UTC Fire and Security interlogix Concord 4 User manual

Concord 4 Installation Manual

P/N 466-2182 • REV J • NOV12

Copyright

© 2012 UTC Fire & Security Americas Corporation, Inc.

Interlogix is part of UTC Climate Controls & Security, a unit of United Technologies

Corporation. All rights reserved.

This document may not be copied in whole or in part or otherwise reproduced without prior

written consent from UTC Fire & Security, Inc., except where specifically permitted under US

and international copyright law.

Disclaimer

The information in this document is subject to change without notice. UTC Fire & Security

assumes no responsibility for inaccuracies or omissions and specifically disclaims any

liabilities, losses, or risks, personal or otherwise, incurred as a consequence, directly or

indirectly, of the use or application of any of the contents of this document. For the latest

documentation, contact your local supplier or visit us online at www.utcfireandsecurity.com.

This publication may contain examples of screen captures and reports used in daily

operations. Examples may include fictitious names of individuals and companies. Any

similarity to names and addresses of actual businesses or persons is entirely coincidental.

Trademarks and

patents

Other trade names used in this document may be trademarks or registered trademarks of the

manufacturers or vendors of the respective products.

Intended use

Use this product only for the purpose it was designed for; refer to the data sheet and user

documentation for details. For the latest product information, contact your local supplier or

visit us online at www.utcfireandsecurity.com.

Contact information

www.utcfireandsecurity.com. or www.interlogix.com

Technical support

www.interlogix.com/customer-support.

Concord 4 Installation Manual i

Content

Important information iii

Chapter 1 Introduction 1

Planning the installation 2

SuperBus 2000 bus devices 3

Chapter 2 Installation 5

Installation overview 6

Mounting the panel 10

Intrusion detection devices 15

Smoke detectors 15

Speakers and sirens 18

SuperBus 2000 touchpads 22

SuperBus 2000 modules 22

Phones 28

Power 30

Chapter 3 Programming 33

Overview 34

Quick programming mode 36

Tier 1 programming menus 37

Tier 2 programming menus 40

Security menu 45

Phones menu 50

Phone options menu 54

Timers menu 57

Light control menu 59

Touchpad options menu 60

Reporting menu 61

Siren options menu 66

Sensors menu 67

Audio verification menu 71

Accessory modules menu 73

Onboard options menu 78

Macro keys menu 81

User programming mode 82

Downloader programming 93

Chapter 4 Testing and troubleshooting 95

Testing the system 96

ii Concord4 Installation Manual

Troubleshooting 106

Appendix A System planning sheets 117

Customer information 118

Wireless devices 118

Hardware devices 119

Zone and sensor assignments 121

System settings index and record 124

Appendix B Reference tables 129

Sensor group characteristics 130

Sensor text 134

System event triggers 136

Sensor group event triggers 137

Sensor number event triggers 138

System feature event triggers 141

Response characteristics 143

Response numbers 143

Specifications 145

Concord 4 Installation Manual iii

Importantinformation

Intended use

Use this product only for the purpose it was designed for; refer to the data sheet

and user documentation for details. For the latest product information, contact

your local supplier or visit us online at www.utcfireandsecurity.com.

Changes or modifications not expressly approved by UTC Fire & Security can

void the user’s authority to operate the equipment.

About this manual

This manual provides information for planning, installing, programming, and

testing this security system. Planning sheets are included for you to record

hardware layout and software programming settings.

Use this manual for the following panels:

600-1021-95R

Concord 4 RF

600-1022-95R

Concord Express V4

600-1040

Concord Commercial V4

600-1042

Concord Hybrid

When necessary, this manual refers you to other documentation with compatible

peripherals.

The Concord 4 User Manual (P/N 466-2183) contains user worksheets that you

should fill out during the installation and programming ofthe system. For

multiple-partition systems, we suggest a user manual for each partition.

Read these instructions and all related documentation entirely before installing or

operating this product.

