Operating Instructions: Photoelectric Blocking - Bravo

Description

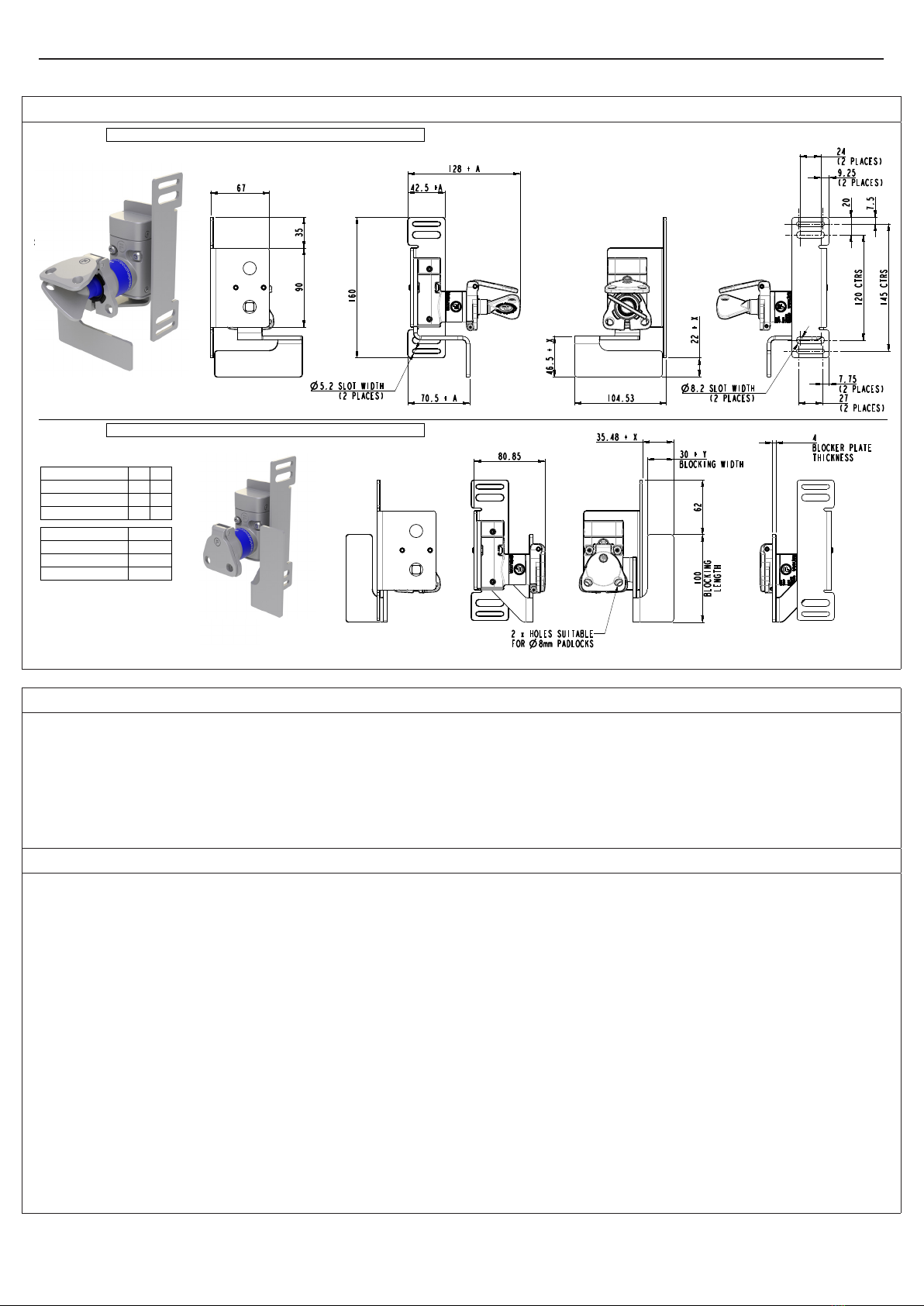

USP'S Bravo prevents unexpected start-up in areas safeguarded

by light curtains, an individual takes the safety key when entering

the area and while they have that key on their person the light

curtain remains blocked and therefore the protective stop function

is maintained, this ensures the hazard cannot be reset or restarted

until the key is returned to the unit. Bravo provides the same peace

of mind for an operator entering past a light curtain as a safety key

or interlock blocking device does with physical guards. Additional

padlock points on the dustcover allow any subsequent individuals

entering the area to apply their own means of control to the device.

As a purely mechanical component complete with an integrated

mounting plate it is easily retrotted or added to an existing system,

with a compatible light curtain, without the need for wiring or

programming.

Options & Ordering Information

Description Part No.

Bravo Device for left-hand blocking, with 100mm Blocker

Plate and right-angled mounting bracket BRV2A-1-1-CLSL-MP1

Bravo Device for right-hand blocking, with 100mm Blocker

Plate and right-angled mounting bracket BRV4A-1-1-CLSL-MP1

Bravo device for left-hand blocking, with 50mm Blocker Plate

and right-angled mounting plate BRV2A-2-1-CLSL-MP1

Bravo device for right-hand blocking, with 50mm Blocker

Plate and right-angled mounting plate BRV4A-2-1-CLSL-MP1

Bravo device for left-hand blocking, with 50mm Blocker Plate

plus 20mm extension and right-angled mounting plate BRV2A-3-1-CLSL-MP1

Bravo device for right-hand blocking, with 50mm Blocker

Plate plus 20mm extension and right-angled mounting BRV4A-3-1-CLSL-MP1

Bravo device for left-hand blocking, with 100mm Blocker

Plate and right-angled mounting plate plus 20mm width BRV2A-1-1-CLSL-MP2

Bravo device for right-hand blocking, with 100mm Blocker

Plate and right-angled mounting plate plus 20mm width BRV4A-1-1-CLSL-MP2

Bravo device for left-hand blocking, with 50mm Blocker Plate

and right-angled mounting plate plus 20mm width BRV2A-2-1-CLSL-MP2

Bravo device for right-hand blocking, with 50mm Blocker

Plate and right-angled mounting plate plus 20mm width BRV4A-2-1-CLSL-MP2

Bravo device for left-hand blocking, with 50mm Blocker Plate

plus 20mm extension and right-angled mounting plate plus

20mm width

BRV2A-3-1-CLSL-MP2

Bravo device for right-hand blocking, with 50mm Blocker

Plate plus 20mm extension and right-angled mounting plate

plus 20mm width

BRV4A-3-1-CLSL-MP2

Bravo device for left-hand blocking, with 100mm Blocker

Plate and right-angled mounting plate plus 40mm width BRV2A-1-1-CLSL-MP3

Bravo device for right-hand blocking, with 100mm Blocker

Plate and right-angled mounting plate plus 40mm width BRV4A-1-1-CLSL-MP3

Bravo device for left-hand blocking, with 50mm Blocker Plate

and right-angled mounting plate plus 40mm width BRV2A-2-1-CLSL-MP3

Bravo device for right-hand blocking, with 50mm Blocker

Plate and right-angled mounting plate plus 40mm width BRV4A-2-1-CLSL-MP3