CONTENTS

Introduction …………………………………………………………………1

Warning and Caution ………………………………………………………2

Chapter 1 Description of Components ………………………………. 4

1-1 Components ……………………………………………………………………. 4

1-1-1 Structure of Standard Set Parts ……………………………………………… 4

1-1-2 Optional Parts (Sold Separately) ……………………………………………. 5

1-2 Connection with I/O Unit and Camera………………………………………6

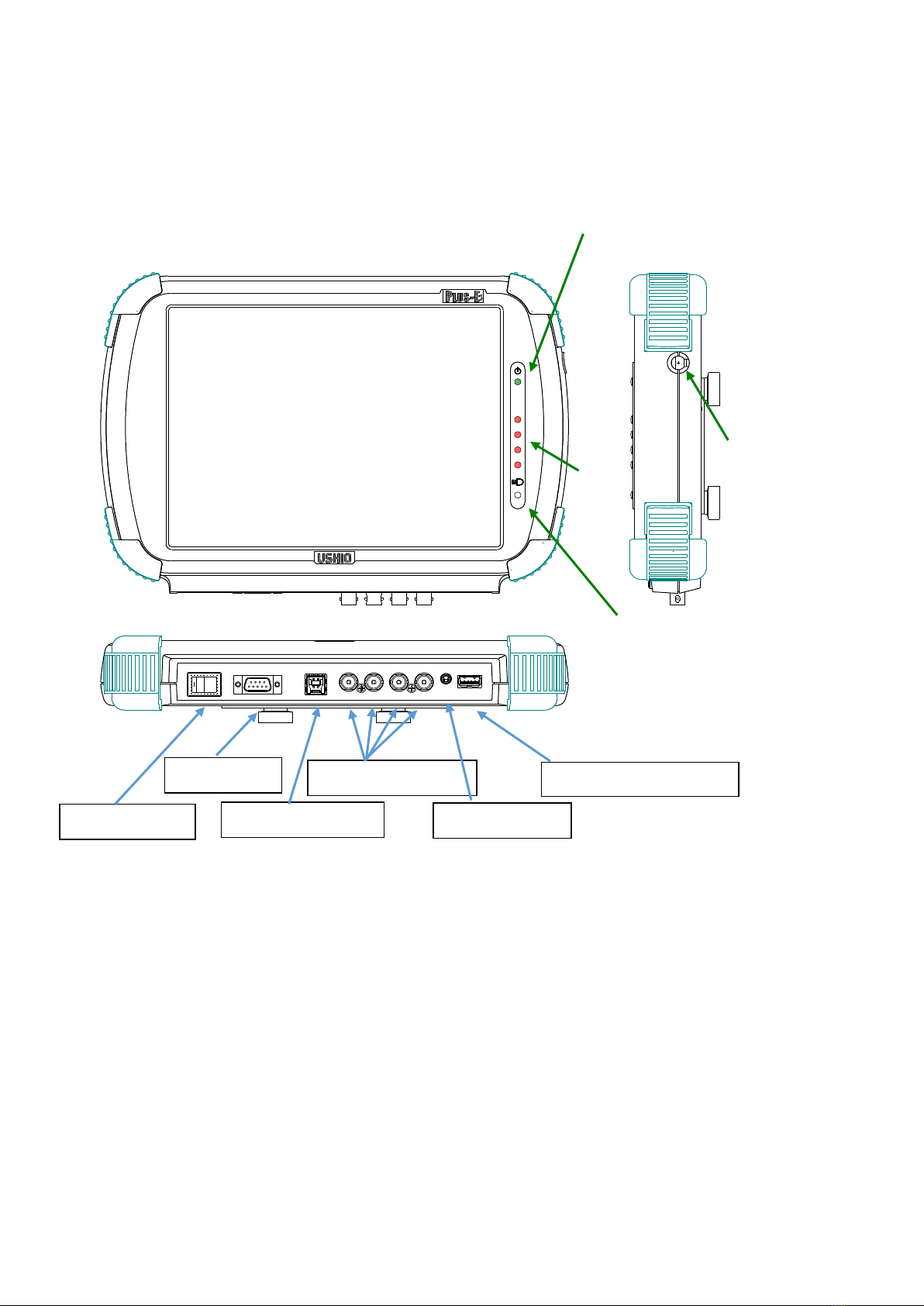

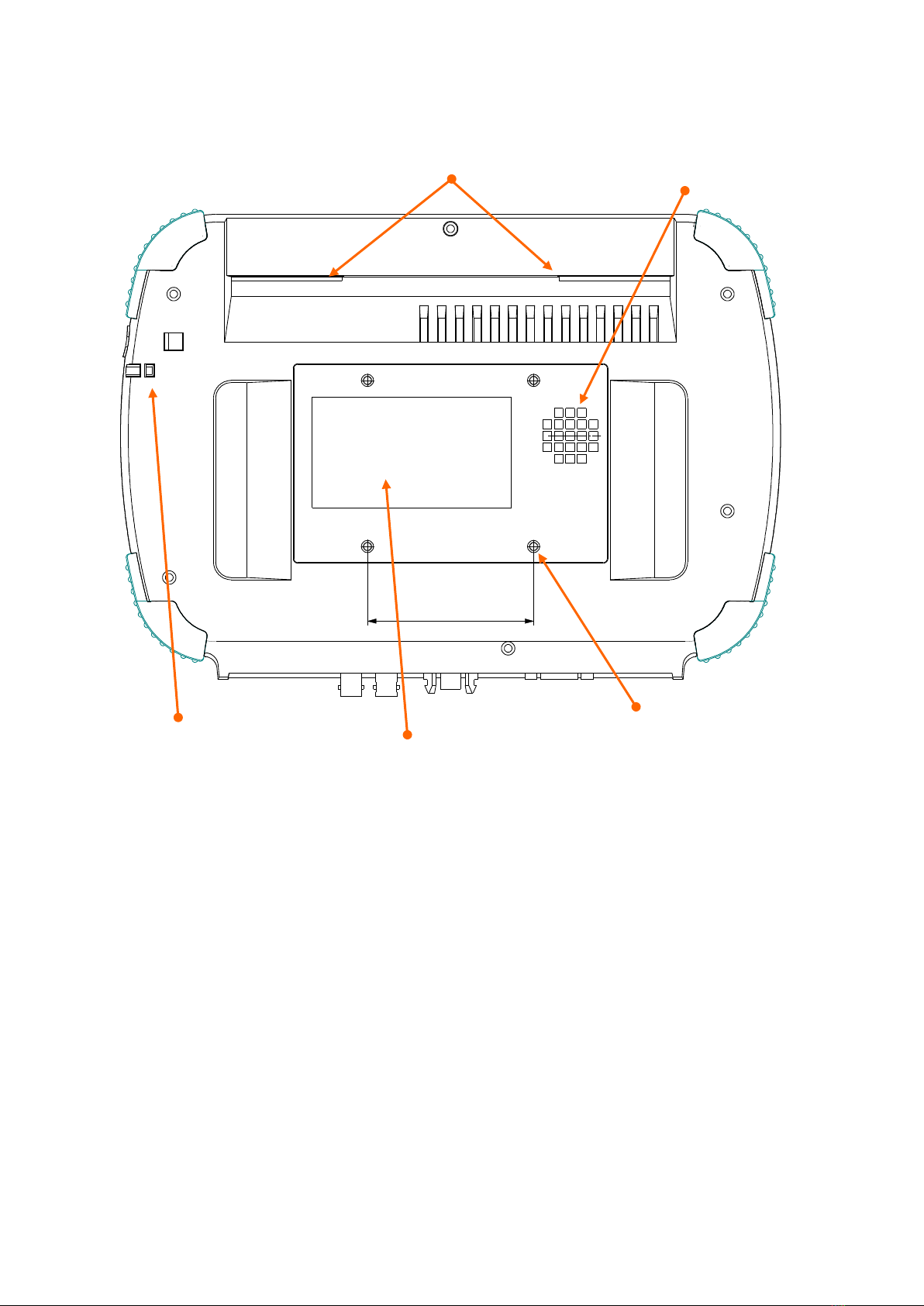

1-3 Structure of Main Unit ………………………………………………………….7

1-4 I/O Unit ………………………………………………………………………….9

1-5 I/O Cable ……………………………………………………………………….10

Chapter 2 Basic Operation ……………………………………………12

2-1 Power On and Initial Screen ………………………………………………….12

2-2 Main Men u ………………………………………………………………13

2-3 Setup Preference …………………………………………………………….14

2-4 System Setting ………………………………………………………………….18

2-5 Area Setup ………………………………………………………………………25

2-5-1 Area Setup (Advanced Setting : Off) …………………….………..…………25

2-5-2 Area Setup (Advanced Setting : On) ……………….………..…………………32

2-6 Reference Image Capture …………………………………………………….33

2-7 How to Test Monitoring ………………………………………………………. 40

2-8 How to Monitor …………………………………………………………………42

2-9 How to Use USB memory ……………………………………………………….50

2-10 How to Display the Log ……………………………………………………….55

2-11 Camera Connection ……………………………………………………………57

Chapter 3 Device Specification ………………………………………….58

3-1 Device Specification …………………………………………………………….58

3-2 Signal Time Chart …………………………………………………………………59

3-3 Interface Circuit ………………………………………………………………… 60

Chapter 4 Warranty Condition …………………………………………61