Note: A qualified service person, complying with all applicable codes, should

perform all required hardware installation.

Concord 4 Installation Manual 1

Chapter 1

Introduction

Summary

This chapter provides information to help you plan your Concord 4 panel and

system installation.

Content

Planning the installation 2

Standard panel 2

SuperBus 2000 bus devices 3

Chapter 1: Introduction

2 Concord4 Installation Manual

Planning the installation

This section describes system capabilities to help you get familiar with the

system. Appendix A “System planning sheets” on page 117 provides planning

sheets that let you record the hardware and programming configuration of the

system. Fill in all necessary information ahead of time to help prepare for system

installation.

Standard panel

Table 1 below shows the standard panel capabilities.

Table 1: Panel capabilities

Capabilities

Concord Express v4

Concord 4/Concord Commercial

v4

Zones

32

96

Partitions

2

6

Bus devices

16

16

User codes

16

230

Table 2 describes the basic panel (out-of-box) hardware capabilities for all

panels.

Table 2: Basic panel hardware capabilities

Power

Input for an AC step-down, plug-in style transformer.

Auxiliary power output

Output that supplies 9 to 14 VDC with up to 1 amp for bus devices

and hardwired detectors, such as smoke and motion detectors.

Bus A and B

Input and output that provides communication between bus devices

and the panel.

Siren driver

Output that can drive an 8-ohm load and provides intrusion and fire

alarm sounds for partition 1 (15 watts maximum).

Two onboard outputs

Can be used to activate other signaling devices based on system

events.

Out 1 is a 9 to 14 VDC source output, limited to 1.0 amp max.

Out 2 is an open-collector output, rated up to 14 VDC, 300 mA max

Microphone input

Input used for 2-way audio when used in conjunction with the

Interrogator 200 audio verification module.

Eight supervised hardwired

zones

Inputs for various hardwired detectors. Zone 8 can be set up in

programming to accept two-wire smoke detectors. It sources 9 to 14

VDC, 90mA max.

Chapter 1: Introduction

Concord 4 Installation Manual 3

Built-in RF receiver

Allows use of up to 96 (Concord 4) or 32 (Concord Express v4)

319.5 MHz. crystal and/or SAW learn mode wireless sensors and

touchpads.

Phone line connection

Allows panel to communicate with central monitoring station and/or

pagers.

SuperBus2000 bus devices

The following components can be used with the Concord 4 panel:

Table 3: SuperBus devices

Touchpads

Use the following touchpads for installer/user programming

and system operation.

•SuperBus 2000 2x16 LCD touchpad

•SuperBus 2000 2x20 LCD touchpad

•SuperBus 2000 2x20 VFD touchpad

•SuperBus 2000 ATP 1000 touchpad

•SuperBus 2000 ATP 2100 touchpad

•SuperBus 2000 ATP 2600 touchpad

Use the following touchpads for installer quick programming,

system operation and user programming:

•SuperBus 2000 fixed display touchpad

•SuperBus 2000 FTP 1000 touchpad

SuperBus 2000 RF transceiver

Use the transceiver toreceive signals from sensors and

touchpad that may be on the fringe of panel reception. The

transceiver is compatible with all 319.5 MHz crystal and SAW

learn mode wireless sensors and touchpads.

Power line carrier transformer

Allows the use of X10 powerhouse lamp modules for light

control and light activation during alarms.

SuperBus 2000 voice only

module

Provides an output for a speaker that sounds system status

and alarm voice messages.

SuperBus 2000 phone

interface/voice module

Allows system access and control using touchtone

telephones, onsite or offsite. The module includes an output

for a speaker that sounds system status and alarm voice

messages

Chapter 1: Introduction

4 Concord4 Installation Manual

SnapCards

The following SnapCards expand the system as described:

8Z input Snapcard: Provides eight additional hardwired zone

inputs, of which two are dedicated for using two-wire smoke

detectors.

