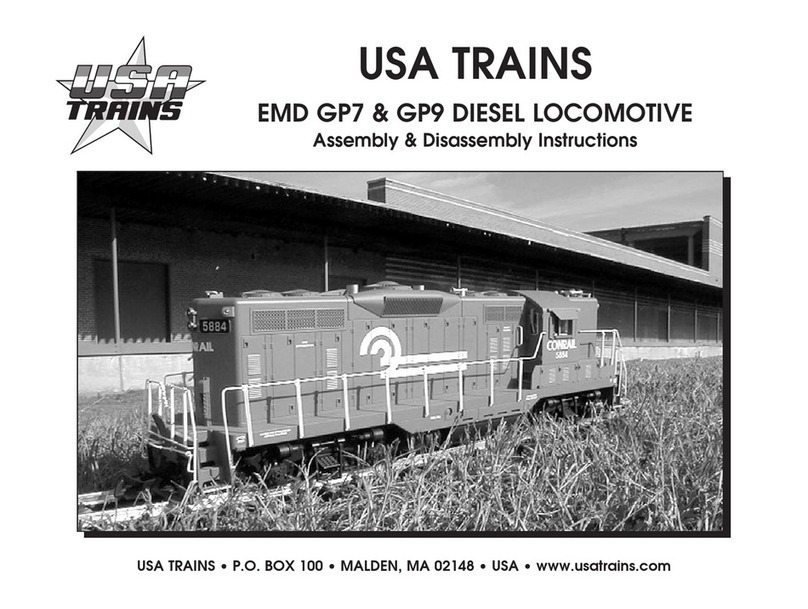

CONTROL BOX SWITCH

The locomotive contains three switches to operate the on/off motors,

on/off smoke generator, and on/off lights. To access the switches, pull up

gently on the grab rail of the vent grill on the front of the locomotive. (see

diagram below)

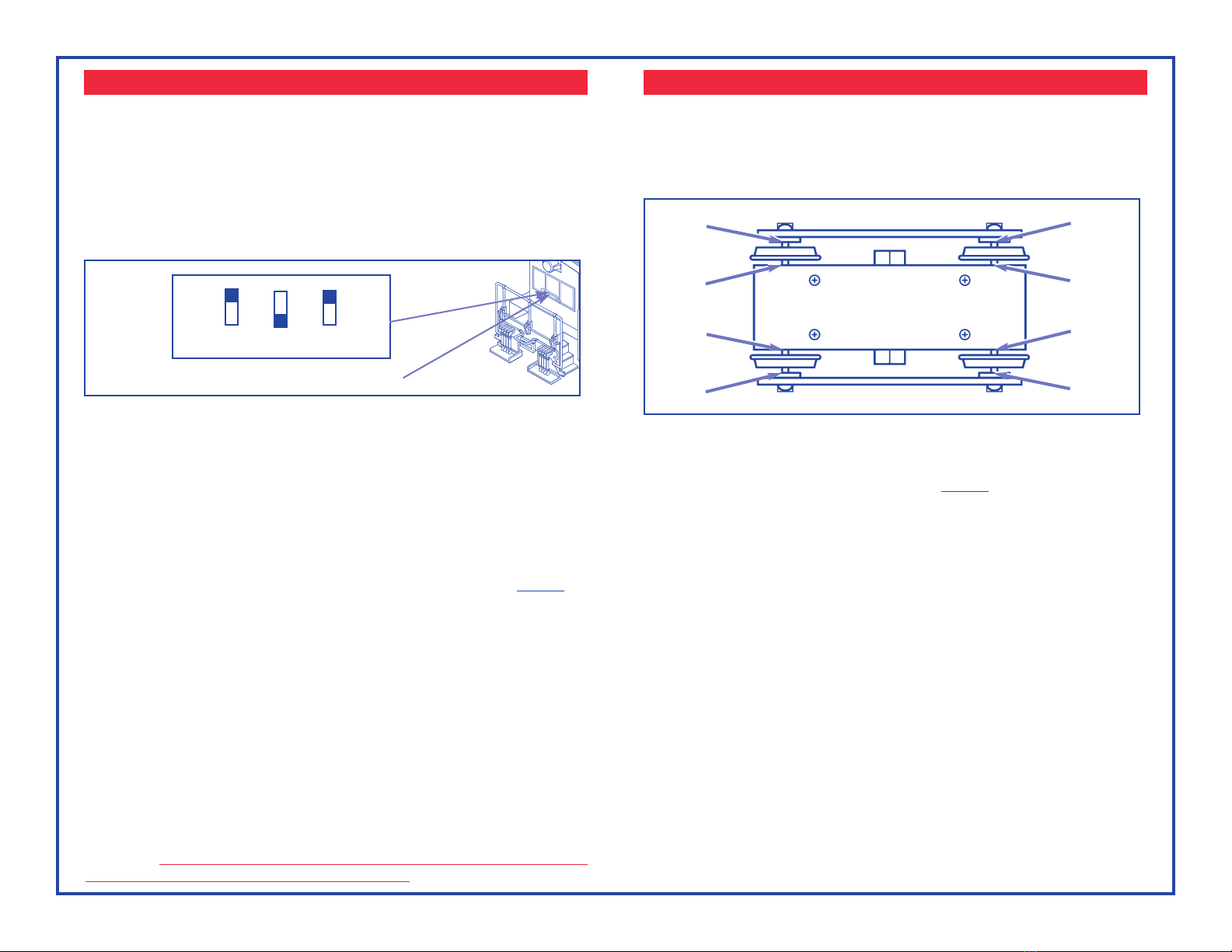

LUBRICATION

Your locomotive was lubricated at the factory and under normal oper-

ating conditions will not need to be lubricated during the first 50 hours of

operation. The locomotive has three lubrication points. (See diagram

below)

1. SIDEFRAME JOURNAL BOX: The axle ends fit into brass bushings which

brings power into the locomotive. These brass bushings should periodically

be cleaned out and lubricated with a small amount of U.S.A.Trains electri-

cally conductive lubricant (USA Trains Part #R50002). Use only our conduc-

tive lubricant to avoid loss of electrical contact which could cause your

locomotive to loose power or run erratically. The frequency of lubrication

depends on your operating conditions.

2. AXLE LUBRICATION: Two drops of oil should be placed on all four con-

tact points where the axle enters the gear box. An ultra light oil such as

Hob-E-Lube (#HL653) is recommended.

3. GEAR BOX LUBRICATION: Under normal operating conditions, the gear

box should not have to be lubricated. However, you may want to lubri-

cate the gears after each 100 hours of operation by removing the four

screws on the bottom of the gear box to expose the gears and applying

moly grease by Hob-E-Lube to the gears on the axle only. Do not apply

grease to any electrical contacts inside the gear box as you may hinder

the electrical contacts required for smooth operation.

WHEEL/SLIDE SHOES

The NW-2 and calf units are equipped with twelve electrical pickup

points-six per motor truck. Each of these must be cleaned periodically to

ensure proper electrical contact with the track and to ensure smooth

operation of your locomotive. Clean all four wheels and the bottom sur-

face of the slide shoes periodically to ensure good electrical contact with

the track. A good indication that you need to clean these contacts is

flickering lights, non-operation of the smoke unit, or a jerking motion of the

locomotive.

1

2

GEAR BOX

2

1

1

2

2

1

(3)

Gently pull upward and outward on the grabrail to access the switch box

OPERATION

MAINTAINING AND SERVICING YOUR NW-2 AND CALF