4 output SnapCard: Provides four form C relay outputs that

can be set up to activate other signaling devices, based on

system events, schedules, or direct control.

4Z input/output combo SnapCard: Provides three hardwired

zone inputs, one two-wire smoke detector loop, and two

outputs that can be set up to activate other signaling devices,

based on system events, schedules, or direct control.

SuperBus 2000 8Z input

module (HIM)

Provides eight additional hardwire zone inputs.

SuperBus 2000 four-relay

output module (HOM)

Provides four form C relay outputs that can be set up to

activate other signaling devices, based on system events.

Interrogator 200 audio

verification module

Allows central station operators to listen in and talk to

occupants on the premises to verify the emergency when an

alarm report is received.

SuperBus 2000 energy saver

module (ESM)

Provides a money-saving and convenient way to monitor and

control temperatures. The ESM uses low- and high-

temperature limits to save energy by overriding the existing

HVAC thermostat.

SuperBus 2000 automation

module

Provides a connection to a compatible home automation

device.

SuperBus 2000 wireless

cellular gateway

Allows users to control and monitor the status of their system

from the alarm.com internet website.

SuperBus 2000 2-amp power

supply

Provides an additional 12 VDC, 2 amps for powering system

devices and is supervised via the panel data bus.

Concord 4 Installation Manual 5

Chapter 2

Installation

Summary

This chapter provides information on locating and installing the panel and system

components.

Content

Error! Bookmark not defined.

Chapter 2: Installation

6 Concord4 Installation Manual

Installationoverview

Before starting the installation, plan your system layout and programming using

the worksheets provided in Appendix A “System planning sheets” on page 117.

Note: Class 2, Class 3, and power-limited fire alarm circuits must be installed

using FPL,FPLR, FPLP, or substitute cable permitted by the National Electrical

Code ANSI/NFPA 70 or Class 2, Class 3, and power-limited fire alarm circuit

conductors must be installed as Class 1 or higher circuits.

Note: Class 2, Class 3, and power-limited burglar alarm circuits must be installed

using CL2, CL2R, CL2P,or substituting cable permitted by ANSI/NFPA 70. Wire

that extends beyond the cable jacket must be separated from all other

conductors by a minimum of 0.25 in. or by a nonconductive barrier.

Use the following installation guidelines:

•Centrally locate the panel with relation to detection devices whenever

possible, to help reduce wire run lengths and labor.

•Locate the panel where the temperature will not exceed 120°F (49°C) or fall

below 32°F (0°C).

•Avoid running wires parallel with electrical wiring or fixtures such as

fluorescent lighting, to prevent wire runs from picking up electrical noise.

•Mount the panel at a comfortable working height (about 45 to 55 in. from the

floor to the bottom of the panel, as shown in Figure 1 on page 7).

•Leave space to the left and right of the panel for wiring, phone jack, and

mounting optional modules. Allow at least 9 in. (23 cm) above the panel

cabinet for antennas. Allow at least 24 in. (62 cm) in front of the panel to open

the panel door.

Chapter 2: Installation

Concord 4 Installation Manual 7

Figure 1: Panel and component locations on a wall

Total system power and wire length guidelines

The panel can supply up to 1 amp (1,000 mA) in full load alarm condition for

system devices connected to panel terminals 4 (+12V), 7 and 8 (speaker

terminals), 9 (OUT1), 11 (+12V), 24 (2W SMK ZONE 8), and SnapCard

terminals.

For 24-hour backup, the total standby current draw for all devices connected to

panel terminals 4 (+12V), 9 (OUT1), 11 (+12V), 24 (if configured for 2-wire

smoke loop), and SnapCard terminals is limited to 90 mA (during normal standby

condition) using a 4.5 or 5.0 Ah battery, or 190 mA (during normal standby

condition) using a 7.0 Ah battery.

The total system wire length allowed can vary depending on devices powered by

the panel, the wire length between devices and the panel, and the combined wire

length of all devices.

Chapter 2: Installation

8 Concord4 Installation Manual

Table 4 below describes the maximum wire length allowed between compatible

devices and the panel, and the minimum and maximum current draw of each

device.

Table 4: Wire length requirements

Device

Max. wire

length to

panel

Standby mA

draw

Alarm mA draw

SuperBus 2000 2x16 LCD alphanumeric

touchpad

22 ga.: 300 ft.

18 ga.: 750 ft.

15 mA

90 mA

SuperBus 2000 ATP 1000 alphanumeric

touchpad

22 ga.: 300 ft.

18 ga.: 750 ft.

12 mA

110 mA

SuperBus 2000 ATP 2100 alphanumeric

touchpad

22 ga.: 300 ft.

18 ga.: 750 ft.

30 mA

165 mA

SuperBus 2000 ATP 2600 alphanumeric

touchpad

22 ga.: 300 ft.

18 ga.: 750 ft.

30 mA

165 mA

SuperBus 2000 fixed display touchpad

22 ga.: 300 ft.

18 ga.: 700 ft.

11 mA

65 mA

SuperBus 2000 FTP 1000 fixed display

touchpad

22 ga.: 300 ft.

18 ga.: 700 ft.

12 mA

75 mA

SuperBus 2000 RF transceiver

22 ga.: 1,000

ft.

18 ga.: 2,500

ft.

45 mA

55 mA

SuperBus 2000 phone interface/voice module

22 ga.: 40 ft.

18 ga.: 120 ft.

25 mA

600 mA

SuperBus 2000 voice-only module

22 ga.: 40 ft.

18 ga.: 120 ft.

20 mA

300 mA (jumper)

600 mA (no

jumper)

SuperBus 2000 2 amp power supply

No load

No load

4 input/2 output SnapCard

N/A

20 mA

185 mA*

8Z hardwired zone expander SnapCard

N/A

38 mA

230 mA*

4 output SnapCard

N/A

1 mA

130 mA*

SuperBus 2000 8Z input module

22 ga.: 1,800

ft.

18 ga.: 4,000

ft.

18 mA

35 mA

SuperBus 2000 4-relay output module

22 ga.: 350 ft.

18 ga.: 900 ft.

12 mA

180 mA

Chapter 2: Installation

Concord 4 Installation Manual 9

Device

Max. wire

length to

panel

Standby mA

draw

Alarm mA draw

SuperBus 2000 energy saver module

22 ga.: 1,600

ft.

18 ga.: 4,000

ft.

20 mA

20 mA

SuperBus 2000 automation module

22 ga.: 1,500

ft.

18 ga.: 4,000

ft.

30 mA

35 mA

SuperBus 2000 wireless cellular gateway

22 ga.: 40 ft.

18 ga.: 90 ft.

65 mA

1600 mA

Interrogator 200

22 ga.: 3,200

ft.

18 ga.: 4,500

ft.

10 mA

10 mA

Interrogator AVM

22 ga.: 110 ft.

18 ga.: 260 ft.

45 mA

300 mA

Two-wire smoke detectors (ESL 429AT,

429C, 429CT, 521B, 521BXT, 521NCSXT

22 ga.: 330 ft.

18 ga.: 330 ft.

70 µA

60 mA

Two-wire smoke detectors (system sensor

2400, 2400TH)

22 ga.: 330 ft.

18 ga.: 330 ft.

120 µA

80 mA

Hardwired interior siren (13-949)

22 ga.: 750 ft.

18 ga.: 1,500

ft.

0 mA

85 mA

Piezo dynamic exterior siren (13-950)

22 ga.: 750 ft.

18 ga.: 1,500

ft.

0 mA

150 mA

Speaker siren (60-528 or 13-060)

18 ga.: 100 ft.

0 mA

500 mA

*Maximum current draw for the SnapCards does not include the load which may be applied to

their auxiliary DC supply.

Table 5 below describes the total system wire lengths allowed for all SuperBus

2000 devices when installing systems using unshielded or shielded cable. After

determining panel location, run all necessary wires to that location using the

information in Table 6 on page 10.

Table 5: Wire lengths

Wire type

Total system wire

18-gauge, unshielded

18-gauge, shielded

4,000 ft.

3,000 ft.

Chapter 2: Installation

10 Concord4 Installation Manual

Wire type

Total system wire

22-gauge, unshielded

22-gauge, shielded

4,000 ft.

3,000 ft.

Table 6: Device wire requirements

Device

Wire requirements

AC power transformer

2-conductor, 18-gauge, 25 ft. max.

Earth ground

Single conductor, 16-gauge solid, 25 ft. max.

Telephone (RJ-31X)

4-conductor

Detection devices

2- or 4-conductor, 22-gauge, 1,000 ft. max.

2- or 4-conductor, 18-gauge, 2,500 ft. max.

(based on 30 ohms max. loop resistance

including device)

Speakers

2-conductor, 18-gauge, 100 ft. max.

SuperBus 2000 devices

4-conductor, 22- or 18-gauge

Interrogator 200 AVM power and microphone

4-conductor, 22-gauge, shielded

2-wire smoke detectors

2-conductor, 22-gauge, 330 ft. max.

2-conductor, 18-gauge, 830 ft. max.

Mounting the panel

Mount the panel to the wall or wall studs.

Caution: Make sure you are free of static electricity whenever you work on the

panel with the cover open. To discharge any static, first touch the metal panel

chassis, and then stay in contact with the chassis when touching the circuit

board. We recommend using a grounding strap.

To mount the panel:

1. Remove the panel door and remove the necessary wiring knockouts. Be

careful not to damage the circuit board.

2. Feed all wires through wiring knockouts and place the panel in position

against the wall.

3. Level the panel and mark the top and bottom mounting holes (see Figure 2 on

page 11).

4. Install anchors where studs are not present.

Chapter 2: Installation

Concord 4 Installation Manual 11

5. Partially insert screws into the two top mounting hole locations, then hang the

panel on the two screws.

6. Recheck for level, insert the two lower screws, and tighten all four mounting

screws.

Figure 2: Panel components and mounting holes

Mounting hole

Backup battery terminals

Programming

touchpad header

Mounting hole

Antennas

Mounting hole

Snapcard connector

Processor

Terminal strip

Mounting hole

Grounding the panel

For maximum protection from lightning strikes and transients, connect the

enclosure to earth ground as shown in Figure 3 below. Use 16-gauge, solid

copper wire from an earth grounded cold water pipe clamp to the enclosure.

Figure 3: Grounding the panel

Grounding wire

Water pipe

Grounding clamp

Note: For best results, we recommend that you crimp a spade lug on the wire

end at the panel and secure the lug to the enclosure.

Chapter 2: Installation

12 Concord4 Installation Manual

Antenna shrouds

Install a plastic antenna shroud (included with panel) over each antenna and

snap them into the holes on the top of the enclosure (skip this step for hybrid and

commercial systems).

Chapter 2: Installation

Concord 4 Installation Manual 13

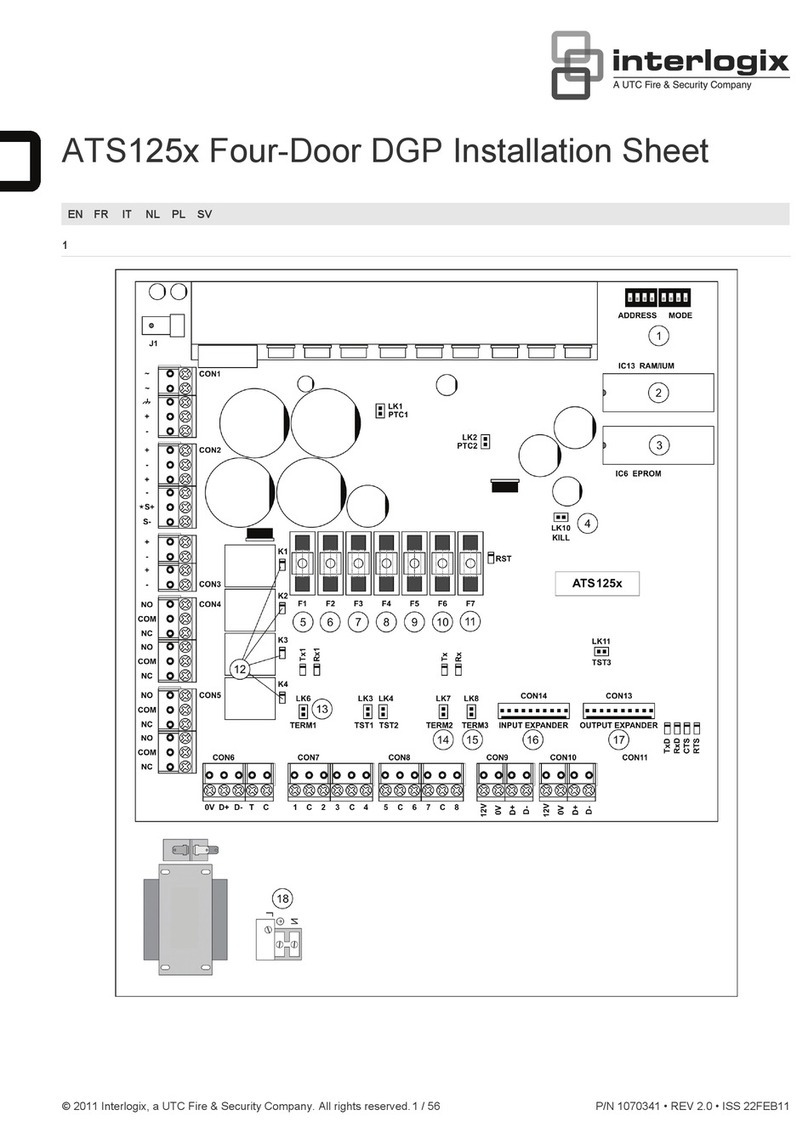

Optional SnapCards

Use the SnapCard header on the right side of the panel (Figure 4 below) to install

an optional SnapCard. Install the SnapCard onto the panel SnapCard header

and secure it in place with two screws, included with the SnapCard. To connect

all necessary input/output wiring, refer to the SnapCard documentation.

Figure 4: Installing a SnapCard

Mounting hole

Snapcard connector

Snapcard

Mounting hole

Chapter 2: Installation

14 Concord4 Installation Manual

Panel terminals

Figure 5 below shows an overview of panel terminals. The following sections

provide details on how to connect devices to the panel.

Figure 5: Panel terminals

TIP

(+) RING

(-)

BRN GRY

GRN RED

(-) (+)

(-) (+)

_+NC COM

SW SW GND #1 #2

+12V - Red

BUS A - Green

BUS B - White or Yellow

GND - Black

1234567 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

16.5 VAC GND +12V ABSPKR SPKR OUT1 OUT2 +12V MIC GND ZONE1 ZONE2 GND ZONE3 ZONE4 GND ZONE5 ZONE6 GND ZONE7 ZONE8 GRN BRN GRY RED

Zones

The panel comes with factory programmed onboard hardwired zones. Install 2

kohm, end-of-line (EOL) resistors on all unused factory programmed onboard

hardwired zones. If you don’t want to install EOL resistors, delete any unused

zones from memory.

Zone inputs 1 through 8 are supervised using the included 2-kohm, end-of-line

resistors at the last device on each circuit. All eight zones accept either normally

open (NO) or normally closed (NC) detection devices.

Other UTC Fire and Security Security System manuals

UTC Fire and Security

UTC Fire and Security Interlogix ATS125 Series Assembly instructions

UTC Fire and Security

UTC Fire and Security Interlogix ATS1236 Assembly instructions

UTC Fire and Security

UTC Fire and Security Kidde KN-COEG-3 User manual

UTC Fire and Security

UTC Fire and Security Interlogix ATS1235 Assembly instructions

Popular Security System manuals by other brands

Smanos

Smanos W120 instruction manual

DSC

DSC Power 832 PC5010 instruction manual

AFRISO

AFRISO GS 1.1 operating instructions

Audiovox

Audiovox PRO-9642a Pursuit Series owner's manual

STI

STI Stopper Station Series manual

Safety Technology International

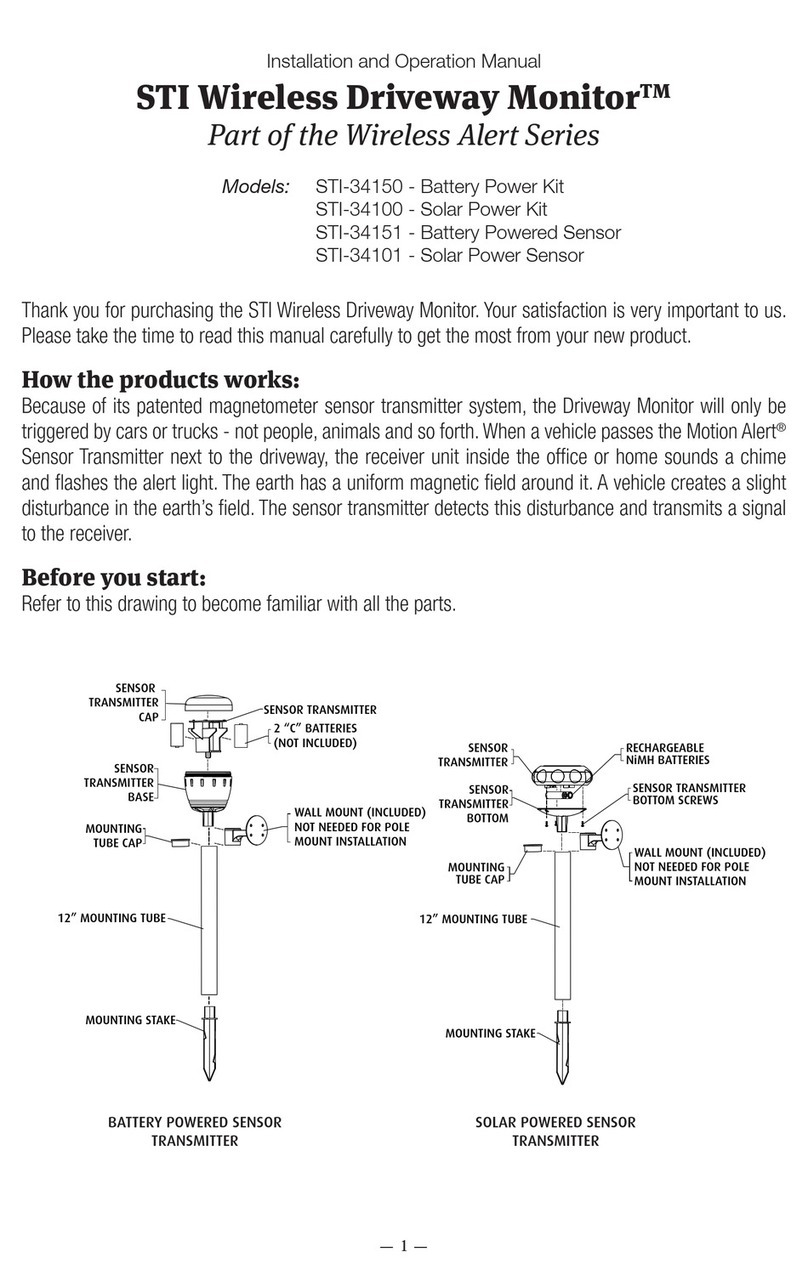

Safety Technology International STI-34150 Installation and operation manual